|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Aug 24, 2017 6:54 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Thu Aug 24, 2017 6:54 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 11:14 AM 8/23/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

Joe and Charlie,

The switch controls an electronic lamp ballast driving two 75W UVC producing. I don't know if that is inductive or resistive load. Steady state amperage is 800ma

And found this white paper(excerpt) on electronic ballasts. :

"Design Considerations for Electronic Ballasts

Inrush currents at turn-on, produced from some electronic

ballasts can cause premature relay contact failures.

These inrush currents can be much higher than those

experienced with traditional tungsten or magnetic ballast

loads because many electronic ballasts employ large

energy storage capacitors. Such capacitors can charge up

to 400V for a 277V line voltage, and will briefly draw high

current from the line to achieve this voltage.

As mentioned above, these typically short inrush currents

can climb as high as 100 times the nominal operating

levels. |

ALL devices with metallic contacts have

difficulties with capacitive loads.

The majority of my experiences with

premature contact failures involved

capacitive loads.

Consider adding inrush limiting to the

switched pathway

http://tinyurl.com/yacaagsp

These are negative temperature coefficient

resistors with substantial room temperature

resistance that falls to insignificant

resistance after being allowed to warm up

under the steady state load.

I've only had occasion to use these once

on an airplane (P-180). The techs working

the experimental airplane came to my desk

complaining that the things kept 'blowing

up'. Turns out they had mounted the device

to adjacent lamp housing such that internal

heating was transferred to the housing.

The devices were not being allowed to warm up,

internal dissipation remained high and they

went into self destruction.

So be sure to mount these such that free air

is the only heat sink.

It may take a bit of fiddling to get the

optimum part . . . but this one seems

a likely starting point for your quest.

http://tinyurl.com/y92bs8ba

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Thu Aug 24, 2017 10:41 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Thu Aug 24, 2017 10:41 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

Thanks Bob,

Although suspicion has risen that my step-down power supply is the culprit (40a inrush), I appreciate learning about inrush current limiters for their small form and small price compared to clunky hi amperage/price relays, mechanical or solid state.

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Aug 25, 2017 5:59 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Fri Aug 25, 2017 5:59 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 01:36 PM 8/24/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

After further investigation, suspicion has grown about the inrush current to the power supply that I'm using.

The ballast mfgr says any inrush to the ballast is not a problem for the garden-variety installation. The thing that is different about my install is the inclusion of a step-down power supply that specs 40A inrush current...8x the switch spec of 5A.

Stay tuned

John |

Okay, I've lost my mental image of the

configuration. Can you sketch and scan

a schematic of the major components along

with location of the switch?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Sat Aug 26, 2017 9:00 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Sat Aug 26, 2017 9:00 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

Bob,

Here's the schematic, and late breaking...the ballast mfgr engineer informed me that the max inrush for the ballast is 101 A. Combined with the Pwr Supply's 40A inrush, rough duty for a 5A switch.

Thanks for looking at this,

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

MeanWell RS-100-24 -spec.pdf |

| Filesize: |

123.13 KB |

| Downloaded: |

619 Time(s) |

| Description: |

|

Download |

| Filename: |

M4 wireout.pdf |

| Filesize: |

8.61 KB |

| Downloaded: |

543 Time(s) |

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Aug 27, 2017 4:38 pm Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Sun Aug 27, 2017 4:38 pm Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 12:00 PM 8/26/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

Bob,

Here's the schematic, and late breaking...the ballast mfgr engineer informed me that the max inrush for the ballast is 101 A. Combined with the Pwr Supply's 40A inrush, rough duty for a 5A switch.

Thanks for looking at this,

John

|

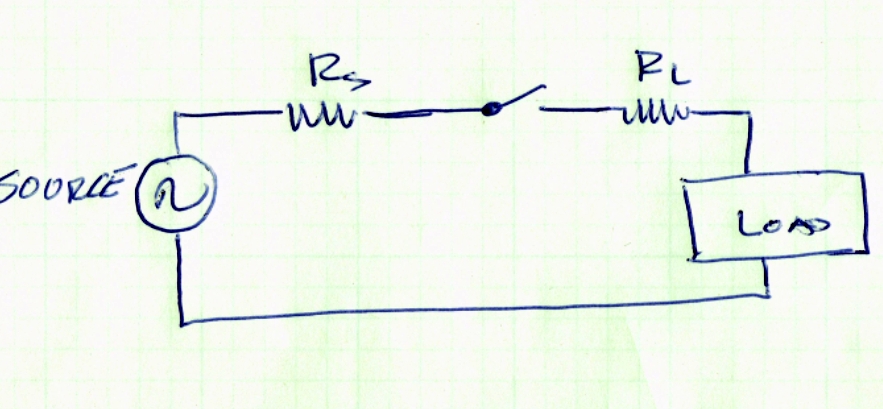

Okay, let's talk about 'inrush' currents.

