|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Fri May 30, 2014 2:26 pm Post subject: Info on MGL Enigma Posted: Fri May 30, 2014 2:26 pm Post subject: Info on MGL Enigma |

|

|

While trying to fathom why the CHT readings on the MGL Enigma EFIS had stopped on my friend's Rotax 912 powered JA Highlander I delved into the manual for the EFIS and its RDAC unit (the box that all senders report to before their data is passed along to the EFIS). On page 6 or so of the RDAC manual there is a picture of the back of the Enigma with a note that the battery under a rectangular cover should be changed every two years. Upon removing said cover I discovered a CR2032 lithium battery. I checked its voltage output and found it to be 2.9 volts. A new one that the aircraft owner just happened to have in his tool kit (he maintains medical equipment for a living) put out 3.3 volts so we replaced the old one.

More investigation into the setup menus for EFIS revealed that there is an option for a Rotax sender for the CHT setup and when we checked the unit we found it had reset to a J type thermocouple. Resetting it to the Rotax sender solved the problem and the EFIS began reporting good CHT values.

Curious to find out if the low output of the CR2032 was responsible for the glitch in the CHT setup I delved into the manual for the EFIS and could find no reference to it in the manual's table of contents, index, or during a long skim of its contents. The same was true of the RADC manual with the exception of the picture and note mentioned earlier.

Now we find that the same thing has happened to the oil pressure reading. Again the setup has been changed to reflect a different type of sender, only this time restoring it to the Rotax sender option has not fixed it. There are two sender options for each of resistive type senders and voltage type. On either resistive option (the Rotax option is a resistive sender) the bar graph on the EFIS locks up and does not read. When I set it to either of the voltage type it then reads but it reads backward, i.e. as the engine revs up the reading drops and vice versa.

The oil pressure sender is a VDO unit and I have located it in VDO's technical offerings online. VDO recommends that the sender be installed dry with no teflon tape or thread sealant so that it will ground properly so we have an investigative path when we return to the airplane this weekend.

MGL has taken the Enigma technical info off line and the aircraft's owner has not been able to find any information on the CR2032 battery as to what it does or how to change it properly.

Does anyone out there know about it?

Thanks,

Rick Girard

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Fri May 30, 2014 3:20 pm Post subject: Info on MGL Enigma Posted: Fri May 30, 2014 3:20 pm Post subject: Info on MGL Enigma |

|

|

On 5/30/2014 5:25 PM, Richard Girard wrote:

| Quote: | While trying to fathom why the CHT readings on the MGL Enigma EFIS had stopped on my friend's Rotax 912 powered JA Highlander I delved into the manual for the EFIS and its RDAC unit (the box that all senders report to before their data is passed along to the EFIS). On page 6 or so of the RDAC manual there is a picture of the back of the Enigma with a note that the battery under a rectangular cover should be changed every two years. Upon removing said cover I discovered a CR2032 lithium battery. I checked its voltage output and found it to be 2.9 volts. A new one that the aircraft owner just happened to have in his tool kit (he maintains medical equipment for a living) put out 3.3 volts so we replaced the old one.

More investigation into the setup menus for EFIS revealed that there is an option for a Rotax sender for the CHT setup and when we checked the unit we found it had reset to a J type thermocouple. Resetting it to the Rotax sender solved the problem and the EFIS began reporting good CHT values.

Curious to find out if the low output of the CR2032 was responsible for the glitch in the CHT setup I delved into the manual for the EFIS and could find no reference to it in the manual's table of contents, index, or during a long skim of its contents. The same was true of the RADC manual with the exception of the picture and note mentioned earlier.

Now we find that the same thing has happened to the oil pressure reading. Again the setup has been changed to reflect a different type of sender, only this time restoring it to the Rotax sender option has not fixed it. There are two sender options for each of resistive type senders and voltage type. On either resistive option (the Rotax option is a resistive sender) the bar graph on the EFIS locks up and does not read. When I set it to either of the voltage type it then reads but it reads backward, i.e. as the engine revs up the reading drops and vice versa.

