|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Sun May 03, 2020 7:20 am Post subject: DC clamp meter Posted: Sun May 03, 2020 7:20 am Post subject: DC clamp meter |

|

|

Looking for recommendations on a suitable DC clamp meter to do capacity checks on my EarthX batteries. Prices seem to be all over the place. Am curious what kind others might be having good experience with. Thanks all!

Dave

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sun May 03, 2020 6:27 pm Post subject: DC clamp meter Posted: Sun May 03, 2020 6:27 pm Post subject: DC clamp meter |

|

|

At 10:20 AM 5/3/2020, you wrote:

| Quote: | --> AeroElectric-List message posted by: "blues750" <den_beaulieu(at)yahoo.com>

Looking for recommendations on a suitable DC clamp meter to do capacity

checks on my EarthX batteries. Prices seem to be all over the place.

Am curious what kind others might be having good experience with. Thanks all!

Dave |

Help us out with your mission. A 'capacity test' is

a measured depletion and recharge of a battery

to deduce its contained energy.

This could be accomplished at a prescribed discharge

rate commensurate with your anticipated 'endurance

loads' (useful capacity of a battery varies with

load).

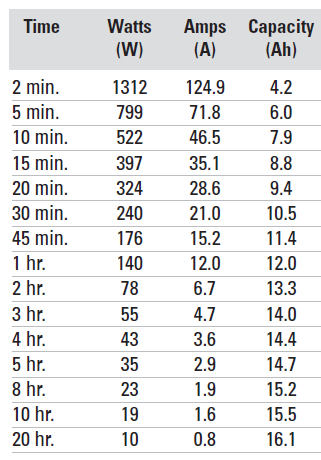

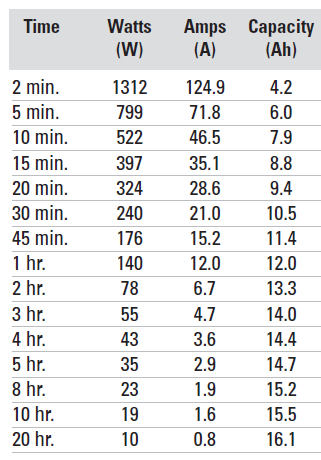

In the attached chart you can see how a battery

rated at 18Ah under a 20Hr discharge rate

delivers only 12Ah if discharge over 1Hr rate.

2/3rds of its capacity is tossed off as internal

heating of the battery.

To accomplish a capacity test, you need a means

for establishing a constant current load at

some selected rate while recording the battery's

output voltage until it falls below some

artfully selected cut-off voltage.

Alternatively, consider a device like

this:

https://tinyurl.com/moaoaus

I have used these on numerous projects

over the years. I'm thinking of upgrading

my 20+ year old device. The newer ones

have some really nice software features.

I'm wondering if you're interested in the

battery's cranking (load bearing) characteristics.

This is a different test that quantifies the

battery's internal resistance -and- state of

the chemistry under heavy load.

For this you need a critter like this

https://tinyurl.com/yag4529y

I have a couple of these HF testers . . .

got a $high$ AutoMeter tester too but

the el-cheeso works just fine for our

purposes.

You hook this to your battery under test.

Just before you crank up the load such that

battery voltage falls to 9V, push the 15

second timer button. Adjust load

during the 15 second interval

to maintain 9V reading. Take note of

the CURRENT delivered by the battery

at the end of 15 seconds.

Acquire this benchmark value for a new

battery. Note the value with a sharpie

on the battery case along with date.

At any later time, should the battery

perform to less than 80% (*) of new,

consider replacing the battery. Same

thing goes with capacity checks 80%

is the 'retirement' value for

batteries in TC, flight-for-hire aircraft.

(*) Of course, you CAN establish your own

benchmarks if some other numbers make

more sense for how you operate your airplane.

But pick other numbers based on understanding,

not because your trying to squeeze more

service out of the battery.

EARTHX batteries (and all other LIFePO4

batteries) are special cases. Your load

test value will probably be more than

9V . . . internal resistance of these

batteries is very low and you probably

can't load it down to 9v without

tripping internal current limits.

