|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Fri Jun 19, 2015 11:22 am Post subject: basic questions on terminal strips Posted: Fri Jun 19, 2015 11:22 am Post subject: basic questions on terminal strips |

|

|

I have two beacons, each beacon has a positive, negative and

synchronization wire. I need to connect the wires from each beacon and

then send them forward. I have chosen to accomplish this with a

terminal strip.

I have noticed that the terminal strips do use star washers. Should I

use a star washer atop my ring terminals? Or maybe I should use thread

locker on the terminal strip screw?

Also, is it okay to stack two ring terminals on one side of the

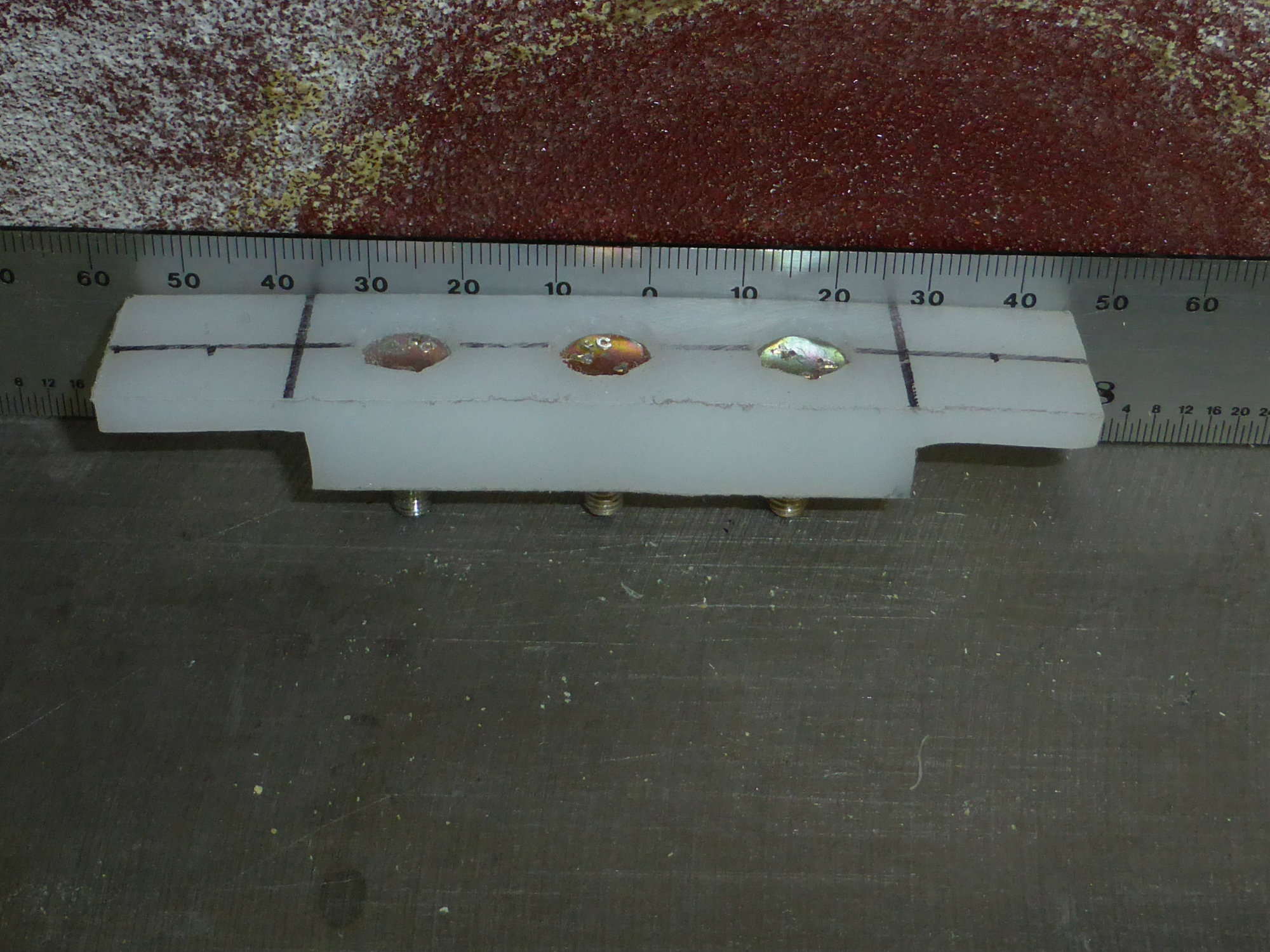

terminal strip (as shown in the attached photo)?