The oil pressure sender is a VDO unit and I have located it in VDO's technical offerings online. VDO recommends that the sender be installed dry with no teflon tape or thread sealant so that it will ground properly so we have an investigative path when we return to the airplane this weekend.

MGL has taken the Enigma technical info off line and the aircraft's owner has not been able to find any information on the CR2032 battery as to what it does or how to change it properly.

Does anyone out there know about it?

Thanks,

Rick Girard

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

|

I can't help with specific info on the MGL, but using that battery for 'backup' is fairly common in electronics. If you use a desktop PC, odds are good that there's one on the motherboard. My old Garmin III Pilot gps has one in it. (Note that they make that case style in both a lithium 'primary' battery, and a lithium rechargeable battery, & it's sometimes difficult to tell which the mfgr is using.) In the applications I've seen, the battery keeps a CMOS memory alive, and that's where basic configuration settings are stored in a lot of devices. If the battery goes too low to keep the CMOS memory active, the device will forget whatever settings were stored there. I would think that more current tech, especially in an a/c device, would avoid using CMOS memory & the required battery, but some really high dollar avionics still use it.

On many PC's, if the battery dies, after battery replacement you sometimes have to do a 'hard reset' by shorting a pair of pins on the motherboard to completely clear the CMOS memory before re-entering all the parameters needed.

Sounds like it's time for a Skype call to S Africa.

Charlie

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jay(at)horriblehyde.com

Guest

|

Posted: Sat May 31, 2014 7:37 am Post subject: Info on MGL Enigma Posted: Sat May 31, 2014 7:37 am Post subject: Info on MGL Enigma |

|

|

I have forwarded this to my colleague, who happens to own MGL J. I call him on Monday to follow up.

Jay

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Richard Girard

Sent: 31 May 2014 12:26 AM

To: aeroelectric-list(at)matronics.com

Subject: Info on MGL Enigma

While trying to fathom why the CHT readings on the MGL Enigma EFIS had stopped on my friend's Rotax 912 powered JA Highlander I delved into the manual for the EFIS and its RDAC unit (the box that all senders report to before their data is passed along to the EFIS).

On page 6 or so of the RDAC manual there is a picture of the back of the Enigma with a note that the battery under a rectangular cover should be changed every two years. Upon removing said cover I discovered a CR2032 lithium battery. I checked its voltage output and found it to be 2.9 volts. A new one that the aircraft owner just happened to have in his tool kit (he maintains medical equipment for a living) put out 3.3 volts so we replaced the old one.

More investigation into the setup menus for EFIS revealed that there is an option for a Rotax sender for the CHT setup and when we checked the unit we found it had reset to a J type thermocouple. Resetting it to the Rotax sender solved the problem and the EFIS began reporting good CHT values.

Curious to find out if the low output of the CR2032 was responsible for the glitch in the CHT setup I delved into the manual for the EFIS and could find no reference to it in the manual's table of contents, index, or during a long skim of its contents. The same was true of the RADC manual with the exception of the picture and note mentioned earlier.

Now we find that the same thing has happened to the oil pressure reading. Again the setup has been changed to reflect a different type of sender, only this time restoring it to the Rotax sender option has not fixed it. There are two sender options for each of resistive type senders and voltage type. On either resistive option (the Rotax option is a resistive sender) the bar graph on the EFIS locks up and does not read. When I set it to either of the voltage type it then reads but it reads backward, i.e. as the engine revs up the reading drops and vice versa.

The oil pressure sender is a VDO unit and I have located it in VDO's technical offerings online. VDO recommends that the sender be installed dry with no teflon tape or thread sealant so that it will ground properly so we have an investigative path when we return to the airplane this weekend.

MGL has taken the Enigma technical info off line and the aircraft's owner has not been able to find any information on the CR2032 battery as to what it does or how to change it properly.

Does anyone out there know about it?

Thanks,

Rick Girard

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

| Quote: | | [/b][/b][/b][b]http://www.matronics.com/Navigator?AeroElectric-List[b] |

0123456789

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jay(at)horriblehyde.com

Guest

|

Posted: Mon Jun 02, 2014 1:03 am Post subject: Info on MGL Enigma Posted: Mon Jun 02, 2014 1:03 am Post subject: Info on MGL Enigma |

|

|

Here is the reply from Rainier, the owner and founder of MGL:

The CR2032 battery is only used to maintain items that change frequently like calculated fuel levels, local pressure settings etc.

