|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

cluros(at)gmail.com

Guest

|

Posted: Sat Jun 09, 2018 3:58 pm Post subject: Rotax Charging System Posted: Sat Jun 09, 2018 3:58 pm Post subject: Rotax Charging System |

|

|

Hello aeroelectric list,

My friend has a Searey with a Rotax 914. He's currently AOG with a non charging electrical system. I don't know the Rotax electrical system at all but the battery is an Odyssey in apparently good shape. System voltage reads between 11.8 and 11.6 with engine running depending on what loads are turned on. Increasing engine RPM has no effect on voltage. That's all the info we have right now.

Would someone who knows this system please get in touch to help diagnose the problem and suggest a proper fix?

Thank you.

Sebastien

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Sat Jun 09, 2018 6:05 pm Post subject: Re: Rotax Charging System Posted: Sat Jun 09, 2018 6:05 pm Post subject: Re: Rotax Charging System |

|

|

The most likely problem is the voltage regulator.

Read this thread, especially post number 6 by Mike Miller.

http://www.vansairforce.com/community/showthread.php?t=80487

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sun Jun 10, 2018 6:56 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 6:56 am Post subject: Rotax Charging System |

|

|

Joe,

Regarding the link you posted on Van's, it ends with the following statement:

"Installing a higher output (non Rotax) regulator may shift the next failure to another component, maybe the alternator $tator coil$."

I don't understand how this could be. I thought that the output (low, medium, high, etc) was determined by the dynamo, and that the regulator-rectifier merely took what it was given and transformed it (regulate) into what the 12v system needs. I further thought that adding a regulator capable of handling higher output would simply mean that the regulator would be stressed more lightly. Do you agree with the poster's statement? I am interested because I replaced the "Rotax regulator" (actually Ducati) with the Silent Hektik.

Ken

On Sat, Jun 9, 2018 at 6:11 PM user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

The most likely problem is the voltage regulator.

Read this thread, especially post number 6 by Mike Miller.

http://www.vansairforce.com/community/showthread.php?t=80487

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480762#480762

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jun 10, 2018 7:54 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 7:54 am Post subject: Rotax Charging System |

|

|

At 09:54 AM 6/10/2018, you wrote:

| Quote: | Joe,

Regarding the link you posted on Van's, it ends with the following statement:

"Installing a higher output (non Rotax) regulator may shift the next failure to another component, maybe the alternator $tator coil$."

I don't understand how this could be. I thought that the output (low, medium, high, etc) was determined by the dynamo, and that the regulator-rectifier merely took what it was given and transformed it (regulate) into what the 12v system needs. I further thought that adding a regulator capable of handling higher output would simply mean that the regulator would be stressed more lightly. Do you agree with the poster's statement? I am interested because I replaced the "Rotax regulator" (actually Ducati) with the Silent Hektik.

Ken |

It kind of depends on the cause for original failure.

The PM/RR power systems are not as gently current

limited as their wound-field cousins on cars. Further,

the PM alternators are not as easily cooled . . . they

tend to be tightly enclosed with respect to air movement.

The Rectifier/Regulator products) for which I'm privy

to schematics) do not include electronically derived

current limiting.

Given these two conditions, both the alternator

and rectifier regulator are subject to the effects

of over heat brought on by sustained overloading.

Overloaded operations can be realized by any

combination of system loads and battery

recharging loads. Assuming that the designer

has not inadvertently expected too much from

the alternator to run electrowhizzies, then

battery recharge demands from a badly dischared

battery might just stack on top of each other

for an interval long enough to smoke something.

The Ducatti rectifier-regulator supplied with

Rotax 9xx engines has been notoriously weak in

the knees. There have been numerous rectifier-

regulators with more robust designs, Silent

Hektik being a noteworthy example.

The statement in question has some validity

in that a builder that has suffered multiple

Ductatti failures may indeed suffer alternator

failures after upgrading the rectifier-regulator.

This is because failures due to persistent overloading

will open the weakest link in the chain . . . in

the original case, a Ducatti R-R. Beef up that

link and a different link may become vulnerable.

The prophylactic against such failures is

crew implementation of current limiting with

the aid of an alternator loadmeter.

