|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

tomhanaway

Joined: 12 Aug 2006

Posts: 111

Location: Murphy, NC

|

Posted: Sat Jul 12, 2014 1:15 pm Post subject: Dual master solenoids Posted: Sat Jul 12, 2014 1:15 pm Post subject: Dual master solenoids |

|

|

Working my way through Nuckoll's Z-13 wiring diagram.

I'm building an 8-a VFR with single battery, single alternator.

I'm not excited about the use of his "always hot" main bus because of the additional wire runs it would create from the buss mounted close to the rear mounted battery and difficulty accessing fuses for those wires.

I'd like to run all electrical busses from the always hot side of the starter solenoid (always hot when master solenoid is hot).

Given this scenario, it seems that the really significant system weakness is the failure of the master solenoid. I was thinking that a second master solenoid, with a separate wire and switch, wired in parallel at the battery, would address this issue.

Does this make sense or am I missing something obvious (or not so obvious)?

Thanks,

Tom H.

Sent from my iPad

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

RV-10. Built and sold

RV-8a. Building |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jul 12, 2014 3:14 pm Post subject: Dual master solenoids Posted: Sat Jul 12, 2014 3:14 pm Post subject: Dual master solenoids |

|

|

At 04:14 PM 7/12/2014, you wrote:

| Quote: |

Working my way through Nuckoll's Z-13 wiring diagram.

I'm building an 8-a VFR with single battery, single alternator.

I'm not excited about the use of his "always hot" main bus because

of the additional wire runs it would create from the buss mounted

close to the rear mounted battery and difficulty accessing fuses for

those wires.

|

That's not a "MAIN BUS" . . . it's the MAIN BATTERY

always-hot with exceedingly limited but often important

tasks in getting power distributed to your airplane.

GA airplanes have had always-hot busses since the

clock and hour-meter fuses were mounted right next

to the battery master contactor in the tail . . . in

Cessnas I worked on in 1965.

Study Z-13 again (or perhaps Z-11 which is a single

alternator version). Also the notes for the z-figures

along with the chapter on system reliability.

| Quote: | I'd like to run all electrical busses from the always hot side of

the starter solenoid (always hot when master solenoid is hot).

|

Not sure what's driving this . . . The Z-figures are

the culmination of over 45+ years experience in TC

aviation enhanced by 25+ years in OBAM aviation exploiting

the freedoms not enjoyed by TC aviation . . . to craft an

architecture that meets YOUR mission requirements . . .

not those of a bureaucracy most of whom do not build or

fly airplanes.

| Quote: | Given this scenario, it seems that the really significant system

weakness is the failure of the master solenoid. I was thinking that

a second master solenoid, with a separate wire and switch, wired in

parallel at the battery, would address this issue.

Does this make sense or am I missing something obvious (or not so obvious)?

|

It's not clear that you understand the philosophy behind

the various architectures and functionality of their

several features.

Suggest you PLAN for Z-13/8 by having all the WIRES

in place to have a second alternator . . . unless you're

going to have a vacuum pump, the consider NOT plugging

a perfectly good source of mechanical energy with a

cover plate.

Print out copies of http://tinyurl.com/7jqypwj one for

each bus. It generally takes three.

List each load services by the various busses along

with their magnitudes and flight configurations that

the loads are expected/necessary.

You may not need a battery bus . . . but get all your

loads defined first . . . then decide what bus

structures are needed.

Do you plan any sort of electronic ignition. The

RV8 is low wing so you no doubt have electric

fuel pumps. Does any of your proposed electrics

need memory keep-alive power? I single alternator,

what's your goal for battery-only endurance? The

load analysis study will let you set necessary battery

size based on predicted loads. There's lot of

sifting of requirements that will drive what

gets powered from which busses.

Go with Z-13/8 with second 4-pound alternator

and your alternator-out endurance deliberations

get a WHOLE LOT easier.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Sat Jul 12, 2014 9:54 pm Post subject: Dual master solenoids Posted: Sat Jul 12, 2014 9:54 pm Post subject: Dual master solenoids |

|

|

TOM,

Then you may as well have two of everything.