Setup is stored in a flash memory section of a secondary processor chip in the EFIS. This does not need a backup battery.

If setup data stored here is not maintained there is usually only one

cause: The supply voltage to that processor is raised briefly (micro-seconds to mill-seconds) above about 8V. This can happen if the supply to the EFIS contains sharp voltage spikes (typically caused by bad regulators or high voltage ignition is coupling into ground or supply). This can also happen if there are static discharges typically caused by airflow over metal parts that are not grounded.

Eventually, this will damage the flash memory which is the part that dies first in our experience.

When this happens we replace the processor chip. If you have a techie handy - it is a type ATMEL ATMega128. It is a SMD package but easy to solder/desolder if you have the experience. Once replaced I would also recommend replacing the 16Mhz crystal right next to this chip - it tends to wear out over a long time (we replace these as a matter of course when we get an Enigma in for repairs). No specific programming of the new processor needs to be done as the firmware will detect a new processor and do the programming and setup of this chip automatically (the first start-up will take a bit longer and you will see some messages on the display to this effect).

Rainier

--

MGL Avionics

Postal:

Postnet Suite X15

Somerset West 7129

South Africa

Physical:

5 Fuchsia street

Somerset West 7130

South Africa

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

HH Enterprises - Aircraft assembly, repair, wiring and avionics

- Flight instruction

- General and Electrical Engineering services

� (NHD Elec Eng, BTech Elec Eng, GDE ELec Eng)- Great dinner parties and conversation

- General adventuring, climbing, kayaking and living

Blog: www.rawhyde.wordpress.com

Cel: 083 300 8675

Email: jay(at)horriblehyde.com (jay(at)horriblehyde.com)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Charlie England

Sent: 31 May 2014 01:20 AM

To: aeroelectric-list(at)matronics.com

Subject: Re: Info on MGL Enigma

On 5/30/2014 5:25 PM, Richard Girard wrote:

| Quote: |

While trying to fathom why the CHT readings on the MGL Enigma EFIS had stopped on my friend's Rotax 912 powered JA Highlander I delved into the manual for the EFIS and its RDAC unit (the box that all senders report to before their data is passed along to the EFIS).

On page 6 or so of the RDAC manual there is a picture of the back of the Enigma with a note that the battery under a rectangular cover should be changed every two years. Upon removing said cover I discovered a CR2032 lithium battery. I checked its voltage output and found it to be 2.9 volts. A new one that the aircraft owner just happened to have in his tool kit (he maintains medical equipment for a living) put out 3.3 volts so we replaced the old one.

More investigation into the setup menus for EFIS revealed that there is an option for a Rotax sender for the CHT setup and when we checked the unit we found it had reset to a J type thermocouple. Resetting it to the Rotax sender solved the problem and the EFIS began reporting good CHT values.

Curious to find out if the low output of the CR2032 was responsible for the glitch in the CHT setup I delved into the manual for the EFIS and could find no reference to it in the manual's table of contents, index, or during a long skim of its contents. The same was true of the RADC manual with the exception of the picture and note mentioned earlier.

Now we find that the same thing has happened to the oil pressure reading. Again the setup has been changed to reflect a different type of sender, only this time restoring it to the Rotax sender option has not fixed it. There are two sender options for each of resistive type senders and voltage type. On either resistive option (the Rotax option is a resistive sender) the bar graph on the EFIS locks up and does not read. When I set it to either of the voltage type it then reads but it reads backward, i.e. as the engine revs up the reading drops and vice versa.

The oil pressure sender is a VDO unit and I have located it in VDO's technical offerings online. VDO recommends that the sender be installed dry with no teflon tape or thread sealant so that it will ground properly so we have an investigative path when we return to the airplane this weekend.

MGL has taken the Enigma technical info off line and the aircraft's owner has not been able to find any information on the CR2032 battery as to what it does or how to change it properly.