Thanks.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

555.49 KB |

| Viewed: |

17593 Time(s) |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Fri Jun 19, 2015 5:12 pm Post subject: Re: basic questions on terminal strips Posted: Fri Jun 19, 2015 5:12 pm Post subject: Re: basic questions on terminal strips |

|

|

Unless the wires will be taken apart frequently or need to be exposed for testing, I prefer to make a permanent splice. Terminal strips could be a trouble spot due to loose screws or corrosion. If a terminal strip is used, an internal tooth star washer between the ring terminals and screw head is a good idea. Temporary thread locker could also be used. When I install two ring terminals under one screw, I orientate them back to back so that a ring terminal does not have to be bent. A thin film of grease will help prevent corrosion. Grease does not hinder conduction because the screw pressure forces the grease out. Thus there is still metal to metal contact. Wires should be supported close to the ring terminals to prevent any relative motion due to vibration. Your installation looks neat with the cushion clamps.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Jun 19, 2015 5:39 pm Post subject: basic questions on terminal strips Posted: Fri Jun 19, 2015 5:39 pm Post subject: basic questions on terminal strips |

|

|

At 02:20 PM 6/19/2015, you wrote:

I have two beacons, each beacon has a positive, negative and

synchronization wire. I need to connect the wires from each beacon and

then send them forward. I have chosen to accomplish this with a

terminal strip.

I have noticed that the terminal strips do use star washers. Should I

use a star washer atop my ring terminals? Or maybe I should use thread

locker on the terminal strip screw?

Also, is it okay to stack two ring terminals on one side of the

terminal strip (as shown in the attached photo)?

Thanks.

As a general rule, new designs will minimize the use of threaded fasteners . . . particularly screws into soft threads (Yeah, circuit breakers do that . . . you just gotta live with some things!). Those barrier strips are brass screws into brass nuts formed out of the two-barrel, hollow rivet that makes up the conductor between screws.

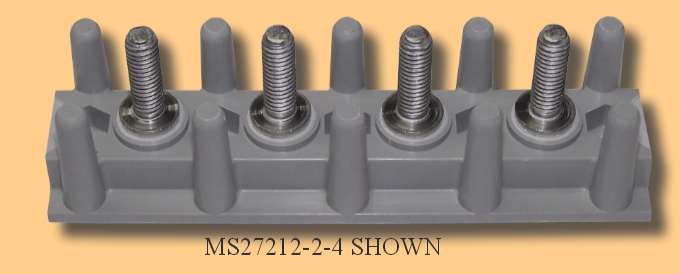

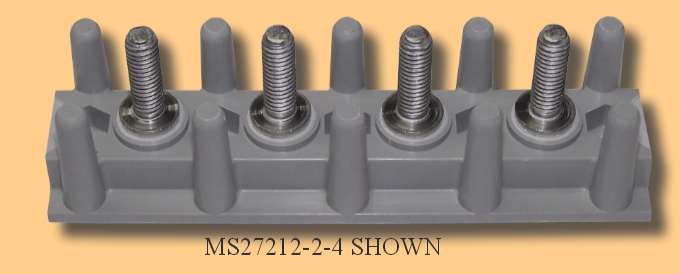

The preferred terminal strip is illustrated below. CAPTIVE studs designed to take a stack of terminals and press them together in gas-tight harmony with the universe.

[img]cid:.0[/img][/b]

These things are not cheap. However, you can make your own from a block of phenolic, Delrin or similar structural insulator. Press hex headed studs into undersized, counterbores and pot the back side with epoxy. Crank a nut down on TOP of the block to capture the stud.

Now you can stack as many terminals on the studs as you like while maintaining gas-tight integrity between the stack of terminals. A metal locking nut on a quality steel screw will squish things together with a great deal more robustness than those brass screws into internally threaded, brass sleeves.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

89.78 KB |

| Viewed: |

17582 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Jun 19, 2015 5:45 pm Post subject: basic questions on terminal strips Posted: Fri Jun 19, 2015 5:45 pm Post subject: basic questions on terminal strips |

|

|

| Quote: | | These things are not cheap. |

http://tinyurl.com/qd233vg

but you can make your own . . .

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Fri Jun 19, 2015 9:03 pm Post subject: basic questions on terminal strips Posted: Fri Jun 19, 2015 9:03 pm Post subject: basic questions on terminal strips |

|

|

Thanks everyone for the ideas regarding terminal strips. I will make my own using the captive stud approach as suggested by Bob. I feel much better about that approach than the terminal strip I had chosen.

On Fri, Jun 19, 2015 at 5:37 PM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 02:20 PM 6/19/2015, you wrote:

I have two beacons, each beacon has a positive, negative and

synchronization wire. I need to connect the wires from each beacon and

then send them forward. I have chosen to accomplish this with a

terminal strip.

I have noticed that the terminal strips do use star washers. Should I

use a star washer atop my ring terminals? Or maybe I should use thread

locker on the terminal strip screw?

Also, is it okay to stack two ring terminals on one side of the

terminal strip (as shown in the attached photo)?

Thanks.

As a general rule, new designs will minimize the use of threaded fasteners . . . particularly screws into soft threads (Yeah, circuit breakers do that . . . you just gotta live with some things!). Those barrier strips are brass screws into brass nuts formed out of the two-barrel, hollow rivet that makes up the conductor between screws.

The preferred terminal strip is illustrated below. CAPTIVE studs designed to take a stack of terminals and press them together in gas-tight harmony with the universe.

[img]cid:.0[/img]

These things are not cheap. However, you can make your own from a block of phenolic, Delrin or similar structural insulator. Press hex headed studs into undersized, counterbores and pot the back side with epoxy. Crank a nut down on TOP of the block to capture the stud.

