|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

dan(at)syz.com

Guest

|

Posted: Sun Jan 20, 2019 12:55 pm Post subject: Relocating red cube Posted: Sun Jan 20, 2019 12:55 pm Post subject: Relocating red cube |

|

|

Hi everyone.

I've had ongoing fuel pressure fluctuation issues from time to time and am trying to improve every piece of the puzzle to see if I can make them go away.

One of the things I'm doing is relocating my red cube fuel flow transducer from the tunnel (as per plans) to the positive pressure side of the fuel pump (which a lot of people do). According to the FT-60 red cube documentation which I recently stumbled across (https://buy-ei.com/wp-content/uploads/2018/03/FT-60-Info-Rev-F.pdf) they come right out and say "If the aircraft has a fuel pump(s), the flow transducer MUST be installed downstream of the last fuel pump. Installing the transducer upstream of the fuel pump(s) can cause vapor lock and jumpy/inaccurate readings." That sentence definitely conflicts with the plans for putting it in the tunnel, and makes me hopeful that this will make a difference in taming my pressure fluctuations (not to mention should also help the erroneous readings it gives when the electric boost pump is on).

But I'm struggling a bit with where exactly to put it. The two options for the positive pressure side of the fuel pump mean either between the engine pump and servo, or between the servo and spider. Most people I've heard who have moved it have placed it between the servo and spider.

However, in the installation instructions for Electronics International's FP-5 (https://buy-ei.com/wp-content/uploads/FP-5L-II.pdf) which uses the red cube, they suggest mounting locations. Applicable to my fuel injected engine without a fuel return line from the servo, they say to refer to the drawings on page 17 or 18, both of which place the red cube between the fuel pump and servo. Their drawings placing the cube between the servo and spider are marked as being only applicable on aircraft with a fuel return line from the fuel servo.

Has this been noticed before and I'm just late to the party? Or do most people who have been relocating the cube also have a fuel return line, which is why it's been common to mount between the servo and spider? Does anyone know what the reason might be to not install the red cube between the servo and spider on an installation without a fuel return line from the servo?

Thanks!

Dan

---

Dan Charrois

President, Syzygy Research & Technology

Phone: 780-961-2213

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Sun Jan 20, 2019 2:25 pm Post subject: Relocating red cube Posted: Sun Jan 20, 2019 2:25 pm Post subject: Relocating red cube |

|

|

Dan,

I used the location between the mechanical pump and the servo on a

Mooney I had before the RV, because that was where the STC instructions

said to put it. On my RV-10, I put it between the servo and the spider,

near the right front corner of the oil sump, before the line goes up to

the spider. Both locations delivered stable readings. I'd say

convenience to get relatively straight hose runs in and out of the cube

is the main point.

Kelly

On 1/20/2019 2:54 AM, Dan Charrois wrote:

| Quote: |

Hi everyone.

I've had ongoing fuel pressure fluctuation issues from time to time and am trying to improve every piece of the puzzle to see if I can make them go away.

One of the things I'm doing is relocating my red cube fuel flow transducer from the tunnel (as per plans) to the positive pressure side of the fuel pump (which a lot of people do). According to the FT-60 red cube documentation which I recently stumbled across (https://buy-ei.com/wp-content/uploads/2018/03/FT-60-Info-Rev-F.pdf) they come right out and say "If the aircraft has a fuel pump(s), the flow transducer MUST be installed downstream of the last fuel pump. Installing the transducer upstream of the fuel pump(s) can cause vapor lock and jumpy/inaccurate readings." That sentence definitely conflicts with the plans for putting it in the tunnel, and makes me hopeful that this will make a difference in taming my pressure fluctuations (not to mention should also help the erroneous readings it gives when the electric boost pump is on).

But I'm struggling a bit with where exactly to put it. The two options for the positive pressure side of the fuel pump mean either between the engine pump and servo, or between the servo and spider. Most people I've heard who have moved it have placed it between the servo and spider.

However, in the installation instructions for Electronics International's FP-5 (https://buy-ei.com/wp-content/uploads/FP-5L-II.pdf) which uses the red cube, they suggest mounting locations. Applicable to my fuel injected engine without a fuel return line from the servo, they say to refer to the drawings on page 17 or 18, both of which place the red cube between the fuel pump and servo. Their drawings placing the cube between the servo and spider are marked as being only applicable on aircraft with a fuel return line from the fuel servo.

Has this been noticed before and I'm just late to the party? Or do most people who have been relocating the cube also have a fuel return line, which is why it's been common to mount between the servo and spider? Does anyone know what the reason might be to not install the red cube between the servo and spider on an installation without a fuel return line from the servo?

Thanks!