If you want to capcheck your EARTHX,

fire up your airplane's anticipated

endurance mode accessories and measure

the time before auto-disconnect. Make

note of that time for the new battery.

Think about replacing the battery when

those minutes fall by 25% or so.

As for DC clamp-on ammeters, they've

been around for some time. I have

a Fluke meter I bought about 20 years

ago . . . hall-effect device . . . works

mostly okay for large measurements

(10+ amps) but flakiness typical of

contemporary technology at low current

levels.

I have one like this

https://tinyurl.com/y9gb4cgs

. . . but haven't had much occasion to

exercise it's capability. It has a

ZERO read function on DC amps that

wipes out most of the variability

in the hall-sensor at low current

readings. Seems to work well. Will follow

up when I've learned more . . . but

the price/performance numbers are

certainly attractive.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

35.55 KB |

| Viewed: |

10091 Time(s) |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Mon May 04, 2020 9:12 am Post subject: Re: DC clamp meter Posted: Mon May 04, 2020 9:12 am Post subject: Re: DC clamp meter |

|

|

"Help us out with your mission."

Hi Bob, I simply want to put a typical inflight load on the fuly charged battery and perform the below method /test as my benchmark for battery capacity check and/or replacement. When at 80% of the benchmark, replace battery. I was going to use old style truck headlight bulbs for a resistive load. Cranking capacity is not a significant concern for my style of flying operation... (famous last words?) Thanks for input and reply so far!!

From the Earth FAQ's listing...

Test Method #2 (with timer and DC current meter):

a. Fully charge the battery with an appropriate charger.

b. Turn on all electrical loads and start a timer. The same load must be used in subsequent years for accuracy.

c. Measure and record the battery’s discharge amps using a DC clamp-on current meter at the positive terminal of the battery.

d. Using the measured amps in the previous step and the battery’s nameplate rated capacity (in Ah), calculate the time to discharge the battery to 80%.

Time to Discharge 80% (Hours)=Rated Capacity in Ah * .8Measured Discharge Amps

For Example (16 Ah Rated Capacity, 5 amp measured discharge rate)

Time to Discharge 80%=16 Ah * .85= 2.56 hours

e. Terminate the test after the number of hours calculated in the previous step has expired or if the battery is over-discharged (shuts off discharge current). If the battery is still supplying power at the termination of the test, then the battery’s capacity is greater than 80%. If the battery’s capacity is greater than 80% of it rated or capable of supporting the aircraft’s emergency load for the required amount of time, then the battery has passed the test.

f. Fully charge the battery with an appropriate charger.[/i]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue May 05, 2020 8:56 am Post subject: DC clamp meter Posted: Tue May 05, 2020 8:56 am Post subject: DC clamp meter |

|

|

At 12:12 PM 5/4/2020, you wrote:

| Quote: | --> AeroElectric-List message posted by: "blues750" <den_beaulieu(at)yahoo.com>

"Help us out with your mission."

Hi Bob, I simply want to put a typical inflight load on the fuly charged battery and perform the below method /test as my benchmark for battery capacity check and/or replacement. When at 80% of the benchmark, replace battery. I was going to use old style truck headlight bulbs for a resistive load. Cranking capacity is not a significant concern for my style of flying operation... (famous last words?)

>From the Earth FAQ's listing...

Test Method #2 (with timer and DC current meter):

a. Fully charge the battery with an appropriate charger.

b. Turn on all electrical loads and start a timer. The same load must be used in subsequent years for accuracy.

c. Measure and record the battery’s discharge amps using a DC clamp-on current meter at the positive terminal of the battery.

d. Using the measured amps in the previous step and the battery’s nameplate rated capacity (in Ah), calculate the time to discharge the battery to 80%.

Time to Discharge 80% (Hours)=Rated Capacity in Ah * .8Measured Discharge Amps

For Example (16 Ah Rated Capacity, 5 amp measured discharge rate)

Time to Discharge 80%=16 Ah * .85= 2.56 hours |

If one is going to test the battery in-situ, i.e.

on the airplane with plan-b endurance loads running,

then the exact current demand is somewhat irrelevant

to the test. Just time the interval until electro-

whizzies shut down. That time represents the present

capacity-at-plan-b-load. You can do that with a

new battery to benchmark T1. The replacement

milestone would be at T0.80 of the as-new value.