Does anyone out there know about it?

Thanks,

Rick Girard

It isn't necessary to have relatives in Kansas City in order to be unhappy.

- Groucho Marx

|

I can't help with specific info on the MGL, but using that battery for 'backup' is fairly common in electronics. If you use a desktop PC, odds are good that there's one on the motherboard. My old Garmin III Pilot gps has one in it. (Note that they make that case style in both a lithium 'primary' battery, and a lithium rechargeable battery, & it's sometimes difficult to tell which the mfgr is using.) In the applications I've seen, the battery keeps a CMOS memory alive, and that's where basic configuration settings are stored in a lot of devices. If the battery goes too low to keep the CMOS memory active, the device will forget whatever settings were stored there. I would think that more current tech, especially in an a/c device, would avoid using CMOS memory & the required battery, but some really high dollar avionics still use it.

On many PC's, if the battery dies, after battery replacement you sometimes have to do a 'hard reset' by shorting a pair of pins on the motherboard to completely clear the CMOS memory before re-entering all the parameters needed.

Sounds like it's time for a Skype call to S Africa.

Charlie | Quote: | | [/b][/b][/b][/b][/b]http://www.matronics.com/Navigator?AeroElectric-List[/b][/b][/b] |

0123456

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 02, 2014 5:45 am Post subject: Info on MGL Enigma Posted: Mon Jun 02, 2014 5:45 am Post subject: Info on MGL Enigma |

|

|

At 04:02 AM 6/2/2014, you wrote:

Here is the reply from Rainier, the owner and founder of MGL:

The CR2032 battery is only used to maintain items

that change frequently like calculated fuel

levels, local pressure settings etc.

Setup is stored in a flash memory section of a

secondary processor chip in the EFIS. This does not need a backup battery.

If setup data stored here is not maintained there is usually only one

cause: The supply voltage to that processor is

raised briefly (micro-seconds to mill-seconds)

above about 8V. This can happen if the supply to

the EFIS contains sharp voltage spikes (typically

caused by bad regulators or high voltage ignition

is coupling into ground or supply).� This can

also happen if there are static discharges

typically caused by airflow over metal parts that are not grounded.

Eventually, this will damage the flash memory

which is the part that dies first in our experience.

When this happens we replace the processor chip.

If you have a techie handy - it is a type ATMEL

ATMega128. It is a SMD package but easy to

solder/desolder if you have the experience. Once

replaced I would also recommend replacing the

16Mhz crystal right next to this chip - it tends

to wear out over a long time (we replace these as

a matter of course when we get an Enigma in for

repairs). No specific programming of the new

processor needs to be done as the firmware will

detect a new processor and do the programming and

setup of this chip automatically (the first

start-up will take a bit longer and you will see

some messages on the display to this effect).

I am exceedingly skeptical of these assertions.

I don't know of a single 5v regulator offered to

the task of conditioning power for electronics

that doesn't handily mitigate any of the commonly

known variables on the ship's bus. DO-160 offers

a clear and concise path to living confidently

in the world of DC powered vehicles.

Crystals that 'wear out'?

Static discharges ? ! ? ! . . . again, for any

piece of hardware to be qualified for installation

on a TC aircraft, it has to be capable of withstanding

discharges of a 150pF capacitor through 330 ohm

resistor fed directly to every input/output pin

on the device under test. TEN times for positive

spikes, TEN more times for negative spikes.

Sound brutal . . . but the components and architecture

for designing to this level of stress is rudimentary

and has been as common to the designer's toolbox as

a hammer is to a carpenter's toolbox. I quit doing

the test 25 years ago after learning what it took

to pass . . . easily . . . every time.

If the stresses cited are genuine risks to MGL's

products, then they've failed to understand

and embrace the real world stresses found in

mobile DC powered system of all stripe . . . not

the least of which are airplanes.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 02, 2014 6:45 am Post subject: Info on MGL Enigma Posted: Mon Jun 02, 2014 6:45 am Post subject: Info on MGL Enigma |

|

|

At 04:02 AM 6/2/2014, you wrote:

Here is the reply from Rainier, the owner and founder of MGL:

The CR2032 battery is only used to maintain items that change frequently like calculated fuel levels, local pressure settings etc.