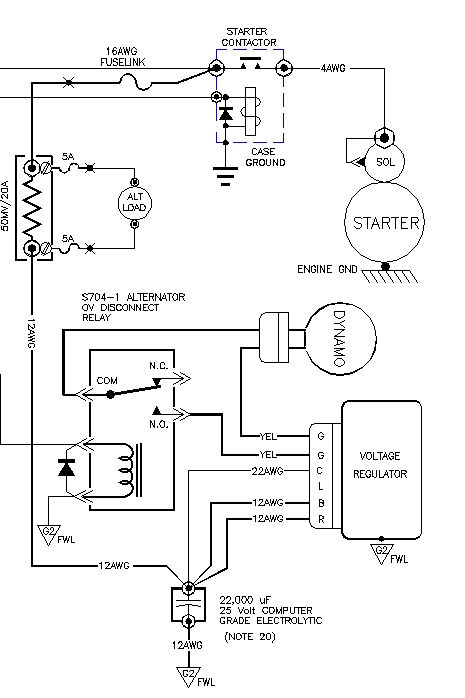

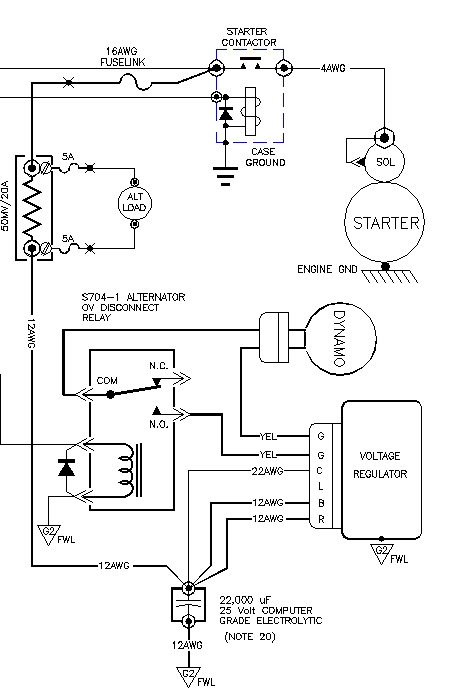

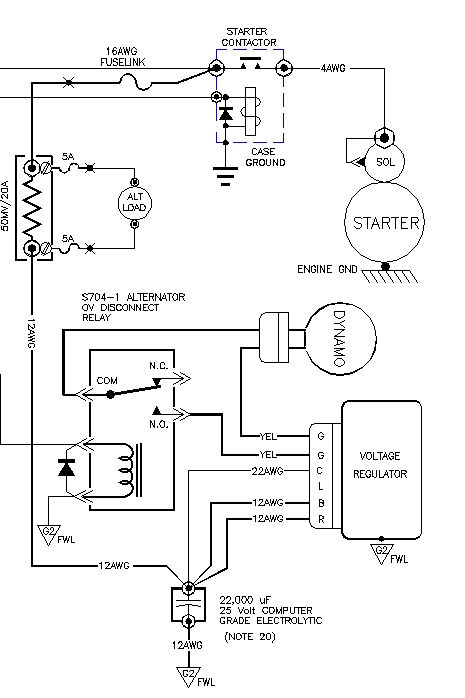

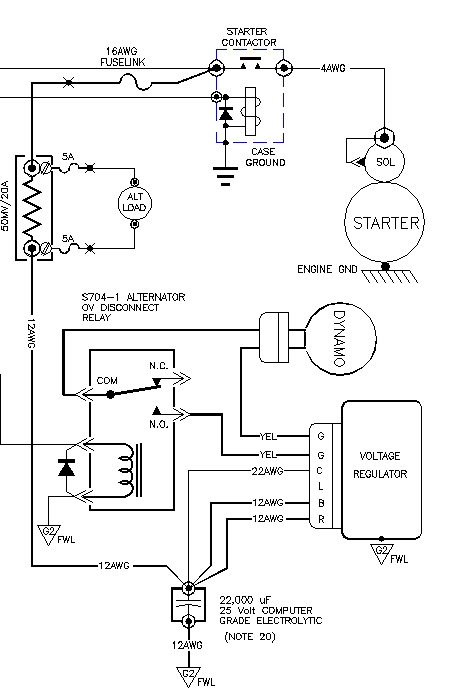

[img]cid:.0[/img]

I've got a couple dozen of these instruments left over

from the AEC9007 days. These can be paired with an appropriate

shunt to show read time loads on the PM/RR system.

