|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Mon Dec 18, 2017 6:41 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 6:41 am Post subject: The old nose wheel shimmy issue |

|

|

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?-sent from the I-droid implanted in my forearm

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

Tim Olson

Joined: 25 Jan 2007

Posts: 2878

|

Posted: Mon Dec 18, 2017 6:54 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 6:54 am Post subject: The old nose wheel shimmy issue |

|

|

I have 2 holes in my gear leg to provide for a little more

adjustment precision. No big deal on that.

Are you 100% sure that the shimmy is nosewheel? I really doubt

it is. Almost everyone who has a shimmy, has it in the

mains, although it FEELS like a nosewheel shimmy. I really

don't find much for issue with the nosewheel at all, other

than making sure you have a good breakout force on the

rotation. And, of course, there is that need to take out the

play of the donuts occasionally. I can't remember how many

I have in there, but at least 2.

Tim

On 12/18/2017 08:40 AM, Kelly McMullen wrote:

| Quote: | Well, mine has gotten noticeable enough to do something about. Of course

I reviewed my archives and Tim's website as refresher.

Taking the cowling off and checking things I found that I could not

tighten the big nut to the next flat, so the amount of pull is

irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg,

which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done

the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the

nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate

cotter pin position for the pivot nut?

-sent from the I-droid implanted in my forearm

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

philperry9

Joined: 23 Nov 2011

Posts: 381

|

Posted: Mon Dec 18, 2017 6:56 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 6:56 am Post subject: The old nose wheel shimmy issue |

|

|

I had the same 1/4â vertical play and found the bushing to be the culprit. A little bit of play in that bushing easily makes a 1/4â out at the wheel.

Vans sells over sized bushings, so I purchased one and found to was too over sized.

My cousin is a machinist, so be sent me a set of snap gauges and I measured it. Then we turned the oversized bushing down to match the hole with .002â gap.

Itâs currently sitting in the center console of my truck so I donât have a report yet. Hopefully in the next few weeks I can have it installed and see if they addressed the play.

Sent from my iPhone

| Quote: | On Dec 18, 2017, at 8:40 AM, Kelly McMullen <apilot2(at)gmail.com> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.

Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?

-sent from the I-droid implanted in my forearm

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

partner14

Joined: 12 Jan 2008

Posts: 540

Location: Granbury Texas

|

Posted: Mon Dec 18, 2017 7:01 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 7:01 am Post subject: The old nose wheel shimmy issue |

|

|

Yes, I have suggested that everyone drill a 2nd hole 30 degrees off from the first hole. This will give you the ability to make the correct adjustment without leaving it too loose or too tight.

Don McDonald

1,000 hours now.

On Monday, December 18, 2017, 8:52:44 AM CST, Kelly McMullen <apilot2(at)gmail.com> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?-sent from the I-droid implanted in my forearm

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Don A. McDonald

40636 |

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Mon Dec 18, 2017 7:05 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 7:05 am Post subject: The old nose wheel shimmy issue |

|

|

Thanks Tim. Yes, I had 3 friends observe my taxi in from last flight and comment on how much the nose wheel was shimmying.Yes, I have had main gear shimmy in the past. Nose is at lower speed and higher frequency shimmy.

I'll check with the fish scale, get somewhere around 25-30 lb pull and then drill new hole.

-sent from the I-droid implanted in my forearm

On Mon, Dec 18, 2017 at 7:54 AM, Tim Olson <Tim(at)myrv10.com (Tim(at)myrv10.com)> wrote:

| Quote: | --> RV10-List message posted by: Tim Olson <Tim(at)MyRV10.com>

I have 2 holes in my gear leg to provide for a little more

adjustment precision.  No big deal on that.

Are you 100% sure that the shimmy is nosewheel? I really doubt

it is. Almost everyone who has a shimmy, has it in the

mains, although it FEELS like a nosewheel shimmy. I really

don't find much for issue with the nosewheel at all, other

than making sure you have a good breakout force on the

rotation. And, of course, there is that need to take out the

play of the donuts occasionally. I can't remember how many

I have in there, but at least 2.