Dan

---

Dan Charrois

President, Syzygy Research & Technology

Phone: 780-961-2213

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

rjones560xl@gmail.com

Joined: 29 Jul 2015

Posts: 64

Location: Las Vegas, NV

|

Posted: Sun Jan 20, 2019 3:58 pm Post subject: Relocating red cube Posted: Sun Jan 20, 2019 3:58 pm Post subject: Relocating red cube |

|

|

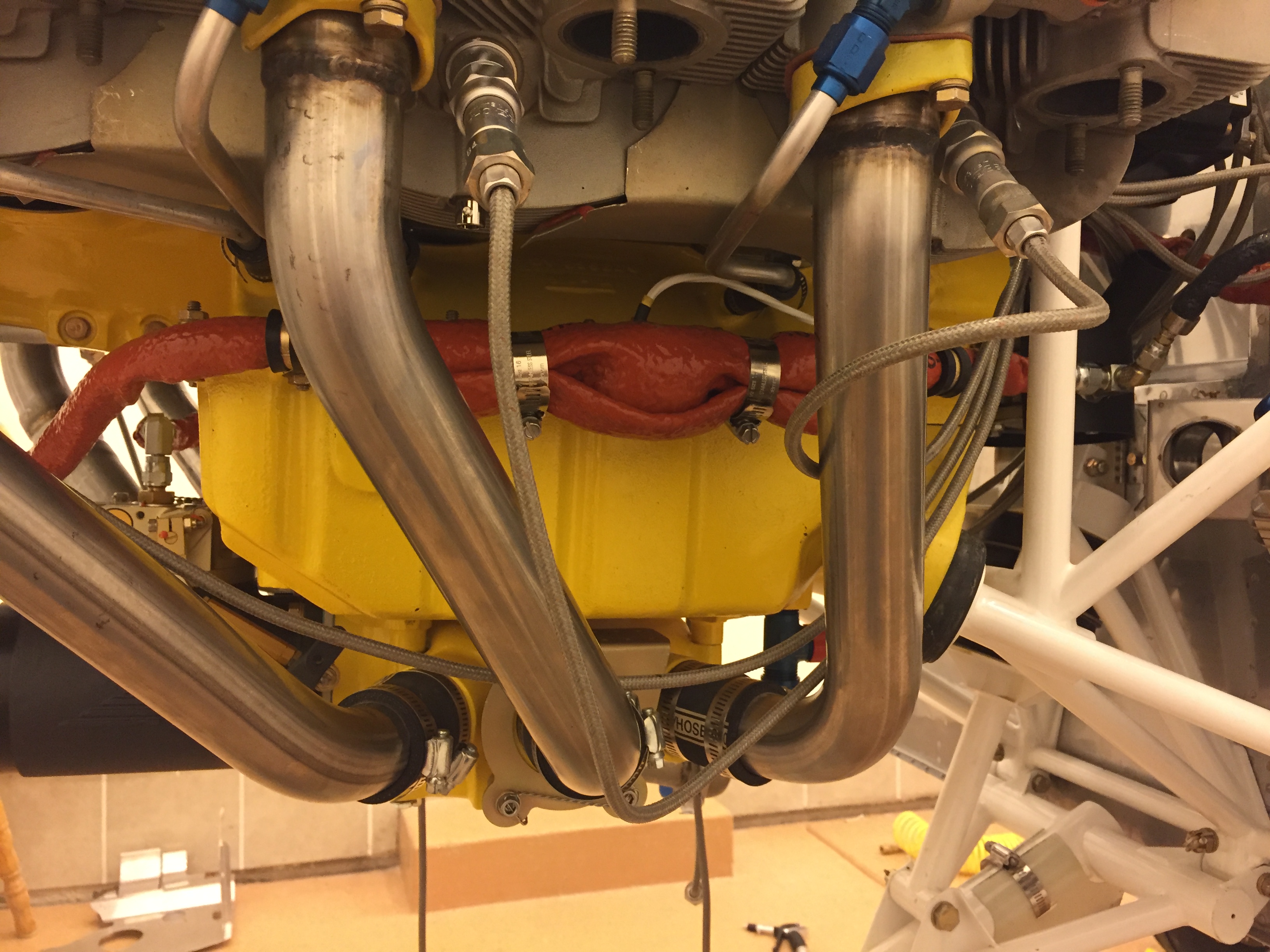

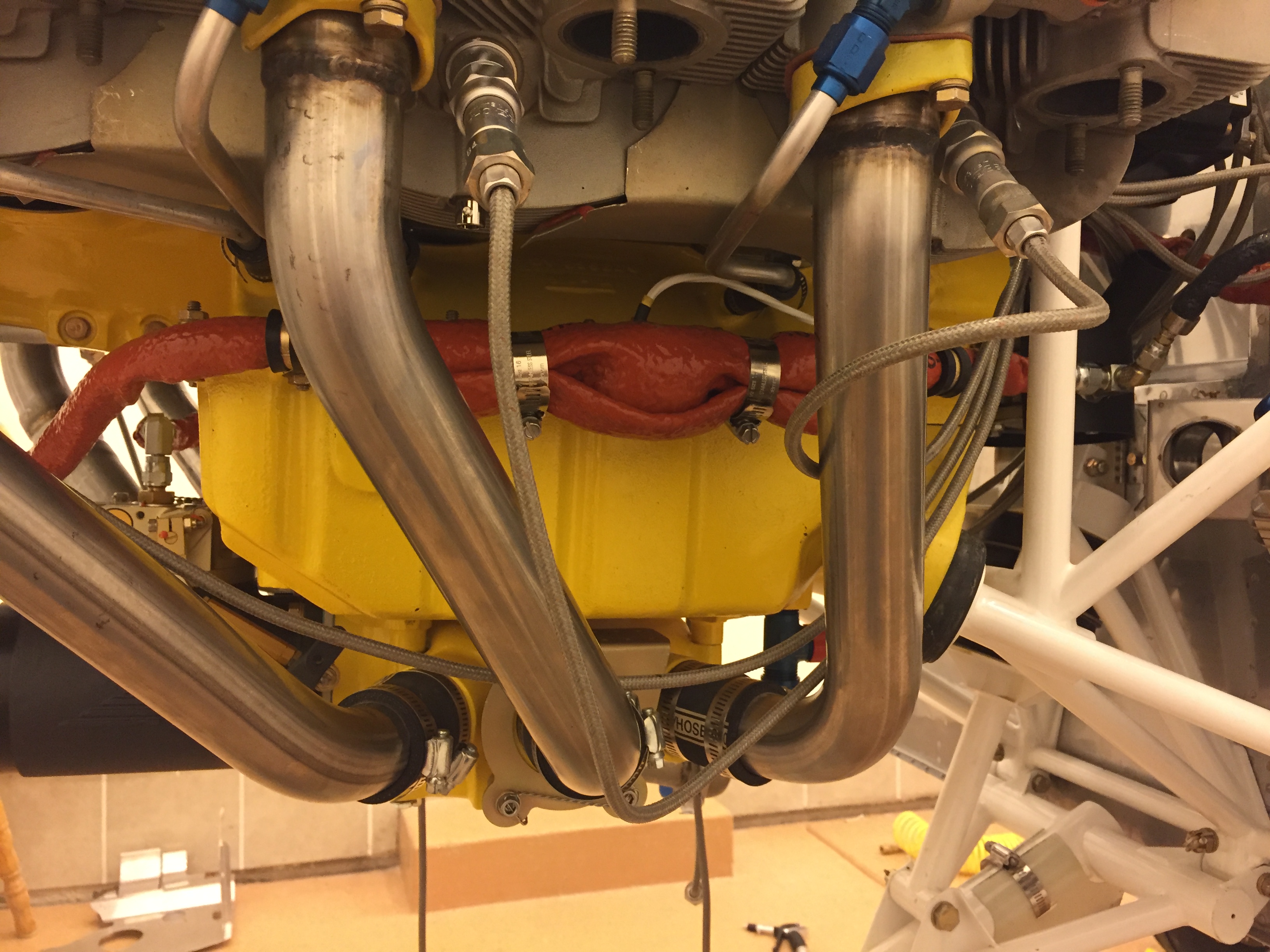

I have an Airflow Performance FM300 on the front of a Barrett Cold Air Induction manifold. Putting the Red Cube after the fuel Servo was a non starter for me because there was not enough room after the Servo to mount it without tight turns before and after the Red Cube. I finally mounted it the left side on the fuel line run from the engine driven fuel pump to the Servo. This gave me a fairly straight run before and after. I used Axel clamps to support the fuel lines at the front and back of the oil pan. The fuel lines were fire sleeved of course and a got about 12 inches of fire sleeve to go over the Red Cube. I punched a hole in the sleeve for the wires and used hose clamps to secure the ends after everything was tightened down. You can see that I had to fold it up to secure it.

I canât say how well this works because I am still working on wiring avionics.

Robert Jones

| Quote: | On Jan 20, 2019, at 01:54, Dan Charrois <dan(at)syz.com> wrote:

Hi everyone.

I've had ongoing fuel pressure fluctuation issues from time to time and am trying to improve every piece of the puzzle to see if I can make them go away.