[img]cid:.0[/img]

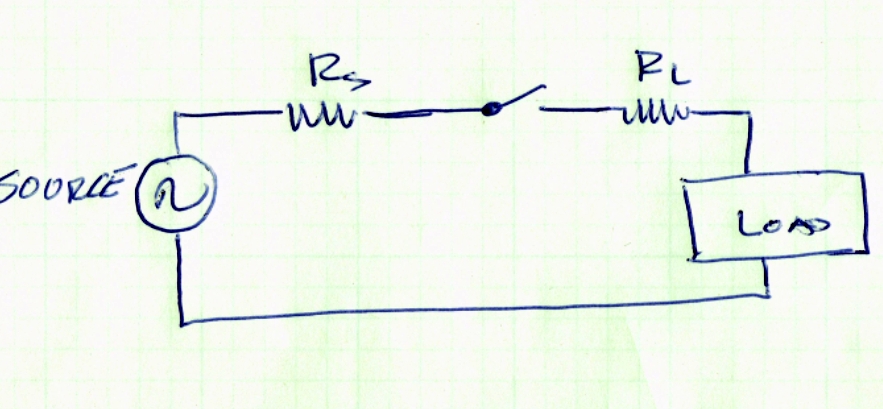

Here's a simple model of an inrush-energy study that will

suffice for this discussion. In reality, the model is

much more complex with features (inductances and capacitances)

combined with dynamics of the power source and timing . . .

if you close a switch at the exact instant the AC voltage

is at its peak, then MAXIMUM inrush currents can be expected.

On the other hand, if you can somehow close the switch while

the incoming voltage is zero . . . then inrush effects on

the switch will be . . . uh . . . almost zero.

I show two resistances, Rs which is the source resistance.

This component sets the maximum current that can flow if a

dead short is placed across the source. It also set the

requirements for 'interrupt current ratings' on circuit

breakers and fuses.

Then I've show a load resistance Rl which is controlled

by the configuration of your products input components,

in this case . . . a combined ballast and power supply.

The ballast mfgr has quoted a rather impressive inrush

current number . . . which is only partly significant.

Consider a range CAPACITORS sized from picofarads

to farads. The exact instant that your switch contacts

close, the inrush current will be V(applied)/Rs+Rl and

may very well be on the order of 100 amps . . . which

says NOTHING about the size of the capacitor, only that

V is applied over the total resitance for some period of

time after contact closure.

If C is picofarads, the DURATION of the inrush event is

very short, perhaps measured in picoseconds. If C is

Farads (like some of those capacitors favored by

installers of mobile gray-matter mashers) then the

duration of inrush event is orders of magnitude more

severe.

The ability of a switch to manage that event has roots

in contact mass, spring rates of closing forces and

velocity of the moving contact mass as it crashes into it's

stationary mate.

Contact bounce is an inevitable feature of ALL mechanical

switches. Further, the severity of bounce is only loosely

related to the switches pedigree. Here's a study I did

on a system with mil-spec, sealed relays that were GOING

to stick irrespective of how well the device was

built.

http://tinyurl.com/pstsggm

As you can see in this article, the sticking

wasn't even a high energy event. The relays were being

used in a situation well inside their catalog ratings . . .

but a combination of capacitance and PROPAGATION delay

down and back over a crude coaxial feed line stacked

up to offer the 'perfect low energy relay welder'.

The 100A inrush value offered by your supplier simply

acknowledges that there is some capacitive component

across the input to their product . . . but no help

for how large it might be.

Obviously, the COMBINATION of that inrush energy event

and contact bounce on your switch of choice has produced

a condition prone to sticking.

What kind of switch are we talking about? How long does

it take to produce a failure event? Have you been able to

duplicate the sticking even in a laboratory environment?

