|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jan 06, 2019 6:06 am Post subject: Sifting design goals and establishing protocols Posted: Sun Jan 06, 2019 6:06 am Post subject: Sifting design goals and establishing protocols |

|

|

| Quote: |

Bob,

What would then be the method to recognize an alternator failure except for a preflight check? As long as the remaining alternator is capable of handling the actual load, there would be no warning to the pilot.. |

It's pretty easy to get wound up with

worries about failures . . . especially

un-annunciated or hidden failures. Electro-

whizzies top the list . . . mostly due

to a general lack of understanding for

crafting a failure-tolerant system from

reasonably reliable parts.

Check out the chapter on system reliability

in the 'Connection. We almost never

concern ourselves with dual failures.

Your posting properly notes that once

airborne, you'd have no notice for

loss of the #2 alternator . . . which

is sitting there spinning away with

nothing to do.

Failure rates on equipment items must

certainly be in many hundreds if not

a few thousands of hours. Consider

two devices, say alternators, having

MTBF numbers on the order of 1000

hours.

To deduce such numbers, one has to

either test a bunch of alternators

for thousands of hours (time consuming

and expensive) or do an analysis

based on stress levels to critical

features and/or a statistical process

study of field history. One thing

we do know about automotive alternators

is that they tend to run a long time.

Then what is the likelihood that two

alternators with demonstrated service

histories will crap out on the same

airplane in a single 4-hour window

(one tank of fuel)? The answer is

vanishingly small if not zero.

If the #2 alternator does fail in

flight, you won't know about it until

next pre-flight . . . unless you add

#2 alternator testing to your shutdown

checklist.

The bid takeaway here is that the

probability for one alternator failure

is small, dual failures is practically

zero.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jan 06, 2019 9:01 am Post subject: Sifting design goals and establishing protocols Posted: Sun Jan 06, 2019 9:01 am Post subject: Sifting design goals and establishing protocols |

|

|

At 09:38 AM 1/6/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: Alec Myers <alec(at)alecmyers.com>

Twin piston engined aircraft routinely have two alternators online simultaneously and it is widely accepted that due to different set points on their respective regulators that only one with carry a load when both are operational. It is immaterial which. |

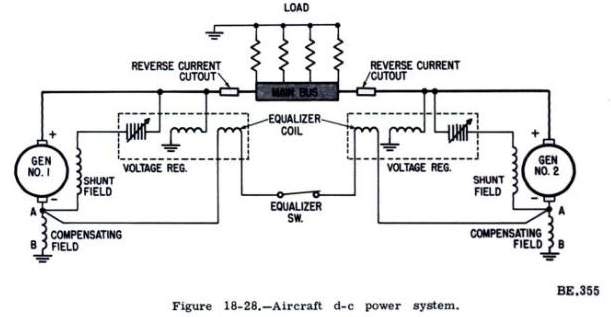

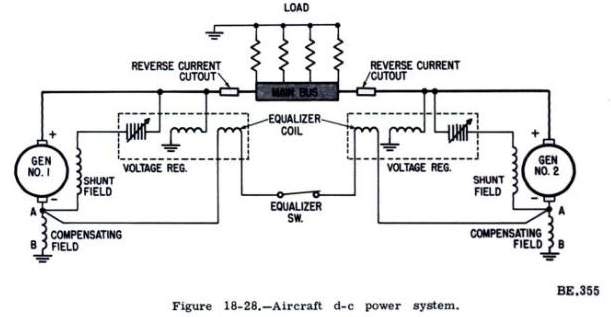

This was a 'hard sell' for years after

alternators replaced generators. Generator

wear rates are related to ampere-hours of

service due to brush wear while alternator

wear is largely independent of electrical

demand in service. It was prudent to have

dual regulators 'talk' to each other to

balance the load between two generators.

[img]cid:.0[/img]

Equalizer busses are still present on the

starter-generators of some production turbine

aircraft.

| Quote: | Preflight procedures are to isolate each alternator in turn and verify that in either case the remaining alternator carries the electrical load demanded of it.

|

When alternators came along, there were

a number of 'paralleling' schemes implemented

with varying degrees of success. Some designers

more aware of the practical results for accurate

paralleling have adopted the run-em-both-and-let-

the-'good'-one-carry-the-loads approach.

The same idea was carried out with the B&C

standby alternator philosophy . . . leave both

on line but set the s/b alternator deliberately

low while adding an "alternator loaded" warning

feature to annunciate failure of the main

alternator.

This is illustrated in Figure Z-12. The

same philosophy could be incorporated in

Igor's RV by controlling the #2 alternator

with an SB-1 regulator . . . but I perceive

little value to be gained with the increase

in complexity.

It made a lot of sense to let us shoe-horn

the standby systems onto TC aircraft (the

FAA's professional worriers worried less).

Simply adding a second alternator with stock

LR-3 regulator offers the same reliability.

I proposed a paralleling system for the Cessna

303 waaayy back when. Demonstrated it and then

had to price it. Powers-that-be of the era

decided the advantages were not worth the cost.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

62.75 KB |

| Viewed: |

2687 Time(s) |

|

|

|

| Back to top |

|

|

supik

Joined: 22 Aug 2018

Posts: 70

|

Posted: Sun Jan 06, 2019 5:21 pm Post subject: Re: Sifting design goals and establishing protocols Posted: Sun Jan 06, 2019 5:21 pm Post subject: Re: Sifting design goals and establishing protocols |

|

|

When utilizing LR-3 regulators for both alternators set at the same volts output will they share the loads equally? 50:50? If yes, wouldn't you adjust regulator #2 (30amp alt) slightly lower to prevent it from running at 100% if the loads get high? Very unlikely that I will routinely get above 60amps, that's more of a hypothetical question.

System monitoring & failure identification:

Would be monitoring the respective bus voltages & amp outputs from the respective alternators adequate?

Main distribution bus fed from alt #1

E-bus fed from alt #2

Thanks,

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Igor

RV10 in progress |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun Jan 06, 2019 5:44 pm Post subject: Sifting design goals and establishing protocols Posted: Sun Jan 06, 2019 5:44 pm Post subject: Sifting design goals and establishing protocols |

|

|

At 07:21 PM 1/6/2019, you wrote:

| Quote: | --> AeroElectric-List message posted by: "supik" <bionicad(at)hotmail.com>

When utilizing LR-3 regulators for both alternators set at the same volts output will they share the loads equally? 50:50? |

No . . . not with reliability

| Quote: | | If yes, wouldn't you adjust regulator #2 (30amp alt) slightly lower to prevent it from running at 100% if the loads get high? Very unlikely that I will routinely get above 60amps, that's more of a hypothetical question. |

Independently controlled alternators/generators

on the same bus will not accurately parallel.

| Quote: | System monitoring & failure identification:

Would be monitoring the respective bus voltages & amp outputs from the respective alternators adequate?

Main distribution bus fed from alt #1

E-bus fed from alt #2 |

Do a Z-14 and make them totally independent

of each other.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|