Tim

On 12/18/2017 08:40 AM, Kelly McMullen wrote:

| Quote: | Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.

Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?

-sent from the I-droid implanted in my forearm

|

====================================

-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

Tim Olson

Joined: 25 Jan 2007

Posts: 2878

|

Posted: Mon Dec 18, 2017 7:13 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 7:13 am Post subject: The old nose wheel shimmy issue |

|

|

Interesting. This is the first time I can actually remember anyone

actually having the shimmy be nosewheel related. I guess I'd

do a tire balance then. And while you have it on the balancer,

make sure it's still round perhaps.

Tim

On 12/18/2017 09:04 AM, Kelly McMullen wrote:

| Quote: | Thanks Tim. Yes, I had 3 friends observe my taxi in from last flight and

comment on how much the nose wheel was shimmying.

Yes, I have had main gear shimmy in the past. Nose is at lower speed and

higher frequency shimmy.

I'll check with the fish scale, get somewhere around 25-30 lb pull and

then drill new hole.

-sent from the I-droid implanted in my forearm

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Dec 18, 2017 8:06 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 8:06 am Post subject: The old nose wheel shimmy issue |

|

|

I know nosewheel shimmy is common on the two place RV's as AntiSplat

Aero offers a machining to replace wheel bearings with sealed, precision

bearings, Shaving of tread to ensure tire roundness and then spin balancing.

Obviously our design is a bit different with the donuts.

Will try the obvious things and see if that gets rid of it. I think it

was Les commented that his went away after balancing all three wheels.

Hard to tell how much shimmy might transfer between the gear legs.

On 12/18/2017 8:13 AM, Tim Olson wrote:

| Quote: |

Interesting. This is the first time I can actually remember anyone

actually having the shimmy be nosewheel related. I guess I'd

do a tire balance then. And while you have it on the balancer,

make sure it's still round perhaps.

Tim

On 12/18/2017 09:04 AM, Kelly McMullen wrote:

> Thanks Tim. Yes, I had 3 friends observe my taxi in from last flight

> and comment on how much the nose wheel was shimmying.

> Yes, I have had main gear shimmy in the past. Nose is at lower speed

> and higher frequency shimmy.

> I'll check with the fish scale, get somewhere around 25-30 lb pull and

> then drill new hole.

>

> -sent from the I-droid implanted in my forearm

>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

kearney

Joined: 20 Sep 2008

Posts: 563

|

Posted: Mon Dec 18, 2017 9:04 am Post subject: Re: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 9:04 am Post subject: Re: The old nose wheel shimmy issue |

|

|

Hi

As Kelley noted, I used a motorcycle wheel balanced on all three wheels. It worked quite well. Of Kate I have noticed that I am getting a shimmy again. WheN I last had my pants off (wheel!!!) I noticed a lot of crud on the wheels. I wonder if that has caused an imbalance.

Anyway, I will be doing my annual after Christmas and plan to replace my main tyres and rebalance everything along with setting nosewheel breakout pressure. Iâll report back after I do this - this will be in lat Jan as I will be away till then.

Cheers

Les

PS. Merry Christmas to all my RV10 brethren!

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Lenny Iszak

Joined: 23 Mar 2008

Posts: 270

|

Posted: Mon Dec 18, 2017 10:15 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 10:15 am Post subject: The old nose wheel shimmy issue |

|

|

At around 300 hours I noticed that my nosewheel tire was way out of round. It was still the crappy AeroClassic tire that came from Vanâs. It wasnât worn, but it was deformed. Something to check.

| Quote: | On Dec 18, 2017, at 11:06 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

I know nosewheel shimmy is common on the two place RV's as AntiSplat Aero offers a machining to replace wheel bearings with sealed, precision bearings, Shaving of tread to ensure tire roundness and then spin balancing.

Obviously our design is a bit different with the donuts.

Will try the obvious things and see if that gets rid of it. I think it was Les commented that his went away after balancing all three wheels. Hard to tell how much shimmy might transfer between the gear legs.

On 12/18/2017 8:13 AM, Tim Olson wrote:

>

> Interesting. This is the first time I can actually remember anyone

> actually having the shimmy be nosewheel related. I guess I'd

> do a tire balance then. And while you have it on the balancer,

> make sure it's still round perhaps.