Setup is stored in a flash memory section of a secondary processor chip in the EFIS. This does not need a backup battery.

If setup data stored here is not maintained there is usually only one

cause: The supply voltage to that processor is raised briefly (micro-seconds to mill-seconds) above about 8V. This can happen if the supply to the EFIS contains sharp voltage spikes (typically caused by bad regulators or high voltage ignition is coupling into ground or supply).� This can also happen if there are static discharges typically caused by airflow over metal parts that are not grounded.

Eventually, this will damage the flash memory which is the part that dies first in our experience.

When this happens we replace the processor chip. If you have a techie handy - it is a type ATMEL ATMega128. It is a SMD package but easy to solder/desolder if you have the experience. Once replaced I would also recommend replacing the 16Mhz crystal right next to this chip - it tends to wear out over a long time (we replace these as a matter of course when we get an Enigma in for repairs). No specific programming of the new processor needs to be done as the firmware will detect a new processor and do the programming and setup of this chip automatically (the first start-up will take a bit longer and you will see some messages on the display to this effect).

I am exceedingly skeptical of these assertions.

I don't know of a single 5v regulator offered to

the task of conditioning power for electronics

that doesn't handily mitigate any of the commonly

known variables on the ship's bus. DO-160 offers

a clear and concise path to living confidently

in the world of DC powered vehicles.

Crystals that 'wear out'?

Static discharges ? ! ? ! . . . again, for any

piece of hardware to be qualified for installation

on a TC aircraft, it has to be capable of withstanding

15KV discharges of a 150pF capacitor through 330 ohm

resistor fed directly to every input/output pin

on the device under test. TEN times for positive

spikes, TEN more times for negative spikes.

Sound brutal . . . but the components and architecture

for designing to this level of stress is rudimentary

and has been as common to the designer's toolbox as

a hammer is to a carpenter's toolbox. I quit doing

the test 25 years ago after learning what it took

to pass . . . easily . . . every time.

If the stresses cited are genuine risks to MGL's

products, then they've failed to understand

and embrace the real world stresses found in

mobile DC powered system of all stripe . . . not

the least of which are airplanes.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jay(at)horriblehyde.com

Guest

|

Posted: Mon Jun 02, 2014 11:39 pm Post subject: Info on MGL Enigma Posted: Mon Jun 02, 2014 11:39 pm Post subject: Info on MGL Enigma |

|

|

Hello again listers,

Here is a further response from Rainier:

I did not say that spikes or similar ARE the cause of what it going on.

It might be something completely unrelated. It's a pretty complex system.

There are no old style linear regulators in the system.

There are three high frequency switch mode supplies and all input power is

protected by a heavy duty transorb apart from other filtering (mostly

inductive/capacitive).

Nevertheless, we are talking about a system that has multiple connectivity

to other electrical systems on the aircraft - anything going on anywhere and

the EFIS gets it. We are taking about transient events at RF frequencies.

Do-160 simply does not cater for this on a long term bases. But that is

another story.

So, honestly, without actually having the system on a bench and

investigating - and conclusively finding the cause, going on like that is

not called for here.

Getting back to the Flash memory - yes it does fail if it gets transient

power events that make it through the system by whatever path. It may take

years. However that is by no means the only possible cause. Flash is known

to wear over time. Manufacturers of these devices guarantee 10 years of data

retention typically, even if no writes take place - yet these devices are

used throughout the industry for missions where it is assumed that they will

never fail. Usually they don't.

In this case we don't even know if this memory has failed. It might be

something else - perhaps the communications link between main CPU and the

processor that contains this memory has gone faulty. It could be anything.

I'm guessing. That is all I can do without having the Enigma on my bench.