Remember the cardinal rule..." build in simplicity and lightness"Â

Bob  Verwey On 12 Jul 2014 11:22 PM, "Tomhanaway" <tomhanaway1(at)gmail.com (tomhanaway1(at)gmail.com)> wrote:[quote] --> AeroElectric-List message posted by: Tomhanaway <tomhanaway1(at)gmail.com (tomhanaway1(at)gmail.com)>

Working my way through Nuckoll's Z-13 wiring diagram.

I'm building an 8-a VFR with single battery, single alternator.

I'm not excited about the use of his "always hot" main bus because of the additional wire runs it would create from the buss mounted close to the rear mounted battery and difficulty accessing fuses for those wires.

I'd like to run all electrical busses from the always hot side of the starter solenoid (always hot when master solenoid is hot).

Given this scenario, it seems that the really significant system weakness is the failure of the master solenoid. I was thinking that a second master solenoid, with a separate wire and switch, wired in parallel at the battery, would address this issue.

Does this make sense or am I missing something obvious (or not so obvious)?

Thanks,

Tom H.

Sent from my iPad

===========

-

ric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

MS -

k">http://forums.matronics.com

===========

e -

-Matt Dralle, List Admin.

t="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

tomhanaway

Joined: 12 Aug 2006

Posts: 111

Location: Murphy, NC

|

Posted: Sun Jul 13, 2014 2:56 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 2:56 am Post subject: Dual master solenoids |

|

|

I understand that but it doesn't answer my question.

Is there anything from an electrical point of view that keeps this from working. I.e., the backup master solenoid would have 12 vdc at both terminals whenever the primary master solenoid is turned on even if the aux master solenoid switch is not on. My goal is to have the aux solenoid sitting idle unless activated by a switch.

Tom

Sent from my iPad

On Jul 13, 2014, at 1:50 AM, Bob Verwey <bob.verwey(at)gmail.com (bob.verwey(at)gmail.com)> wrote:

[quote]

TOM,

Then you may as well have two of everything.

Remember the cardinal rule..." build in simplicity and lightness"

Bob Verwey On 12 Jul 2014 11:22 PM, "Tomhanaway" <tomhanaway1(at)gmail.com (tomhanaway1(at)gmail.com)> wrote: | Quote: | --> AeroElectric-List message posted by: Tomhanaway <tomhanaway1(at)gmail.com (tomhanaway1(at)gmail.com)>

Working my way through Nuckoll's Z-13 wiring diagram.

I'm building an 8-a VFR with single battery, single alternator.

I'm not excited about the use of his "always hot" main bus because of the additional wire runs it would create from the buss mounted close to the rear mounted battery and difficulty accessing fuses for those wires.

I'd like to run all electrical busses from the always hot side of the starter solenoid (always hot when master solenoid is hot).

Given this scenario, it seems that the really significant system weakness is the failure of the master solenoid. I was thinking that a second master solenoid, with a separate wire and switch, wired in parallel at the battery, would address this issue.

Does this make sense or am I missing something obvious (or not so obvious)?

Thanks,

Tom H.

Sent from my iPad

===========

-

ric-List" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

MS -

k">http://forums.matronics.com

===========

e -

-Matt Dralle, List Admin.

t="_blank">http://www.matronics.com/contribution

===========

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

RV-10. Built and sold

RV-8a. Building |

|

| Back to top |

|

|

kleh(at)dialupatcost.ca

Guest

|

Posted: Sun Jul 13, 2014 3:47 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 3:47 am Post subject: Dual master solenoids |

|

|

I don't see a problem with a dual master although I wonder if it really

achieves your goal or achieves it as elegantly as one of the Z

architectures. The failures of contactors that I've seen are failures to

activate not failures during flight. I do agree that any truly essential

system such as engine power should not be tied to a single contactor but

the battery buss and/or essential buss concept seem like a better

solution where applicable. Don't forget that a backup has little value

unless tested regularly. For example, I test my backup EFI during taxi

on every flight and it has always worked perfectly. I happened to test

it in flight yesterday and discovered that it has started to miss at

high power which pretty much means it has been useless dead weight for

some undetermined length of time as I do not often test it at high power

settings.

Ken

On 13/07/2014 6:55 AM, Tomhanaway wrote:

| Quote: | I understand that but it doesn't answer my question.

