|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

italianjon

Joined: 05 Aug 2015

Posts: 68

|

Posted: Sat Feb 11, 2017 9:56 am Post subject: Arplst PV50 - Last Stand... Sort of... Posted: Sat Feb 11, 2017 9:56 am Post subject: Arplst PV50 - Last Stand... Sort of... |

|

|

Hi All,

If you recall I posted about a year ago, relating to PV50 and some vibration problems. Well, it has been an interesting year, and some stories which I won't write on a public forum, but I might share over a beer at a fly-in. A lot of the year has been a learning curve, and I used the time waiting for the PH-Reg to come through, to experiment and learn more

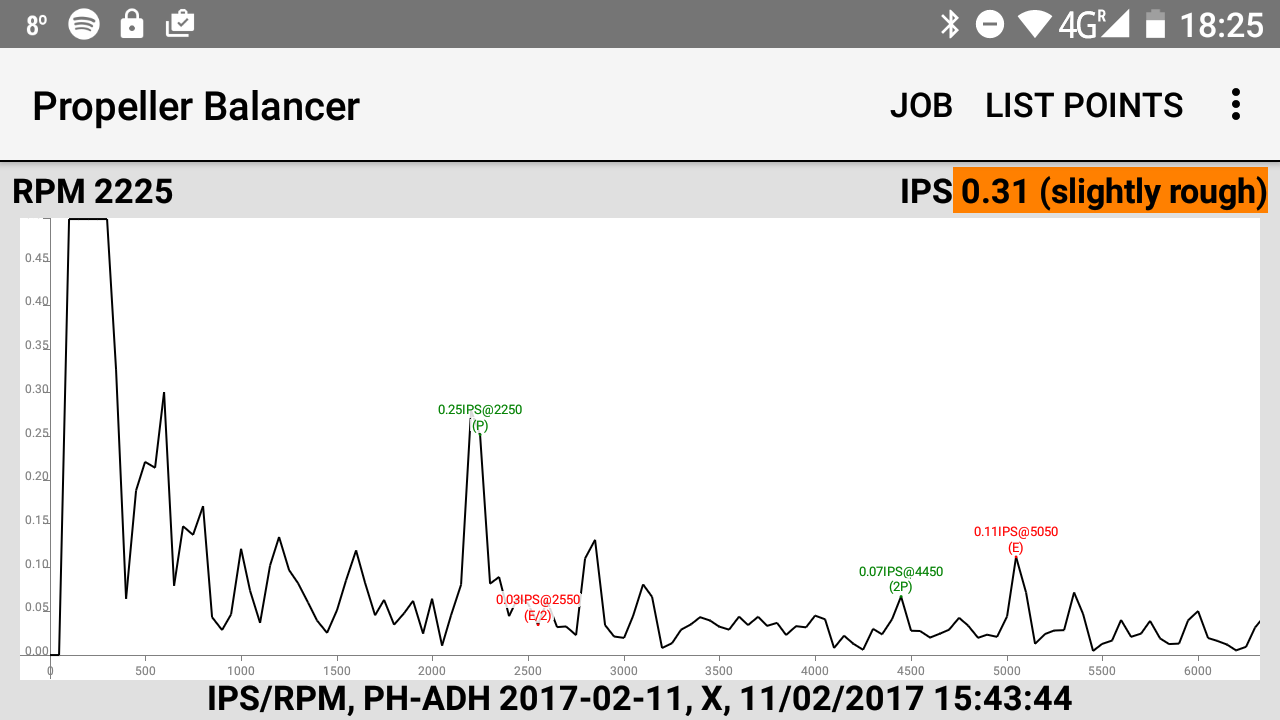

Today I was coming to the end of a careful adjustments on the propeller, but still, alas, there is an imbalance. I'm getting about 0.25 IPS on the prop (attached is the outcome of the spectrum), this is now the main and seemingly only contributor to the vibration.

I've managed to get all three blade-pitches to within 0.16 degres across all three blades, and the tracking is less than 3 mm. The blades are quite firmly seated now, after I have installed new plastic blocks. All of this has had no real effect.

Today was a very quiet day at the airfield. There was only myself and my "plane work buddy". On one of the blades I heard a "tick", and on closer inspection it is evident something is loose on the inside (One of the static balance weights, I am assuming)

Does anyone have any experience at all in setting the static weights on a PV50 blade? Is it possible without manufacturer support?