[img]cid:.1[/img]

Sort term operations at or above 100 percent would

be okay, like to recharge a battery that has started

the engine and then supported electrowhizzies out to

the departure runway.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

108.44 KB |

| Viewed: |

16071 Time(s) |

|

| Description: |

|

| Filesize: |

223.33 KB |

| Viewed: |

16071 Time(s) |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Sun Jun 10, 2018 8:03 am Post subject: Re: Rotax Charging System Posted: Sun Jun 10, 2018 8:03 am Post subject: Re: Rotax Charging System |

|

|

Ken,

While I have great respect for Mike M. and admire his knowledge, I do disagree with that ending statement. Heat caused by high current can damage alternator windings. But the total current is determined by the load, not by the regulator. I do not think that the Silent Hektik regulator will stress the alternator any more than the Ducati regulator.

Two years ago I replaced the Ducati regulator in my RV-12 with a cheap John Deere regulator from eBay. I made an adapter plate using 1/8" aluminum because the mounting holes did not line up. I used heat conductive grease on both sides of the mounting plate. A thermocouple attached to the John Deere regulator measured a maximum temperature of 157 degrees Fahrenheit on a 90+ degree day.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jun 10, 2018 8:34 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 8:34 am Post subject: Rotax Charging System |

|

|

| Quote: |

Sort term operations at or above 100 percent would

be okay, like to recharge a battery that has started

the engine and then supported electrowhizzies out to

the departure runway. |

I was remiss in the omission of a second

prophylactic which is load analysis confirmed

by experience which shows the PM/RR system is not

going to be overtaxed by predicted, normal

operations. If you have verified that normal

ops loads are within system ratings, then

failures can be assumed to be caused by

abnormal conditions like lack of regulator

robustness, attempting to recharge a really

depleted battery during flight ops, shorted

cell in battery, etc.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Sun Jun 10, 2018 9:30 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 9:30 am Post subject: Rotax Charging System |

|

|

Joe, do you have a part number for the John Deere regulator that will replace the Ducati?

Thank you

On Sun, Jun 10, 2018 at 9:03 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Ken,

While I have great respect for Mike M. and admire his knowledge, I do disagree with that ending statement. Heat caused by high current can damage alternator windings. But the total current is determined by the load, not by the regulator. I do not think that the Silent Hektik regulator will stress the alternator any more than the Ducati regulator.

Two years ago I replaced the Ducati regulator in my RV-12 with a cheap John Deere regulator from eBay. I made an adapter plate using 1/8" aluminum because the mounting holes did not line up. I used heat conductive grease on both sides of the mounting plate. A thermocouple attached to the John Deere regulator measured a maximum temperature of 157 degrees Fahrenheit on a 90+ degree day.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480768#480768

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Sun Jun 10, 2018 9:39 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 9:39 am Post subject: Rotax Charging System |

|

|

Just looking at the Silent Hektik website and it seems to say that it regulates between 13 and 14.2 V. Wouldn't this be totally inappropriate (way too low) for lead acid and especially AGM batteries? Or can it be set anywhere from 13 to 14.2? 14.2 still wouldn't be ideal for Odyssey but it is within their specs.

On Sun, Jun 10, 2018 at 8:53 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 09:54 AM 6/10/2018, you wrote:

| Quote: | Joe,

Regarding the link you posted on Van's, it ends with the following statement:

"Installing a higher output (non Rotax) regulator may shift the next failure to another component, maybe the alternator $tator coil$."

I don't understand how this could be. I thought that the output (low, medium, high, etc) was determined by the dynamo, and that the regulator-rectifier merely took what it was given and transformed it (regulate) into what the 12v system needs. I further thought that adding a regulator capable of handling higher output would simply mean that the regulator would be stressed more lightly. Do you agree with the poster's statement? I am interested because I replaced the "Rotax regulator" (actually Ducati) with the Silent Hektik.

Ken |

It kind of depends on the cause for original failure.

The PM/RR power systems are not as gently current

limited as their wound-field cousins on cars. Further,

the PM alternators are not as easily cooled . . . they

tend to be tightly enclosed with respect to air movement.

The Rectifier/Regulator products) for which I'm privy

to schematics) do not include electronically derived

current limiting.

Given these two conditions, both the alternator

and rectifier regulator are subject to the effects

of over heat brought on by sustained overloading.

