|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Ernie

Joined: 11 Jan 2006

Posts: 513

|

Posted: Wed Apr 01, 2015 11:52 am Post subject: Main Air Tank Install. Posted: Wed Apr 01, 2015 11:52 am Post subject: Main Air Tank Install. |

|

|

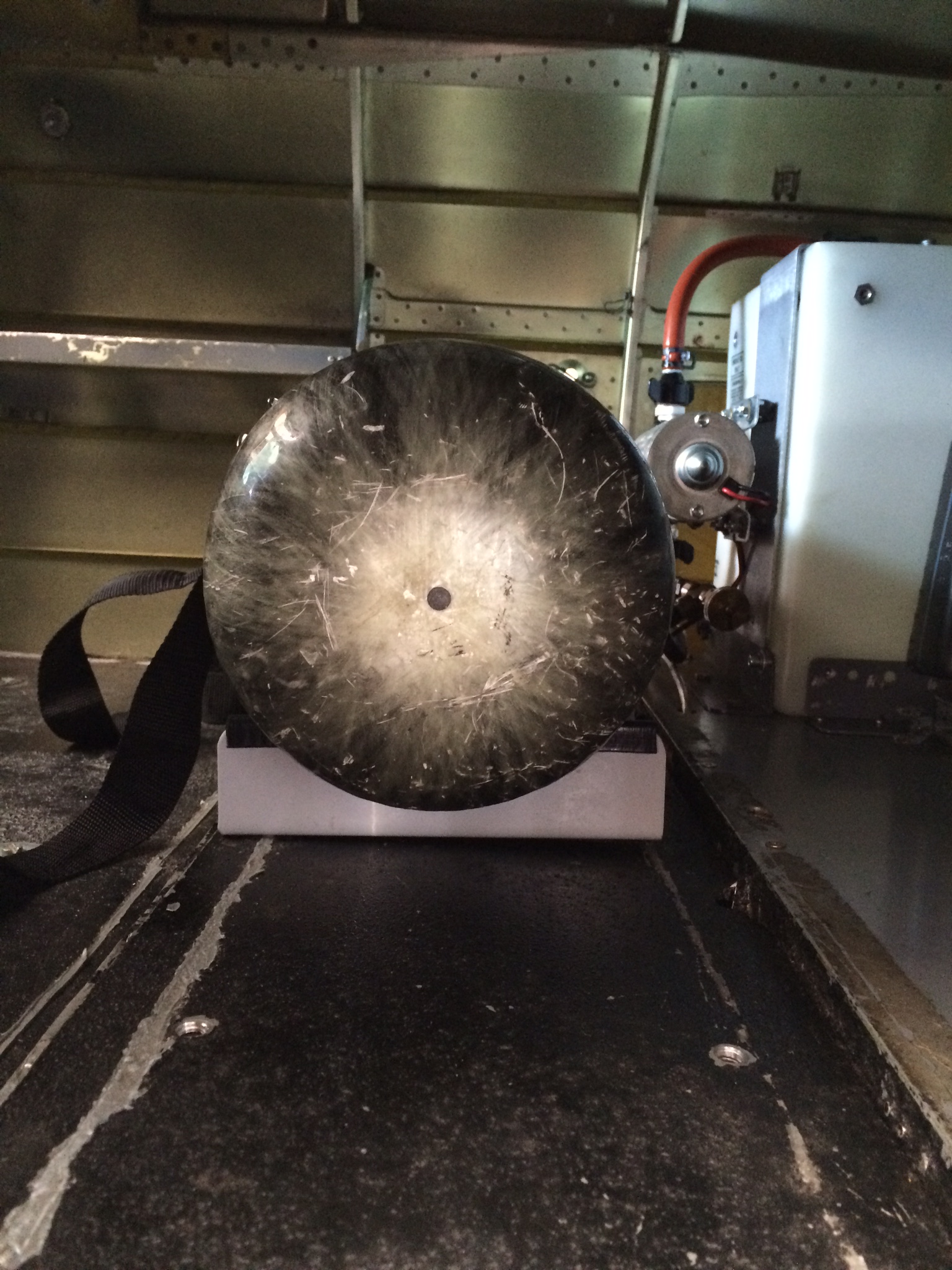

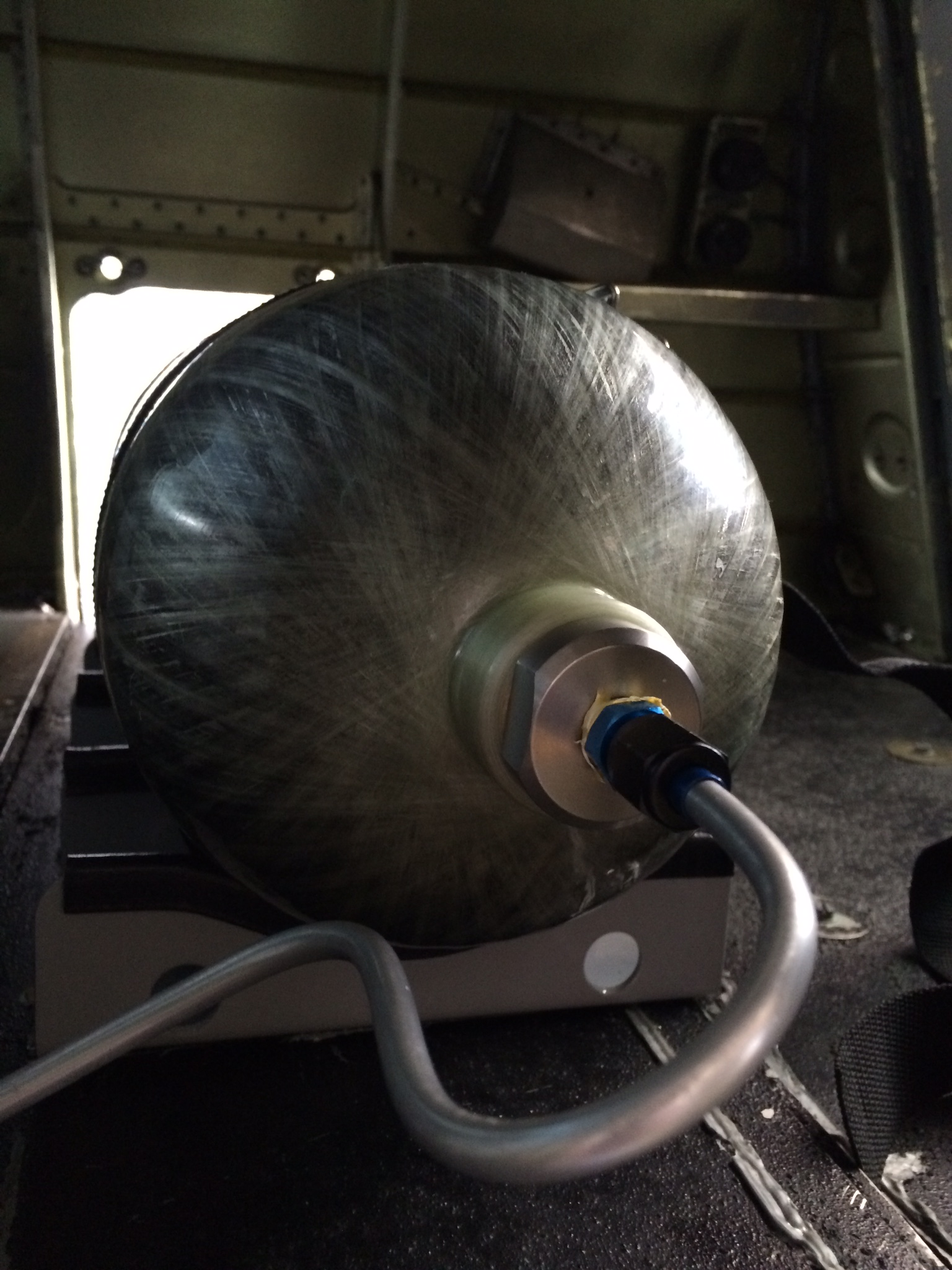

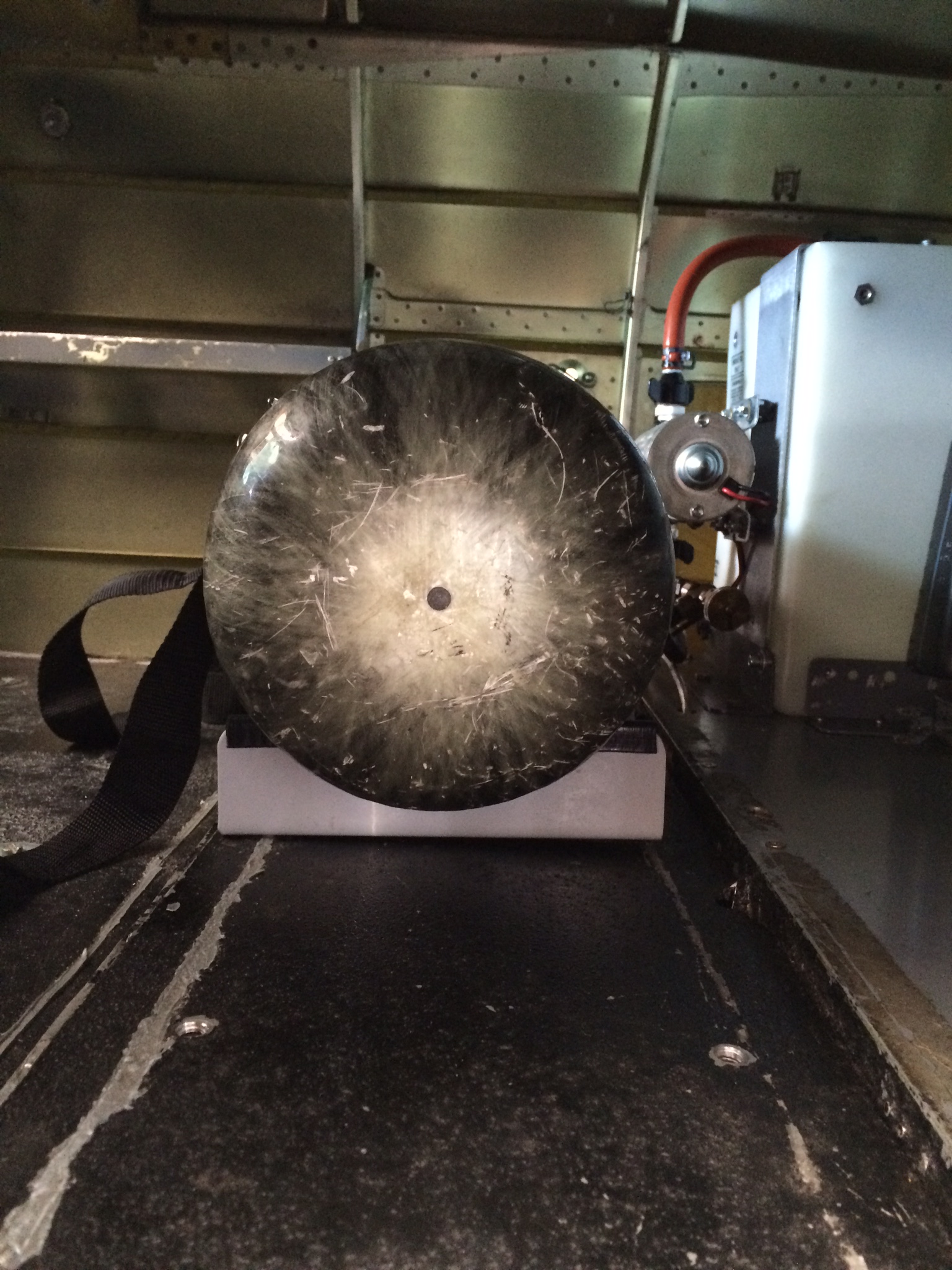

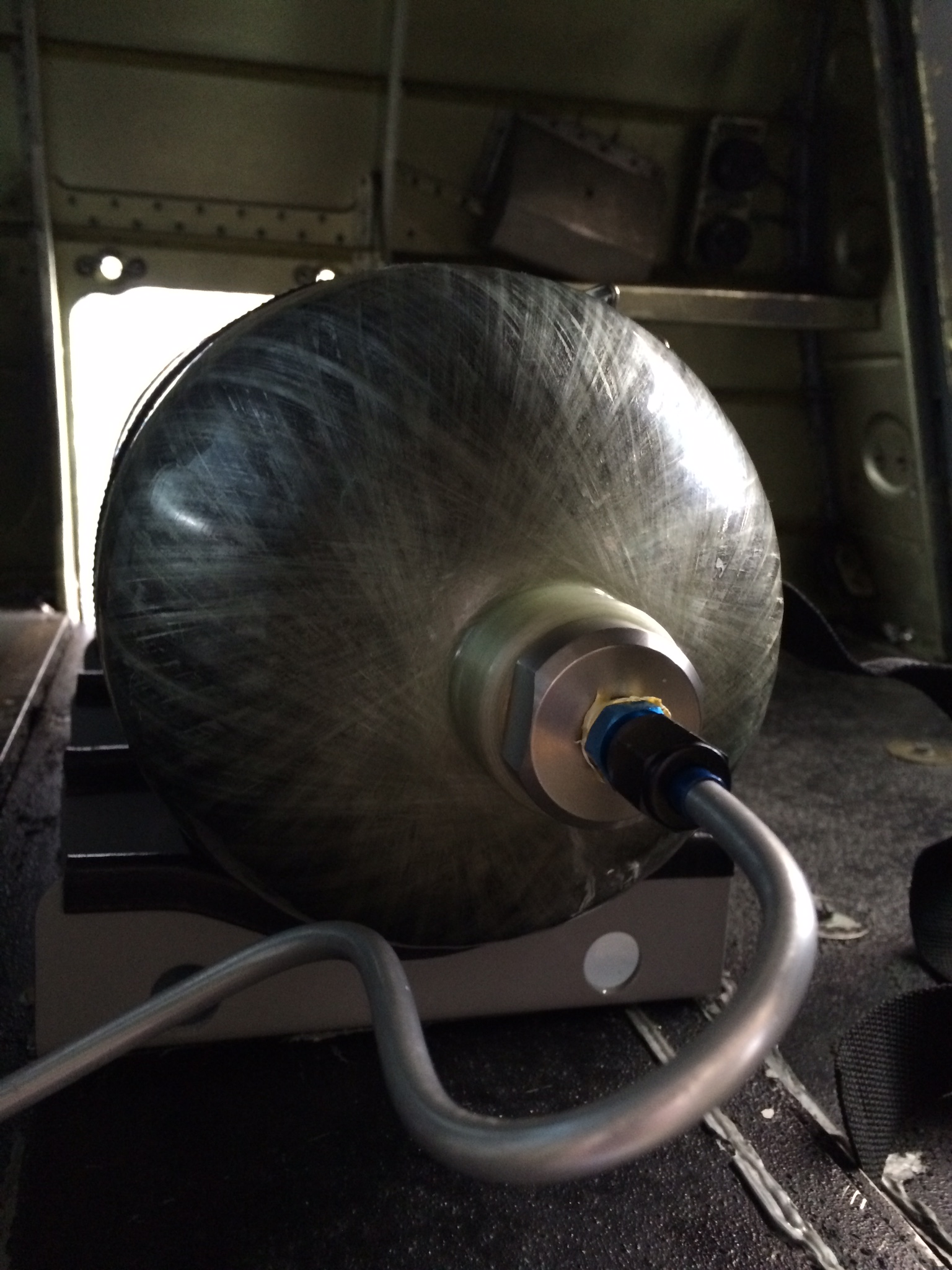

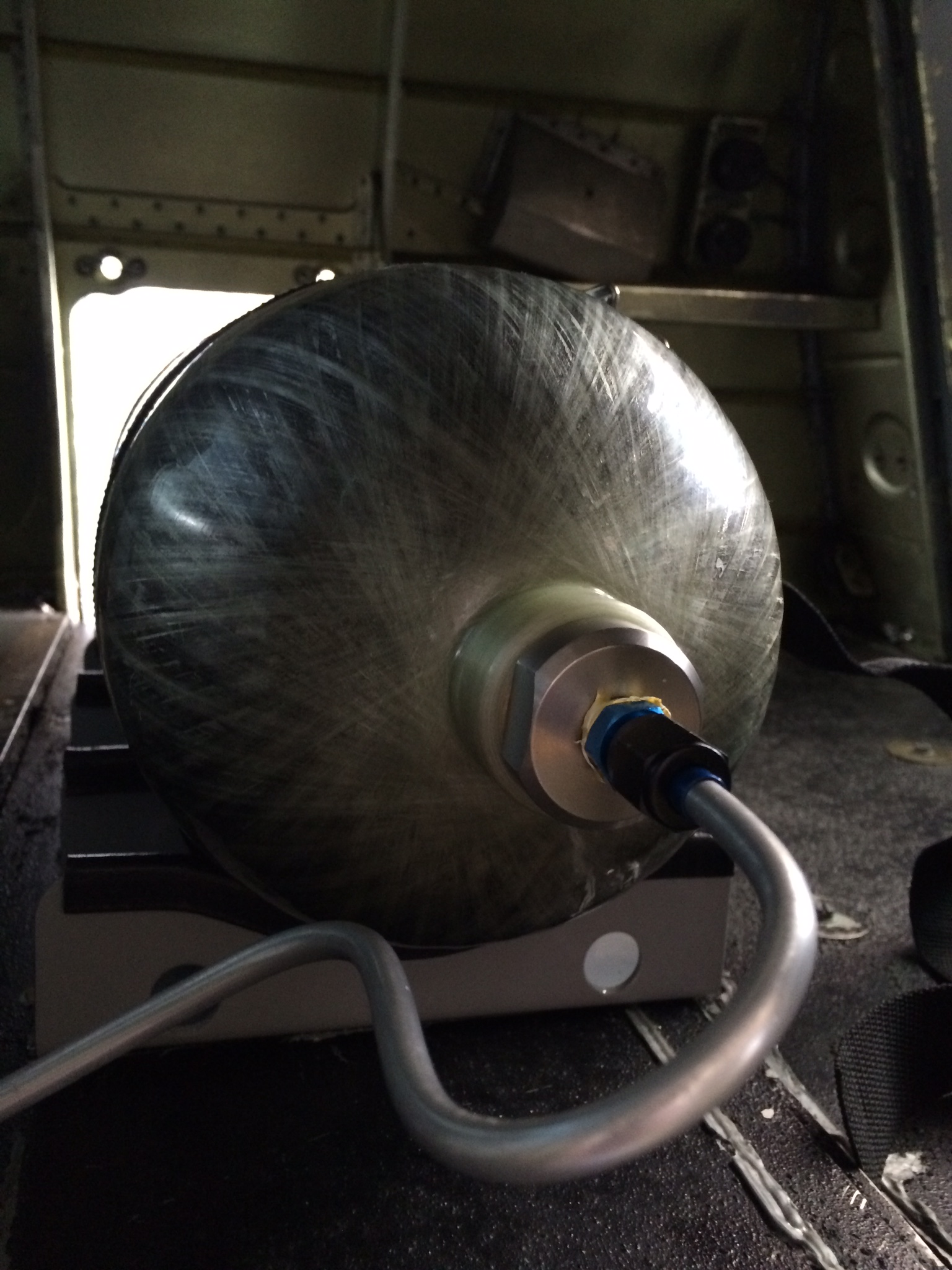

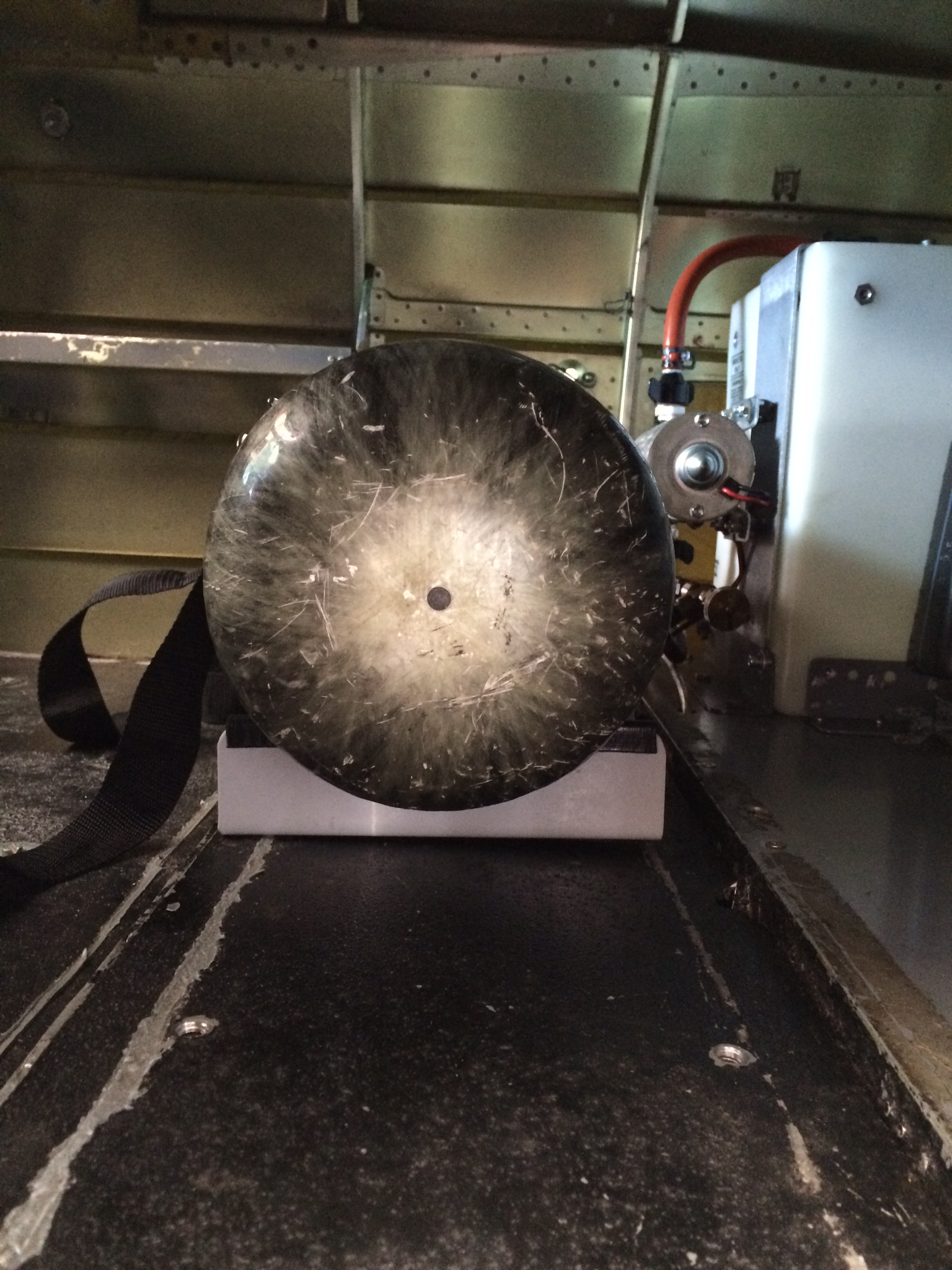

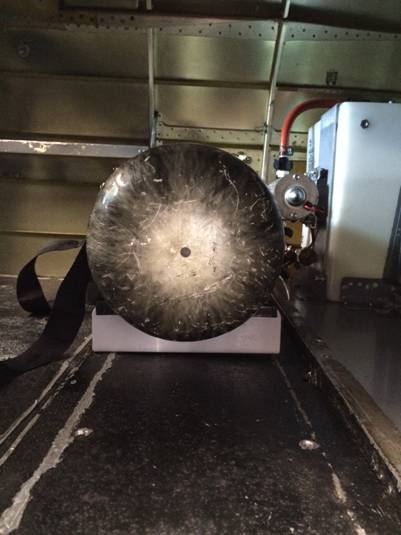

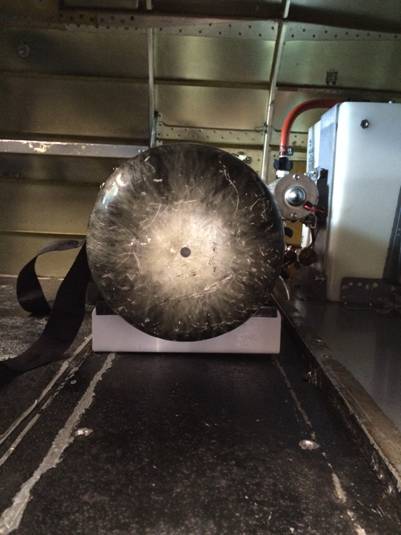

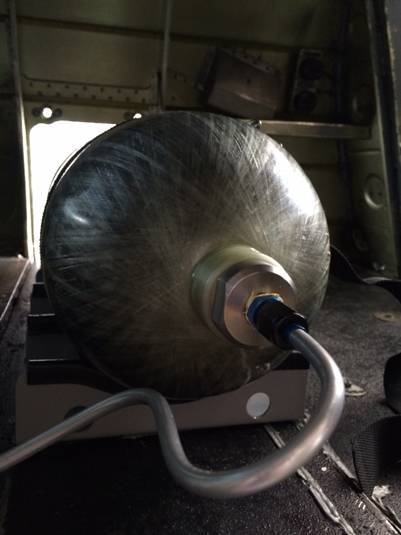

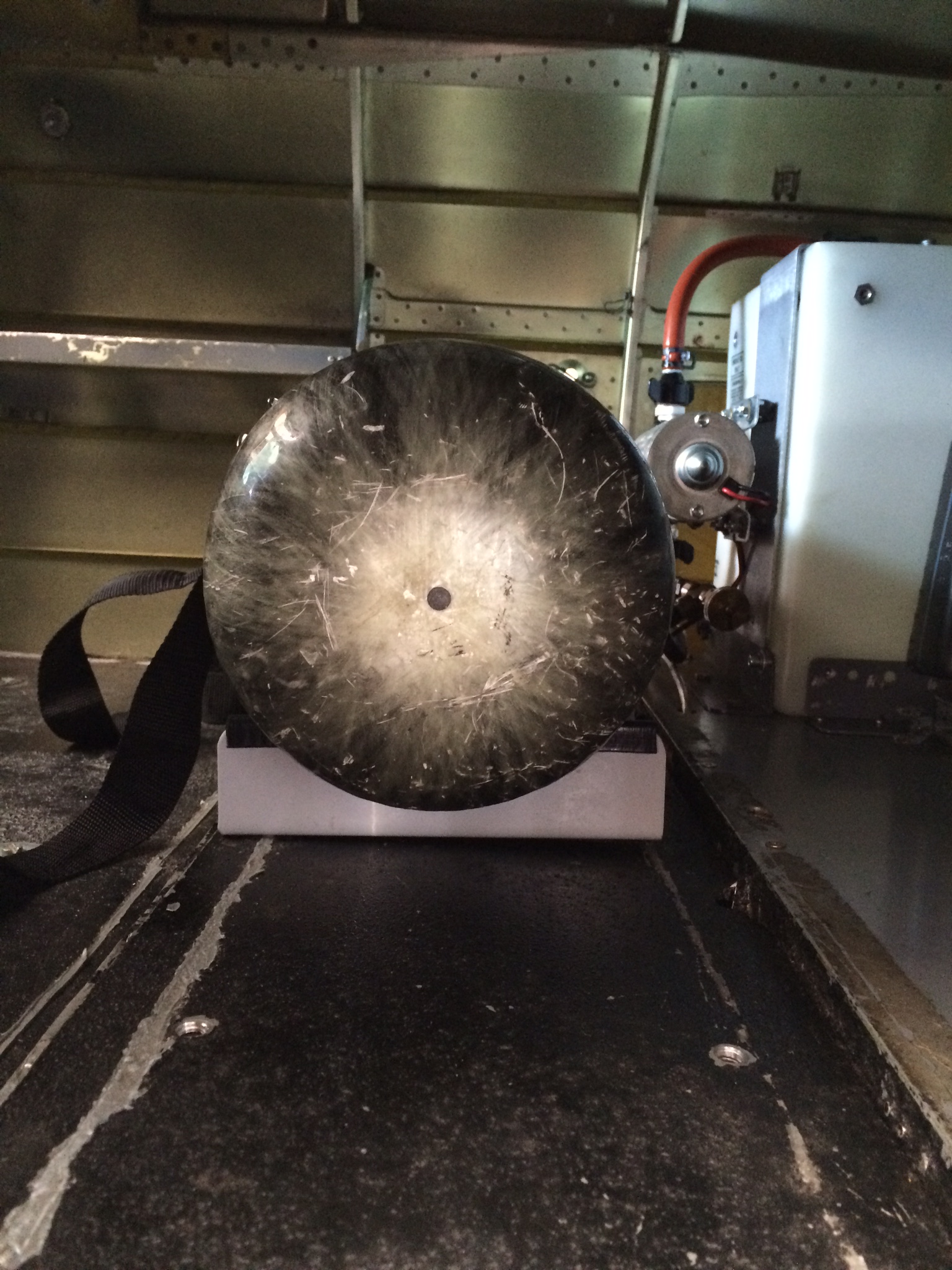

