|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

JonathanMilbank

Joined: 14 Apr 2012

Posts: 390

Location: Aberdeen area

|

Posted: Thu Jan 30, 2020 5:42 am Post subject: CKT exhaust springs breaking Posted: Thu Jan 30, 2020 5:42 am Post subject: CKT exhaust springs breaking |

|

|

Over the last couple of years, my CKT exhaust system fitted to a Europa with Rotax 912ULS has broken a few springs and not in the same location each time. I never seem to be able to fly for more than about 30 hours before I find another broken spring, each time with a short 1/2" straight piece remaining after the hook has disappeared. The coils never break.

As per CKT instructions, I never use metal tools like vice grips and only use a plastic cable tie for pulling the spring onto the welded anchors. The last time when I replaced a spring, I cut lengths of old metal hydraulic brake tube to fit inside the spring coils before passing locking wire through for safety. This attempt at vibration damping obviously didn't prevent another breakage.

The aircraft carburettors are well balanced using Carbmate and the Airmaster propeller is also well balanced, so my aircraft runs "sewing machine" smoothly. The replacement springs from CKT were bought as a packet of 8, if I recall correctly and are the simple type with a hook at each end.

I'm also considering to copy the 2-stroke microlight flyers, by wiping a thick bead of high temperature silicone rubber sealant along the length of the spring coils on the side furthest from the exhaust header tubes, which after setting will hopefully act as a vibration damper. Dow Corning Momentive RTV106 red silicone sealant is what I have in mind and works at a temperature of up to 260C ( 500F ).

Your advice please, thanks.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

tennant

Joined: 19 Apr 2011

Posts: 121

|

Posted: Thu Jan 30, 2020 7:29 am Post subject: Re: CKT exhaust springs breaking Posted: Thu Jan 30, 2020 7:29 am Post subject: Re: CKT exhaust springs breaking |

|

|

Hi Jonathan,

I had a similar experience in the beginning but not with a CKT exhaust. The springs were stainless steel. Stainless steel does not like contact vibration and the constant contact microwelding quickly rubs through the wire. I have used galvanised spring steel for about 15 years without a breakage.

Don't ask where I got them as it must have been some DIY store!!

Your idea of a silicone damper sounds like a good idea though.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Barry Tennant

D-EHBT

At EDLM - Germany |

|

| Back to top |

|

|

clivesutton

Joined: 23 Jan 2013

Posts: 187

Location: KENILWORTH

|

Posted: Thu Jan 30, 2020 7:53 am Post subject: Re: CKT exhaust springs breaking Posted: Thu Jan 30, 2020 7:53 am Post subject: Re: CKT exhaust springs breaking |

|

|

Hi Jonathan,

I've had the same problems for some time - and they persist despite trying more than 1 CKT design of spring, lining the 'hole' down the middle of the spring with silicone tubing held in place by a combination of Red silicone and adding a length of central locking-wire as you describe.

In an effort to try and get to the bottom of the problem I have measured the natural frequency of the 8 springs fitted (try recording the twang emitted when you ping the springs, with your mobile phone on the ground) - so that i can draw up a Campbell Diagram - that compares the spread of spring resonances with the forcing frequencies generated by the engine (i did this stuff for a living once). Here is an example diagram that possibly illustrates the concept better than my text: https://www.originlab.com/www/products/GraphGallery.aspx?GID=130

The idea is that the natural frequencies of these springs [like everything else on the aircraft btw], sit waiting for excitation by forcing at the same frequency - in our case, by an out-of-balance (OOB) force from the engine (these OOB forces are normal - though relatively small, in all engines btw).

Typically, when something goes into resonance, just a small level of excitation can result in a large motion - and a commensurate increase in the amount of strain, and therefore stress, in a component - depending on how it is mounted and how it is vibrating. Excessive vibration does not always result in breakage, it may just be irritating of course.

The implication/potential remedy is that there are probably a few engine speeds that are best avoided for e.g. cruising - if we are to avoid exciting the exhaust springs into resonance.

BTW, i also notice that the points between my springs and their exhaust pipe/silencer 'hook stubs' are worn away/thinner - which hints at the failure mode. My gut feeling is that in addition to the heat in service and possible fatigue damage initiation caused by e.g. use of a screwdriver to fit a spring [which like you, i never do], material thickness reduction is probably what happens to induce a spring to 'let go'. With this in mind, I have been playing with putting a blob of CKT's graphite exhaust socket grease in this area - but the results are inconclusive so far.