Are there a lot of fielded devices that may need

upgrading? One sure bet for fixing the problem and staying

with your existing switch is to add some electronics behind

the panel . . . perhaps a solid state relay with ZERO CROSSING

detection that reduces inrush to a minimum.

http://tinyurl.com/y7rst4a6

http://tinyurl.com/y8g8zyj9

Another possibility is to change the switch. Just a

difference in brand for the same physical switch

can make a big difference. Adding to Rl in the

inrush loop, either inrush limiter or perhaps just

a 3 ohm, 5 watt resistor (1A running current across

three ohms is 3 volts drop, 3W dissipated . . . but

a reduction in inrush MAGNITUDE by a factor of 3

or more . . . with an insignificant change in

over all performance.

Making the elegant decision demands more data. Perhaps

'scope traces on the inrush event. A study of bounce

characteristics of the switch. Better data on exactly

what the inputs to your loads look like will help.

But it seems likely that a change in brand/style

of switch is the shortest path and perhaps even

doable as a field retrofit. The elegant equation

demands a lot more 'numbers'

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

214.33 KB |

| Viewed: |

17117 Time(s) |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Mon Aug 28, 2017 8:14 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Mon Aug 28, 2017 8:14 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

Bob,

A thousand thanks!

And I found your explorations and findings about the relay failures on rolll trim control boards fascinating, if for no other reason than the failure symptoms are almost identical to what I'm seeing with my product.

My switch failures are beginning to occur after about 30-60 cycles. Thinking that the sticking was purely mechanical, and acknowledging the problem to users, I suggested unplugging the machine, squirting WD40 into the pushbutton recess and cycling the switch until they got a blister on their finger, to erode/smooth the imagined rough edges of the switch internals. It either worked or customers just didn't want to talk to a crazy person any more, because very few reported a continuing problem. I even rigged up a reciprocating saw with a 'boxing glove' to wear-in the switch, as a misguided, pre-conditioning preventative.

Your analysis, with remedies, is a crescendo of angelic voices, coincident with brilliant, golden light, illuminating the path out of blasphemous tinkering to electronic righteousness. I feel cleansed.

One more impertinent question:

In the zero-crossing relay suggested, the load side spec is 250vac (at) 2a. The steady-state ballast load is 800ma and the motor draws about 2a. Will the relay take it? or am I missing something here?

Thanks again,

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Tue Aug 29, 2017 5:10 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Tue Aug 29, 2017 5:10 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

What if a solid state relay and a mechanical relay are connected in parallel? The solid state relay will turn on a fraction of a second prior to the mechanical contacts closing and will conduct while the mechanical contacts are bouncing. Once the mechanical contacts have stopped bouncing, then they will carry the full load.

Or use only a solid state relay rated for the current.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Aug 29, 2017 5:29 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Tue Aug 29, 2017 5:29 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 11:14 AM 8/28/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

Bob,

A thousand thanks!

And I found your explorations and findings about the relay failures on rolll trim control boards fascinating, if for no other reason than the failure symptoms are almost identical to what I'm seeing with my product.

My switch failures are beginning to occur after about 30-60 cycles. Thinking that the sticking was purely mechanical, and acknowledging the problem to users, I suggested unplugging the machine, squirting WD40 into the pushbutton recess and cycling the switch until they got a blister on their finger, to erode/smooth the imagined rough edges of the switch internals. It either worked or customers just didn't want to talk to a crazy person any more, because very few reported a continuing problem. I even rigged up a reciprocating saw with a 'boxing glove' to wear-in the switch, as a misguided, pre-conditioning preventative. |

Yup, been there . . . or at least some of

my compadres have. There was a chronic difficulty

with nuisance tripping the ov system on the

A36/B55 series aircraft . . .that stuck its

head up several times over a span of some

30 years. One attempt at a fix included taking

brand new alternators and running them at load

on a drive stand for 20 hours or so before putting

them on the airplane . . . seems the problems were

mitigated with service time.

The operative theory at the time was that QC issues

with slip ring/brush interface was root cause of

the problem. A break-in operation seemed to help.

As it turns out, the brush/slip ring interface

was a NORMAL condition that was only a trigger

for root cause.

Got to watch that same problem pop up about every

5-10 years or so. But it wasn't until my very last

service offered to the then newly amalgamated Textron,

I suggested again, that it wasn't the alternator's

fault . . . but that of the ov regulators ov

protection system.