Is there anything from an electrical point of view that keeps this from

working. I.e., the backup master solenoid would have 12 vdc at both

terminals whenever the primary master solenoid is turned on even if the

aux master solenoid switch is not on. My goal is to have the aux

solenoid sitting idle unless activated by a switch.

Tom

Sent from my iPad

On Jul 13, 2014, at 1:50 AM, Bob Verwey <bob.verwey(at)gmail.com

<mailto:bob.verwey(at)gmail.com>> wrote:

> TOM,

> Then you may as well have two of everything.

>

> Remember the cardinal rule..." build in simplicity and lightness"

>

> Bob Verwey

>

> On 12 Jul 2014 11:22 PM, "Tomhanaway" <tomhanaway1(at)gmail.com

> <mailto:tomhanaway1(at)gmail.com>> wrote:

>

>

> <tomhanaway1(at)gmail.com <mailto:tomhanaway1(at)gmail.com>>

>

> Working my way through Nuckoll's Z-13 wiring diagram.

> I'm building an 8-a VFR with single battery, single alternator.

>

> I'm not excited about the use of his "always hot" main bus because

> of the additional wire runs it would create from the buss mounted

> close to the rear mounted battery and difficulty accessing fuses

> for those wires.

>

> I'd like to run all electrical busses from the always hot side of

> the starter solenoid (always hot when master solenoid is hot).

>

> Given this scenario, it seems that the really significant system

> weakness is the failure of the master solenoid. I was thinking

> that a second master solenoid, with a separate wire and switch,

> wired in parallel at the battery, would address this issue.

>

> Does this make sense or am I missing something obvious (or not so

> obvious)?

>

> Thanks,

> Tom H.

>

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kjashton(at)vnet.net

Guest

|

Posted: Sun Jul 13, 2014 3:48 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 3:48 am Post subject: Dual master solenoids |

|

|

On Jul 13, 2014, at 6:55 AM, Tomhanaway wrote:

| Quote: | Is there anything from an electrical point of view that keeps this from working.

|

There is no electrical reason why your idea won't work but why do it? Master solenoids don't typically fail in-flight. They typically don't fail at all if installed as Bob suggests, unless the posts are tightened incorrectly and twist the internal contacts. If one does fail, you can find a replacement at a FLAPS. If your engine has magnetos, an inflight failure won't matter. If you are using EIs, you'll probably have ignition power straight off the battery so it still won't matter.

Put the cost and the weight-cost of an additional heavy solenoid, additional foot or so of heavy AWG 2-4 wire, additional panel switch and wiring against the low chance you'll ever need it.

-Kent

Cozy IV

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jul 13, 2014 7:00 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 7:00 am Post subject: Dual master solenoids |

|

|

At 06:47 AM 7/13/2014, you wrote:

| Quote: |

<kjashton(at)vnet.net>

On Jul 13, 2014, at 6:55 AM, Tomhanaway wrote:

> Is there anything from an electrical point of view that keeps

this from working.

There is no electrical reason why your idea won't work but why do

it? Master solenoids don't typically fail in-flight.

|

. . . and even if they did, the battery-bus/e-bus

architectures are crafted to keep things comfortable

in the cockpit even if it DID fail . . . in fact,

the germinating idea behind the dual-feedpath e-bus

was to facilitate a deliberate opening of the

battery master contactor as part of load shedding

protocol for battery-only operations.

Suggest you do your own failure mode effects

analysis where you consider the risks for a

failure of any single component of your electrical

system. If you discover a failure that puts

comfortable termination of flight at risk,

then let's talk about it. I'm certain

that with judicious selection of accessories

and distribution of power, you can craft

a system where worries about the battery master

contactor are at the bottom of the risk assessment

list.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

BobsV35B(at)aol.com

Guest

|

Posted: Sun Jul 13, 2014 7:26 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 7:26 am Post subject: Dual master solenoids |

|

|

Just a test .Please excuse my interruption.

Old Bob

Do Not Archive

In a message dated 7/13/2014 10:01:58 A.M. Central Daylight Time, nuckolls.bob(at)aeroelectric.com writes:

| Quote: | --> AeroElectric-List message posted by: "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com>

At 06:47 AM 7/13/2014, you wrote:

| Quote: | --> AeroElectric-List message posted by: Kent or Jackie Ashton

<kjashton(at)vnet.net>

On Jul 13, 2014, at 6:55 AM, Tomhanaway wrote:

> Is there anything from an electrical point of view that keeps

this from working.