Overloaded operations can be realized by any

combination of system loads and battery

recharging loads. Assuming that the designer

has not inadvertently expected too much from

the alternator to run electrowhizzies, then

battery recharge demands from a badly dischared

battery might just stack on top of each other

for an interval long enough to smoke something.

The Ducatti rectifier-regulator supplied with

Rotax 9xx engines has been notoriously weak in

the knees. There have been numerous rectifier-

regulators with more robust designs, Silent

Hektik being a noteworthy example.

The statement in question has some validity

in that a builder that has suffered multiple

Ductatti failures may indeed suffer alternator

failures after upgrading the rectifier-regulator.

This is because failures due to persistent overloading

will open the weakest link in the chain . . . in

the original case, a Ducatti R-R. Beef up that

link and a different link may become vulnerable.

The prophylactic against such failures is

crew implementation of current limiting with

the aid of an alternator loadmeter.

[img]cid:.0[/img]

I've got a couple dozen of these instruments left over

from the AEC9007 days. These can be paired with an appropriate

shunt to show read time loads on the PM/RR system.

[img]cid:.1[/img]

Sort term operations at or above 100 percent would

be okay, like to recharge a battery that has started

the engine and then supported electrowhizzies out to

the departure runway.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

108.44 KB |

| Viewed: |

16065 Time(s) |

|

| Description: |

|

| Filesize: |

223.33 KB |

| Viewed: |

16065 Time(s) |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 426

|

Posted: Sun Jun 10, 2018 9:46 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 9:46 am Post subject: Rotax Charging System |

|

|

Thx Bob and Joe.

On Sun, Jun 10, 2018 at 9:35 AM Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | Joe, do you have a part number for the John Deere regulator that will replace the Ducati?

Thank you

On Sun, Jun 10, 2018 at 9:03 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Ken,

While I have great respect for Mike M. and admire his knowledge, I do disagree with that ending statement. Heat caused by high current can damage alternator windings. But the total current is determined by the load, not by the regulator. I do not think that the Silent Hektik regulator will stress the alternator any more than the Ducati regulator.

Two years ago I replaced the Ducati regulator in my RV-12 with a cheap John Deere regulator from eBay. I made an adapter plate using 1/8" aluminum because the mounting holes did not line up. I used heat conductive grease on both sides of the mounting plate. A thermocouple attached to the John Deere regulator measured a maximum temperature of 157 degrees Fahrenheit on a 90+ degree day.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480768#480768

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Sun Jun 10, 2018 10:00 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 10:00 am Post subject: Rotax Charging System |

|

|

If it's the easy failure then great but I really don't know how to tell the difference between a gen failure and a regulator failure. My regulator is $12 so I keep a spare and would just swap that out. I guess your first line of attack should be as you said: inspect all the wiring you can find for an obvious break / bad ground / short / loose connector / unplugged wire. Give each PIDG connector a strong pull to see if it comes apart. You should be able to hold the connector in one hand and pull the other wire pretty much as hard as you can (it should support a 50 pound pull no problem).

On Sun, Jun 10, 2018 at 10:45 AM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

| Quote: | Thx Bob and Joe.

On Sun, Jun 10, 2018 at 9:35 AM Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | Joe, do you have a part number for the John Deere regulator that will replace the Ducati?

Thank you

On Sun, Jun 10, 2018 at 9:03 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Ken,

While I have great respect for Mike M. and admire his knowledge, I do disagree with that ending statement. Heat caused by high current can damage alternator windings. But the total current is determined by the load, not by the regulator. I do not think that the Silent Hektik regulator will stress the alternator any more than the Ducati regulator.

Two years ago I replaced the Ducati regulator in my RV-12 with a cheap John Deere regulator from eBay. I made an adapter plate using 1/8" aluminum because the mounting holes did not line up. I used heat conductive grease on both sides of the mounting plate. A thermocouple attached to the John Deere regulator measured a maximum temperature of 157 degrees Fahrenheit on a 90+ degree day.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480768#480768

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Sun Jun 10, 2018 10:02 am Post subject: Rotax Charging System Posted: Sun Jun 10, 2018 10:02 am Post subject: Rotax Charging System |

|

|

Whoops, sorry all, wrong address for the last email.

On Sun, Jun 10, 2018 at 10:59 AM, Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | If it's the easy failure then great but I really don't know how to tell the difference between a gen failure and a regulator failure. My regulator is $12 so I keep a spare and would just swap that out. I guess your first line of attack should be as you said: inspect all the wiring you can find for an obvious break / bad ground / short / loose connector / unplugged wire. Give each PIDG connector a strong pull to see if it comes apart. You should be able to hold the connector in one hand and pull the other wire pretty much as hard as you can (it should support a 50 pound pull no problem).