> Tim

> On 12/18/2017 09:04 AM, Kelly McMullen wrote:

>> Thanks Tim. Yes, I had 3 friends observe my taxi in from last flight and comment on how much the nose wheel was shimmying.

>> Yes, I have had main gear shimmy in the past. Nose is at lower speed and higher frequency shimmy.

>> I'll check with the fish scale, get somewhere around 25-30 lb pull and then drill new hole.

>>

>> -sent from the I-droid implanted in my forearm

>>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Lenny Iszak

Palm City, FL

2014 RV-10, N311LZ - 500 hrs |

|

| Back to top |

|

|

rv10free2fly(at)yahoo.com

Guest

|

Posted: Mon Dec 18, 2017 11:01 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 11:01 am Post subject: The old nose wheel shimmy issue |

|

|

Les and fellow builders/flyers

I wish you all a very Merry Christmas and Happy New Year.

Warm regards from downunder.

Patrick

| Quote: | On 19 Dec 2017, at 03:34, kearney <kearney(at)shaw.ca> wrote:

Hi

As Kelley noted, I used a motorcycle wheel balanced on all three wheels. It worked quite well. Of Kate I have noticed that I am getting a shimmy again. WheN I last had my pants off (wheel!!!) I noticed a lot of crud on the wheels. I wonder if that has caused an imbalance.

Anyway, I will be doing my annual after Christmas and plan to replace my main tyres and rebalance everything along with setting nosewheel breakout pressure. Iâll report back after I do this - this will be in lat Jan as I will be away till then.

Cheers

Les

PS. Merry Christmas to all my RV10 brethren!

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=476565#476565

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Dec 18, 2017 11:31 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 11:31 am Post subject: The old nose wheel shimmy issue |

|

|

Well, a morning of work yielded front nose fork pull was around 15-18

lbs. Adjusted that up to about 28-29 lbs, and drilled new cotter pin

hole. Shock disk tower needed the second spacer. Installed that. There

still is a little play at the firewall bushings, but the play at the

wheel is noticeably better with the extra spacer. Now to finish putting

it back together and try it out. Still have wheel balancing if needed.

On 12/18/2017 10:04 AM, kearney wrote:

| Quote: |

Hi

As Kelly noted, I used a motorcycle wheel balanced on all three wheels. It worked quite well. Of Kate I have noticed that I am getting a shimmy again. WheN I last had my pants off (wheel!!!) I noticed a lot of crud on the wheels. I wonder if that has caused an imbalance.

Anyway, I will be doing my annual after Christmas and plan to replace my main tyres and rebalance everything along with setting nosewheel breakout pressure. Iââ¬â¢ll report back after I do this - this will be in lat Jan as I will be away till then.

Cheers

Les

PS. Merry Christmas to all my RV10 brethren!

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=476565#476565

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Mon Dec 18, 2017 11:33 am Post subject: The old nose wheel shimmy issue Posted: Mon Dec 18, 2017 11:33 am Post subject: The old nose wheel shimmy issue |

|

|

I will check mine, but I never got the AeroClassic. I started off with

Desser recaps, as I have had good luck and wear with them.

-sent from the I-droid implanted in my forearm

On Mon, Dec 18, 2017 at 11:14 AM, Lenny Iszak <lenard(at)rapiddecision.com>

wrote:

[quote]

At around 300 hours I noticed that my nosewheel tire was way out of round

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

trigo(at)mail.telepac.pt

Guest

|

Posted: Tue Dec 19, 2017 5:32 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 5:32 am Post subject: The old nose wheel shimmy issue |

|

|

Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

Enviado do meu iPhone

No dia 18/12/2017, Ã s 14:56, Don McDonald <building_partner(at)yahoo.com (building_partner(at)yahoo.com)> escreveu:

| Quote: |

Yes, I have suggested that everyone drill a 2nd hole 30 degrees off from the first hole. This will give you the ability to make the correct adjustment without leaving it too loose or too tight.

Don McDonald

1,000 hours now.