There is no electrical reason why your idea won't work but why do

it? Master solenoids don't typically fail in-flight.

|

. . . and even if they did, the battery-bus/e-bus

architectures are crafted to keep things comfortable

in the cockpit even if it DID fail . . . in fact,

the germinating idea behind the dual-feedpath e-bus

was to facilitate a deliberate opening of the

battery master contactor as part of load shedding

protocol for battery-only operations.

Suggest you do your own failure mode effects

analysis where you consider the risks for a

failure of any single component of your electrical

system. If you discover a failure that puts

comfortable termination of flight at risk,

then let's talk about it. I'm certain

that with judicious selection of accessories

and distribution of power, you can craft

a system where worries about the battery master

contactor are at the bottom of the risk assessment

list.

Bob . . . = Use ilities ay - MATRONICS WEB FORUMS - List Contribution Web Site p;

|

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jul 13, 2014 10:21 am Post subject: Dual master solenoids Posted: Sun Jul 13, 2014 10:21 am Post subject: Dual master solenoids |

|

|

At 10:24 AM 7/13/2014, you wrote:

| Quote: | Just a test .Please excuse my interruption.

Old Bob

Do Not Archive

|

Bob,

I'm replying through the List and with a copy

to you directly. Have you sorted your email

marbles out?

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Sun Jul 13, 2014 6:10 pm Post subject: Re: Dual master solenoids Posted: Sun Jul 13, 2014 6:10 pm Post subject: Re: Dual master solenoids |

|

|

| Quote: | I'm not excited about the use of his "always hot" main bus because of the additional wire runs it would create from the buss mounted close to the rear mounted battery and difficulty accessing fuses for those wires.

I'd like to run all electrical busses from the always hot side of the starter solenoid (always hot when master solenoid is hot). |

Schematics do not indicate how wires are routed in an aircraft. They show the logic of a circuit, not necessarily the physical layout. The heavy wire that supplies power to the main power distribution bus can be connected to either end of the wire between the two contactors (main battery and start). Your idea of connecting to the always hot side of the starter contactor is identical (electrically speaking) to Bob's schematic.

| Quote: | | I was thinking that a second master solenoid, with a separate wire and switch, wired in parallel at the battery, would address this issue. |

Like Bob said, the E-bus circuit addresses this issue. If you would rather backup the main battery contactor, it can be done with an automotive 30 or 40 amp relay at a fraction of the weight. The relay must be disabled during engine cranking, maybe like the attached circuit.

But keep in mind that the more complicated and the more components , the more to go wrong.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

Backup Relay.pdf |

| Filesize: |

164.15 KB |

| Downloaded: |

527 Time(s) |

_________________

Joe Gores |

|

| Back to top |

|

|

tomhanaway

Joined: 12 Aug 2006

Posts: 111

Location: Murphy, NC

|

Posted: Mon Jul 14, 2014 3:15 am Post subject: Re: Dual master solenoids Posted: Mon Jul 14, 2014 3:15 am Post subject: Re: Dual master solenoids |

|

|

Thanks Joe,

Once I started thinking in terms of a relay, this came pretty close to what I was looking for.

Interesting use of a starter enable/disable switch to ensure no cranking current through relay.

Interesting question ( to me, anyway), are heavy duty continuous service relays any less reliable than mechanical relays? If about the same

reliability, what are the reasons that they aren't used more often for a

master solenoid? As you stated, the weight differential is pretty significant.

Thanks again,

Tom

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

RV-10. Built and sold

RV-8a. Building |

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Mon Jul 14, 2014 4:06 am Post subject: Re: Dual master solenoids Posted: Mon Jul 14, 2014 4:06 am Post subject: Re: Dual master solenoids |

|

|

| Quote: | | are heavy duty continuous service relays any less reliable than mechanical relays? If about the same reliability, what are the reasons that they aren't used more often for a master solenoid? |

There are several ways that a relay or contactor can fail. The contacts can develop a high resistance, the coil can burn open, springs or other mechanical parts can break, and etc. I do not know which type is more likely to fail. The current carrying capability determines which relay or contactor to use. Starters can draw a few hundred amps initially to get the engine rotating. A 30 amp automotive relay would not last very long carrying that much current.