One of the things I'm doing is relocating my red cube fuel flow transducer from the tunnel (as per plans) to the positive pressure side of the fuel pump (which a lot of people do). According to the FT-60 red cube documentation which I recently stumbled across (https://buy-ei.com/wp-content/uploads/2018/03/FT-60-Info-Rev-F.pdf) they come right out and say "If the aircraft has a fuel pump(s), the flow transducer MUST be installed downstream of the last fuel pump. Installing the transducer upstream of the fuel pump(s) can cause vapor lock and jumpy/inaccurate readings." That sentence definitely conflicts with the plans for putting it in the tunnel, and makes me hopeful that this will make a difference in taming my pressure fluctuations (not to mention should also help the erroneous readings it gives when the electric boost pump is on).

But I'm struggling a bit with where exactly to put it. The two options for the positive pressure side of the fuel pump mean either between the engine pump and servo, or between the servo and spider. Most people I've heard who have moved it have placed it between the servo and spider.

However, in the installation instructions for Electronics International's FP-5 (https://buy-ei.com/wp-content/uploads/FP-5L-II.pdf) which uses the red cube, they suggest mounting locations. Applicable to my fuel injected engine without a fuel return line from the servo, they say to refer to the drawings on page 17 or 18, both of which place the red cube between the fuel pump and servo. Their drawings placing the cube between the servo and spider are marked as being only applicable on aircraft with a fuel return line from the fuel servo.