Failing that, is there anyone with a spare blade that I could try in the position, to close off this investigation?

I know the engine is not contributing, as the latest spectrum shows nothing significant at key engine frequencies, and in addition I have spectra from other measurements with my aircraft and a Warpdrive installed which shows very good vibration down at 0.08IPS.

Cheers

Jon

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

79.27 KB |

| Viewed: |

6616 Time(s) |

|

|

|

| Back to top |

|

|

kennethatkinson178(at)bti

Guest

|

Posted: Sun Feb 12, 2017 1:20 pm Post subject: Arplst PV50 - Last Stand... Sort of... Posted: Sun Feb 12, 2017 1:20 pm Post subject: Arplst PV50 - Last Stand... Sort of... |

|

|

Hi Jon,

If something is loose inside your PV50 you must dismantle it again and

investigate. The initial balancing, I believe, would have been achieved

by fitting appropiate weights into the centre of the blade roots.I doubt

that any of these would be loose but check!

I did find on my first annual service of my PV50 that the centre

triangular block was loose on the activator tube and the grub screw was

loose!

This year I carried out a static balance following the fitting of new

thrust bearings and bushes.I was surprised at the out of balance that I

had to counteract with 8 mm threaded weights fitted onto the six 8mm hub

assembly bolts. This seemed a suitable method of fitting balance weights

to me? How have you fitted any balance weights? My propeller/engine is

running pretty smoothly now but probably would benefit from dynamic

balancing.

I have a spare set of early PV50 Classic (shorter) 80hp narrow blades,

but they would need serious balancing to match a different hub. Each set

of blades is matched to fit each hub and also each blade must be fitted

in the correct position.

My details are on the members list if you want to contact me otherwise I

will look out for you at a fly-in for some intersting PV50 tales!

Ken Atkinson G-CEKV mono no 19

On 11/02/2017 17:56, italianjon wrote:

| Quote: |

Hi All,

If you recall I posted about a year ago, relating to PV50 and some vibration problems. Well, it has been an interesting year, and some stories which I won't write on a public forum, but I might share over a beer at a fly-in. A lot of the year has been a learning curve, and I used the time waiting for the PH-Reg to come through, to experiment and learn more

Today I was coming to the end of a careful adjustments on the propeller, but still, alas, there is an imbalance. I'm getting about 0.25 IPS on the prop (attached is the outcome of the spectrum), this is now the main and seemingly only contributor to the vibration.

I've managed to get all three blade-pitches to within 0.16 degres across all three blades, and the tracking is less than 3 mm. The blades are quite firmly seated now, after I have installed new plastic blocks. All of this has had no real effect.

Today was a very quiet day at the airfield. There was only myself and my "plane work buddy". On one of the blades I heard a "tick", and on closer inspection it is evident something is loose on the inside (One of the static balance weights, I am assuming)

Does anyone have any experience at all in setting the static weights on a PV50 blade? Is it possible without manufacturer support?

Failing that, is there anyone with a spare blade that I could try in the position, to close off this investigation?

I know the engine is not contributing, as the latest spectrum shows nothing significant at key engine frequencies, and in addition I have spectra from other measurements with my aircraft and a Warpdrive installed which shows very good vibration down at 0.08IPS.

Cheers

Jon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=466013#466013

Attachments:

http://forums.matronics.com//files/screenshot_20170211_182509_207.png

|

---

This email has been checked for viruses by Avast antivirus software.

https://www.avast.com/antivirus

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

grahamsingleton(at)btinte

Guest

|

Posted: Sun Feb 12, 2017 2:05 pm Post subject: Arplst PV50 - Last Stand... Sort of... Posted: Sun Feb 12, 2017 2:05 pm Post subject: Arplst PV50 - Last Stand... Sort of... |

|

|

Jon & Ken

I always used to start by balancing each blade separately on the bench. I built a simple jig having a knife edge fulcrum positioned at the centre of the prop assembly, which supported the blade so that the root of the blade was the correct distance from the centre/fulcrum and the blade was supported somewhere about 75% blade diameter. there is a second fulcrum at about 60% of the span (not critical) where the load is measured accurately, to within 1/2 a gram. This is the moment of the blade about the centre of the prop. Each blade must have the same moment. Surprisingly the actual weight of each blade might not be exactly the same, it's the moment that is critical.