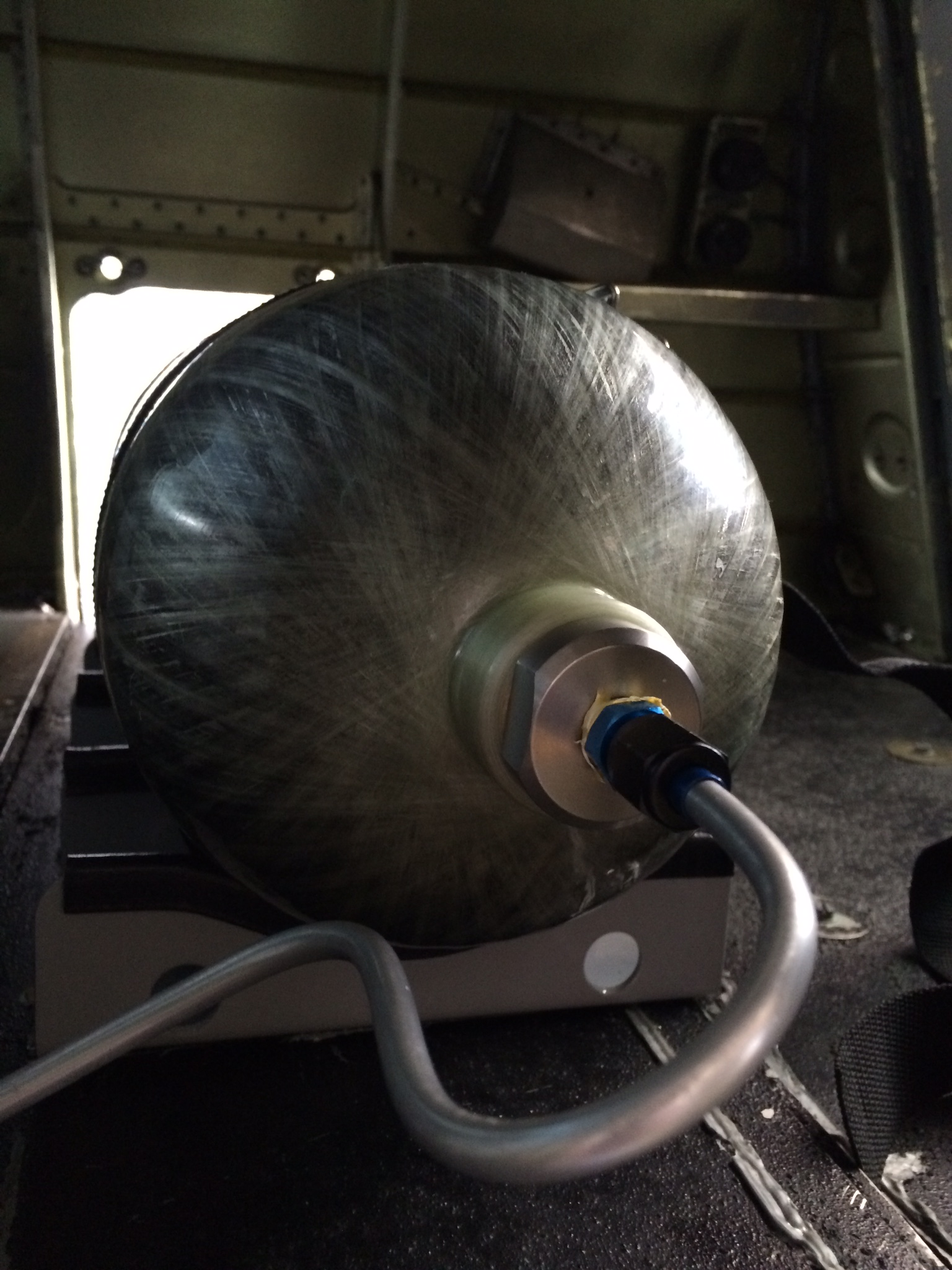

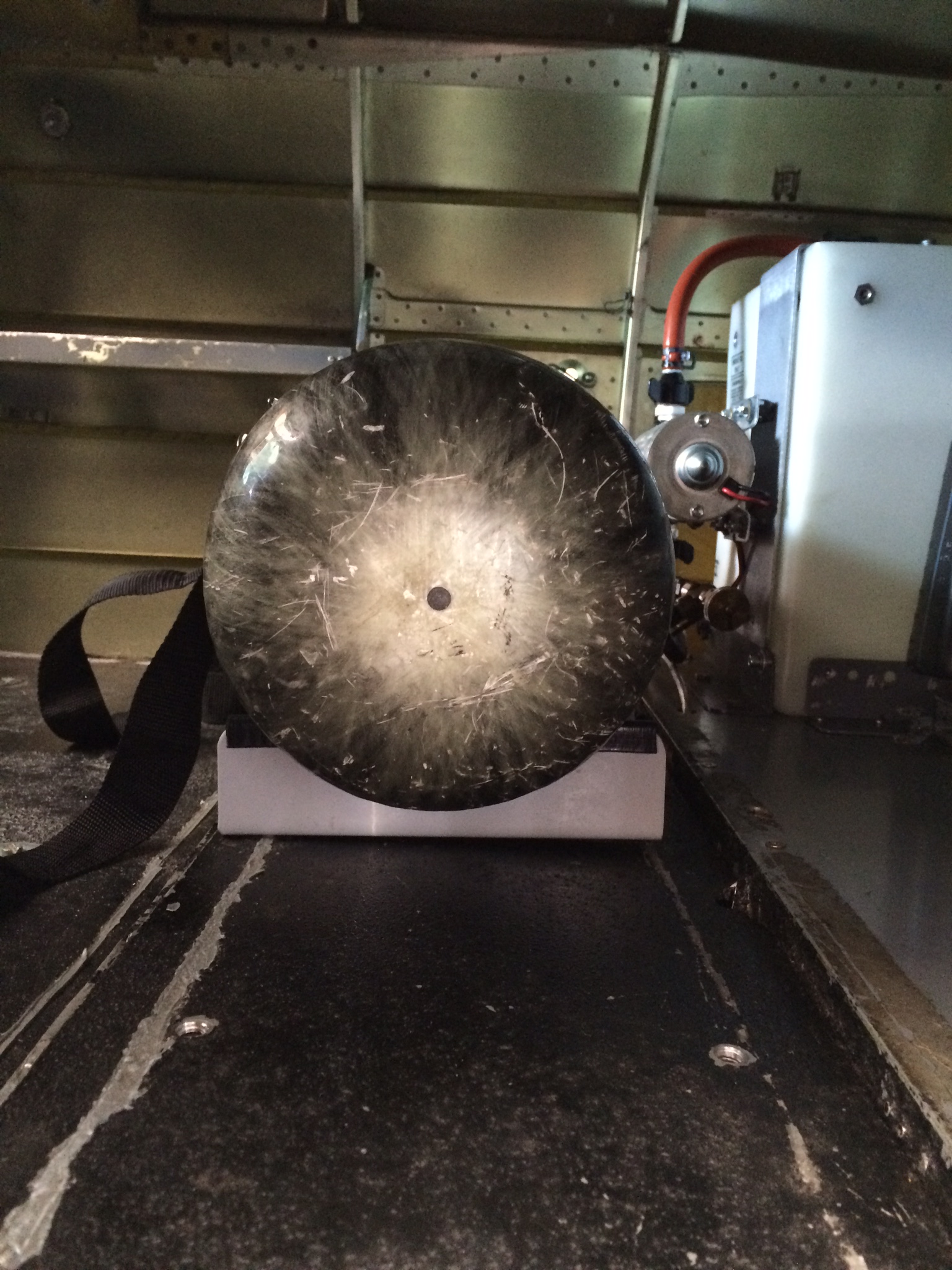

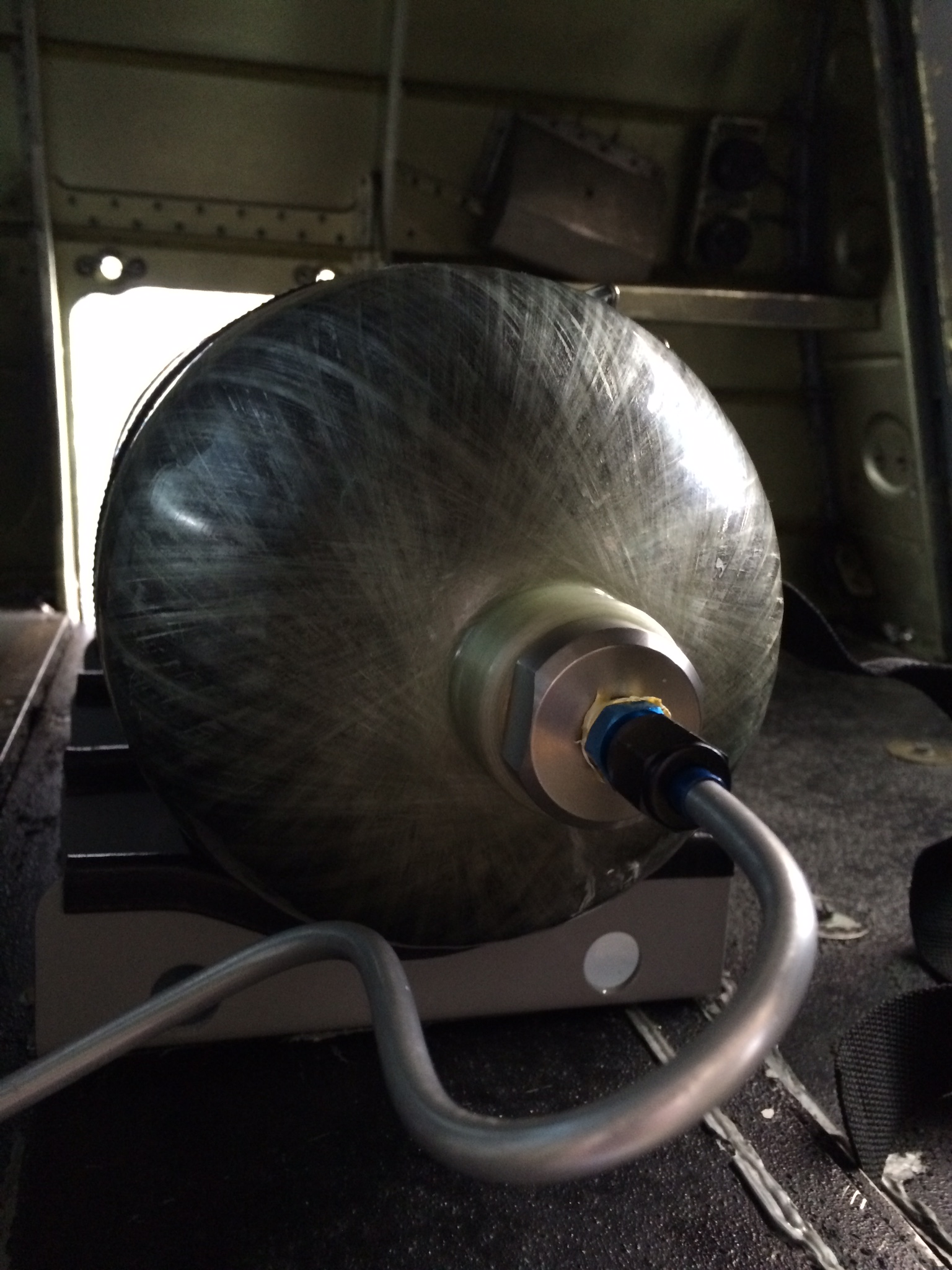

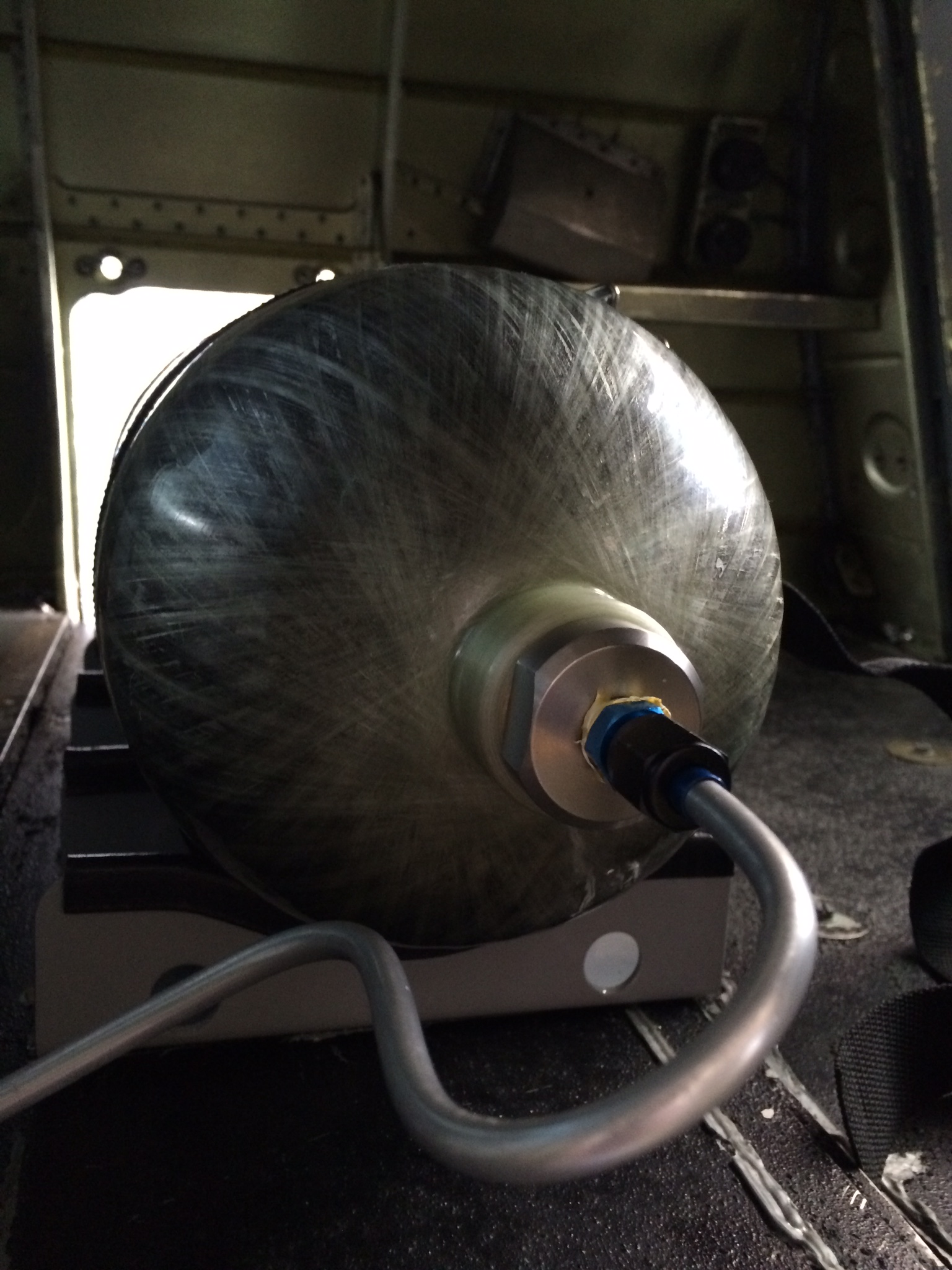

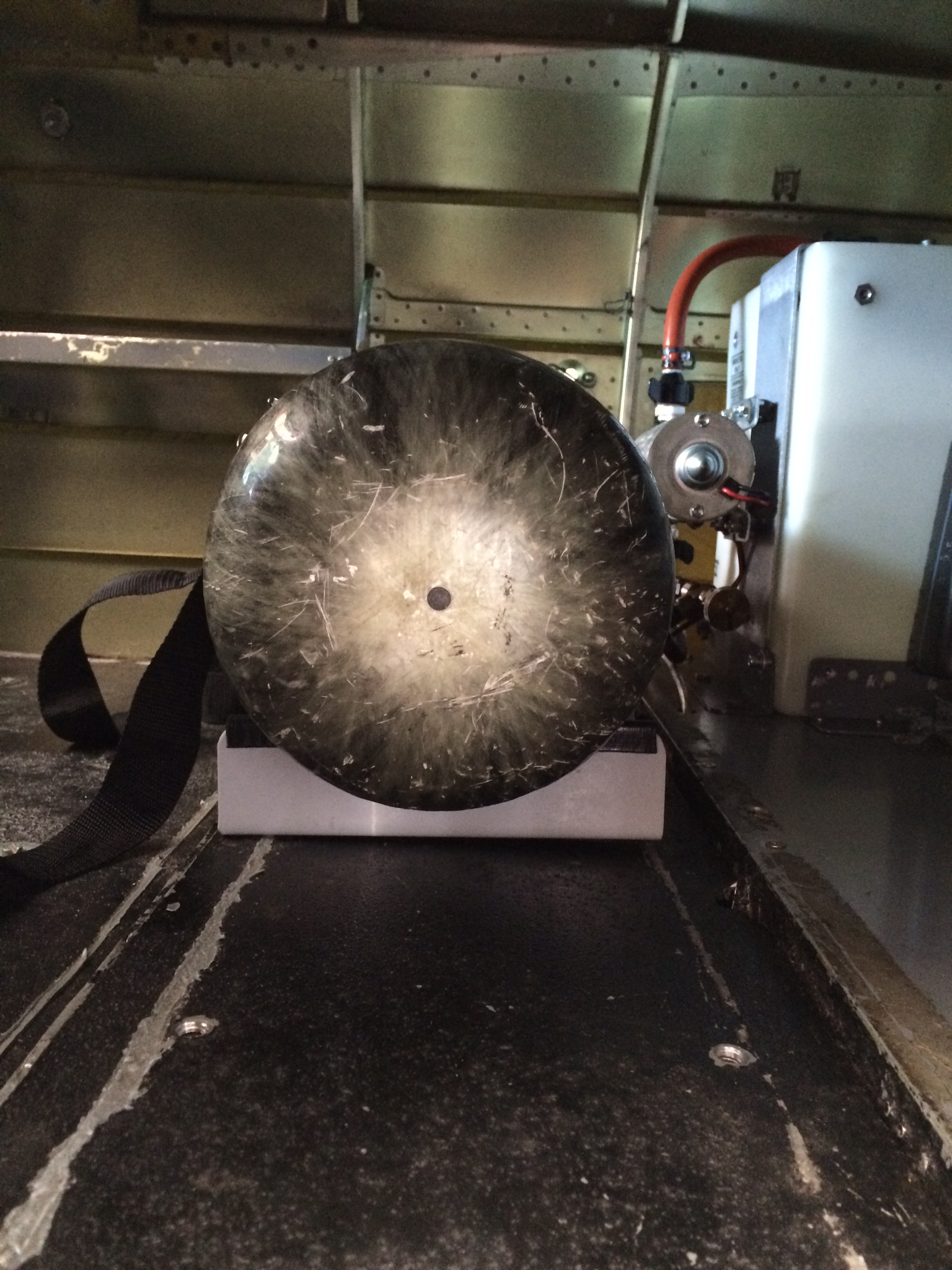

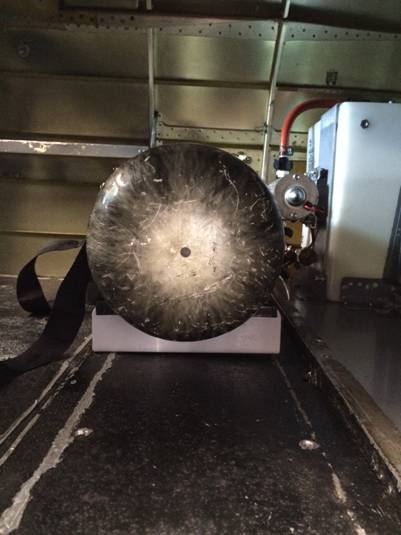

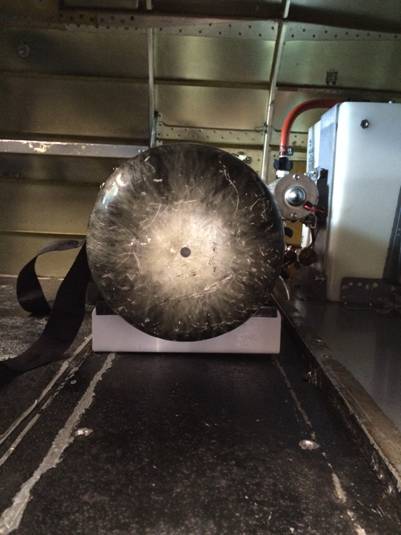

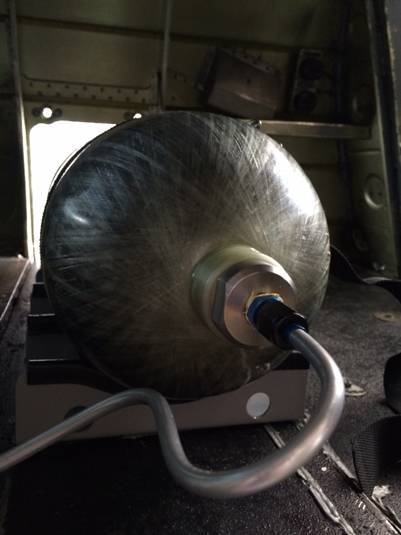

Here is the tank installed. Stock tank is still in airplane, since I'm testing and didn't feel like taking out smoke system and battery. Can still get items in through port side door. Tank can be removed in about 2 minutes. Filled up and ready to test. I turned up my pressure relief valve since there is no fear of overfilling system now. Nice to have the extra reserve air.