Has this been noticed before and I'm just late to the party? Or do most people who have been relocating the cube also have a fuel return line, which is why it's been common to mount between the servo and spider? Does anyone know what the reason might be to not install the red cube between the servo and spider on an installation without a fuel return line from the servo?

Thanks!

Dan

---

Dan Charrois

President, Syzygy Research & Technology

Phone: 780-961-2213

====================================

|

====================================

====================================

====================================

====================================

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

1.76 MB |

| Viewed: |

11529 Time(s) |

|

_________________

Robert J Jones

702-521-1840 |

|

| Back to top |

|

|

TimRVator(at)comcast.net

Guest

|

Posted: Sun Jan 20, 2019 5:57 pm Post subject: Relocating red cube Posted: Sun Jan 20, 2019 5:57 pm Post subject: Relocating red cube |

|

|

I suspended my FP-5 in the line between the fuel servo and flow divider

IAW the drawing on page 20 of the FT-5 manual. I wrapped the transducer

with fire sleeve per the instructions. It has worked well in this

location for 4 years and over four hundred hours. Several other RV's

have done the same thing. I believe Airflow Performance recommended

this location to me.

This location eliminated the surging fuel flow readings I used to see.

My setup:Â RV-10, IO-540 C4B5, standard installation with stock Van's

fuel selector, stock RV-10 airflow performance boost pump in the tunnel,

mechanical fuel pump on the engine. Bendix fuel injection system. No

fuel return line.

--

Tim Lewis -- HEF (Manassas, VA)

CFI, A&P

RV-6A N47TD -- 1104 hrs - sold

RV-10 N31TD -- 1000 hrs

Dan Charrois wrote on 1/20/2019 4:54 AM:

| Quote: |

Hi everyone.

I've had ongoing fuel pressure fluctuation issues from time to time and am trying to improve every piece of the puzzle to see if I can make them go away.

One of the things I'm doing is relocating my red cube fuel flow transducer from the tunnel (as per plans) to the positive pressure side of the fuel pump (which a lot of people do). According to the FT-60 red cube documentation which I recently stumbled across (https://buy-ei.com/wp-content/uploads/2018/03/FT-60-Info-Rev-F.pdf) they come right out and say "If the aircraft has a fuel pump(s), the flow transducer MUST be installed downstream of the last fuel pump. Installing the transducer upstream of the fuel pump(s) can cause vapor lock and jumpy/inaccurate readings." That sentence definitely conflicts with the plans for putting it in the tunnel, and makes me hopeful that this will make a difference in taming my pressure fluctuations (not to mention should also help the erroneous readings it gives when the electric boost pump is on).

But I'm struggling a bit with where exactly to put it. The two options for the positive pressure side of the fuel pump mean either between the engine pump and servo, or between the servo and spider. Most people I've heard who have moved it have placed it between the servo and spider.

However, in the installation instructions for Electronics International's FP-5 (https://buy-ei.com/wp-content/uploads/FP-5L-II.pdf) which uses the red cube, they suggest mounting locations. Applicable to my fuel injected engine without a fuel return line from the servo, they say to refer to the drawings on page 17 or 18, both of which place the red cube between the fuel pump and servo. Their drawings placing the cube between the servo and spider are marked as being only applicable on aircraft with a fuel return line from the fuel servo.

Has this been noticed before and I'm just late to the party? Or do most people who have been relocating the cube also have a fuel return line, which is why it's been common to mount between the servo and spider? Does anyone know what the reason might be to not install the red cube between the servo and spider on an installation without a fuel return line from the servo?

Thanks!

Dan

---

Dan Charrois

President, Syzygy Research & Technology

Phone: 780-961-2213

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

arplnplt(at)gmail.com

Guest

|

Posted: Sun Jan 20, 2019 8:06 pm Post subject: Relocating red cube Posted: Sun Jan 20, 2019 8:06 pm Post subject: Relocating red cube |

|

|

Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

Suspend the transducer with minimal support for maximum flexibility

At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

Dave Leikam

N89DA

| Quote: | On Jan 20, 2019, at 7:53 PM, Tim Lewis <TimRVator(at)comcast.net> wrote:

I suspended my FP-5 in the line between the fuel servo and flow divider IAW the drawing on page 20 of the FT-5 manual. I wrapped the transducer with fire sleeve per the instructions. It has worked well in this location for 4 years and over four hundred hours. Several other RV's have done the same thing. I believe Airflow Performance recommended this location to me.

This location eliminated the surging fuel flow readings I used to see.

My setup: RV-10, IO-540 C4B5, standard installation with stock Van's fuel selector, stock RV-10 airflow performance boost pump in the tunnel, mechanical fuel pump on the engine. Bendix fuel injection system. No fuel return line.

--

Tim Lewis -- HEF (Manassas, VA)

CFI, A&P

RV-6A N47TD -- 1104 hrs - sold

RV-10 N31TD -- 1000 hrs

Dan Charrois wrote on 1/20/2019 4:54 AM:

>

>

> Hi everyone.

>

> I've had ongoing fuel pressure fluctuation issues from time to time and am trying to improve every piece of the puzzle to see if I can make them go away.