So why have the starter current go though the master contactor? The starter contactor could be wired directly to the battery. I think the reason is that contactors have been known to fail closed. Having two contactors in series makes sure that the circuit can be opened.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jul 14, 2014 6:45 am Post subject: Dual master solenoids Posted: Mon Jul 14, 2014 6:45 am Post subject: Dual master solenoids |

|

|

At 07:06 AM 7/14/2014, you wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com>

> are heavy duty continuous service relays any less reliable than mechanical relays? If about the same reliability, what are the reasons that they aren't used more often for a master solenoid? |

"Reliability" is a rather soggy concept.

It can mean different things to most speakers

in a group of conversants. If you

write to Stancore/White-Rogers and ask,

just HOW reliable is your 70-110 contactor?

. . . they MIGHT fire back with a laboratory

study that cites cycle-life of the contactor

under various loads and perhaps environmental

conditions. Write to Tyco about reliability

of their Kilovac contactors and you MIGHT

get another report.

Okay, Tyco's numbers are better than S/W-R

numbers . . . now what?

As I've been explaining in my writing and

presentations for the past 30 years, the

elegant design has little, if any, interest

in those numbers. Lessons-learned in over

a century of building airplanes have demonstrated

that the designer's prime directive is to

reduce risk for a bad day in the cockpit.

To be sure, if money, weight, $time$

to market and cost of ownership were

of no concern, then there are virtually

limitless ways that hedges against risk

can be applied to the system. But applied

without the confidence that comes from

understanding there is a larger risk that

the end-product is burdened with "safety

features" that degrade performance to

far greater degrees than protecting the

airframe and crew.

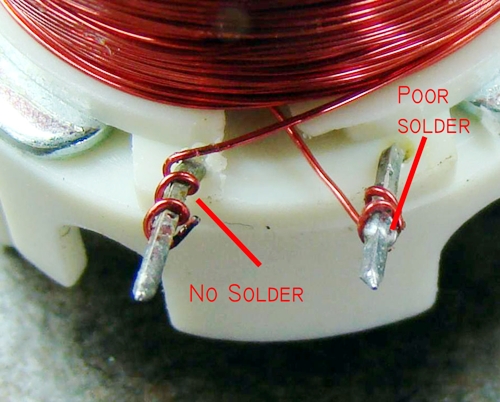

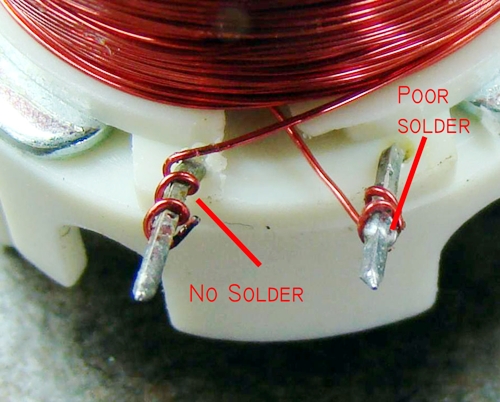

[img]cid:7.1.0.9.0.20140714094258.04cc69a8(at)aeroelectric.com.2[/img]

My teachers would ask, "Okay, you've selected a

whiz-bang part for that location in the airplane,

make your case for the decision." Had I whipped

out the reliability data sheets for the constellation

of choices and said, "See here, look at THOSE numbers!"

they might have banished me to purchasing support

or perhaps the EMC lab.

The first bit of guidance germane to your decision

resides in lessons-learned. Question: How many

times have pilots experienced a bad day in the

cockpit due to in-flight failure of the battery

master contactor?

I haven't a clue . . . because the incidents have

been so few in numbers and so benign as to become

completely buried in COMPONENT failures that

put the whole SYSTEM at risk . . . The aviation

journals are replete with what I have called

"dark n stormy night" stories . . . most of

which are so lacking in data as to defy understanding

of root cause . . . or more illustrative of human

weaknesses than those of the airplane.

Consider that EVERY contactor is RATED and

TESTED in the lab to perform as advertised

for tens of thousands of cycles at rated lioad.

YOUR battery contactor is going to close/open

once per flight cycle . . . perhaps 100 times

per YEAR and under nearly zero-load conditions.