On Sun, Jun 10, 2018 at 10:45 AM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

| Quote: | Thx Bob and Joe.

On Sun, Jun 10, 2018 at 9:35 AM Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | Joe, do you have a part number for the John Deere regulator that will replace the Ducati?

Thank you

On Sun, Jun 10, 2018 at 9:03 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Ken,

While I have great respect for Mike M. and admire his knowledge, I do disagree with that ending statement. Heat caused by high current can damage alternator windings. But the total current is determined by the load, not by the regulator. I do not think that the Silent Hektik regulator will stress the alternator any more than the Ducati regulator.

Two years ago I replaced the Ducati regulator in my RV-12 with a cheap John Deere regulator from eBay. I made an adapter plate using 1/8" aluminum because the mounting holes did not line up. I used heat conductive grease on both sides of the mounting plate. A thermocouple attached to the John Deere regulator measured a maximum temperature of 157 degrees Fahrenheit on a 90+ degree day.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480768#480768

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 11, 2018 12:48 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 12:48 am Post subject: Rotax Charging System |

|

|

At 01:01 PM 6/10/2018, you wrote:

| Quote: | Whoops, sorry all, wrong address for the last email.

On Sun, Jun 10, 2018 at 10:59 AM, Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

If it's the easy failure then great but I really don't know how to tell the difference between a gen failure and a regulator failure. My regulator is $12 so I keep a spare and would just swap that out. I guess your first line of attack should be as you said: inspect all the wiring you can find for an obvious break / bad ground / short / loose connector / unplugged wire. Give each PIDG connector a strong pull to see if it comes apart. You should be able to hold the connector in one hand and pull the other wire pretty much as hard as you can (it should support a 50 pound pull no problem). |

the fist like of attack in any failure resolution

is to make measurements. In the case of PM alternator

rectifier-regulator systems, we know that the output

of the alternator is an AC voltage that is proportional

to engine RPM. We also know that the device is electrically

simple . . . an array of windings of wire on a stator.

No brushes.

So to start with, get out an ohmmeter and look

at the resistance of the windings. Make a measurement

between the two or three wires that come out of the

device. The readings will be quite low . . . under

one ohm. His is where a low resistance ohmmeter

described in the 'Connection and discussed on

these pages would be handy.

The resistance between any two wires of a three

phase alternator should be nearly identical.

Variations between pairs suggests shorted turns

on the stator windings. If the alternator is

a single phase, then the ohmmeter test only

tells you that there is continuity . . . shorted

turns would be revealed only by knowing what

the resistance of the new, undamaged coil.

Then measure from the windings to engine

crankcase. This reading should always be

'infinite' . . . meaning that it's too high

for your instrument to measure. Usually

in excess of 20,000,000 ohms.

You could make an AC measurement of voltage at

the output wires with the engine running.

Idle RPM is fine. Knowing what the voltage is

for a new, known good alternator is a handy

thing to know.

Assuming all the above produces no hint

of a fault, then the only thing left is the

rectifier-regulator. We know that the Ducatti

product is not robust. For a solid state

device not to operate for the lifetime of the

airplane is a pretty rare condition in the

automotive world. The thing has a poor demonstrated

track record in aviation . . . no doubt similarly

poor in the motorcycle world from which I think

it hails.

There are dozens of PMA/RR systems on various

sport and utility vehicles where the RR is

no doubt beefier than the Rotax Ducatti offering.

You are at little risk for trying one of them . . .

A John Deere product has been mentioned. I think

it's similar to the device favored by the Corvair

conversions crowd . . . there's a 30A PMA/RR

system they favor.

The most common problem with the constellation

of off the shelf RR products is lack of adjustability

for regulation set point. Listers have complained

about the less than ideal charging voltage offered

by various 'bricks' with no adjusting screws.

The core principals for evaluating normal

performance and/or trouble shooting are MEASUREMENTS.

Lord Kelvin once opined: "I often say that when you can

measure what you are speaking about, and express it in numbers,

you know something about it; but when you cannot measure it,

when you cannot express it in numbers, your knowledge is of

a meagre and unsatisfactory kind; it may be the beginning of

knowledge, but you have scarcely, in your thoughts, advanced

to the stage of science, whatever the matter may be."

