|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

dlm34077

Joined: 10 Feb 2007

Posts: 115

Location: AZ

|

Posted: Sat Feb 13, 2016 6:20 am Post subject: maintenance tips Posted: Sat Feb 13, 2016 6:20 am Post subject: maintenance tips |

|

|

The 360003 fuel pressure sensor has a tendency to start reading erratically high fuel pressure after several hundred hours; an IA friend said the same is true for the PMA stamped part for about 10-15 times the experimental price. I replaced the part at about 400 hours and again at about 800 hours. The new one started the routine a couple of months ago. After thinking about the transducer, I decided to try cleaning the contacts; I have flown several hours since then and the sensor is operating normally. I think that the problem may be the oil residue, etc swirling about under the cowl and causing contact problems. So far so good.

I believe most 10s have the Matco master cylinders supplied by Vans. I spoke with George Happ of Matco about a problem I have seen on a couple of occasions. Given the geometry of the rudder/brake pedals it is possible through inattention to drag a brake slightly. The master cylinder is not fully extended and therefore can not equalize internal pressures due to covered input port; the result is a temporary faulty brake and perhaps erratic steering as a result. It can happen with long taxi, hot weather and dragging a brake ever so slightly. It has happened to me twice in about 1000 hours. It seems as though a brake bleed is necessary but after a short period the situation resolves itself. At the time of occurrence it seems best to remove one’s feet from the brakes for a second or two and reapply.

David McNeill

N46007 TT 1000+

This email has been sent from a virus-free computer protected by Avast. www.avast.com

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

gengrumpy

Joined: 07 May 2013

Posts: 131

Location: Tullahoma, TN

|

Posted: Sat Feb 13, 2016 6:51 am Post subject: maintenance tips Posted: Sat Feb 13, 2016 6:51 am Post subject: maintenance tips |

|

|

In a prior life with much heavier iron being pushed by a hot air tailpipe, we were taught to only put your feet on the brake pedals when you needed to brake, get on both brakes quickly with equal pressure, and then get totally back off of them. Let the plane accelerate a bit, then do it all over again. A series of slowing down through firm braking, then accelerating until you need to slow it down again.

Constant pressure during taxiing creates heat. Enough heat will cause brake fade and ignite any fluid around the pucksâ¦..

I have used this technique solely since building my -10 nearly 10 years ago, and not only have there been no brake incidents, I replace the pads about every 300 hours (there is still life left in them at that point, I just feel better replacing themâ¦..).

grumpy

| Quote: | On Feb 13, 2016, at 8:16 AM, David <dlm34077(at)cox.net (dlm34077(at)cox.net)> wrote:

The 360003 fuel pressure sensor has a tendency to start reading erratically high fuel pressure after several hundred hours; an IA friend said the same is true for the PMA stamped part for about 10-15 times the experimental price. I replaced the part at about 400 hours and again at about 800 hours. The new one started the routine a couple of months ago. After thinking about the transducer, I decided to try cleaning the contacts; I have flown several hours since then and the sensor is operating normally. I think that the problem may be the oil residue, etc swirling about under the cowl and causing contact problems. So far so good.

I believe most 10s have the Matco master cylinders supplied by Vans. I spoke with George Happ of Matco about a problem I have seen on a couple of occasions. Given the geometry of the rudder/brake pedals it is possible through inattention to drag a brake slightly. The master cylinder is not fully extended and therefore can not equalize internal pressures due to covered input port; the result is a temporary faulty brake and perhaps erratic steering as a result. It can happen with long taxi, hot weather and dragging a brake ever so slightly. It has happened to me twice in about 1000 hours. It seems as though a brake bleed is necessary but after a short period the situation resolves itself. At the time of occurrence it seems best to remove oneâs feet from the brakes for a second or two and reapply.

David McNeill

N46007 TT 1000+

This email has been sent from a virus-free computer protected by Avast. www.avast.com

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

carl.froehlich(at)verizon

Guest

|

Posted: Sat Feb 13, 2016 6:53 am Post subject: maintenance tips Posted: Sat Feb 13, 2016 6:53 am Post subject: maintenance tips |