On Monday, December 18, 2017, 8:52:44 AM CST, Kelly McMullen <apilot2(at)gmail.com (apilot2(at)gmail.com)> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?-sent from the I-droid implanted in my forearm

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rleffler

Joined: 05 Nov 2006

Posts: 680

|

Posted: Tue Dec 19, 2017 6:08 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 6:08 am Post subject: The old nose wheel shimmy issue |

|

|

Any of the available holes in the nut. Many are finding that they have to tighten the nut after the original installation, which caused the original hole not to be in alignment with the holes on the nut. Just ensure that you don’t get it close to the original hole.

Get Outlook for iOS

From: owner-rv10-list-server(at)matronics.com <owner-rv10-list-server(at)matronics.com> on behalf of Carlos Trigo <trigo(at)mail.telepac.pt>

Sent: Tuesday, December 19, 2017 8:31:50 AM

To: rv10-list(at)matronics.com

Subject: Re: The old nose wheel shimmy issue

Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

Enviado do meu iPhone

No dia 18/12/2017, às 14:56, Don McDonald <building_partner(at)yahoo.com (building_partner(at)yahoo.com)> escreveu:

| Quote: |

Yes, I have suggested that everyone drill a 2nd hole 30 degrees off from the first hole. This will give you the ability to make the correct adjustment without leaving it too loose or too tight.

Don McDonald

1,000 hours now.

On Monday, December 18, 2017, 8:52:44 AM CST, Kelly McMullen <apilot2(at)gmail.com (apilot2(at)gmail.com)> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher. Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut? -sent from the I-droid implanted in my forearm

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Bob Leffler

N410BL - Phase I

http://mykitlog.com/rleffler |

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Tue Dec 19, 2017 6:15 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 6:15 am Post subject: The old nose wheel shimmy issue |

|

|

There is no right or wrong way to drill one or two extra holes. What I did yesterday was to tighten the nut to a couple pounds force above specification (knowing it will decrease), then considered which slots in the nut would be furthest from the existing cotter pin holes. I did not want to drill using the same slots the pin was previously, because they would be only 20-25 degrees off the original holes. So I picked slots that gave best chance of getting cotter pin in or out without removing the tire, used the slots as my guide (putting a vertical marker at the back slot to better aim the drill bit. I did remove the tire to allow drilling the side toward the tire, to not risk the new hole not being aligned with the slot. I used my #27 drill bit, but in retrospect I think a brand new #30 would have been better, and I could have enlarged to #27 if necessary.  My main concern was to not weaken the shaft by having pairs of holes too close to each other.

-sent from the I-droid implanted in my forearm

On Tue, Dec 19, 2017 at 6:31 AM, Carlos Trigo <trigo(at)mail.telepac.pt (trigo(at)mail.telepac.pt)> wrote:

| Quote: | Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

Enviado do meu iPhone

No dia 18/12/2017, Ã s 14:56, Don McDonald <building_partner(at)yahoo.com (building_partner(at)yahoo.com)> escreveu:

| Quote: |

Yes, I have suggested that everyone drill a 2nd hole 30 degrees off from the first hole. This will give you the ability to make the correct adjustment without leaving it too loose or too tight.

Don McDonald

1,000 hours now.

On Monday, December 18, 2017, 8:52:44 AM CST, Kelly McMullen <apilot2(at)gmail.com (apilot2(at)gmail.com)> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?-sent from the I-droid implanted in my forearm

|

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

partner14

Joined: 12 Jan 2008

Posts: 540

Location: Granbury Texas

|

Posted: Tue Dec 19, 2017 6:35 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 6:35 am Post subject: The old nose wheel shimmy issue |

|

|

The first hole will be lined up on one of the spaces on the nut. Mark on the tubing where it currently lines up, and mark where it lines up on the next space. Then loosen or tighten the nut half way between those two marks. The drill through the near side. Then drill the far side from the other side, making sure you're 180 degrees.If you have a punch and a center drill, do that first on both sides, then remove the nut and use the drill to finish.