Were you to conduct laboratory reliability

testing for conditions in YOUR airplane, it's

unlikely that you would ever see a failure.

We HAVE seen some failures here on the List.

Detailed analysis revealed failure due to

a variety of reasons including manufacturing

defects

[img]cid:7.1.0.9.0.20140714094258.04cc69a8(at)aeroelectric.com.3[/img]

moisture ingress, and installation error . . . but in no

case were the failures first detected in flight.

Carrying lessons-learned a step further we can conduct

a failure effects study. You do this by ASSUMING that every

part will fail at some point in time. You then analyze

how that failure will affect system performance. For

failures that pose unacceptable risk, you make some

design changes. Except for things like wing struts

and prop bolts, the elegant design drives more toward

failure TOLERANCE than failure PROOF.

See: http://tinyurl.com/ozum5u9

If your studies for optimal design are driving you

toward the purchase of high-dollar hardware -OR-

adding backup components, then perhaps your confidence

born of lessons-learned and artful conduct of

failure analysis is shaky. I suggest that crafting

any of the Z-Figures chosen to match your mission

profiles and hardware will produce an exceedingly

failure tolerant system. I suggest further that

Z13/8 has more bang for the buck/pound/volume than

systems flying in some pretty sophisticated airplanes.

The very first example of Z13-8 flying in an OBAM

aircraft was in an RV-8 in Connecticut about 25

years ago . . . the father-son build team were

delighted with its performance and confidence

levels.

They could loose a battery master contactor

every few months and not suffer a bad day in

the cockpit . . . but I'll bet that the Model

70 contactor installed day-on is still flying.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

237.27 KB |

| Viewed: |

15533 Time(s) |

|

| Description: |

|

| Filesize: |

157.93 KB |

| Viewed: |

15533 Time(s) |

|

|

|

| Back to top |

|

|

uuccio(at)gmail.com

Guest

|

Posted: Tue Jul 15, 2014 5:59 am Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 5:59 am Post subject: Dual master solenoids |

|

|

It's also a safety issue with some starter configurations. For instance if you had a momentary push button for the starter instead of a key switch, even with the master off you would still be able to push the button and turn the prop.

I have this configuration and as an added safety while the aircraft is stopped and the master needs to be on, I always pull the starter CB.

Sacha

| Quote: | On 14 Jul 2014, at 14:06, "user9253" <fransew(at)gmail.com> wrote:

Having two contactors in series makes sure that the circuit can be opened.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

stein(at)steinair.com

Guest

|

Posted: Tue Jul 15, 2014 6:53 am Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 6:53 am Post subject: Dual master solenoids |

|

|

Aside from some anecdotal references that are oft repeated at hangar flying

sessions and on the interwebs, have you or do you know of a specific

instance where a master contactor/solenoid of standard design failed

repeatedly? All mechanical things have "been known to fail", but we build

airplanes around the 99th percentile, not the 1th percentile. If you built

a perfectly safe airplane, it would be one that wouldn't leave the

ground....so to that end you design in for the 99th, but also take into

account the 1th percentiles without doing crazy things like putting in two

master contactors or two tachometers (unless of course you have two

batteries, or two busses, etc..). If you are going to put in two of those,

why not two starter buttons, or two circuit breakers for each circuit, or

two throttle cables, or two rudders, or two elevator pushrods, (after all,

those have also been known to fail)? You still do only have one camshaft

and one propeller and one crankshaft and one carb/fuel injector, one brain,

etc..

My point is that the probability of failure of that specific components is

likely less than the probability of other equally as important mechanical

things in your plane. There is no reason to randomly pick one particular

component and focus on it over another when it has not proven to be a weak

point in the entire aerospace vehicle system design.

Just my 2 cents as usual, but one could come up with all sorts of 1th

percentile "possibilities" that are really not worth expending energy, time,

money, weight or complexity on as the return on all of that in actuality

becomes a negative. Remember, adding things for "redundancy" does not

necessarily and automatically translate into reliability - many times it has

the inverse effect (increased complexity = decreased reliability).