>

> One of the things I'm doing is relocating my red cube fuel flow transducer from the tunnel (as per plans) to the positive pressure side of the fuel pump (which a lot of people do). According to the FT-60 red cube documentation which I recently stumbled across (https://buy-ei.com/wp-content/uploads/2018/03/FT-60-Info-Rev-F.pdf) they come right out and say "If the aircraft has a fuel pump(s), the flow transducer MUST be installed downstream of the last fuel pump. Installing the transducer upstream of the fuel pump(s) can cause vapor lock and jumpy/inaccurate readings." That sentence definitely conflicts with the plans for putting it in the tunnel, and makes me hopeful that this will make a difference in taming my pressure fluctuations (not to mention should also help the erroneous readings it gives when the electric boost pump is on).

>

> But I'm struggling a bit with where exactly to put it. The two options for the positive pressure side of the fuel pump mean either between the engine pump and servo, or between the servo and spider. Most people I've heard who have moved it have placed it between the servo and spider.

>

> However, in the installation instructions for Electronics International's FP-5 (https://buy-ei.com/wp-content/uploads/FP-5L-II.pdf) which uses the red cube, they suggest mounting locations. Applicable to my fuel injected engine without a fuel return line from the servo, they say to refer to the drawings on page 17 or 18, both of which place the red cube between the fuel pump and servo. Their drawings placing the cube between the servo and spider are marked as being only applicable on aircraft with a fuel return line from the fuel servo.

>

> Has this been noticed before and I'm just late to the party? Or do most people who have been relocating the cube also have a fuel return line, which is why it's been common to mount between the servo and spider? Does anyone know what the reason might be to not install the red cube between the servo and spider on an installation without a fuel return line from the servo?

>

> Thanks!

>

> Dan

> ---

> Dan Charrois

> President, Syzygy Research & Technology

> Phone: 780-961-2213

>

>

>

>

>

>

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Jan 21, 2019 4:51 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 4:51 am Post subject: Relocating red cube |

|

|

What you say is correct, but should be clarified. If the line is on or

connects to the engine it must be hose due to the vibration. If in the

tunnel, rigid line is okay.

There are two types of hose that can be used. Standard fuel line with

external fire sleeve is okay. When I got my kit, Vans supplied standard

hose without fire sleeve. It needed to have fire sleeve added. Integral

fire sleeve hose with teflon core is nicer and longer lasting. It is

more flexible, smaller external diameter and does not deteriorate from

heat or age. Fuel lines are best fabricated by professional hose shops.

It may cost you 50 or 100 more, but will eliminate one source of

substantial hazard. While as an A&P I have experience fabricating hoses,

given the time it takes, the need for tooling and proper pressure

testing, I buy my fuel lines from professional aviation hose shop. Just

one more choice to make for each builder.

Kelly

On 1/20/2019 9:03 PM, Dave Leikam wrote:

| Quote: |

Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

Suspend the transducer with minimal support for maximum flexibility

At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

Dave Leikam

N89DA

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

kearney

Joined: 20 Sep 2008

Posts: 563

|

Posted: Mon Jan 21, 2019 6:11 am Post subject: Re: Relocating red cube Posted: Mon Jan 21, 2019 6:11 am Post subject: Re: Relocating red cube |

|

|

| arplnplt(at)gmail.com wrote: | Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

Suspend the transducer with minimal support for maximum flexibility

At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

Dave Leikam

N89DA |

Keeping in mind comments of those with greater experience (Hi Kelley), I would disagree with with Dave's minimal support comment. I would think that vibration is only a problem if the transducer does not move in sync with the engine. If the transducer is securely mounted to the engine, then it will move with the engine and so there would be no vibration issue. There are soft aluminium tubes used on the engine and these are not a problem as they are attached to the engine at both ends.

It is when things vibrate differently from what it is attached to that things get sporty!

I didn't find it hard to make my own braided steel fuel hoses using hose ends and hose tubing from a lo cal speed shop. I used Aeroquip hoses / ends as I wanted to know the provenance of the parts.

Use of a Koul Tool (also available at a speed shop) made making up the hoses fast and simple.

Cheers

Les

RV10: C-GCWZ Sold

RV10: C-GROK Nearing completion

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Jan 21, 2019 6:22 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 6:22 am Post subject: Relocating red cube |

|

|

Les,

I haven't found it a problem to mount the cube to the engine, but EI

recommends against doing that. As for making hoses, true, not difficult,

but there are easy ways to screw it up and not know that it isn't right

if you don't have the experience to inspect the finished hose. Most

shops don't charge that much to do it for you, and properly pressure

test the hose.

On 1/21/2019 7:11 AM, kearney wrote:

| Quote: |

arplnplt(at)gmail.com wrote:

> Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

> Suspend the transducer with minimal support for maximum flexibility

> At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

>

> Dave Leikam

> N89DA

Keeping in mind comments of those with greater experience (Hi Kelley), I would disagree with with Dave's minimal support comment. I would think that vibration is only a problem if the transducer does not move in sync with the engine. If the transducer is securely mounted to the engine, then it will move with the engine and so there would be no vibration issue. There are soft aluminium tubes used on the engine and these are not a problem as they are attached to the engine at both ends.