Sent from Yahoo Mail on Android

| Quote: | On Tue, Dec 19, 2017 at 7:43 AM, Carlos Trigo

<trigo(at)mail.telepac.pt> wrote:

Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

CarlosEnviado do meu iPhone

No dia 18/12/2017, Ã s 14:56, Don McDonald <building_partner(at)yahoo.com (building_partner(at)yahoo.com)> escreveu:

| Quote: |

Yes, I have suggested that everyone drill a 2nd hole 30 degrees off from the first hole. This will give you the ability to make the correct adjustment without leaving it too loose or too tight.

Don McDonald

1,000 hours now.

On Monday, December 18, 2017, 8:52:44 AM CST, Kelly McMullen <apilot2(at)gmail.com (apilot2(at)gmail.com)> wrote:

Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?-sent from the I-droid implanted in my forearm

|

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Don A. McDonald

40636 |

|

| Back to top |

|

|

glastar(at)gmx.net

Guest

|

Posted: Tue Dec 19, 2017 8:16 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 8:16 am Post subject: The old nose wheel shimmy issue |

|

|

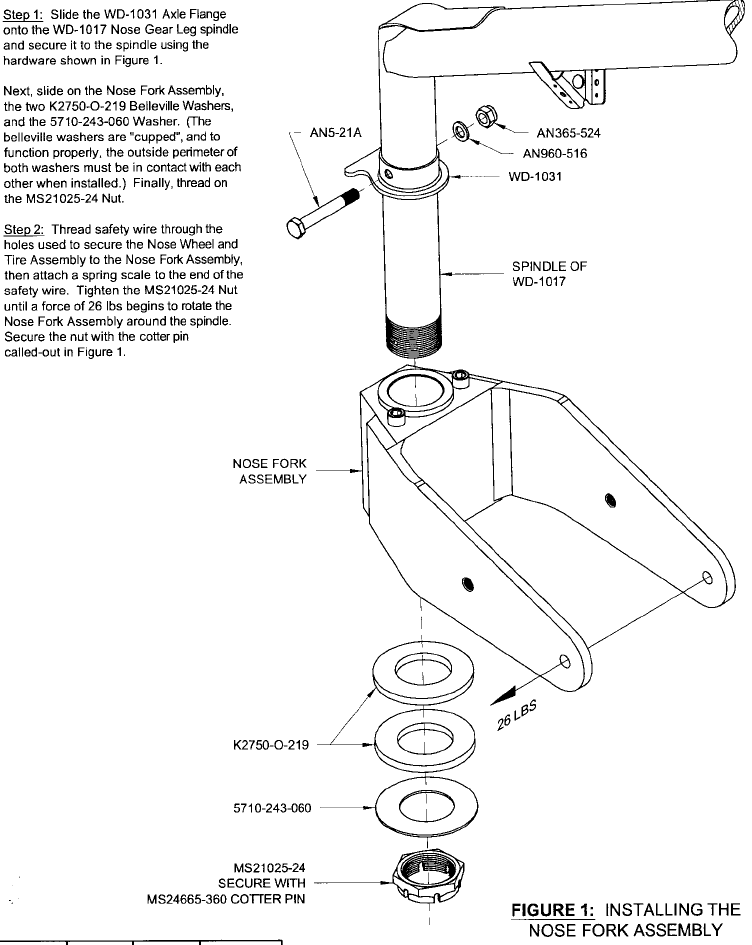