Cheers,

Stein

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Jul 15, 2014 10:56 am Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 10:56 am Post subject: Dual master solenoids |

|

|

At 08:57 AM 7/15/2014, you wrote:

| Quote: |

It's also a safety issue with some starter configurations. For

instance if you had a momentary push button for the starter instead

of a key switch, even with the master off you would still be able to

push the button and turn the prop.

|

Irrespective of the kind of switch that energizes

the starter, I'm aware of no TC aircraft, or any

OBAM aircraft wired per a Z-figure where this is

the cased. The general rule of thumb for all

airplanes is that opening the battery master

contactor removes ALL power from the aircraft

except for those items wired to a battery bus.

Starters should be dead-in-place with the

battery master off.

| Quote: | I have this configuration and as an added safety while the aircraft

is stopped and the master needs to be on, I always pull the starter CB.

|

How was it that you came to wire your airplane

this way?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Jul 15, 2014 11:35 am Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 11:35 am Post subject: Dual master solenoids |

|

|

My point is that the probability of failure of that specific components is

likely less than the probability of other equally as important mechanical

things in your plane. There is no reason to randomly pick one particular

component and focus on it over another when it has not proven to be a weak

point in the entire aerospace vehicle system design.

Precisely . . .

When opening the seminar segment on

reliability, I like to put a z-figure

up on the screen, point to a component

and ask, "What do you need to do if THIS

part malfunctions?"

At least one participant will suggest

that it be replaced with a 'better part'.

That's the segment where I pose the notion

that the flight SYSTEM consists of an airframe,

pilot, environment and expendable resources.

From the time the wheels break ground until

you're parked at the destination, the design

goal is not break a sweat . . . irrespective

of any component failure.

The last few ideas offered at the end of

the segment suggests that it doesn't matter

if you buy electrical parts from Autozone, $high$

parts from Honeywell or TC aircraft parts from

the Cessna warehouse . . . it is possible to

ARCHITECTURE the electrical system such that

no single component failure will induce an

in-flight sweat.

In the final analysis, you're more likely

to have a bad day in the cockpit driven by

events and conditions far removed from

things electrical. #1 cause of engine

stoppage is fuel starvation. #1 cause

for unplanned arrivals with the earth

are most often based on human factors for dealing

with environment: weather, mountains,

night ops, etc.) As we have studied many

times here on the List . . . mishaps

that included electrical issues were

FIRST driven by lapses in assembly skills,

failure tolerant design or poor maintenance.

See: http://tinyurl.com/ky7szec

In other words, "two parts" or a "better

part" would not have produced a better

outcome.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

uuccio(at)gmail.com

Guest

|

Posted: Tue Jul 15, 2014 12:34 pm Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 12:34 pm Post subject: Dual master solenoids |

|

|

| Quote: | It's also a safety issue with some starter configurations. For instance

if you had a momentary push button for the starter instead of a key

switch, even with the master off you would still be able to push the

button and turn the prop.

|

Irrespective of the kind of switch that energizes

the starter, I'm aware of no TC aircraft, or any

OBAM aircraft wired per a Z-figure where this is

the cased. The general rule of thumb for all

airplanes is that opening the battery master

contactor removes ALL power from the aircraft

except for those items wired to a battery bus.

Starters should be dead-in-place with the

battery master off.

Hi Bob, I was referring to the hypothetical situation that Joe brought up

where the starter contactor would be always hot, i.e. wired to the battery

bus.

| Quote: | I have this configuration and as an added safety while the aircraft is

stopped and the master needs to be on, I always pull the starter CB.

|

How was it that you came to wire your airplane

this way?

My apologies, I wasn't very clear... My electrical setup is essentially

Z-16, but the starter button is a push button. So whenever I am tinkering

around on the ground and the master needs to be on, I pull the starter CB

just to be safe. Another situation is when my three year old wants to sit

next to me in the a/c and see the panel light up and pretend he's flying the

aircraft...

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Jul 15, 2014 3:11 pm Post subject: Dual master solenoids Posted: Tue Jul 15, 2014 3:11 pm Post subject: Dual master solenoids |

|

|

My apologies, I wasn't very clear... My electrical setup is essentially

Z-16, but the starter button is a push button. So whenever I am tinkering

around on the ground and the master needs to be on, I pull the starter CB

just to be safe. Another situation is when my three year old wants to sit

next to me in the a/c and see the panel light up and pretend he's flying the

aircraft...

Understand . . . thanks!

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|