It is when things vibrate differently from what it is attached to that things get sporty!

I didn't find it hard to make my own braided steel fuel hoses using hose ends and hose tubing from a lo cal speed shop. I used Aeroquip hoses / ends as I wanted to know the provenance of the parts.

Use of a Koul Tool (also available at a speed shop) made making up the hoses fast and simple.

Cheers

Les

RV10: C-GCWZ Sold

RV10: C-GROK Nearing completion

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=487123#487123

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

arplnplt(at)gmail.com

Guest

|

Posted: Mon Jan 21, 2019 7:33 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 7:33 am Post subject: Relocating red cube |

|

|

I have 600+ hours on my -10. My transducer is mounted just in front of the servo with flex hose in and out. I made a tab from aluminum stock connected to the air cleaner below and clamped to the hose above that allows the whole thing to move slightly forward and aft. 600 hours, no cracks no problem.

I do not have Red Cube. I have the one that comes with Garmin 900x from 2010. Canât remember the manufacturer. Talked directly to them and was told absolutely do not mount directly to the engine for a number of reasons. Also instructed to place after the servo before the spider.

My fuel totals are and have always been within .1 gal of of actual burn.

Extremely accurate.

My 2 cents.

Dave Leikam

N89DA

| Quote: | On Jan 21, 2019, at 8:19 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

Les,

I haven't found it a problem to mount the cube to the engine, but EI recommends against doing that. As for making hoses, true, not difficult, but there are easy ways to screw it up and not know that it isn't right if you don't have the experience to inspect the finished hose. Most shops don't charge that much to do it for you, and properly pressure test the hose.

> On 1/21/2019 7:11 AM, kearney wrote:

>

> arplnplt(at)gmail.com wrote:

>> Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

>> Suspend the transducer with minimal support for maximum flexibility

>> At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

>>

>> Dave Leikam

>> N89DA

> Keeping in mind comments of those with greater experience (Hi Kelley), I would disagree with with Dave's minimal support comment. I would think that vibration is only a problem if the transducer does not move in sync with the engine. If the transducer is securely mounted to the engine, then it will move with the engine and so there would be no vibration issue. There are soft aluminium tubes used on the engine and these are not a problem as they are attached to the engine at both ends.

> It is when things vibrate differently from what it is attached to that things get sporty!

> I didn't find it hard to make my own braided steel fuel hoses using hose ends and hose tubing from a lo cal speed shop. I used Aeroquip hoses / ends as I wanted to know the provenance of the parts.

> Use of a Koul Tool (also available at a speed shop) made making up the hoses fast and simple.

> Cheers

> Les

> RV10: C-GCWZ Sold

> RV10: C-GROK Nearing completion

> Read this topic online here:

> http://forums.matronics.com/viewtopic.php?p=487123#487123

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rjones560xl@gmail.com

Joined: 29 Jul 2015

Posts: 64

Location: Las Vegas, NV

|

Posted: Mon Jan 21, 2019 7:45 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 7:45 am Post subject: Relocating red cube |

|

|

Kelly is correct. Any rigid lines in the engine compartment are going to crack. Flexible lines are a must. I used the braided line with Teflon core and fire sleeve for everything. I am fortunate that I have a hose shop (All Hose) close by. They have also been very helpful with any standard or unusual fitting that I needed. I used stainless steel fittings for all the fuel system, firewall forward. I did not bother with Stainless Steel for the oil lines. After all my oil cooler is aluminum and will melt with a fuel fire anyway. The main thing is to make sure that never happens.

Robert Jones

| Quote: | On Jan 21, 2019, at 04:48, Kelly McMullen <kellym(at)aviating.com> wrote:

What you say is correct, but should be clarified. If the line is on or connects to the engine it must be hose due to the vibration. If in the tunnel, rigid line is okay.

There are two types of hose that can be used. Standard fuel line with external fire sleeve is okay. When I got my kit, Vans supplied standard hose without fire sleeve. It needed to have fire sleeve added. Integral fire sleeve hose with teflon core is nicer and longer lasting. It is more flexible, smaller external diameter and does not deteriorate from heat or age. Fuel lines are best fabricated by professional hose shops. It may cost you 50 or 100 more, but will eliminate one source of substantial hazard. While as an A&P I have experience fabricating hoses, given the time it takes, the need for tooling and proper pressure testing, I buy my fuel lines from professional aviation hose shop. Just one more choice to make for each builder.

Kelly

> On 1/20/2019 9:03 PM, Dave Leikam wrote:

>

> Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

> Suspend the transducer with minimal support for maximum flexibility

> At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

> Dave Leikam

> N89DA

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Robert J Jones

702-521-1840 |

|

| Back to top |

|

|

peter(at)peteraringer.de

Guest

|

Posted: Mon Jan 21, 2019 7:49 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 7:49 am Post subject: Relocating red cube |

|

|

Hi,

regarding the vapor lock problem:

What about a return line into one wing with a valve you can open and close in flight??