Damping = generally good, as it generally reduces the levels of vibration amplitude, though it also can 'lower' the frequency of resonance as well.

Apologies, a bit of an edict . . . More to follow.

Clive

G-YETI

PS: i checked my CKT springs and they exert a static force of 10 newtons per 1.0mm of extension

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

cakeykev(at)gmail.com

Guest

|

Posted: Thu Jan 30, 2020 8:03 am Post subject: CKT exhaust springs breaking Posted: Thu Jan 30, 2020 8:03 am Post subject: CKT exhaust springs breaking |

|

|

I have had lots of CKT springs break. I have tried heat resistant silicon made no difference. I have a complete spare set in the aircraft and change regularly.

I was told it was an old problem and the new springs would be ok. They aren’t and I am glad it’s not just me experiencing issues.

Engine is smooth with no different vibrations than any other 912ULS.

Kevin Challis

| Quote: | On 30 Jan 2020, at 16:33, tennant <barrington.tennant(at)gmail.com> wrote:

Hi Jonathan,

I had a similar experience in the beginning but not with a CKT exhaust. The springs were stainless steel. Stainless steel does not like contact vibration and the constant contact microwelding quickly rubs through the wire. I have used galvanised spring steel for about 15 years without a breakage.

Don't ask where I got them as it must have been some DIY store!!

Your idea of a silicone damper sounds like a good idea though.

--------

Barry Tennant

D-EHBT

At EDLM - Germany

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=494527#494527

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

SPURPURA

Joined: 04 Apr 2015

Posts: 68

Location: KAPV

|

Posted: Thu Jan 30, 2020 2:20 pm Post subject: Re: CKT exhaust springs breaking Posted: Thu Jan 30, 2020 2:20 pm Post subject: Re: CKT exhaust springs breaking |

|

|

I have over 500 hours on my 912s and some of its stainless springs are wearing a bit. When I replace them I’ll use part # 3114T111 from McMaster Carr. My hooks are 4” apart. I think the black oxide will be better as Rotax sells these for replacement at a much higher price.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

N951EU - Tri-gear & 912ULS, N77EU- Mono & 914

I'D RATHER HAVE A BOTTLE IN FRONT OF ME THAN A FRONTAL LABOTAMY. |

|

| Back to top |

|

|

Remi Guerner

Joined: 14 Dec 2010

Posts: 284

|

Posted: Fri Jan 31, 2020 1:06 am Post subject: Re: CKT exhaust springs breaking Posted: Fri Jan 31, 2020 1:06 am Post subject: Re: CKT exhaust springs breaking |