Ernie

[img]cid:ii_14c76825e8c36c6a[/img][img]cid:ii_14c76825d3984dec[/img][img]cid:ii_14c7682646197856[/img]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

833.77 KB |

| Viewed: |

1599 Time(s) |

|

| Description: |

|

| Filesize: |

730.28 KB |

| Viewed: |

1599 Time(s) |

|

| Description: |

|

| Filesize: |

646.34 KB |

| Viewed: |

1599 Time(s) |

|

|

|

| Back to top |

|

|

dougsappllc(at)gmail.com

Guest

|

Posted: Wed Apr 01, 2015 12:36 pm Post subject: Main Air Tank Install. Posted: Wed Apr 01, 2015 12:36 pm Post subject: Main Air Tank Install. |

|

|

Ernie,I'd be a bit cautious about "turning up your pressure relief valve". The other components in the system are made to run at 45 to 50 atms, cranking it up in excess of that may cause failures in other components, especially if your using any additives in the pneumatic system. Standard check valve rubber discs will start to "extrude" at about 60 atms, less if your using a additive.

Good luck,

Doug

On Wed, Apr 1, 2015 at 12:47 PM, Ernest Martinez <erniel29(at)gmail.com (erniel29(at)gmail.com)> wrote:

| Quote: | Here is the tank installed. Stock tank is still in airplane, since I'm testing and didn't feel like taking out smoke system and