Before hot starts you could open the valve and remove the air in the fuel lines with the electric fuel pump flushing with cold fuel from the wing tank. After takeoff you close the valve to have correct fuel flow readings...

Greetings from Germany

Peter Aringer

Am 21.01.2019 um 14:03 schrieb Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>:

| Quote: | --> RV10-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

What you say is correct, but should be clarified. If the line is on or

connects to the engine it must be hose due to the vibration. If in the

tunnel, rigid line is okay.

There are two types of hose that can be used. Standard fuel line with

external fire sleeve is okay. When I got my kit, Vans supplied standard

hose without fire sleeve. It needed to have fire sleeve added. Integral

fire sleeve hose with teflon core is nicer and longer lasting. It is

more flexible, smaller external diameter and does not deteriorate from

heat or age. Fuel lines are best fabricated by professional hose shops.

It may cost you 50 or 100 more, but will eliminate one source of

substantial hazard. While as an A&P I have experience fabricating hoses,

given the time it takes, the need for tooling and proper pressure

testing, I buy my fuel lines from professional aviation hose shop. Just

one more choice to make for each builder.

Kelly

On 1/20/2019 9:03 PM, Dave Leikam wrote:

| Quote: | --> RV10-List message posted by: Dave Leikam <arplnplt(at)gmail.com (arplnplt(at)gmail.com)>

Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

Suspend the transducer with minimal support for maximum flexibility

At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

Dave Leikam

N89DA

|

_-============================================================

_-= - The RV10-List Email Forum -

_-= Use the Matronics List Features Navigator to browse

_-= the many List utilities such as List Un/Subscription,

_-= Archive Search & Download, 7-Day Browse, Chat, FAQ,

_-= Photoshare, and much much more:

_-=

_-= --> http://www.matronics.com/Navigator?RV10-List

_-=

_-============================================================

_-= - MATRONICS WEB FORUMS -

_-= Same great content also available via the Web Forums!

_-=

_-= --> http://forums.matronics.com

_-=

_-============================================================

_-= - NEW MATRONICS LIST WIKI -

_-= Add some info to the Matronics Email List Wiki!

_-= --> http://wiki.matronics.com

_-============================================================

_-= - List Contribution Web Site -

_-= Thank you for your generous support!

_-= -Matt Dralle, List Admin.

_-= --> http://www.matronics.com/contribution

_-============================================================

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

rjones560xl@gmail.com

Joined: 29 Jul 2015

Posts: 64

Location: Las Vegas, NV

|

Posted: Mon Jan 21, 2019 8:18 am Post subject: Relocating red cube Posted: Mon Jan 21, 2019 8:18 am Post subject: Relocating red cube |

|

|

Airflow Performance makes a bypass valve and fittings to mount just before the fuel distributor. It canât be used in flight because all fuel is bypassed back to a Wing tank. Fuel vapors forming after the engine driven fuel pump are very unlikely because of the higher pressure. Vapors forming before the electric fuel pump are the most likely because the pump is sucking instead of pushing, lowering the pressure. I find it hard to believe that pilots are experiencing vapors forming after the engine driven fuel pump. If there are vapors forward they were formed earlier, or after shutdown because of residual heat. The Airflow Performance calve solves the last problem by purging hot fuel and vapors back to a fuel tank before start.

Robert Jones

On Jan 21, 2019, at 07:45, Peter <peter(at)peteraringer.de (peter(at)peteraringer.de)> wrote:

[quote]Hi,

regarding the vapor lock problem:

What about a return line into one wing with a valve you can open and close in flight??

Before hot starts you could open the valve and remove the air in the fuel lines with the electric fuel pump flushing with cold fuel from the wing tank. After takeoff you close the valve to have correct fuel flow readings...

Greetings from Germany

Peter Aringer

Am 21.01.2019 um 14:03 schrieb Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>:

| Quote: | --> RV10-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

What you say is correct, but should be clarified. If the line is on or

connects to the engine it must be hose due to the vibration. If in the

tunnel, rigid line is okay.

There are two types of hose that can be used. Standard fuel line with

external fire sleeve is okay. When I got my kit, Vans supplied standard

hose without fire sleeve. It needed to have fire sleeve added. Integral

fire sleeve hose with teflon core is nicer and longer lasting. It is

more flexible, smaller external diameter and does not deteriorate from

heat or age. Fuel lines are best fabricated by professional hose shops.

It may cost you 50 or 100 more, but will eliminate one source of

substantial hazard. While as an A&P I have experience fabricating hoses,

given the time it takes, the need for tooling and proper pressure

testing, I buy my fuel lines from professional aviation hose shop. Just

one more choice to make for each builder.

Kelly

On 1/20/2019 9:03 PM, Dave Leikam wrote:

| Quote: | --> RV10-List message posted by: Dave Leikam <arplnplt(at)gmail.com (arplnplt(at)gmail.com)>

Whatever you do, use flexible fire sleeve hose after transducer. DO NOT use ridged aluminum fuel line after the transducer or before the spider like under the fuel selector.

Suspend the transducer with minimal support for maximum flexibility

At least one -10 had engine failure due to cracked fuel line because of this. It ended ok with emergency landing at an airport out of IFR. Lots of vibration down there.