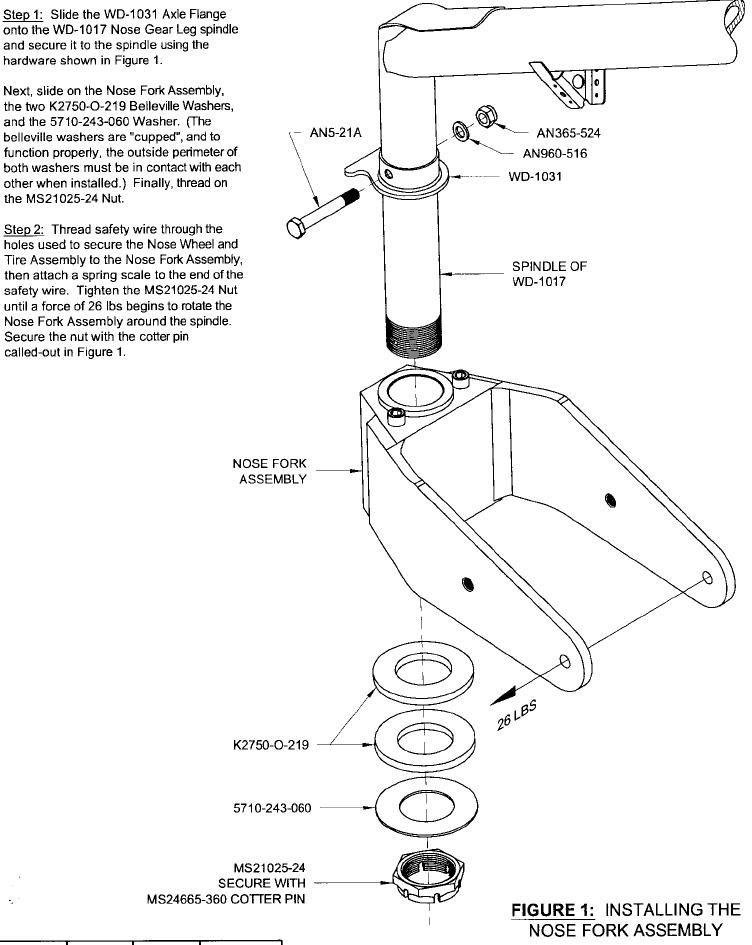

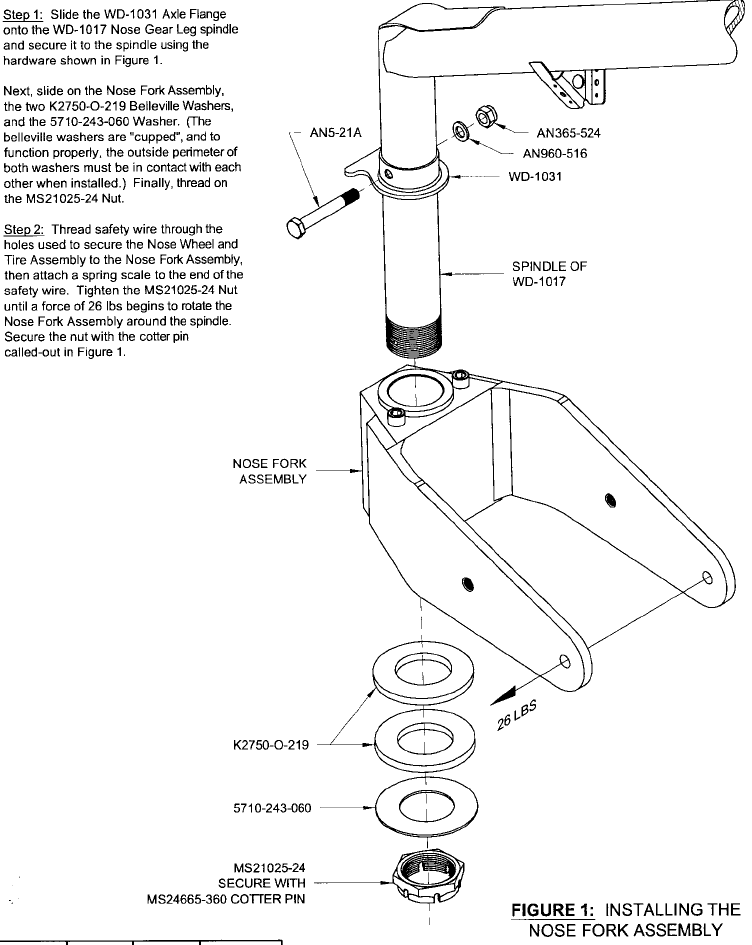

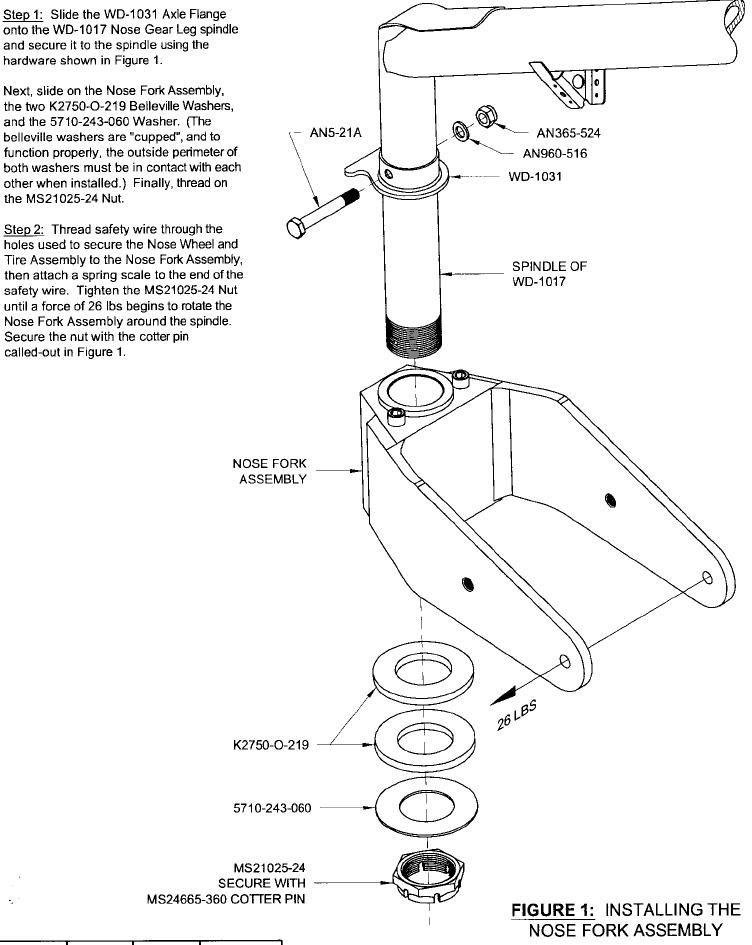

You assemble that setup and then drill a hole through the threated part of WD-1017 to secure the nut with the cotter pin just drill another one 30 deg to that one onto the tighter side

[img]cid:part1.3691CB79.E662623B(at)gmx.net[/img]

On 19.12.2017 14:31, Carlos Trigo wrote:

| Quote: | Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

52.54 KB |

| Viewed: |

16895 Time(s) |

|

|

|

| Back to top |

|

|

partner14

Joined: 12 Jan 2008

Posts: 540

Location: Granbury Texas

|

Posted: Tue Dec 19, 2017 8:48 am Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 8:48 am Post subject: The old nose wheel shimmy issue |

|

|

30 degrees from the original hole.

On Tuesday, December 19, 2017, 10:29:24 AM CST, Werner Schneider <glastar(at)gmx.net> wrote:

You assemble that setup and then drill a hole through the threated part of WD-1017 to secure the nut with the cotter pin just drill another one 30 deg to that one onto the tighter side

[img]cid:cgDBFhMbhOXWvMjx6QxJ[/img]