battery. Can still get items in through port side door. Tank can be removed in about 2 minutes. Filled up and ready to test. I turned up my pressure relief valve since there is no fear of overfilling system now. Nice to have the extra reserve air.

Ernie

[img]cid:ii_14c76825e8c36c6a[/img][img]cid:ii_14c76825d3984dec[/img][img]cid:ii_14c7682646197856[/img]

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

833.77 KB |

| Viewed: |

1597 Time(s) |

|

| Description: |

|

| Filesize: |

646.34 KB |

| Viewed: |

1597 Time(s) |

|

| Description: |

|

| Filesize: |

730.28 KB |

| Viewed: |

1597 Time(s) |

|

|

|

| Back to top |

|

|

Ernie

Joined: 11 Jan 2006

Posts: 513

|

Posted: Wed Apr 01, 2015 1:17 pm Post subject: Main Air Tank Install. Posted: Wed Apr 01, 2015 1:17 pm Post subject: Main Air Tank Install. |

|

|

I didn't give that much thought. I was just thinking about the tubing. I will stay under 60 BAR

Thanks

Ernie

On Wed, Apr 1, 2015 at 4:29 PM, doug sapp <dougsappllc(at)gmail.com (dougsappllc(at)gmail.com)> wrote:

| Quote: | Ernie,I'd be a bit cautious about "turning up your pressure relief valve". The other components in the system are made to run at 45 to 50 atms, cranking it up in excess of that may cause failures in other components, especially if your using any additives in the pneumatic system. Standard check valve rubber discs will start to "extrude" at about 60 atms, less if your using a additive.

Good luck,

Doug

On Wed, Apr 1, 2015 at 12:47 PM, Ernest Martinez <erniel29(at)gmail.com (erniel29(at)gmail.com)> wrote:

| Quote: | Here is the tank installed. Stock tank is still in airplane, since I'm testing and didn't feel like taking out smoke system and battery. Can still get items in through port side door. Tank can be removed in about 2 minutes. Filled up and ready to test. I turned up my pressure relief valve since there is no fear of overfilling system now. Nice to have the extra reserve air.