Now you can stack as many terminals on the studs as you like while maintaining gas-tight integrity between the stack of terminals. A metal locking nut on a quality steel screw will squish things together with a great deal more robustness than those brass screws into internally threaded, brass sleeves.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

89.78 KB |

| Viewed: |

17575 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jun 20, 2015 8:40 am Post subject: basic questions on terminal strips Posted: Sat Jun 20, 2015 8:40 am Post subject: basic questions on terminal strips |

|

|

At 12:01 AM 6/20/2015, you wrote:

| Quote: | Thanks everyone for the ideas regarding terminal strips. I will make my own using the captive stud approach as suggested by Bob. I feel much better about that approach than the terminal strip I had chosen.

|

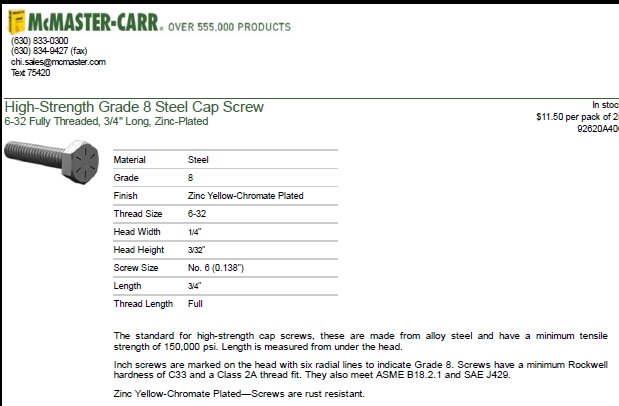

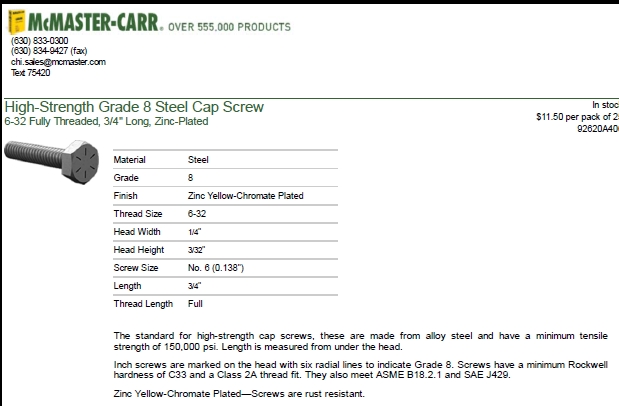

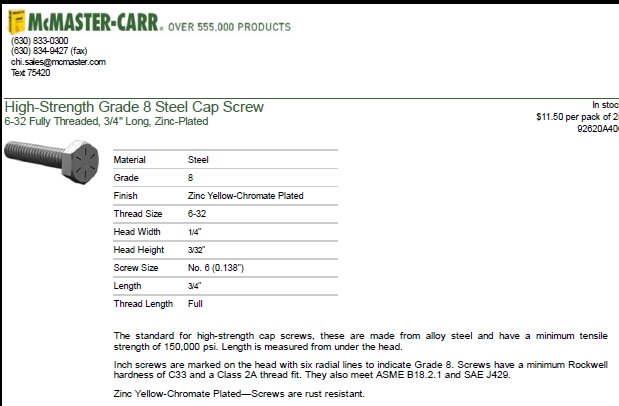

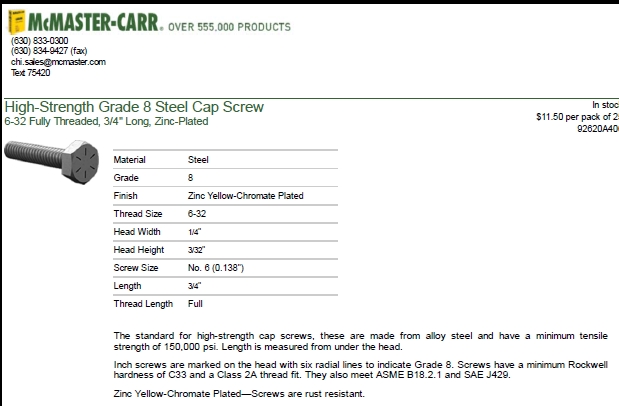

A hex headed screw is easy to 'captivate' in your

base material. I.e. pressing a screw like this

[img]cid:7.1.0.9.0.20150620112938.073a0d68(at)aeroelectric.com.1[/img]

to bottom out in a 1/4" counterbore will force the

hex-points into a good grip on the base. Experiment

a bit . . . I might have used a 9/32" bore . . . it's

been awhile. You don't want to break the base with

"too much grip."

McMaster-Carr can offer you grade-8, hex screws

but you need to buy a pkg of 25. Any good hardware store's

specialty screws bins may offer smaller lots of similar

screws. Use a washer and nut on the top side and

some epoxy fill underneath to finish installing

the stud.

I have a chunk of Delrin about 0.35 x 0.77 x 8 inches

that I'll donate to the cause if you'll photograph your

process and finished product to share with the List.