On 19.12.2017 14:31, Carlos Trigo wrote:

| Quote: | Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

52.54 KB |

| Viewed: |

16895 Time(s) |

|

_________________

Don A. McDonald

40636 |

|

| Back to top |

|

|

trigo(at)mail.telepac.pt

Guest

|

Posted: Tue Dec 19, 2017 2:30 pm Post subject: The old nose wheel shimmy issue Posted: Tue Dec 19, 2017 2:30 pm Post subject: The old nose wheel shimmy issue |

|

|

Ah ok, thank you all

Carlos

Enviado do meu iPhone

No dia 19/12/2017, Ã s 16:43, Don McDonald <building_partner(at)yahoo.com (building_partner(at)yahoo.com)> escreveu:

| Quote: |

30 degrees from the original hole.

On Tuesday, December 19, 2017, 10:29:24 AM CST, Werner Schneider <glastar(at)gmx.net (glastar(at)gmx.net)> wrote:

You assemble that setup and then drill a hole through the threated part of WD-1017 to secure the nut with the cotter pin just drill another one 30 deg to that one onto the tighter side

<inhdmpkiimgembba.png>

On 19.12.2017 14:31, Carlos Trigo wrote:

| Quote: | Don

For someone who is still building, and never heard of this, can you tell me where is that 2nd hole to be drilled?