Ernie

[img]cid:ii_14c76825e8c36c6a[/img][img]cid:ii_14c76825d3984dec[/img][img]cid:ii_14c7682646197856[/img]

|

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

646.34 KB |

| Viewed: |

1596 Time(s) |

|

| Description: |

|

| Filesize: |

730.28 KB |

| Viewed: |

1596 Time(s) |

|

| Description: |

|

| Filesize: |

833.77 KB |

| Viewed: |

1596 Time(s) |

|

|

|

| Back to top |

|

|

markdavis(at)wbsnet.org

Guest

|

Posted: Wed Apr 01, 2015 1:21 pm Post subject: Main Air Tank Install. Posted: Wed Apr 01, 2015 1:21 pm Post subject: Main Air Tank Install. |

|

|

Ernie,

How far did you turn up the pressure? I'd be concerned that unnecessarily high pressures will result in higher operating temps on the compressor and lead to accelerated coking and premature pump failure (all of that Standard Gas Law/Boyles's Law stuff I didn't pay enough attention to in school) and shortened actuator seal life from higher operating pressures. Just wondering about the unintended consequences of tweaking the system pressure up. Increased air reserve is great, but replacing an air compressor ranks pretty high on my Don't Like to Do It List.

Mark Davis

N44YK

From: owner-yak-list-server(at)matronics.com [mailto:owner-yak-list-server(at)matronics.com] On Behalf Of Ernest Martinez

Sent: Wednesday, April 01, 2015 1:48 PM

To: yak-list

Subject: Main Air Tank Install.

Here is the tank installed. Stock tank is still in airplane, since I'm testing and didn't feel like taking out smoke system and battery. Can still get items in through port side door. Tank can be removed in about 2 minutes. Filled up and ready to test. I turned up my pressure relief valve since there is no fear of overfilling system now. Nice to have the extra reserve air.

Ernie

[img]cid:image002.jpg(at)01D06C8D.AA6AD120[/img][img]cid:image004.jpg(at)01D06C8D.AA6AD120[/img][img]cid:image006.jpg(at)01D06C8D.AA6AD120[/img]

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

21.78 KB |

| Viewed: |

1596 Time(s) |

|

| Description: |

|

| Filesize: |

22.9 KB |

| Viewed: |

1596 Time(s) |

|

| Description: |

|

| Filesize: |

28.14 KB |

| Viewed: |

1596 Time(s) |

|

|

|

| Back to top |

|

|

Ernie

Joined: 11 Jan 2006

Posts: 513

|

Posted: Wed Apr 01, 2015 1:29 pm Post subject: Main Air Tank Install. Posted: Wed Apr 01, 2015 1:29 pm Post subject: Main Air Tank Install. |

|

|

I turned it up to 60 BAR, but will tweak it back down to 55.

Ernie

On Wed, Apr 1, 2015 at 5:20 PM, Mark Davis <markdavis(at)wbsnet.org (markdavis(at)wbsnet.org)> wrote:

| Quote: |

Ernie,

How far did you turn up the pressure? I'd be concerned that unnecessarily high pressures will result in higher operating temps on the compressor and lead to accelerated coking and premature pump failure (all of that Standard Gas Law/Boyles's Law stuff I didn't pay enough attention to in school) and shortened actuator seal life from higher operating pressures. Just wondering about the unintended consequences of tweaking the system pressure up. Increased air reserve is great, but replacing an air compressor ranks pretty high on my Don't Like to Do It List.

Mark Davis

N44YK

From: owner-yak-list-server(at)matronics.com (owner-yak-list-server(at)matronics.com) [mailto:owner-yak-list-server(at)matronics.com (owner-yak-list-server(at)matronics.com)] On Behalf Of Ernest Martinez

Sent: Wednesday, April 01, 2015 1:48 PM

To: yak-list

Subject: Main Air Tank Install.

Here is the tank installed. Stock tank is still in airplane, since I'm testing and didn't feel like taking out smoke system and battery. Can still get items in through port side door. Tank can be removed in about 2 minutes. Filled up and ready to test. I turned up my pressure relief valve since there is no fear of overfilling system now. Nice to have the extra reserve air.

Ernie

[img]cid:image002.jpg(at)01D06C8D.AA6AD120[/img][img]cid:image004.jpg(at)01D06C8D.AA6AD120[/img][img]cid:image006.jpg(at)01D06C8D.AA6AD120[/img]

|

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

| Description: |

|

| Filesize: |

21.78 KB |

| Viewed: |

1595 Time(s) |

|

| Description: |

|

| Filesize: |

28.14 KB |

| Viewed: |

1595 Time(s) |

|

| Description: |

|

| Filesize: |

22.9 KB |

| Viewed: |

1595 Time(s) |

|

|

|

| Back to top |

|

|

mark.bitterlich(at)navy.m

Guest

|

Posted: Thu Apr 02, 2015 7:27 am Post subject: Main Air Tank Install. Posted: Thu Apr 02, 2015 7:27 am Post subject: Main Air Tank Install. |

|

|

FYI, a friend did a home-brew replacement of the pressure relief valve on an otherwise stock system in a 50. During a test flight the system reached about 62 atmos, or about 170 (or so) PSI over the maximum recommended pressure setting of 50 Atmos, or 725 PSI. When he lowered the gear, he blew the chevron seals out of one of the main landing gear actuators. I never did ask him how old they were, so there might have been other factors involved. I too lost chevron seals in my 50, but in my case it was from following advise posted on this list of "injecting" air-tool oil into the system. Later, I took one of those seals and sprayed air tool oil on them directly, and within a week it was swollen and soft. Lesson learned.

Additionally, adjusting the pressure relief valve to a higher setting puts more strain on all system components, which includes the engine air-compressor, unless of course you have installed one of several methods to "unload" the compressor in-flight, which Richard Goode has discussed, and which I have also seen used on several Yaks and Sukhoi's as well. Thus I would agree with Doug that increasing system pressure over the maximum design recommendation given by the aircraft manufacturer might have catastrophic circumstances, but at the very least will decrease component life.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

draftsjust417(at)gmail.co

Guest

|

Posted: Thu Apr 02, 2015 7:44 am Post subject: Main Air Tank Install. Posted: Thu Apr 02, 2015 7:44 am Post subject: Main Air Tank Install. |

|

|

Good advice Mark, yes lessons learned.

I have my CJ's air system set for 47 ATM, use castor oil, have new restrictors in LG lines (thanks Doug Sapp) and it seems content to work very well on that.

Justin

N280NC

On Thu, Apr 2, 2015 at 8:27 AM, Bitterlich, Mark G CIV NAVAIR, WD <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)> wrote:

[quote]--> Yak-List message posted by: "Bitterlich, Mark G CIV NAVAIR, WD" <mark.bitterlich(at)navy.mil (mark.bitterlich(at)navy.mil)>

FYI, a friend did a home-brew replacement of the pressure relief valve on an otherwise stock system in a 50. During a test flight the system reached about 62 atmos, or about 170 (or so) PSI over the maximum recommended pressure setting of 50 Atmos, or 725 PSI. When he lowered the gear, he blew the chevron seals out of one of the main landing gear actuators. I never did ask him how old they were, so there might have been other factors involved. I too lost chevron seals in my 50, but in my case it was from following advise posted on this list of "injecting" air-tool oil into the system. Later, I took one of those seals and sprayed air tool oil on them directly, and within a week it was swollen and soft. Lesson learned.

Additionally, adjusting the pressure relief valve to a higher setting puts more strain on all system components, which includes the engine air-compressor, unless of course you have installed one of several methods to "unload" the compressor in-flight, which Richard Goode has discussed, and which I have also seen used on several Yaks and Sukhoi's as well. Thus I would agree with Doug that increasing system pressure over the maximum design recommendation given by the aircraft manufacturer might have catastrophic circumstances, but at the very least will decrease component life.

Mark

--

| | - The Matronics Yak-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Yak-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|