|

|

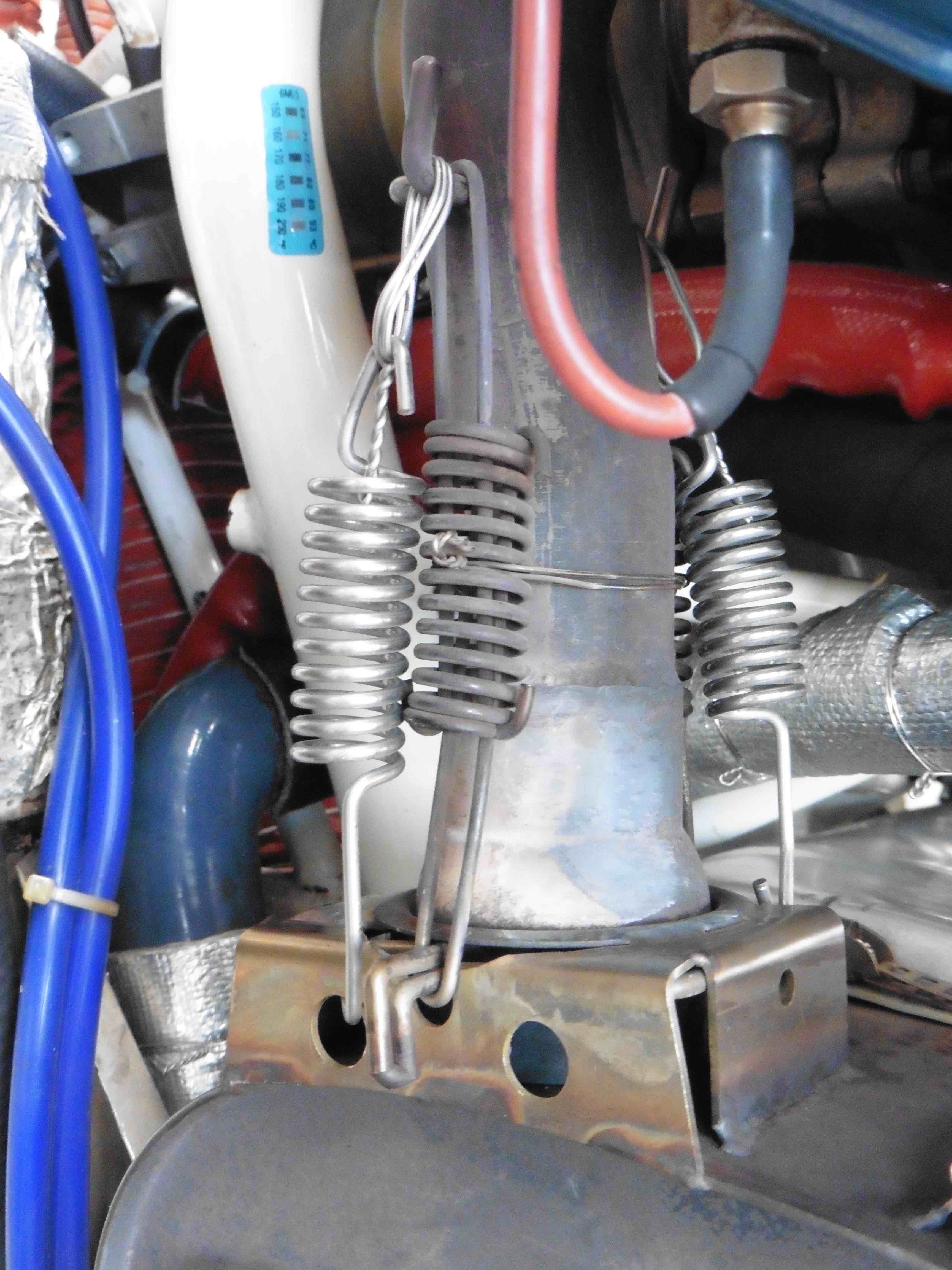

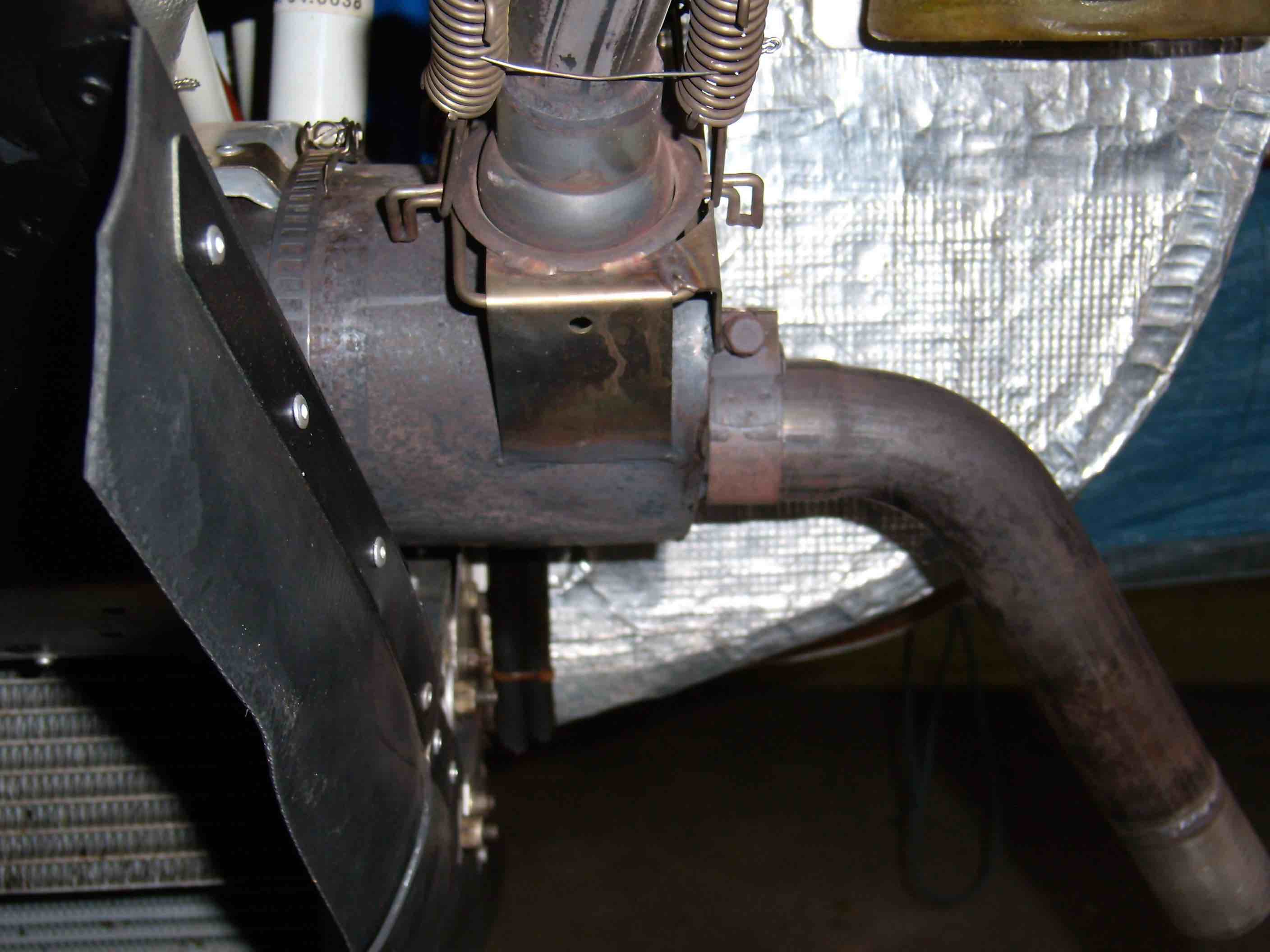

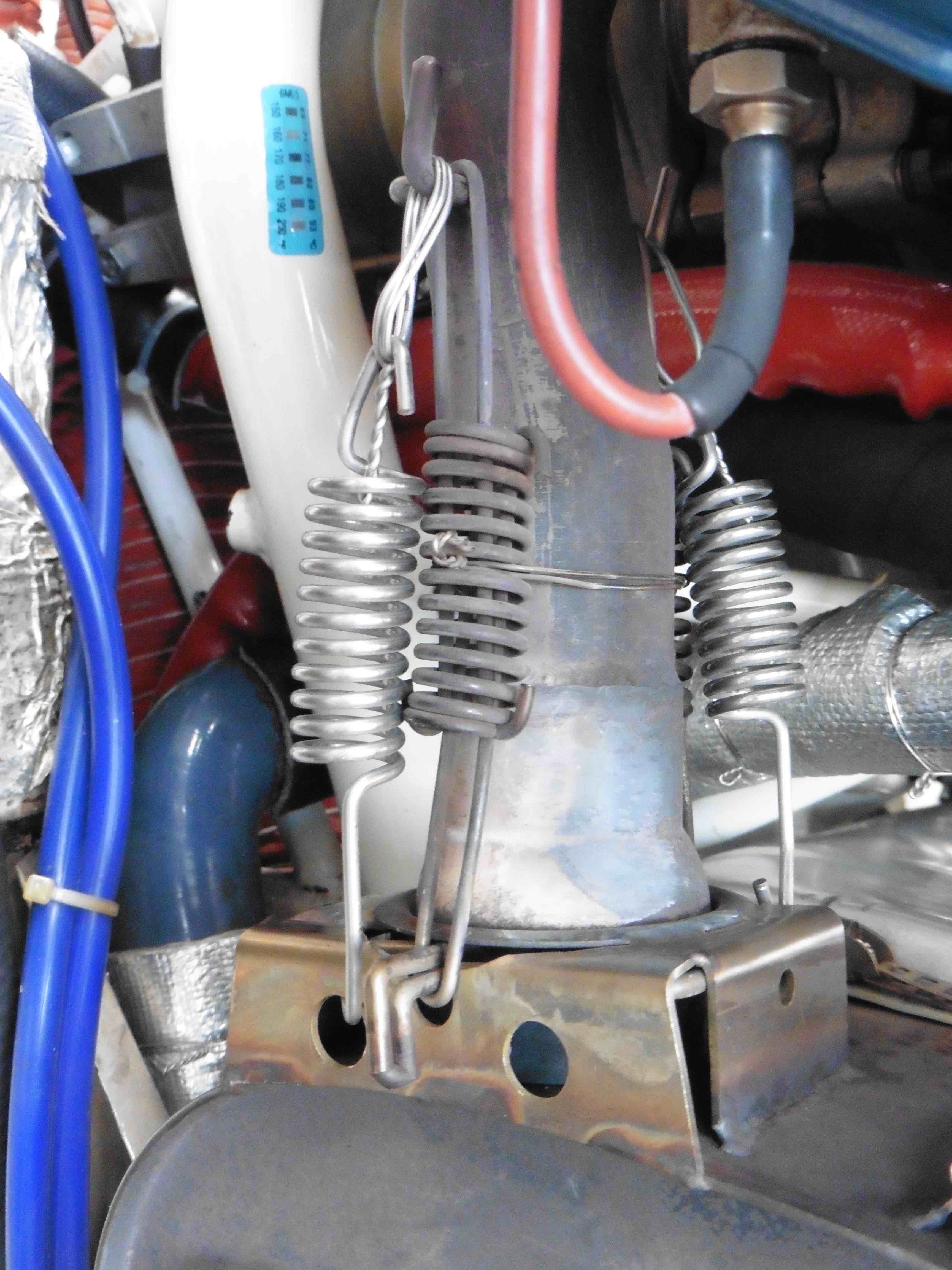

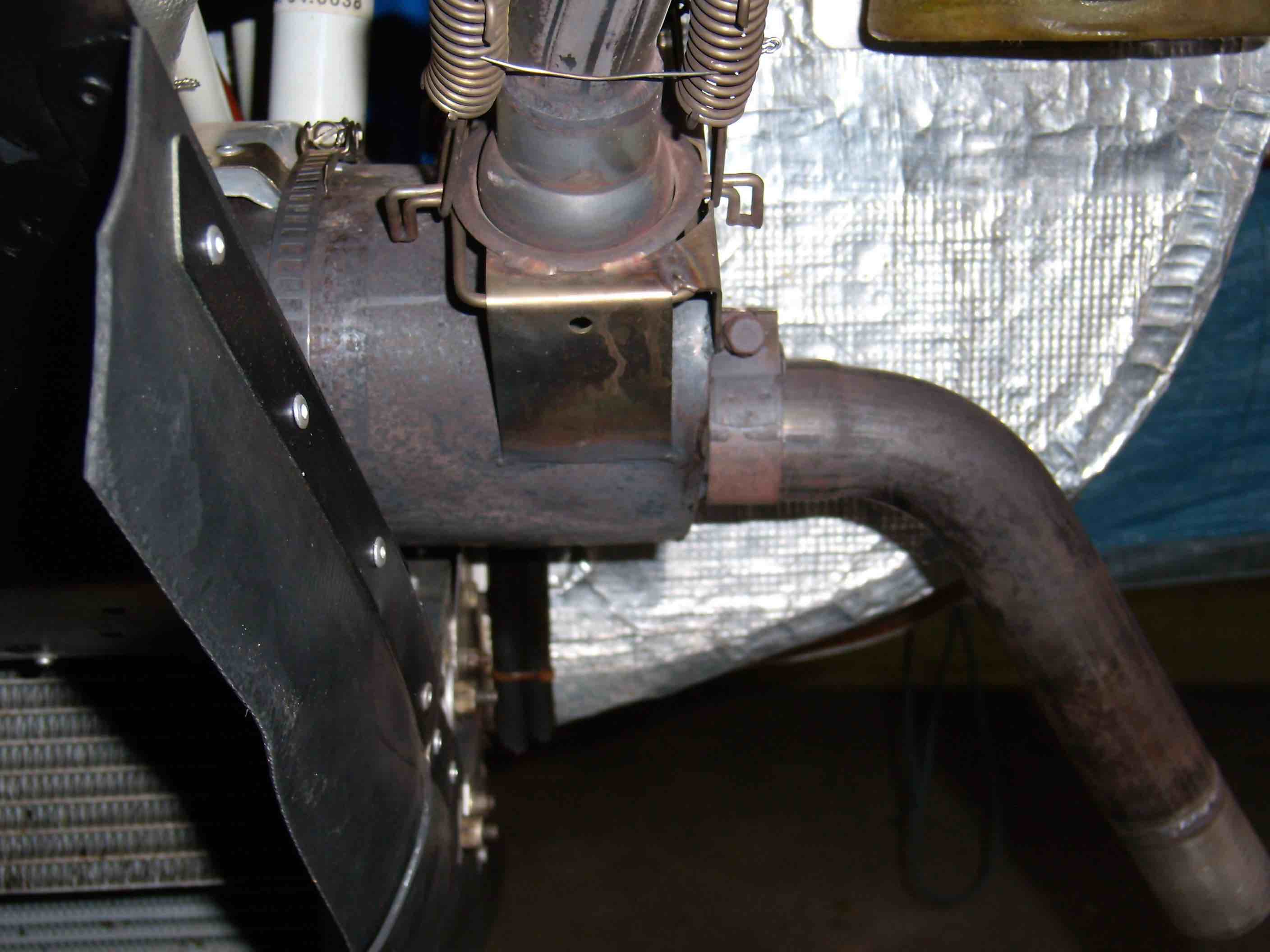

The CKT exhaust on my 912ULS has done 1300 hours without any spring failure so far. The springs are maintained by a safety wire loop which prevent them from vibrating, pic attached. However, I had a consistent leak at the spherical joint on cylinder 3 pipe. I solved that problem using 2 additional springs on that pipe to increase the pressure on the joint. The those two springs are attached using safety wire which allows to adjust the tension.

I believe that the use of 4 springs per pipe with properly adjusted tension could be a solution to also reduce the load per spring, therefore preventing breakage and increase redundancy.

Remi

F-PGKL

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