Electronics do fail - does not matter how much money you spend on the

components. Service history of the Enigma has been excellent. The number of

Enigmas coming back to the factory for repairs is almost nil. That is not

too surprising - it has been designed for open cockpit ultralights and it is

quite tough. But they are getting older now and failures of electronic

components become more of a factor. There is something called a "bathtub

failure curve" - because it looks like it. Failures tend to occur when the

device is new (partly the reason we run them for 48 hours at elevated

temperatures during manufacture) - then things settle down and after some

time failure rates start creeping up slowly as things age.

Components that do age are crystals (They are mechanical devices - high

frequency types in particular have a higher failure rate in our experience).

Then we have ceramic capacitors - a typical EFIS has hundreds of them. Some

start leaking after a while. Most of the time that is not an issue but

sometimes it is. We don't use tantalums because of reliability concerns

(good caps but they have an annoying tendency to blow up). Our electrolytics

are top quality devices - can't even remember any failures. Then we get to

the semiconductors. Well, here we have a pretty random failure pattern. They

do die for no apparent reason. The rate is low but it does happen. Yes, we

use aerospace, automotive and industrial spec devices - we do not use

consumer graded devices at all.

Most failures are perhaps related to PCB failures (usually thermal stress

cracking vias). Some of our PCBs are high tech multi-layer. They are more

sensitive - part of the process. Some assemblies are lead free and the

entire industry has been battling for years with "tin-wiskers".

Microscopic growths of tin between tracks and pads. Only visible under a

microscope. Takes years to cause a problem. That we have had. Lucky this is

not so much of an issue anymore as lead free processes and fluxes have

improved and I have yet to see such an issue on anything produced in the

last 4 or 5 years. "Cold solder joints" - that happens either via repeated

thermal stress cracking a solder joint or a manufacturing defect that may

take years to manifest itself. Yes, it happens. It passes all tests and

optical quality controls (we use an automated AOI machine plus visual checks

at various stages during the assembly

process) - yet it still manages to avoid early detection. Sure, the rate is

low but we make thousands of devices every month. Including devices not

intended for aircraft (and not under our brand name). I would love a zero

failure rate. Failures are bad. Everybody gets annoyed - from the customer

to us. We can't have a zero failure rate - that is a pipe dream. But we can

always work to reduce it to the barest minimum. If we did not do that we'd

be out of business long ago.

Most of our repairs are directly related to what we call "blow ups".

Reverse polarity issues, connecting power or grounds to the wrong places

etc. Interface driver chips (RS232, CAN, switches etc) blown for various

reasons - the items directly connected to the outside World.

All of that happens typically during installation. Mostly with the so called

"professional installers, AMOs etc". I'm not kidding. We find the home

builders are the ones with the least issues - perhaps because most take the

time to study the docs and plan their wiring. There is no rush, no

deadlines. That helps.

Our statistics (which we do keep for obvious reasons) shows this trend very

clearly.

Instruments get dropped, might have a hard time during transport - sometimes

they get soaked in water or oil.

Anyway, I can't really comment on this Enigma until I see it myself (if that

ever happens). If there is a problem, whatever the cause may be - we can fix

it. That is the bottom line.

Rainier

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Tue Jun 03, 2014 5:40 am Post subject: Re: Battery Was MGL Enigma Posted: Tue Jun 03, 2014 5:40 am Post subject: Re: Battery Was MGL Enigma |

|

|

It is hard to say that a 3V battery measuring 2.9V is dead or not depending on load. The nominal discharge current of the battery is 0.2 mA. Putting a 150k in parallel will show 2.9V or above for a still good battery. But since getting there is half the work, change it.

http://www.adafruit.com/datasheets/maxell_cr2032_datasheet.pdf

See DX.com (Deal Extreme) for a 10 pack of Sony 3V CR2032 Lithium Ion

$5.98. Free shipping

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Jun 03, 2014 11:00 am Post subject: Info on MGL Enigma Posted: Tue Jun 03, 2014 11:00 am Post subject: Info on MGL Enigma |

|

|

At 02:37 AM 6/3/2014, you wrote:

--> AeroElectric-List message posted by: "Jay Hyde" <jay(at)horriblehyde.com>

Hello again listers,

Here is a further response from Rainier:

I did not say that spikes or similar ARE the cause of what it going on.

It might be something completely unrelated. It's a pretty complex system.