Now measure the moment of each blade and adjust by adding a small amount of lead in the hole drilled down the blade from the root. The lead shot is secured with epoxy resin and you will find it is about 300mm out from the root.

I hope that's clear enough to understand, I learned this method from Jerry Davis who used to be the UK agent for Arplast.

Graham

On Sunday, 12 February 2017, 21:21, Ken Atkinson <kennethatkinson178(at)btinternet.com> wrote:

--> Europa-List message posted by: Ken Atkinson <kennethatkinson178(at)btinternet.com (kennethatkinson178(at)btinternet.com)>

Hi Jon,

If something is loose inside your PV50 you must dismantle it again and

investigate. The initial balancing, I believe, would have been achieved

by fitting appropiate weights into the centre of the blade roots.I doubt

that any of these would be loose but check!

I did find on my first annual service of my PV50 that the centre

triangular block was loose on the activator tube and the grub screw was

loose!

This year I carried out a static balance following the fitting of new

thrust bearings and bushes.I was surprised at the out of balance that I

had to counteract with 8 mm threaded weights fitted onto the six 8mm hub

assembly bolts. This seemed a suitable method of fitting balance weights

to me? How have you fitted any balance weights? My propeller/engine is

running pretty smoothly now but probably would benefit from dynamic

balancing.

I have a spare set of early PV50 Classic (shorter) 80hp narrow blades,

but they would need serious balancing to match a different hub. Each set

of blades is matched to fit each hub and also each blade must be fitted

in the correct position.

My details are on the members list if you want to contact me otherwise I

will look out for you at a fly-in for some intersting PV50 tales!

Ken Atkinson G-CEKV mono no 19

On 11/02/2017 17:56, italianjon wrote:

| Quote: | --> Europa-List message posted by: "italianjon" <jon.catilli(at)gmail.com (jon.catilli(at)gmail.com)>

Hi All,

If you recall I posted about a year ago, relating to PV50 and some vibration problems. Well, it has been an interesting year, and some stories which I won't write on a public forum, but I might share over a beer at a fly-in. A lot of the year has been a learning curve, and I used the time waiting for the PH-Reg to come through, to experiment and learn more

Today I was coming to the end of a careful adjustments on the propeller, but still, alas, there is an imbalance. I'm getting about 0.25 IPS on the prop (attached is the outcome of the spectrum), this is now the main and seemingly only contributor to the vibration.

I've managed to get all three blade-pitches to within 0.16 degres across all three blades, and the tracking is less than 3 mm. The blades are quite firmly seated now, after I have installed new plastic blocks. All of this has had no real effect.

Today was a very quiet day at the airfield. There was only myself and my "plane work buddy". On one of the blades I heard a "tick", and on closer inspection it is evident something is loose on the inside (One of the static balance weights, I am assuming)

Does anyone have any experience at all in setting the static weights on a PV50 blade? Is it possible without manufacturer support?

Failing that, is there anyone with a spare blade that I could try in the position, to close off this investigation?

I know the engine is not contributing, as the latest spectrum shows nothing significant at key engine frequencies, and in addition I have spectra from other measurements with my aircraft and a Warpdrive installed which shows very good vibration down at 0.08IPS.

Cheers

Jon

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=466013#466013

Attachments:

http://forums.matronics.com//files/screenshot_20170211_182509_207.png

|

---

This email has been checked for viruses by Avast antivirus software.

http://www.matronics.co========================http://========================

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

italianjon

Joined: 05 Aug 2015

Posts: 68

|

Posted: Mon Feb 13, 2017 2:50 am Post subject: Re: Arplst PV50 - Last Stand... Sort of... Posted: Mon Feb 13, 2017 2:50 am Post subject: Re: Arplst PV50 - Last Stand... Sort of... |

|

|

Hi Ken and Graham,

Thank you for the informative replies.

Ken, I can confirm everything inside the hub is secure and a good fit. There is very little play in the system now. I learnt a lot last year when I stripped the propeller down with Pete Jeffers; and put into action some of his excellent advice. What I am referring to, with the “tick” sound of something loose, is when one of the blades is removed from the assembly and you rotate it around, such the tip faces upwards then rotate 180° downwards you can hear a “tick” sound from the (I think) lead weights inside the blade In other words the static balance mass seems to have come loose. It only got noticed because the airfield was so quiet on Saturday. It’s also consistent with Graham’s “300mm” comment. The sound “ticks” towards the tip when held downwards, and ‘mid-blade” when held tip-upwards. Therefore, with the information provided by both of you, my current hypothesis, which fits the evidence, is that the weight has loosened itself from the epoxy resin on the side towards the tip but the resin has remained fixed in place.