Having the tools with which to explore 'the numbers'

in a system that functions well are keys to discovering

how to make it work better . . . or to repair the

thing when it quits. As the honorable Lord Kelvin

suggests, the numbers are foundations for understanding

how things work.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Mon Jun 11, 2018 6:51 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 6:51 am Post subject: Rotax Charging System |

|

|

Thank you for the reply Bob. I thought that the normal Rotax system was a generator, not an alternator. Is this correct?

On Mon, Jun 11, 2018, 1:53 AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 01:01 PM 6/10/2018, you wrote:

| Quote: | Whoops, sorry all, wrong address for the last email.

On Sun, Jun 10, 2018 at 10:59 AM, Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

|

If it's the easy failure then great but I really don't know how to tell the difference between a gen failure and a regulator failure. My regulator is $12 so I keep a spare and would just swap that out. I guess your first line of attack should be as you said: inspect all the wiring you can find for an obvious break / bad ground / short / loose connector / unplugged wire. Give each PIDG connector a strong pull to see if it comes apart. You should be able to hold the connector in one hand and pull the other wire pretty much as hard as you can (it should support a 50 pound pull no problem).

the fist like of attack in any failure resolution

is to make measurements. In the case of PM alternator

rectifier-regulator systems, we know that the output

of the alternator is an AC voltage that is proportional

to engine RPM. We also know that the device is electrically

simple . . . an array of windings of wire on a stator.

No brushes.

So to start with, get out an ohmmeter and look

at the resistance of the windings. Make a measurement

between the two or three wires that come out of the

device. The readings will be quite low . . . under

one ohm. His is where a low resistance ohmmeter

described in the 'Connection and discussed on

these pages would be handy.

The resistance between any two wires of a three

phase alternator should be nearly identical.

Variations between pairs suggests shorted turns

on the stator windings. If the alternator is

a single phase, then the ohmmeter test only

tells you that there is continuity . . . shorted

turns would be revealed only by knowing what

the resistance of the new, undamaged coil.

Then measure from the windings to engine

crankcase. This reading should always be

'infinite' . . . meaning that it's too high

for your instrument to measure. Usually

in excess of 20,000,000 ohms.

You could make an AC measurement of voltage at

the output wires with the engine running.

Idle RPM is fine. Knowing what the voltage is

for a new, known good alternator is a handy

thing to know.

Assuming all the above produces no hint

of a fault, then the only thing left is the

rectifier-regulator. We know that the Ducatti

product is not robust. For a solid state

device not to operate for the lifetime of the

airplane is a pretty rare condition in the

automotive world. The thing has a poor demonstrated

track record in aviation . . . no doubt similarly

poor in the motorcycle world from which I think

it hails.

There are dozens of PMA/RR systems on various

sport and utility vehicles where the RR is

no doubt beefier than the Rotax Ducatti offering.

You are at little risk for trying one of them . . .

A John Deere product has been mentioned. I think

it's similar to the device favored by the Corvair

conversions crowd . . . there's a 30A PMA/RR

system they favor.

The most common problem with the constellation

of off the shelf RR products is lack of adjustability

for regulation set point. Listers have complained

about the less than ideal charging voltage offered

by various 'bricks' with no adjusting screws.

The core principals for evaluating normal

performance and/or trouble shooting are MEASUREMENTS.

Lord Kelvin once opined: "I often say that when you can

measure what you are speaking about, and express it in numbers,

you know something about it; but when you cannot measure it,

when you cannot express it in numbers, your knowledge is of

a meagre and unsatisfactory kind; it may be the beginning of

knowledge, but you have scarcely, in your thoughts, advanced

to the stage of science, whatever the matter may be."

Having the tools with which to explore 'the numbers'

in a system that functions well are keys to discovering

how to make it work better . . . or to repair the

thing when it quits. As the honorable Lord Kelvin

suggests, the numbers are foundations for understanding

how things work.

Bob . . .

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Mon Jun 11, 2018 7:24 am Post subject: Re: Rotax Charging System Posted: Mon Jun 11, 2018 7:24 am Post subject: Re: Rotax Charging System |

|

|

It seems that generator, alternator, and dynamo have all been used interchangeably. I prefer to use dynamo. Rotax literature calls it a generator. Many Americans call it an alternator. The important thing is to understand how it works. Permanent magnets attached to a spinning engine flywheel move past stationary coils of wire resulting in induced alternating current.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Mon Jun 11, 2018 8:22 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 8:22 am Post subject: Rotax Charging System |

|

|

Oh, well that explains a lot. I thought it was a "generator" with brushes making DC current.