We started a stone simple fix before my

contract ran out. At least I didn't have to

endure the machinations and pretzel twisting

it took to get one set of guts lifted out of

a regulator with a decades long, stellar track

record and installed inside the regulator enclosure for

the Beech products. i.e. a presto-changeo

creation of a form-fit-function replacement

for a regulator that had NEVER been subjected to

DO-160 study for suitability to task. A task

that we would have accomplished in mere

days back in the day . . . took nearly a year

under the 'new order'.

| Quote: | Your analysis, with remedies, is a crescendo of angelic voices, coincident with brilliant, golden light, illuminating the path out of blasphemous tinkering to electronic righteousness. I feel cleansed.  |

You're too kind . . . but you appreciate the

the kind of thought processes and experiments

that have to be conducted to (1) eliminate that

which does not work, (2) identify that which

does work and (3) sift all the options in quest of

the elegant solution.

That relay study on roll trim cards took about

two years as the activities had to be interleaved

with more pressing matters. And I was the only

one working on it. A 'tiger team' of similarly

thoughtful and motivated students of the physical

arts would have been very helpful. Same story with pitch

trim motor failures that plagued Beech to the tune

of $millions$ in warranty claims and lost

customer confidence.

Maybe I'll publish that paper one day . . . it's

a real zinger . . . and like the roll trim relay

studies, it took years of looking for the answers

to 'what if' and 'how about this'. Sorta like

technological whack-a-mole. Then one day, one

of the heads that popped up was the Eureka mole.

| Quote: | One more impertinent question:

In the zero-crossing relay suggested, the load side spec is 250vac (at) 2a. The steady-state ballast load is 800ma and the motor draws about 2a. Will the relay take it? or am I missing something here? |

Good eye. Yeah, if THAT option is attractive, you'll

need a beefier device. Maybe something like this.

http://tinyurl.com/y8bfqm5o

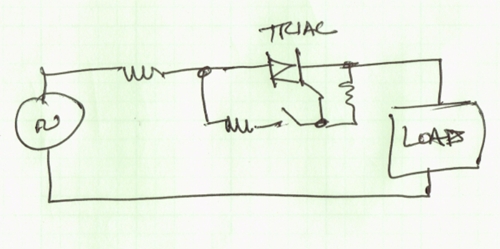

While on a patient transfer from Wichita today I

had a brain-fart that might be the simplest

solution. You could craft your own buffer

circuit for the switch from a triac and a couple

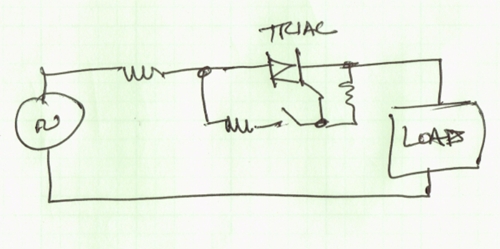

resistors like this.

[img]cid:.0[/img]

This could be nothing more than two resistors

soldered together with the triac, lead wires

attached and then coated in some insulating

encapsulant . . . maybe RTV, E6000 or thixotropic

epoxy. In technical terms this is known as a

"Kludge".

This would reduce stresses on your switch to mere

tens of milliamps and then only for tens of

microseconds at each re-triggering event just

after the ac wave form zero-crossing. Even if the

switch were close at the top of the wave form,

current through the switch and its series resistor

would be limited to an amp or so and again, for

tens of microseconds.

This buffer for your switch contacts raises

potential for a new failure mode. . . corrosion

over time on switch contacts causing them

to STOP conducting . . . not enough 'cleansing

current' flowing during each switch closure

to keep them free of oxides. But that risk

is generally years out into the future.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

74.53 KB |

| Viewed: |

17087 Time(s) |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Tue Aug 29, 2017 7:36 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Tue Aug 29, 2017 7:36 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

| Quote: | | Quote: | | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net (jonlaury(at)impulse.net)> In the zero-crossing relay suggested, the load side spec is 250vac (at) 2a. The steady-state ballast load is 800ma and the motor draws about 2a. Will the relay take it? or am I missing something here? |

|

On Aug 29, 2017, at 6:29 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote: | Quote: | Good eye. Yeah, if THAT option is attractive, you'll need a beefier device. Maybe something like this.

http://tinyurl.com/y8bfqm5o

|

Careful... the linked SSR is a DC-DC device. It's basically an opto-isolated MOSFET or Darlington. It might work as a rectifier, but only briefly!

For this application the output side has got to be labeled for AC, then it'll contain a triac or souce-connected N-MOSFETs.