I was concerned that I do not have enough skills to address the issue, but from what Graham has written I might.

Graham, can I explore this a bit more with you? I understand in principle all that you are saying, and you wrote, regarding the blade-moment jig, a similar thing to me about a year ago. I have constructed a jig, which has a pivot point in-line with the centre of rotation and a balance support which can be placed along the blade to measure the moment.

From the polar plot of my vibration analysis, I can see that at cruise RPM the imbalance is aligned perfectly with the blade with the loose weight. This would be consistent with a mass that moves outwards in the rotation radius and “pulls” more.

What is not clear to me, using your method are the following: -

1) In my single blade, where as I mentioned above, the epoxy seems to still be in place, how could I remove this without damaging the blade, in order to remove the weight and reset it?

2) What is the best method to install the weight once it’s out? I guess it’s along the lines of bathe the lead weight in epoxy and slide it along until the desired blade-moment is achieved and then wait for the epoxy to set.

Then I have one last question: -

3) If I can’t remove the lead weight from inside the blade, I am thinking about removing one of the washers currently installed on the dynamic balance arm to see if this moves the dynamic balance towards the polar centre? Is this a reasonable approach?

I am going to revisit the blade-moment measurements. When I tried a year ago, everything was OK. But, the method I used was to lower the tip on to the mass scale; which would, of course (if the assumptions above are correct) reset the lead weight to the correct position for the measurement. I will ensure that the weight is towards the tip, on the suspect blade and then re-measure.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

grahamsingleton(at)btinte

Guest

|

Posted: Mon Feb 13, 2017 3:28 am Post subject: Arplst PV50 - Last Stand... Sort of... Posted: Mon Feb 13, 2017 3:28 am Post subject: Arplst PV50 - Last Stand... Sort of... |

|

|

Hi Jon

as a matter of interest who built your Europa? Is it a Classic or an XS?

Turning to the blade with loose weight, you will need a long drill, maybe 5 or 6mm diameter. You should be able to see the hole at the centre of the root of the blade, carefully drill down the blade allowing the existing hole to guide the drill. At some point the loose bit of lead should drop out. If the hole is already open some weight may have been lost which would account for the out of balance.

The penny washers on the balance arms are there to assist turning the blade when it is under load. (I don't fully understand how they do that) Nothing to do with prop balance and there should be the same number of washers on each blade.

Graham

On Monday, 13 February 2017, 10:52, italianjon <jon.catilli(at)gmail.com> wrote:

--> Europa-List message posted by: "italianjon" <jon.catilli(at)gmail.com (jon.catilli(at)gmail.com)>

Hi Ken and Graham,

Thank you for the informative replies.

Ken, I can confirm everything inside the hub is secure and a good fit. There is very little play in the system now. I learnt a lot last year when I stripped the propeller down with Pete Jeffers; and put into action some of his excellent advice. What I am referring to, with the “tick� sound of something loose, is when one of the blades is removed from the assembly and you rotate it around, such the tip faces upwards then rotate 180° downwards you can hear a “tick� sound from the (I think) lead weights inside the blade In other words the static balance mass seems to have come loose. It only got noticed because the airfield was so quiet on Saturday. It’s also consistent with Graham’s “300mm� comment. The sound “ticks� towards the tip when held downwards, and ‘mid-blade� when held tip-upwards. Therefore, with the information provided by both of you, my current hypothesis, which fits the evidence, is that the weight has loosened itself from the epoxy resi!

n on the side towards the tip but the resin has remained fixed in place.

I was concerned that I do not have enough skills to address the issue, but from what Graham has written I might.

Graham, can I explore this a bit more with you? I understand in principle all that you are saying, and you wrote, regarding the blade-moment jig, a similar thing to me about a year ago. I have constructed a jig, which has a pivot point in-line with the centre of rotation and a balance support which can be placed along the blade to measure the moment.

| Quote: | From the polar plot of my vibration analysis, I can see that at cruise RPM the imbalance is aligned perfectly with the blade with the loose weight. This would be consistent with a mass that moves outwards in the rotation radius and “pulls� more.

|

What is not clear to me, using your method are the following: -

1) In my single blade, where as I mentioned above, the epoxy seems to still be in place, how could I remove this without damaging the blade, in order to remove the weight and reset it?