531.67 KB |

| Viewed: |

8972 Time(s) |

|

| Description: |

|

| Filesize: |

180.17 KB |

| Viewed: |

8972 Time(s) |

|

|

|

| Back to top |

|

|

Bill & Sue

Joined: 10 Jan 2006

Posts: 48

Location: Malvern, Worcs. UK (Defford, Croft Farm)

|

Posted: Fri Jan 31, 2020 1:56 am Post subject: Re: CKT exhaust springs breaking Posted: Fri Jan 31, 2020 1:56 am Post subject: Re: CKT exhaust springs breaking |

|

|

I don't have a solution for (not) breaking springs other than carrying spares, but I have found that buying Rotax springs from a Karting shop is rather cheaper. Same spring, less than half the price....

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

JonathanMilbank

Joined: 14 Apr 2012

Posts: 390

Location: Aberdeen area

|

Posted: Fri Jan 31, 2020 6:40 am Post subject: Re: CKT exhaust springs breaking Posted: Fri Jan 31, 2020 6:40 am Post subject: Re: CKT exhaust springs breaking |

|

|

What marvellous responses in such a short time, from so many of you! This underscores the great value of continuing to support Matt's website.

Being inherently lazy and not wishing to try out all of your suggestions simultaneously, I'll start with Remi's suggestion which seems either to dampen resonant vibrations, or perhaps to divide each spring into two lengths with much higher resonant frequencies.

Many thanks to all of you.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Gary.Leinberger(at)miller

Guest

|

Posted: Fri Jan 31, 2020 8:50 am Post subject: CKT exhaust springs breaking Posted: Fri Jan 31, 2020 8:50 am Post subject: CKT exhaust springs breaking |

|

|

I had the same problem until I ran a bead of the Dow Corning Momentive RTV106 red silicone sealant. Problem solved - haven't broken one since.

Gary Leinberger

A237

Europa High Top XS with 912S

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rowlandcarson(at)gmail.co

Guest

|

Posted: Fri Jan 31, 2020 11:58 am Post subject: CKT exhaust springs breaking Posted: Fri Jan 31, 2020 11:58 am Post subject: CKT exhaust springs breaking |

|

|

On 2020-01-31, at 16:47, Gary Leinberger <Gary.Leinberger(at)millersville.edu> wrote:

| Quote: | I had the same problem until I ran a bead of the Dow Corning Momentive RTV106 red silicone sealant. Problem solved - haven't broken one since.

|

Gary - exactly where did you run the bead of silicon RTV? A picture would be great!

in friendship

Rowland

| Rowland Carson ... that's Rowland with a 'w' ...

| <rowlandcarson(at)gmail.com> http://www.rowlandcarson.org.uk

| Skype, Twitter: rowland_carson Facebook: Rowland Carson

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|