Or better, a picture of that

Thanks

Carlos

|

<inhdmpkiimgembba.png>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Thu Dec 28, 2017 5:38 am Post subject: The old nose wheel shimmy issue Posted: Thu Dec 28, 2017 5:38 am Post subject: The old nose wheel shimmy issue |

|

|

Follow-up I am making sloooow progress on the nose gear shimmy issue. I tightened the belleville nut to around 28 lbs, drilled new cotter pin hole, added washer to the donut stack, went out and tried again.Performed test, and got results so many reported....much better, but shimmy still there at 12-16 kts. Borrowed a wheel balancer (Desser used to sell, stand with axle, cones,external bearings) and sure enough, nose wheel required the same 1.5 oz of wt. Some report lead wts hard to find. I used steel wts, but likely will replace with lead later to better concentrate the wt. Available lead weights: http://www.matcomfg.com/WEIGHTLEADBALANCE-idv-3682-44.html

I note that with research, nose wheel shimmy is common, which may trigger main gear shimmy. Many nose wheels require balancing, and almost all need 1.5 oz directly opposite the valve stem.

When I am satisfied that I have the balance as good as can get, will test again. After reading reports that go back at least 8 years, the problem and solutions are pretty uniform...belleville nut force, donut compression and balancing of the wheel, with almost identical weight needed in same place. I do have the correct Matco wheel and axle, and a Desser recap nose tire with the tube that Tim recommends.

I will balance the mains after I rotate the tires for outside wear.

Kelly Â

P.S. From frigid Aridzona with 36 right now, going to 71 this afternoon.

No, I don't miss the -20 in MN and WI, nor the -50 from Fairbanks. 8^)

-sent from the I-droid implanted in my forearm

On Mon, Dec 18, 2017 at 8:04 AM, Kelly McMullen <apilot2(at)gmail.com (apilot2(at)gmail.com)> wrote:

| Quote: | Thanks Tim. Yes, I had 3 friends observe my taxi in from last flight and comment on how much the nose wheel was shimmying.Yes, I have had main gear shimmy in the past. Nose is at lower speed and higher frequency shimmy.

I'll check with the fish scale, get somewhere around 25-30 lb pull and then drill new hole.

-sent from the I-droid implanted in my forearm

On Mon, Dec 18, 2017 at 7:54 AM, Tim Olson <Tim(at)myrv10.com (Tim(at)myrv10.com)> wrote:

| Quote: | --> RV10-List message posted by: Tim Olson <Tim(at)MyRV10.com>

I have 2 holes in my gear leg to provide for a little more

adjustment precision.  No big deal on that.

Are you 100% sure that the shimmy is nosewheel? I really doubt

it is. Almost everyone who has a shimmy, has it in the

mains, although it FEELS like a nosewheel shimmy. I really

don't find much for issue with the nosewheel at all, other

than making sure you have a good breakout force on the

rotation. And, of course, there is that need to take out the

play of the donuts occasionally. I can't remember how many

I have in there, but at least 2.

Tim

On 12/18/2017 08:40 AM, Kelly McMullen wrote:

| Quote: | Well, mine has gotten noticeable enough to do something about. Of course I reviewed my archives and Tim's website as refresher.

Taking the cowling off and checking things I found that I could not tighten the big nut to the next flat, so the amount of pull is irrelevant at the moment.

Has anyone tried new Belleville washers?

Secondly, I noticed about a 1/4" of up/down play on the nose gear leg, which I assume is compression of the donuts. (I am at about 130 hours).

Will check today to see if another washer is needed. Yes, I have done the service bulletin upgrade, and there was no play at the time.

I guess the next step will be to get a wheel balancer and balance the nose wheel. Then do the mains at annual condition inspection.

Has anyone drilled the bottom of the gear leg to get an intermediate cotter pin position for the pivot nut?

-sent from the I-droid implanted in my forearm

|

====================================

-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?RV10-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|