If Jon isn't hesitant to use offshore sources for his parts, he might try these...

http://www.ebay.com/itm/112021093981

I've used a couple in mains-powered projects and had no trouble with them. They're not a brand anyone has ever heard of, but they seem to work, the price is right, and the screw terminals lend themselves to a field retrofit better than a PCB-mounted SIP package.

If heat sinking or a safety cover are desired, see...

http://www.ebay.com/itm/112159075071

and...

http://www.ebay.com/itm/112266161948

Keep in mind also that anything from China with a $0.99 price tag and a name brand like OMRON printed on it is going to be a case of blatant IP theft.

Eric

[Edited to correct spelling of Jon's name, and for formatting.]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Tue Aug 29, 2017 10:41 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Tue Aug 29, 2017 10:41 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

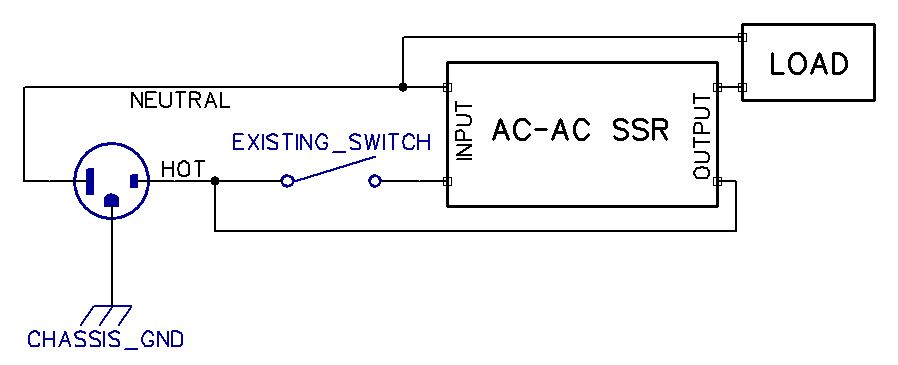

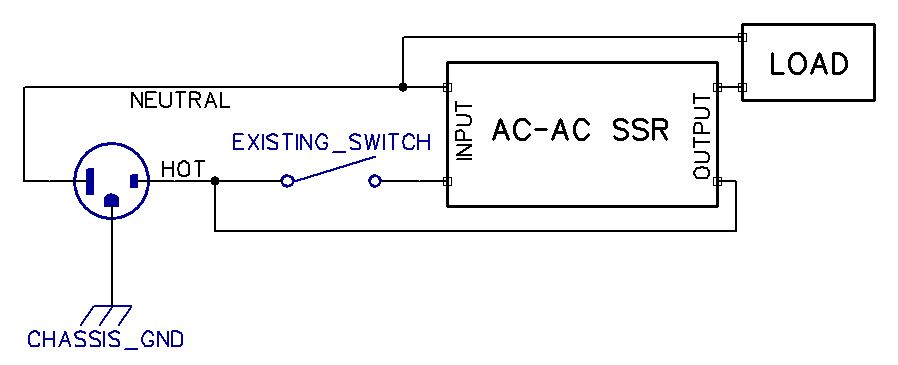

Upon reflection, the SSR that I linked to won't work without some redesign of the machine's circuitry, as it needs a DC input. The easiest retrofit for Jon to do would be to use an AC-AC SSR and control it with the existing switch that's already in the machine.

Here's an eBay search for parts that will work: http://preview.tinyurl.com/ybqcog6g

These SSRs are available from 10A to 100A; just change the eBay search term.

If using a known-source part is an issue, here's a Digi-Key search for AC-AC zero-cross SSRs, 5A or greater, sorted by price: http://preview.tinyurl.com/yamzd5vc

Connect as shown in the attached diagram.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

37.62 KB |

| Viewed: |

17052 Time(s) |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Sun Sep 03, 2017 8:20 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Sun Sep 03, 2017 8:20 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

[quote="Eric Page"] | Quote: |

Keep in mind also that anything from China with a $0.99 price tag and a name brand like OMRON printed on it is going to be a case of blatant IP theft. |

Hi Eric

Thanks for your suggestion and I did buy a lot of 3 "Omron" AC-AC SSR's from Ebay. They're labelled with Omron's logo and Made in China, $25. Probably not Omron product, right?

The question that looms large in my mind is, are they truly zero-crossing relays? Is there a way to test that function without a lot of expensive equipment? Or who would have the needed equipment so that I could have them tested?