If finding the 'golden' hardware is problematic,

I can pick it up on my next trip to ICT. Shoot

me a mailing address.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

112.5 KB |

| Viewed: |

17559 Time(s) |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sat Jun 20, 2015 9:22 am Post subject: basic questions on terminal strips Posted: Sat Jun 20, 2015 9:22 am Post subject: basic questions on terminal strips |

|

|

Thanks Bob. I think I have what I need in the shop to do it about three different ways, and if not it should be easy to find right here in Anchorage.

On Sat, Jun 20, 2015 at 8:38 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 12:01 AM 6/20/2015, you wrote:

| Quote: | Thanks everyone for the ideas regarding terminal strips. I will make my own using the captive stud approach as suggested by Bob. I feel much better about that approach than the terminal strip I had chosen.

|

Â

A hex headed screw is easy to 'captivate' in your

base material. I.e. pressing a screw like this

[img]cid:7.1.0.9.0.20150620112938.073a0d68(at)aeroelectric.com.1[/img]

to bottom out in a 1/4" counterbore will force the

hex-points into a good grip on the base. Experiment

a bit . . . I might have used a 9/32" bore . . . it's

been awhile. You don't want to break the base with

"too much grip."

McMaster-Carr can offer you grade-8, hex screws

but you need to buy a pkg of 25. Any good hardware store's

specialty screws bins may offer smaller lots of similar

screws. Use a washer and nut on the top side and

some epoxy fill underneath to finish installing

the stud.

I have a chunk of Delrin about 0.35 x 0.77 x 8 inches

that I'll donate to the cause if you'll photograph your

process and finished product to share with the List.

If finding the 'golden' hardware is problematic,

I can pick it up on my next trip to ICT. Shoot

me a mailing address.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

112.5 KB |

| Viewed: |

17557 Time(s) |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sat Jun 20, 2015 11:35 am Post subject: basic questions on terminal strips Posted: Sat Jun 20, 2015 11:35 am Post subject: basic questions on terminal strips |

|

|

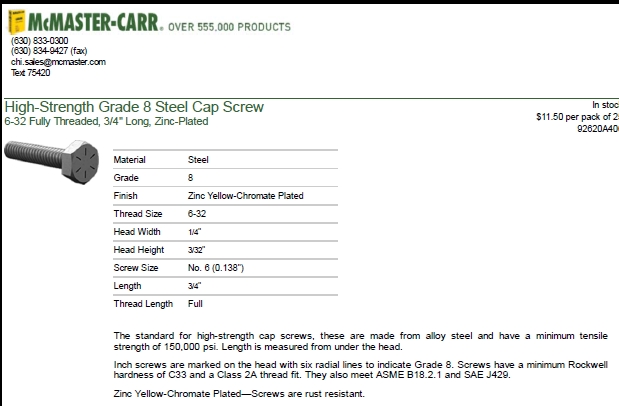

UHMW + standard AN3 hardware seems to have worked pretty well. Pics attached.

On Sat, Jun 20, 2015 at 9:20 AM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

| Quote: | Thanks Bob. I think I have what I need in the shop to do it about three different ways, and if not it should be easy to find right here in Anchorage.

On Sat, Jun 20, 2015 at 8:38 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 12:01 AM 6/20/2015, you wrote:

| Quote: | Thanks everyone for the ideas regarding terminal strips. I will make my own using the captive stud approach as suggested by Bob. I feel much better about that approach than the terminal strip I had chosen.

|

Â

A hex headed screw is easy to 'captivate' in your

base material. I.e. pressing a screw like this

[img]cid:7.1.0.9.0.20150620112938.073a0d68(at)aeroelectric.com.1[/img]

to bottom out in a 1/4" counterbore will force the

hex-points into a good grip on the base. Experiment

a bit . . . I might have used a 9/32" bore . . . it's

been awhile. You don't want to break the base with

"too much grip."

McMaster-Carr can offer you grade-8, hex screws

but you need to buy a pkg of 25. Any good hardware store's

specialty screws bins may offer smaller lots of similar

screws. Use a washer and nut on the top side and

some epoxy fill underneath to finish installing

the stud.

I have a chunk of Delrin about 0.35 x 0.77 x 8 inches

that I'll donate to the cause if you'll photograph your

process and finished product to share with the List.

If finding the 'golden' hardware is problematic,

I can pick it up on my next trip to ICT. Shoot

me a mailing address.

Bob . . .

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

112.5 KB |

| Viewed: |

17547 Time(s) |

|

| Description: |

|

| Filesize: |

556.46 KB |

| Viewed: |

17547 Time(s) |

|

| Description: |

|

| Filesize: |

554.27 KB |

| Viewed: |

17547 Time(s) |

|

|

|

| Back to top |

|

|

ceengland7(at)gmail.com

Guest

|

Posted: Sat Jun 20, 2015 4:28 pm Post subject: basic questions on terminal strips Posted: Sat Jun 20, 2015 4:28 pm Post subject: basic questions on terminal strips |