Thank you Joe. Any luck on a part number or a way to determine an appropriate John Deere regulator?

On Mon, Jun 11, 2018 at 8:24 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

It seems that generator, alternator, and dynamo have all been used interchangeably. I prefer to use dynamo. Rotax literature calls it a generator. Many Americans call it an alternator. The important thing is to understand how it works. Permanent magnets attached to a spinning engine flywheel move past stationary coils of wire resulting in induced alternating current.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480790#480790

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Jun 11, 2018 9:04 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 9:04 am Post subject: Rotax Charging System |

|

|

At 11:21 AM 6/11/2018, you wrote:

| Quote: | | Oh, well that explains a lot. I thought it was a "generator" with brushes making DC current. |

The only place brushed generators are used these

days is on turbine engines where the motor that

starts the engine becomes a generator when the

engine is running.

If it's a piston engine, the power source will

be some form of alternator. When the alternator

is built into the engine, it will generally be

a Permanent Magnet device. On the 912/914 Rotax

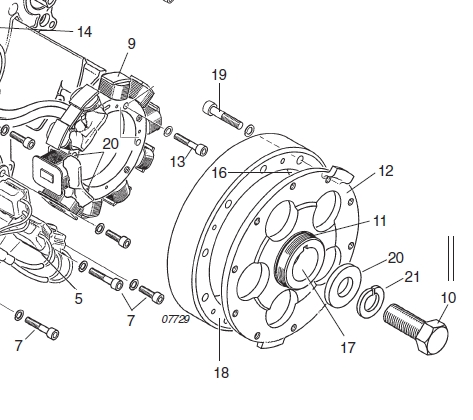

engines . . .

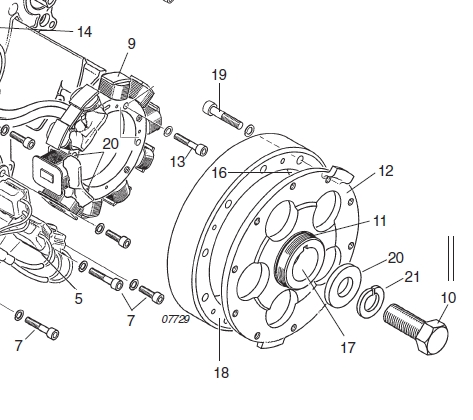

[img]cid:.0[/img]

A stator assembly (9) carries the power generation

windings along with special coils that power dual

ignition system. These windings are 'charged' by

magnets in a flywheel hub (1 on the crankshaft. on the crankshaft.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

103.68 KB |

| Viewed: |

15953 Time(s) |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Mon Jun 11, 2018 9:13 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 9:13 am Post subject: Rotax Charging System |

|

|

A DC Generator uses SLIP-RINGS.

A AC Generator uses a COMMUTATOR.

BRUSHES are used on both applications.

A ALTERNATOR develops AC and then it is RECTIFIED to DC using Diodes.

Why? Because it is more efficient and cost wise more practical to create AC an rectify it to DC.

There are way too many definitions of a DYNOMOTOR.

Some were mechanically driven.

Some were electrically driven.

Some were driven at 400 Hz with a DC output.

Some used a Mechanical Multi-vibrator to produce AC to drive it and then it had a DC output via Slip-Rings.

Today the term has changed to include DYNAMETER aka DYNO which are used to determine Horse Power.

Barry

On Mon, Jun 11, 2018 at 12:21 PM, Sebastien <cluros(at)gmail.com (cluros(at)gmail.com)> wrote:

| Quote: | Oh, well that explains a lot. I thought it was a "generator" with brushes making DC current.

Thank you Joe. Any luck on a part number or a way to determine an appropriate John Deere regulator?

On Mon, Jun 11, 2018 at 8:24 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

It seems that generator, alternator, and dynamo have all been used interchangeably. I prefer to use dynamo. Rotax literature calls it a generator. Many Americans call it an alternator. The important thing is to understand how it works. Permanent magnets attached to a spinning engine flywheel move past stationary coils of wire resulting in induced alternating current.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480790#480790

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

===========

|

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Mon Jun 11, 2018 10:15 am Post subject: Re: Rotax Charging System Posted: Mon Jun 11, 2018 10:15 am Post subject: Re: Rotax Charging System |

|

|

Search eBay for AM101406 or MIA881279

Chances are that the $20 ones are the same as the more expensive ones.