John

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 247

|

Posted: Sun Sep 03, 2017 9:43 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Sun Sep 03, 2017 9:43 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

| jonlaury wrote: |

Hi Eric

Thanks for your suggestion and I did buy a lot of 3 "Omron" AC-AC SSR's from Ebay. They're labelled with Omron's logo and Made in China, $25. Probably not Omron product, right?

The question that looms large in my mind is, are they truly zero-crossing relays? Is there a way to test that function without a lot of expensive equipment? Or who would have the needed equipment so that I could have them tested?

John |

There's probably no way to know for sure if they're genuine unless you have a known-good example to compare against. Chinese knock-off products frequently have noticeable errors or differences in printing quality or method in the part markings (i.e. the real part may be laser-etched while the knock-off is screen printed). Even this comparison isn't foolproof, as the manufacturer may produce differences between lots or between factories.

OMRON is a Japanese company, but like everyone else, they probably run -- or contract with -- factories in China.

Anyone with an oscilloscope should be able to determine if they're zero-cross SSRs by viewing the output waveform at switch-on. There is potential to destroy an oscilloscope when measuring mains voltages, so be sure that whoever does this for you knows what they're doing WRT test setup, isolation and high voltage measurement. It goes without saying that you touch ONLY the low voltage control side of the circuit during the test.

Knock-off or not, if they're marked as zero-cross SSRs, I'd be very surprised if they're not. It's a pretty trivial thing to accomplish.

If you find that they're not, the AC-AC Fotek brand parts on eBay that I linked to in my last post look like they are...

http://www.fotek.com.hk/solid/SSR-2.htm

...and anything you get from Digi-Key, Newark, Mouser, Allied, Jameco, etc. will be genuine and function as specified.

Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Sep 03, 2017 10:40 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Sun Sep 03, 2017 10:40 am Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 11:20 AM 9/3/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

[quote="Eric Page"]

>

>

> Keep in mind also that anything from China with a $0.99 price tag and a name brand like OMRON printed on it is going to be a case of blatant IP theft.

Hi Eric

Thanks for your suggestion and I did buy a lot of 3 "Omron" AC-AC SSR's from Ebay. They're labelled with Omron's logo and Made in China, $25. Probably not Omron product, right?

The question that looms large in my mind is, are they truly zero-crossing relays? Is there a way to test that function without a lot of expensive equipment? Or who would have the needed equipment so that I could have them tested? |

The SSR contains a triac (bi-directional, triggered

switch). It's the same critter I sugeseted in my po'

boy's SSR Kludge a fews posts back.

By nature, ANY AC solid state relay will be

as close to a 'zero crossing' controller as

you can get. On the upswing of each half of

an AC waveform, a network of components are arranged

to bias the TRIAC gate to the threshold of trigger.

After that time, the TRIAC becomes almost a dead

short (about 1.5v drop) and the switch can be

deemed to be "ON".

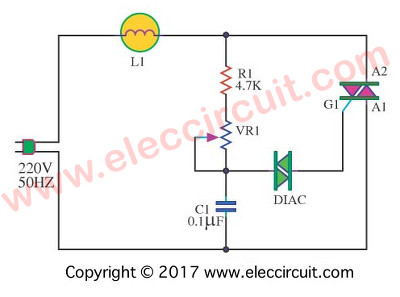

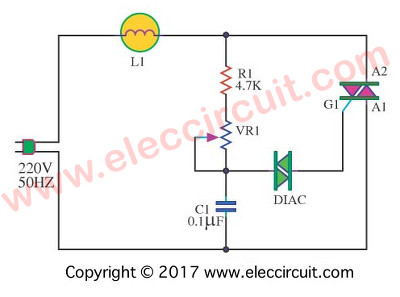

Here's a rudimentary lamp dimmer schematic:

Notice one of the devices in the trigger network

is called a DIAC . . . this is a voltage sensitive

two terminal device that 'triggers' above some

specified voltage. DIMMING is accomplished

by adjusting the resistance in the R/C network

to control DELAY in rise of the trigger volage.

The more resistance, the longer the delay. A

longer delay moves the TRIAC trigger further away

from zero crossing thus REDUCING energy fed to the

load.

Here's a rudimentary solid state AC "relay"

Here we see a little different trigger network for the

TRIAC. In this case, an LED is optically coupled to a

light sensitive DIAC such that if the LED is illuminated,

the DIAC will fire and trigger the TRIAC at the lowest

practical amplitude in the upward excursion of each

half of the AC waveform.