|

|

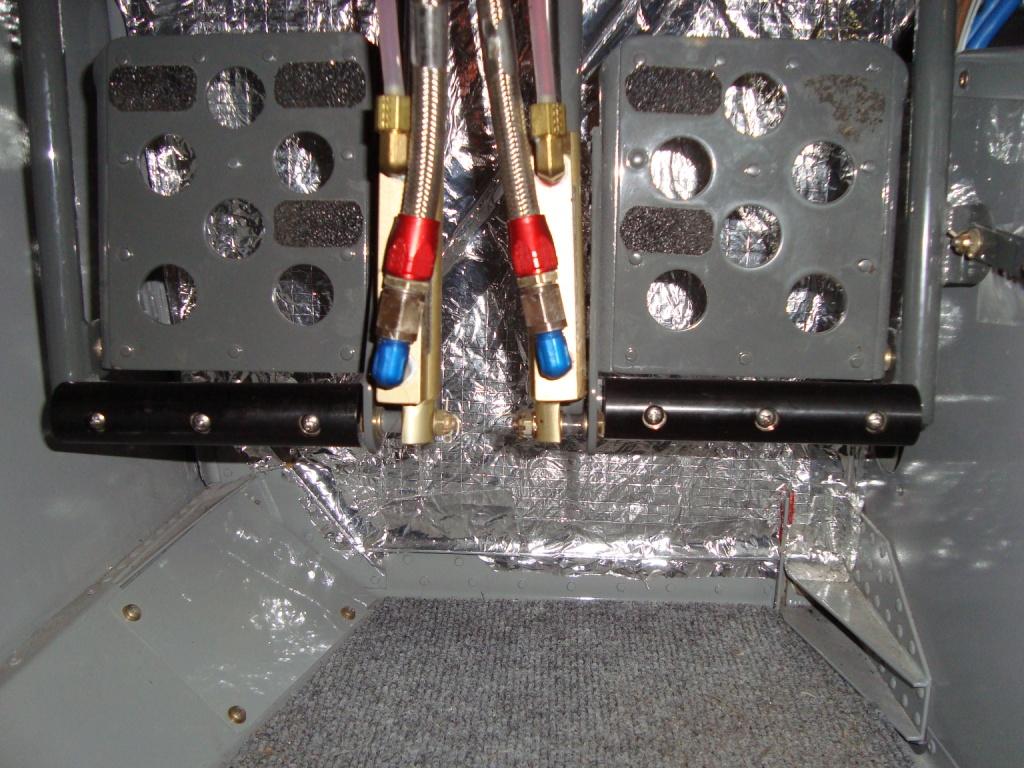

It is easy to drag a brake. Here is a note I sent out a few months ago on the subject.

My son and son-in-law are Naval Aviators. As is easy to do, both have a tendency to drag the brakes. A good friend of mine, Tom Doran, made these extension on his milling machine from 1” Delron. He even made me one out of steel for me to use as a drilling gig. I used a couple of hose clamps to attached the gig and drill the #19 holes.

While I did this to help the son and son-in-law I confess I found them to be much better than just the stock set up.

Carl

From: owner-rv10-list-server(at)matronics.com [mailto:owner-rv10-list-server(at)matronics.com] On Behalf Of David

Sent: Saturday, February 13, 2016 9:17 AM

To: rv10-list(at)matronics.com

Subject: maintenance tips

The 360003 fuel pressure sensor has a tendency to start reading erratically high fuel pressure after several hundred hours; an IA friend said the same is true for the PMA stamped part for about 10-15 times the experimental price. I replaced the part at about 400 hours and again at about 800 hours. The new one started the routine a couple of months ago. After thinking about the transducer, I decided to try cleaning the contacts; I have flown several hours since then and the sensor is operating normally. I think that the problem may be the oil residue, etc swirling about under the cowl and causing contact problems. So far so good.

I believe most 10s have the Matco master cylinders supplied by Vans. I spoke with George Happ of Matco about a problem I have seen on a couple of occasions. Given the geometry of the rudder/brake pedals it is possible through inattention to drag a brake slightly. The master cylinder is not fully extended and therefore can not equalize internal pressures due to covered input port; the result is a temporary faulty brake and perhaps erratic steering as a result. It can happen with long taxi, hot weather and dragging a brake ever so slightly. It has happened to me twice in about 1000 hours. It seems as though a brake bleed is necessary but after a short period the situation resolves itself. At the time of occurrence it seems best to remove one’s feet from the brakes for a second or two and reapply.

David McNeill

N46007 TT 1000+

This email has been sent from a virus-free computer protected by Avast.

www.avast.com

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

63.36 KB |

| Viewed: |

3094 Time(s) |

|

| Description: |

|

| Filesize: |

142.42 KB |

| Viewed: |

3094 Time(s) |

|

|

|

| Back to top |

|

|

flying-nut(at)cfl.rr.com

Guest

|

Posted: Sat Feb 13, 2016 7:17 am Post subject: maintenance tips Posted: Sat Feb 13, 2016 7:17 am Post subject: maintenance tips |

|

|

Along with 'heel pads' you can put an additional compression spring on the master cylinder shaft to help it relax fully. The angle of the pedal just naturally makes it easy to drag the brakes.

As John Miller posted, short, hard brake pressure is always preferable to dragging the brakes due to the heat. Tail-dragger pilots should be used to that already.

AFAIK, the original Matco brake disks are a little thinner than their Cleveland counterparts and don't have as much mass to store a lot of heat.

Linn

On 2/13/2016 9:49 AM, Carl Froehlich wrote:

| Quote: | <![endif]--> <![endif]-->

It is easy to drag a brake. Here is a note I sent out a few months ago on the subject.

My son and son-in-law are Naval Aviators. As is easy to do, both have a tendency to drag the brakes. A good friend of mine, Tom Doran, made these extension on his milling machine from 1 Delron. He even made me one out of steel for me to use as a drilling gig. I used a couple of hose clamps to attached the gig and drill the #19 holes.

While I did this to help the son and son-in-law I confess I found them to be much better than just the stock set up.