Note that the terminals are arraigned in a different order than the Ducati. The mounting holes are also spaced differently. Be sure to use heat conductive grease on the mounting base to carry heat away.

| Quote: | | Any luck on a part number or a way to determine an appropriate John Deere regulator? |

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

cluros(at)gmail.com

Guest

|

Posted: Mon Jun 11, 2018 10:28 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 10:28 am Post subject: Rotax Charging System |

|

|

Thank you Joe and thank you all. I think we now have a good plan for tackling this problem.

On Mon, Jun 11, 2018 at 11:15 AM, user9253 <fransew(at)gmail.com (fransew(at)gmail.com)> wrote:

| Quote: | --> AeroElectric-List message posted by: "user9253" <fransew(at)gmail.com (fransew(at)gmail.com)>

Search eBay for AM101406 or MIA881279

Chances are that the $20 ones are the same as the more expensive ones.

Note that the terminals are arraigned in a different order than the Ducati. The mounting holes are also spaced differently. Be sure to use heat conductive grease on the mounting base to carry heat away.

> Any luck on a part number or a way to determine an appropriate John Deere regulator?

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480794#480794

====================================

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

====================================

FORUMS -

eferrer" target="_blank">http://forums.matronics.com

====================================

WIKI -

errer" target="_blank">http://wiki.matronics.com

====================================

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/contribution

====================================

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

retasker

Joined: 31 Dec 2016

Posts: 7

|

Posted: Mon Jun 11, 2018 10:57 am Post subject: Rotax Charging System Posted: Mon Jun 11, 2018 10:57 am Post subject: Rotax Charging System |

|

|

When talking about automotive or aviation devices, it is the AC generator (alternator) that uses slip rings and a DC generator that uses a commutator. The AC generator creates DC with diodes. A DC

generator creates DC using the commutator to feed the same polarity to the output as the rotor rotates.

Dick Tasker

FLYaDIVE wrote:

| Quote: | A DC Generator uses SLIP-RINGS.

A AC Generator uses a COMMUTATOR.

BRUSHES are used on both applications.

A ALTERNATOR develops AC and then it is RECTIFIED to DC using Diodes.

Why? Because it is more efficient and cost wise more practical to create AC an rectify it to DC.

There are way too many definitions of a DYNOMOTOR.

Some were mechanically driven.

Some were electrically driven.

Some were driven at 400 Hz with a DC output.

Some used a Mechanical Multi-vibrator to produce AC to drive it and then it had a DC output via Slip-Rings.

Today the term has changed to include DYNAMETER aka DYNO which are used to determine Horse Power.

Barry

On Mon, Jun 11, 2018 at 12:21 PM, Sebastien <cluros(at)gmail.com <mailto:cluros(at)gmail.com>> wrote:

Oh, well that explains a lot. I thought it was a "generator" with brushes making DC current.

Thank you Joe. Any luck on a part number or a way to determine an appropriate John Deere regulator?

On Mon, Jun 11, 2018 at 8:24 AM, user9253 <fransew(at)gmail.com <mailto:fransew(at)gmail.com>> wrote:

It seems that generator, alternator, and dynamo have all been used interchangeably. I prefer to use dynamo. Rotax literature calls it a generator. Many Americans call it an alternator.

The important thing is to understand how it works. Permanent magnets attached to a spinning engine flywheel move past stationary coils of wire resulting in induced alternating current.

--------

Joe Gores

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=480790#480790 <http://forums.matronics.com/viewtopic.php?p=480790#480790>

===========

-

Electric-List" rel="noreferrer" target="_blank">http://www.matronics.com/ <http://www.matronics.com/>Navigator?AeroElectric-List

===========

FORUMS -

eferrer" target="_blank">http://forums.matronics.com <http://forums.matronics.com>

===========

WIKI -

errer" target="_blank">http://wiki.matronics.com <http://wiki.matronics.com>

===========

b Site -

-Matt Dralle, List Admin.

rel="noreferrer" target="_blank">http://www.matronics.com/ <http://www.matronics.com/>contribution

===========

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|