So technically, this relay does not close at the true

zero crossing . . . but it's very close. Within 10 volts

or so. Good enough for most applications.

These relays will work to mitigate your switch failure

issues as the current flowing in the LED loop is on the

order of 30mA or less. But you DO need a DC source of

power to energize the LED. It's only a few volts but it

does add to system complexity. You could rig a bridge

rectifier, a capacitor and a couple resistors to provide

the low energy source of DC.

But if you need to fabricate something anyhow, perhaps

the Kludge I offered earlier is the more elegant configuration.

The short answer is: You don't need to test these relays

for their zero-crossing qualities since chief complaint

is switch failure. The relays will take care of the switch

problem after you figure out how to integrate the SSR

into your design.

There are AC/AC SSR's . . . they feature TWO opto couplers

back to back so that an LED source of either polarity

will turn the SSR ON.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Mon Sep 04, 2017 11:30 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Mon Sep 04, 2017 11:30 am Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

DNA

What I absolutely love about AEL.

Thanks to both of you, Bob and Eric, for piquing my curiosity, making me stretch to expand my knowledge and skill set. The forum is in every way the embodiment of the adage, "Give a man a fish and he eats tonight. Teach him to fish...he and his family eat for a lifetime"

I've got some 47 Ω, 3A NTC thermistors I'm going to try, with the idea that I could, inexpensively, make up a bunch of low tech field-repair devices that can be installed with two wire nuts by users. For unshipped units henceforth, I plan to use the AC/AC SSR's until I can find a suitable, beefier power switch.

All good things,

John

[[/b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Sep 05, 2017 3:09 pm Post subject: Non-aero app: 120/240 AC through 24vdc switch? Posted: Tue Sep 05, 2017 3:09 pm Post subject: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

At 02:30 PM 9/4/2017, you wrote:

| Quote: | --> AeroElectric-List message posted by: "jonlaury" <jonlaury(at)impulse.net>

DNA

What I absolutely love about AEL.

Thanks to both of you, Bob and Eric, for piquing my curiosity, making me stretch to expand my knowledge and skill set. The forum is in every way the embodiment of the adage, "Give a man a fish and he eats tonight. Teach him to fish...he and his family eat for a lifetime"

I've got some 47 Ω, 3A NTC thermistors I'm going to try, with the idea that I could, inexpensively, make up a bunch of low tech field-repair devices that can be installed with two wire nuts by users. For unshipped units henceforth, I plan to use the AC/AC SSR's until I can find a suitable, beefier power switch. |

3A? Try to pick an NTC with (1) operating current

close to your measured running loads and (2) max

applied voltage of 120vac or greater. See

this for the nitty-gritty guidelines . . .

http://tinyurl.com/yahtoncs

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Wed Sep 06, 2017 12:00 pm Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Wed Sep 06, 2017 12:00 pm Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

In the first section of the article re selecting the right ICL, I'm asked for Capacitance. But neither the ballast nor the power supply list that info on their product cut-sheets.

Is there away to deduce the capacitance from other supplied info? E.G., inrush current on PS is 40A (at) 250vac. Ballast is 100A (at) 120vac

Power Supply and Ballast data sheets attached.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

WH7-120-L datasheet.pdf |

| Filesize: |

76.45 KB |

| Downloaded: |

543 Time(s) |

| Description: |

|

Download |

| Filename: |

Meanwell RS-100-24-spec.pdf |

| Filesize: |

123.13 KB |

| Downloaded: |

493 Time(s) |

|

|

| Back to top |

|

|

jonlaury

Joined: 06 Nov 2006

Posts: 336

|

Posted: Wed Sep 06, 2017 12:27 pm Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? Posted: Wed Sep 06, 2017 12:27 pm Post subject: Re: Non-aero app: 120/240 AC through 24vdc switch? |

|

|

"3A?"

The steady state load is about 1A, to keep the ballast happy. There's a user selected load of 1.5A that has a 25 second cycle to open circuit. Often the selection is repeated multiple times in quick succession. So the 3A was to allow a little headroom for motor surge (Does a PM motor have a surge?) and 2.5 steady state. I installed the 3A ICL yesterday and everything seems to work fine with the ICL temp settling at about 145 deg F on my meat thermometer held on with a clothes pin.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|