2) What is the best method to install the weight once it’s out? I guess it’s along the lines of bathe the lead weight in epoxy and slide it along until the desired blade-moment is achieved and then wait for the epoxy to set.

Then I have one last question: -

3) If I can’t remove the lead weight from inside the blade, I am thinking about removing one of the washers currently installed on the dynamic balance arm to see if this moves the dynamic balance towards the polar centre? Is this a reasonable approach?

I am going to revisit the blade-moment measurements. When I tried a year ago, everything was OK. But, the method I used was to lower the tip on to the mass scale; which would, of course (if the assumptions above are correct) reset the lead weight to the correct position for the measurement. I will ensure that the weight is towards the tip, on the suspect blade and then re-measure.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?pcs.com/Navigator?Europa-List" target="_blank">http://www.matronics.com/Na= - MATRONICS WEB FORUMS========================http://www.ma======================

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

italianjon

Joined: 05 Aug 2015

Posts: 68

|

Posted: Mon Feb 13, 2017 10:29 am Post subject: Re: Arplst PV50 - Last Stand... Sort of... Posted: Mon Feb 13, 2017 10:29 am Post subject: Re: Arplst PV50 - Last Stand... Sort of... |

|

|

Hi Graham,

I have BXUM, Dave's old classic girl. (Although she's PH-ADH now)

Next weekend I am away, but the weekend after 25th/26th, I will take off the Arplast and carefully measure the blade-moments.

When I reinsert the weights, how did you do it in the past. Was my thoughts about mixing the lead with epoxy and sliding it along the bore until the correct moment is achieved correct? Or should I be doing something else to install the lead weight?

I will leave the penny washers alone, I need to check if they have the same number, but I am sure they do. I'm not sure where I got the info from about dynamically balancing them.

Cheers

Jon

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

grahamsingleton(at)btinte

Guest

|

Posted: Mon Feb 13, 2017 2:11 pm Post subject: Arplst PV50 - Last Stand... Sort of... Posted: Mon Feb 13, 2017 2:11 pm Post subject: Arplst PV50 - Last Stand... Sort of... |

|

|

Jon

BXUM! I rode RH seat from UK to Ivalo and back with Dave. We went to visit Jos Okhuisen, who is still a friend of mine.

If you can get all the lead out of the blade, (unlikely because you must not drill too deep) Then add weight right to the end of the drilling.

You could use tungsten carbide grinding dust if you can find any, (heavier than lead or fine lead shot. Add it dry to check then mix with epoxy and reinstall enough to give correct moment.

When you get to the stage of adding weights to dynamically balnce the prop try adding a single penny washer to one of the spinner screws.

(AN970-3)

If you speak French you could try talking to Alain Petit, who built your prop. Another old friend. I have an old email address but don't know if it still in use. <hal.1(at)wanadoo.fr>

Graham in the circuit for Ivalo, 300 miles north of the Arctic Cicle.

[img]cid:c78be75b-34b1-ddd3-ae0b-71656ecc8e0c(at)yahoo.com[/img]

On Monday, 13 February 2017, 18:51, italianjon <jon.catilli(at)gmail.com> wrote:

--> Europa-List message posted by: "italianjon" <jon.catilli(at)gmail.com (jon.catilli(at)gmail.com)>Hi Graham,I have BXUM, Dave's old classic girl. (Although she's PH-ADH now)Next weekend I am away, but the weekend after 25th/26th, I will take off the Arplast and carefully measure the blade-moments.When I reinsert the weights, how did you do it in the past. Was my thoughts about mixing the lead with epoxy and sliding it along the bore until the correct moment is achieved correct? Or should I be doing something else to install the lead weight?I will leave the penny washers alone, I need to check if they have the same number, but I am sure they do. I'm not sure where I got the info from about dynamically balancing them.CheersJonRead this topic online here:http://forums.matronics.com/viewtopic.php?p=466134#466134_-= the many List utilities such as List Un/Subscription,http:// - MATRONICS WEB FORUMS --========================p; - NEW MATRONICS LIST WIKI -http://www.matronics.com/con======================

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

601.5 KB |

| Viewed: |

6557 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|