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sun Jun 21, 2015 8:02 am Post subject: basic questions on terminal strips Posted: Sun Jun 21, 2015 8:02 am Post subject: basic questions on terminal strips |

|

|

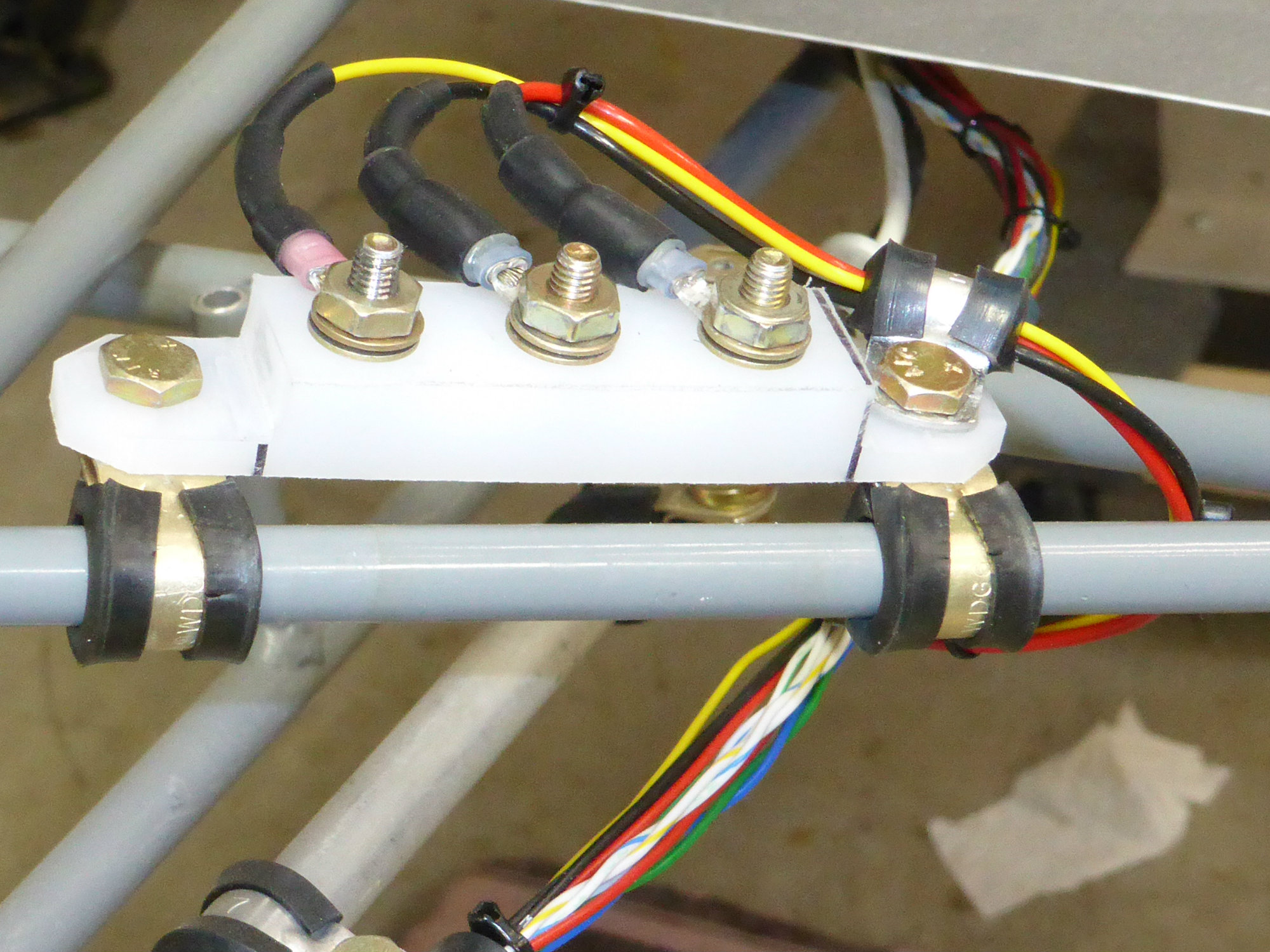

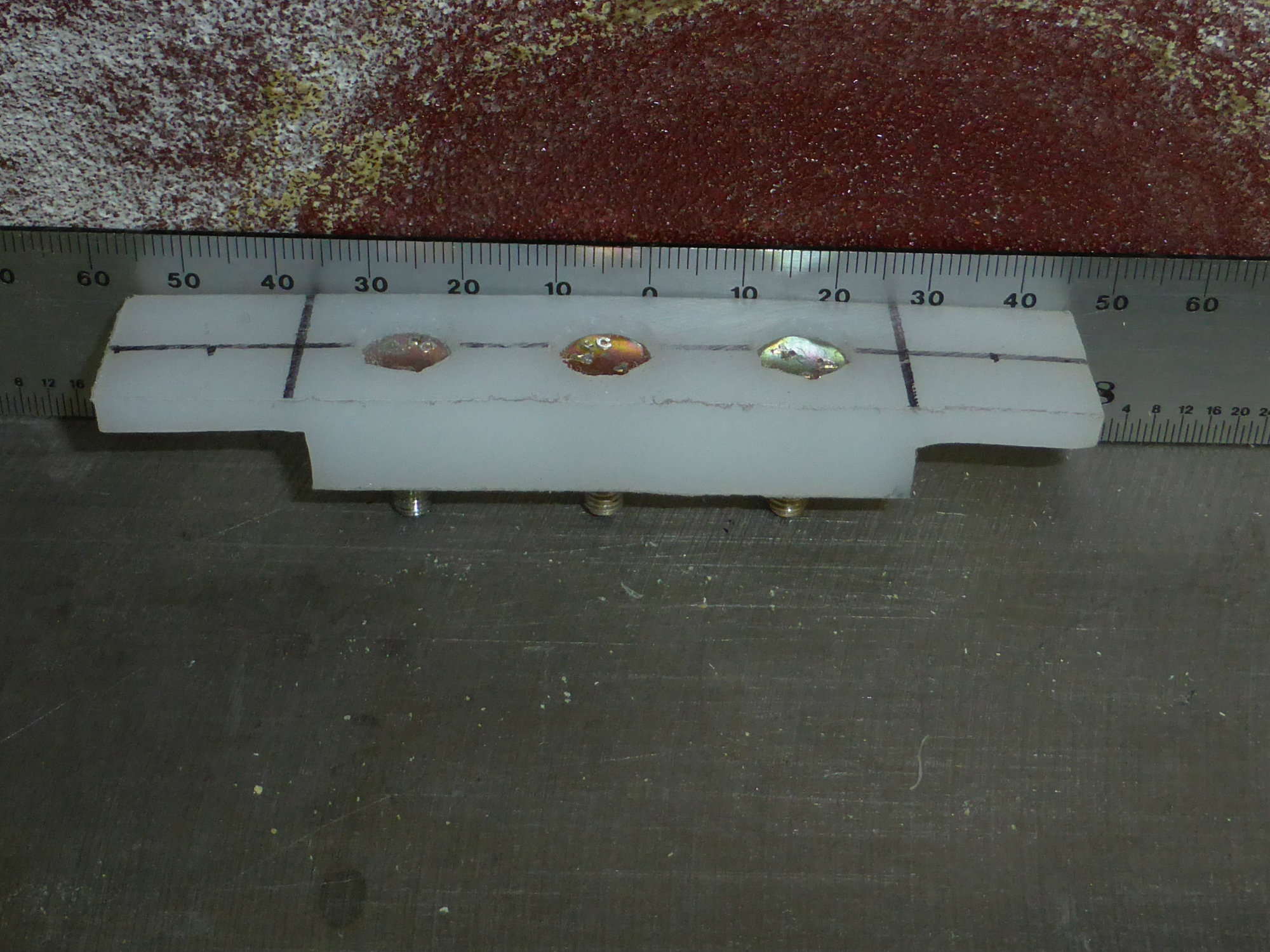

Pic showing temp/partial installation:

On Sun, Jun 21, 2015 at 7:24 AM, Robert L. Nuckolls, III

<nuckolls.bob(at)aeroelectric.com> wrote:

| Quote: | At 12:20 PM 6/20/2015, you wrote:

Thanks Bob. I think I have what I need in the shop to do it about three

different ways, and if not it should be easy to find right here in

Anchorage.

Take pictures . . .

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

548.26 KB |

| Viewed: |

17525 Time(s) |

|

|

|

| Back to top |

|

|

JohnInReno

Joined: 08 Sep 2007

Posts: 150

|

Posted: Sun Jun 21, 2015 8:30 am Post subject: basic questions on terminal strips Posted: Sun Jun 21, 2015 8:30 am Post subject: basic questions on terminal strips |

|

|

Me too! However, you can "view source" and see the message.

john

On 6/21/2015 7:26 AM, Bill Bradburry wrote:

[quote]

Does anyone know what happens here? I too often get emails from a friend

like this where there is nothing in the body of the email.

Bill

--

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

John Morgensen

RV-9A - Born on July 3, 2013

RV4 - for sale |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jun 21, 2015 8:52 am Post subject: basic questions on terminal strips Posted: Sun Jun 21, 2015 8:52 am Post subject: basic questions on terminal strips |

|

|

At 11:00 AM 6/21/2015, you wrote:

| Quote: | | Pic showing temp/partial installation: |

You done good my friend . . . just remember

that as you add wires to any post, there

should be no intervening hardware between

terminals . . . i.e. the terminal strip

hardware is there to separate, support and

put the super-mash on the stack of terminals

. . . no hardware should be tasked with carrying

electrons.

In your particular case, the currents are low;

failure to observe that process goal is not fraught

with risk.

I'll use your photos to do a comic-book

for aeroelectric.com wherein we'll mention

the time-honored recipes for success to

manage wires from 22AWG through 000.

Thanks for sharing.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Sun Jun 21, 2015 5:10 pm Post subject: Re: basic questions on terminal strips Posted: Sun Jun 21, 2015 5:10 pm Post subject: Re: basic questions on terminal strips |

|

|

I do not see a nut under the ring terminals. Is there one? Ring terminals need to be squashed between two nuts, not between a nut and plastic because plastic will flow over time, causing the connection to loosen.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sun Jun 21, 2015 5:20 pm Post subject: basic questions on terminal strips Posted: Sun Jun 21, 2015 5:20 pm Post subject: basic questions on terminal strips |

|

|

There's a washer under the terminals.