. . . then why even mention it? The customer

does not benefit from a narration of possible

causes . . . especially when those causes include

things that 'might' be wrong with his airplane.

But to assert that stresses external to the

product's enclosure can zap a micro-controller

does nothing to engender confidence in the rest of

hardware under the best of circumstances.

There are no old style linear regulators in the system.

There are three high frequency switch mode supplies and all input power is

protected by a heavy duty transorb apart from other filtering (mostly

inductive/capacitive).

<SNIP>

Electronics do fail - does not matter how much money you spend on the

components. Service history of the Enigma has been excellent. The number of

Enigmas coming back to the factory for repairs is almost nil.

When we conduct a reliability study on an assembly,

powers-that-be don't really start smiling until

your aggregate MTBF drops below 1 x 10 minus 7

failures per flight hour. For critical systems

1 x 10 minus 9 is the target.

So if your device has 100 components in it, INDIVIDUAL

failure rates have to be 100x better than the aggregate.

If this guy has crystals that warrant routine replacement

base on some fielded experience . . . he is well

advised to change brands.

<snip>

intended for aircraft (and not under our brand name). I would love a zero

failure rate. Failures are bad. Everybody gets annoyed - from the customer

to us. We can't have a zero failure rate - that is a pipe dream. But we can

always work to reduce it to the barest minimum. If we did not do that we'd

be out of business long ago.

Most of our repairs are directly related to what we call "blow ups".

Reverse polarity issues, connecting power or grounds to the wrong places

etc. Interface driver chips (RS232, CAN, switches etc) blown for various

reasons - the items directly connected to the outside World.

One cannot necessarily design every i/o port

to withstand the vagaries of neophyte installations

but failures of components not connected directly

to the outside world is cause for concern.

All of that happens typically during installation. Mostly with the so called

"professional installers, AMOs etc". I'm not kidding. We find the home

builders are the ones with the least issues - perhaps because most take the

time to study the docs and plan their wiring. There is no rush, no

deadlines. That helps.

Our statistics (which we do keep for obvious reasons) shows this trend very

clearly.

Instruments get dropped, might have a hard time during transport - sometimes

they get soaked in water or oil.

Anyway, I can't really comment on this Enigma until I see it myself (if that

ever happens). If there is a problem, whatever the cause may be - we can fix

it. That is the bottom line.

To be sure, nobody can offer "zero failure rates" but

they can be exceedingly small. Builders anticipating operations

over long stretches of unfriendly terrain or in IMC would be well

advised to craft 'plan-b', 'plan-c' or whatever in the

event the whole system goes belly-up. "Barest minimum"

failure rates are un-quantified.

If we had any hardware coming back from the field

suffering some of the failures cited above . . .

things around here would, shall we say, get

very 'tense'?

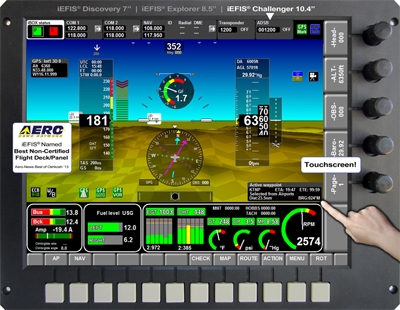

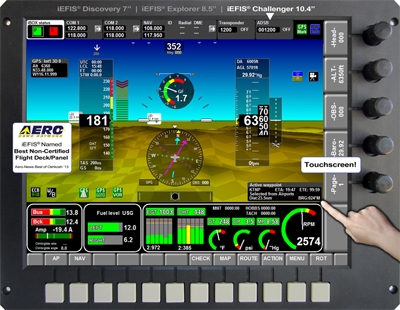

A display with this kind of data . ..

[img]cid:.0[/img]

implies certain capabilities. Capabilities that

require TC aircraft designers to go Level A

software/hardware, careful partitioning of

functions and probably dual screens.

Do your own Failure Modes Effects Analysis

based on how you need to use this hardware.

Have a solid alternative for every situation

when it isn't working.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

123.89 KB |

| Viewed: |

6335 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|