Dave Leikam

http:==========================bsp; - MATRONICS W href="http://forums.matronics.com">http://forums.matronics.com==============================================

http://wiki.matronics.com

|

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Robert J Jones

702-521-1840 |

|

| Back to top |

|

|

dan(at)syz.com

Guest

|

Posted: Mon Jan 21, 2019 1:16 pm Post subject: Relocating red cube Posted: Mon Jan 21, 2019 1:16 pm Post subject: Relocating red cube |

|

|

Hi again everyone.

To add some more info to the discussion, I just heard back from a tech at Electronics International (the makers of the red cube) to get their take on placement.

Obviously, they disagree with the placement in the tunnel between the electric and mechanical pump. In addition to the "water hammer" effect of placing it in that location that causes erratically high readings, they said their transducers were designed for fuel to be pushed through, not sucked through.

As far as the discussion of where specifically to locate it past both pumps (between pump to servo or servo to spider), they suggested that in a case without a return line from the servo they suggest their diagram on page 18 (between the pump and servo). They said their rationale for not placing it between servo to spider in that situation is based on maintaining the calibrated pressure on the outlet from the servo (based on the number of orifices/volume it's serving). Apparently, the cube in that position has the potential of changing this pressure provided by the servo slightly, and as such their STC for installation without a return line disallows that. With that said, they know that many homebuilt owners have installed it between the servo and divider, without return lines, and obviously it's working for them.

Dan

---

Dan Charrois

President, Syzygy Research & Technology

Phone: 780-961-2213

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Kelly McMullen

Joined: 16 Apr 2008

Posts: 1188

Location: Sun Lakes AZ

|

Posted: Mon Jan 21, 2019 6:14 pm Post subject: Relocating red cube Posted: Mon Jan 21, 2019 6:14 pm Post subject: Relocating red cube |

|

|

There is not a vapor lock problem. Some engines will run a bit rough at taxi power after a hot start, but that is uneven fuel delivery, and maybe some vapor, but it isn't a lock. Hot starting is the challenge of getting the right mixture during cranking, not vapor lock. I have been flying with a Bendix RSA-5 system for 20 years now. On the 200 hp 4 cyl Lycoming in the Mooney preceding my RV-10, it was easy to flood the engine when hot. With the 6 cyl 540 engine, it isn't as prone to flooding, it is just getting the right mixture. The mechanical pump doesn't necessarily generate enough pressure at cranking speeds. I get better hot start reliability with the boost pump on, and then bring in the mixture slowly. When right, the engine fires and keeps running. Without the boost pump it often fires and then quits. W'ith the RSA system it is just a matter of finding what procedure is most reliable. If the approach from the mixture cutoff isn't working, and adding throttle doesn't help, you can perhaps go to full rich and flood engine, then lean out until it fires. | Quote: | | Sent from my TRS-80 Model 100 |

On Mon, Jan 21, 2019 at 8:54 AM Peter <peter(at)peteraringer.de (peter(at)peteraringer.de)> wrote:

[quote]Hi,

regarding the vapor lock problem:

What about a return line into one wing with a valve you can open and close in flight??

Before hot starts you could open the valve and remove the air in the fuel lines with the electric fuel pump flushing with cold fuel from the wing tank. After takeoff you close the valve to have correct fuel flow readings...

Greetings from Germany

Peter Aringer

Am 21.01.2019 um 14:03 schrieb Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>:

| Quote: | --> RV10-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

What you say is correct, but should be clarified. If the line is on or

connects to the engine it must be hose due to the vibration. If in the

tunnel, rigid line is okay.

There are two types of hose that can be used. Standard fuel line with

external fire sleeve is okay. When I got my kit, Vans supplied standard

hose without fire sleeve. It needed to have fire sleeve added. Integral

fire sleeve hose with teflon core is nicer and longer lasting. It is

more flexible, smaller external diameter and does not deteriorate from

heat or age. Fuel lines are best fabricated by professional hose shops.

It may cost you 50 or 100 more, but will eliminate one source of

substantial hazard. While as an A&P I have experience fabricating hoses,

given the time it takes, the need for  tooling and proper pressure

testing, I buy my fuel lines from professional aviation hose shop. Just

one more choice to make for each builder.

Kelly

On 1/20/2019 9:03 PM, Dave Leikam wrote:

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor

KCHD |

|

| Back to top |

|

|

tmoushon(at)gmail.com

Guest

|

Posted: Tue Jan 22, 2019 6:19 am Post subject: Relocating red cube Posted: Tue Jan 22, 2019 6:19 am Post subject: Relocating red cube |

|

|

Data point

My -10 started flying in May2016. Since then, I have acquired 370 hours and an instrument rating in it. I have G3x touch and review my data after each flight (retired). I copied another builders red cube location and my pressure and flow has been rock solid. My YIO-540-D4A5 had two threaded holes in the sump where I installed a piece of angle. I installed the cube there using black baffle material to isolate it from vibration. Tom Swarengen (TS FlightLine) made all my fire sleeved lines. No issues to date.

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|