On Sun, Jun 21, 2015 at 5:10 PM, user9253 <fransew(at)gmail.com> wrote:

| Quote: |

I do not see a nut under the ring terminals. Is there one? Ring terminals need to be squashed between two nuts, not between a nut and plastic because plastic will flow over time, causing the connection to loosen.

Joe

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=443879#443879

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 22, 2015 5:26 am Post subject: basic questions on terminal strips Posted: Mon Jun 22, 2015 5:26 am Post subject: basic questions on terminal strips |

|

|

At 08:10 PM 6/21/2015, you wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com>

I do not see a nut under the ring terminals. Is there one? Ring terminals need to be squashed between two nuts, not between a nut and plastic because plastic will flow over time, causing the connection to loosen.

Joe

--------

Joe Gores

|

Good eye . . . I had noticed that but neglected to

articulate it.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 22, 2015 5:38 am Post subject: basic questions on terminal strips Posted: Mon Jun 22, 2015 5:38 am Post subject: basic questions on terminal strips |

|

|

At 08:18 PM 6/21/2015, you wrote:

| Quote: | --> AeroElectric-List message posted by: Ken Ryan <keninalaska(at)gmail.com>

There's a washer under the terminals. |

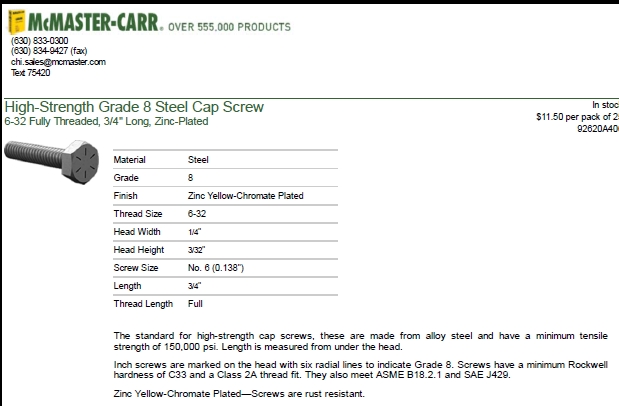

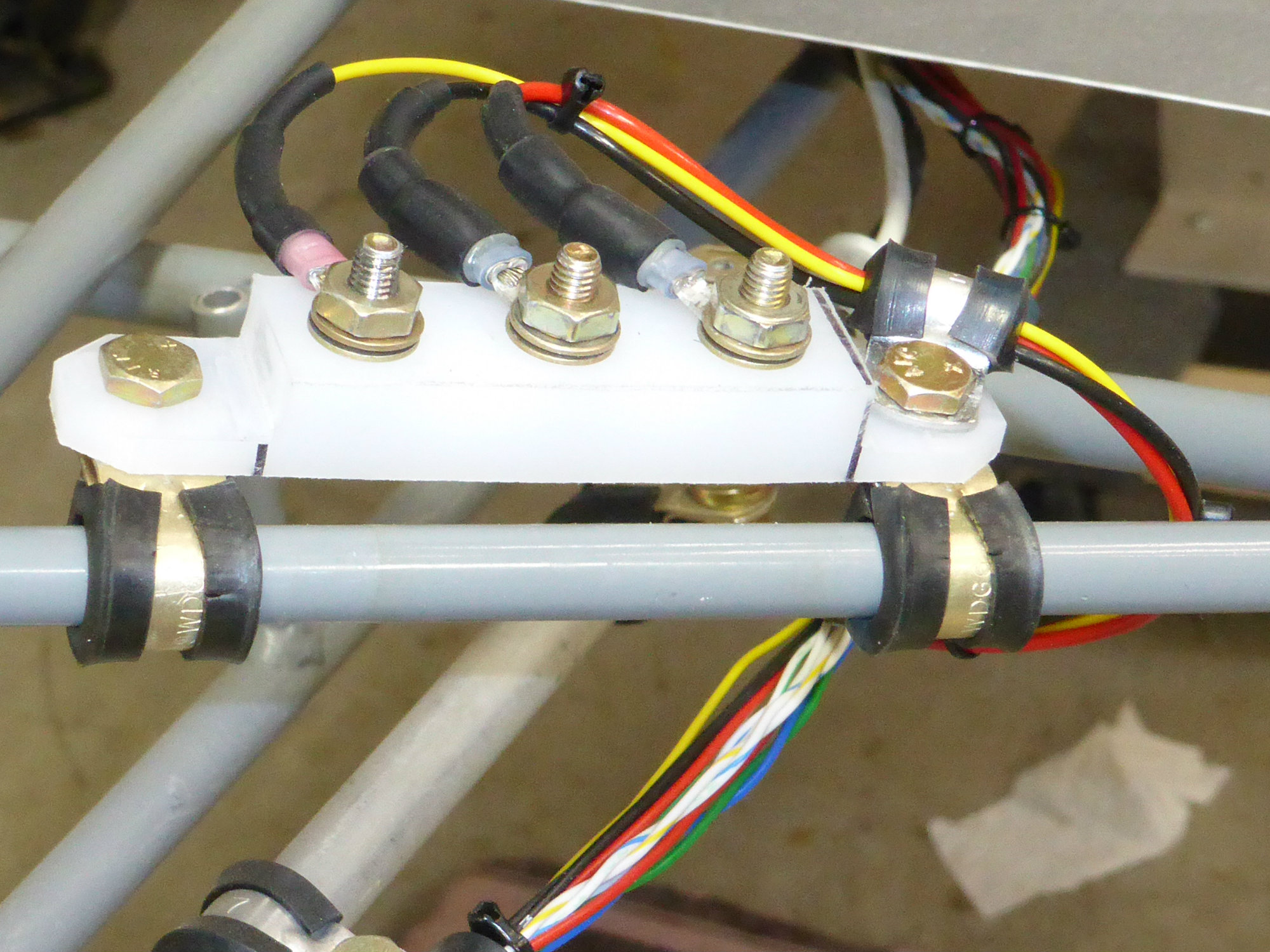

What Joe is referencing is the fact that

'gas tightness' in the interface between

current carrying parts depends on the pressure

established and maintained by either crimping

or, in this case, squeezing between two very

stable forces in the clamping mechanism. Force

from a nut driven down onto the terminals is

reacted by a plastic surface under the stack.

The plastic is not stable under continuous

pressure and will relieve to some degree over

time and temperature cycles.

In your particular application, the currents

and duty-cycles involved do not imposed large

stresses on those interfaces . . . and you'll

be find with what you have. But were you crafting

say, a distribution point for fat wires carrying

tens of amps continuously and perhaps hundreds

of amps cranking . . . the need to bring those

terminals together with TWO nuts is greater.

You can see that the base of these studs is part

of the metal that makes up the stud. Terminals

stacked on these studs can be brought up to

and held at gas-tight pressures without adding

the nut under it. With the DIY terminal block

the bottom nut takes on this duty. You're okay

as is for THIS application but folks reading this

thread later need to be aware of the physics.

[img]cid:.0[/img]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

90.27 KB |

| Viewed: |

17501 Time(s) |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Mon Jun 22, 2015 7:04 am Post subject: basic questions on terminal strips Posted: Mon Jun 22, 2015 7:04 am Post subject: basic questions on terminal strips |

|

|

Might have to re-make it. I have doubts that the UHMW will "flow" enough (with 15 inch-pounds of torque) to loosen connections. Anybody here qualified to interpreting attached document regarding this question?