Carl

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of David

Sent: Saturday, February 13, 2016 9:17 AM

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Subject: maintenance tips

The 360003 fuel pressure sensor has a tendency to start reading erratically high fuel pressure after several hundred hours; an IA friend said the same is true for the PMA stamped part for about 10-15 times the experimental price. I replaced the part at about 400 hours and again at about 800 hours. The new one started the routine a couple of months ago. After thinking about the transducer, I decided to try cleaning the contacts; I have flown several hours since then and the sensor is operating normally. I think that the problem may be the oil residue, etc swirling about under the cowl and causing contact problems. So far so good.

I believe most 10s have the Matco master cylinders supplied by Vans. I spoke with George Happ of Matco about a problem I have seen on a couple of occasions. Given the geometry of the rudder/brake pedals it is possible through inattention to drag a brake slightly. The master cylinder is not fully extended and therefore can not equalize internal pressures due to covered input port; the result is a temporary faulty brake and perhaps erratic steering as a result. It can happen with long taxi, hot weather and dragging a brake ever so slightly. It has happened to me twice in about 1000 hours. It seems as though a brake bleed is necessary but after a short period the situation resolves itself. At the time of occurrence it seems best to remove ones feet from the brakes for a second or two and reapply.

David McNeill

N46007 TT 1000+

This email has been sent from a virus-free computer protected by Avast.

www.avast.com

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

philperry9

Joined: 23 Nov 2011

Posts: 381

|

Posted: Sat Feb 13, 2016 9:42 am Post subject: maintenance tips Posted: Sat Feb 13, 2016 9:42 am Post subject: maintenance tips |

|

|

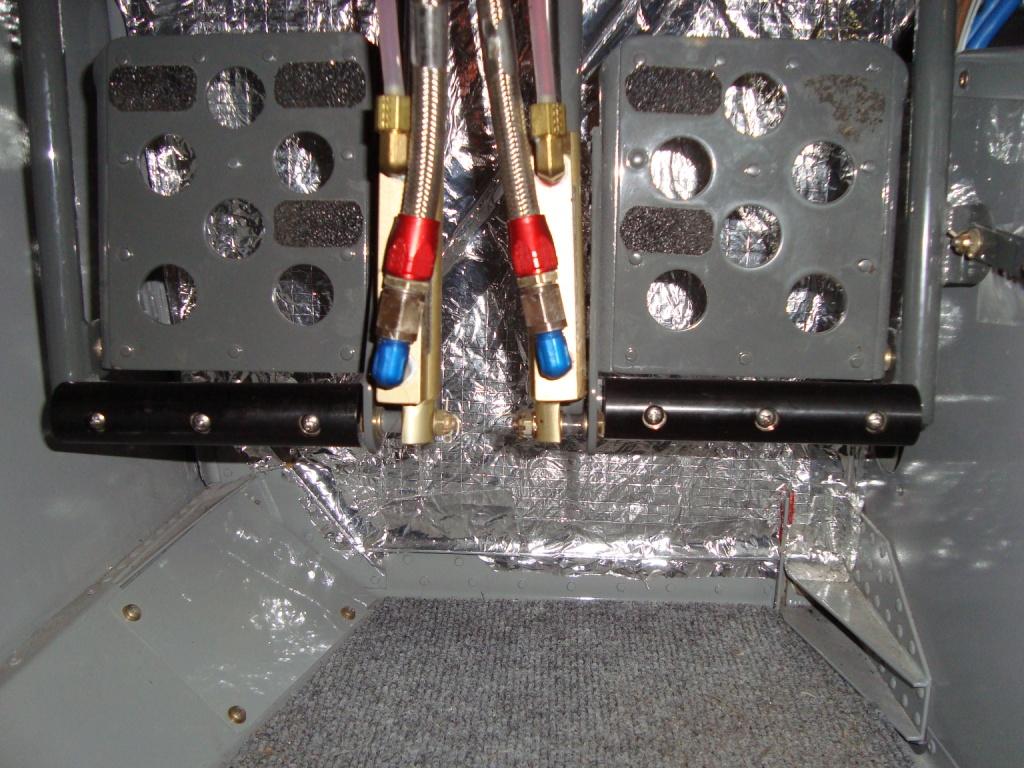

Here's my setup for return springs to assist the internal spring on the

master cylinders.

On the bottom is a delrin washer to help protect the master cylinder from

the spring.

Then the spring.

Then on top of that is a collar for the spring to press against on the top

and to adjust the tension you feel on the brake pedals.

All hardware purchased in the aviation department of Ace Hardware.

Probably around $7 per master cylinder.

Phil

[image: Inline image 1]

On Sat, Feb 13, 2016 at 9:13 AM, Linn Walters <flying-nut(at)cfl.rr.com> wrote:

[quote] Along with 'heel pads' you can put an additional compression spring on the

master cylinder shaft to help it relax fully. The angle of the pedal just

naturally makes it easy to drag the brakes.

As John Miller posted, short, hard brake pressure is always preferable to

dragging the brakes due to the heat. Tail-dragger pilots should be used to

that already.

AFAIK, the original Matco brake disks are a little thinner than their

Cleveland counterparts and don't have as much mass to store a lot of heat

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|