On Mon, Jun 22, 2015 at 5:37 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 08:18 PM 6/21/2015, you wrote:

| Quote: | --> AeroElectric-List message posted by: Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)>

There's a washer under the terminals. |

What Joe is referencing is the fact that

'gas tightness' in the interface between

current carrying parts depends on the pressure

established and maintained by either crimping

or, in this case, squeezing between two very

stable forces in the clamping mechanism. Force

from a nut driven down onto the terminals is

reacted by a plastic surface under the stack.

The plastic is not stable under continuous

pressure and will relieve to some degree over

time and temperature cycles.

In your particular application, the currents

and duty-cycles involved do not imposed large

stresses on those interfaces . . . and you'll

be find with what you have. But were you crafting

say, a distribution point for fat wires carrying

tens of amps continuously and perhaps hundreds

of amps cranking . . . the need to bring those

terminals together with TWO nuts is greater.

You can see that the base of these studs is part

of the metal that makes up the stud. Terminals

stacked on these studs can be brought up to

and held at gas-tight pressures without adding

the nut under it. With the DIY terminal block

the bottom nut takes on this duty. You're okay

as is for THIS application but folks reading this

thread later need to be aware of the physics.

[img]cid:.0[/img]

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

90.27 KB |

| Viewed: |

17500 Time(s) |

|

| Description: |

|

Download |

| Filename: |

uhmw.pdf |

| Filesize: |

21.64 KB |

| Downloaded: |

680 Time(s) |

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 22, 2015 7:35 am Post subject: basic questions on terminal strips Posted: Mon Jun 22, 2015 7:35 am Post subject: basic questions on terminal strips |

|

|

At 10:01 AM 6/22/2015, you wrote:

| Quote: | | Might have to re-make it. I have doubts that the UHMW will "flow" enough (with 15 inch-pounds of torque) to loosen connections. Anybody here qualified to interpreting attached document regarding this question? |

I wouldn't loose any sleep over it. The

argument goes more to support standard practices

based on the full spectrum of stresses.

It is not terribly relevant to your application.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Dennis Johnson

Joined: 10 Jan 2006

Posts: 89

Location: N. Calif.

|

|

| Back to top |

|

|

handainc(at)madisoncounty

Guest

|

Posted: Mon Jun 22, 2015 8:41 am Post subject: basic questions on terminal strips Posted: Mon Jun 22, 2015 8:41 am Post subject: basic questions on terminal strips |

|

|

Using those, you could use a plain nut of the top side of the plastic, inset as per Bobs example and have eequivalent to the factory unit if you can figure out some way to tighten the nut on the bolt. Using a larger drill to allow use of thin walled socket, cinching down the nut tightly, and the anchoring it in place with epoxy should provide a very serviceable part that achieves the physics Bob references.

M. Haught

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|