You should measure or accurately calculate plan-b

loads to (1) predict plan-b endurance based on

battery specifications and (2) verify the battery's

capabilities at the time of your benchmark

test on a new battery.

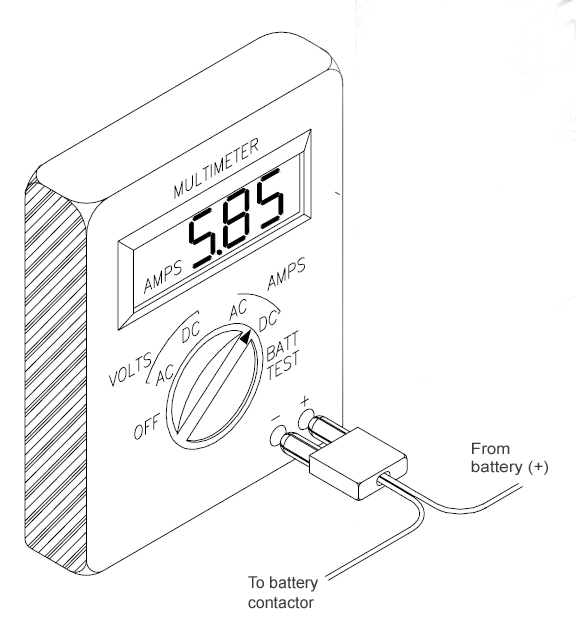

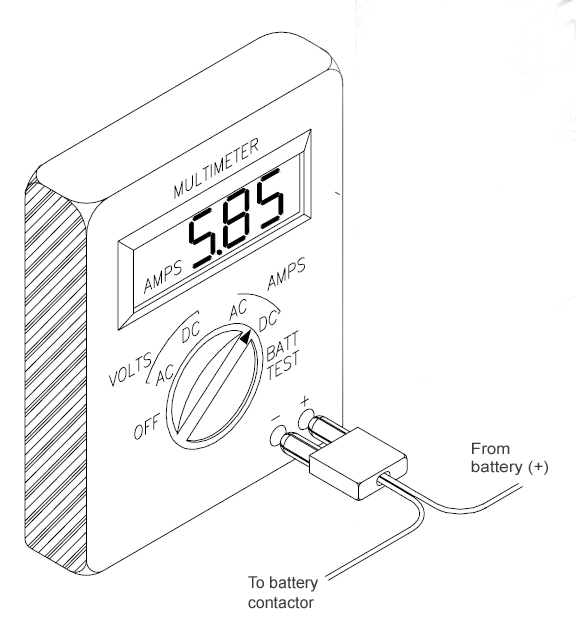

You can easily measure plan-b loads by inserting

an ammeter in series with your battery lead and

turning on the plan-b compliment of electro-

whizzies. This is a good thing to do to verify

your load analysis values.

| Quote: | e. Terminate the test after the number of hours calculated in the previous step has expired or if the battery is over-discharged (shuts off discharge current). If the battery is still supplying power at the termination of the test, then the battery’s capacity is greater than 80%. If the battery’s capacity is greater than 80% of it rated or capable of supporting the aircraft’s emergency load for the required amount of time, then the battery has passed the test.

f. Fully charge the battery with an appropriate charger.[/i] |

The Earth-X testing is okay but I think

overly complicated. YOUR primary interest

as the guy sitting in the left seat is

"how long will the panel stay lit up"?

Doing the in-situ test tells you what the

battery will do right now. The 80% value

is a somewhat arbitrary number established

by convention and experience with rechargeable

batteries (when a battery drops to 80% of

as new capacity, it's on the down-hill-slide

toward useless).

Your multimeter probably has a 10 amp DC

current measurement capability that can be

used to quantify your real, plan-b loads.

You don't need to buy a special instrument

for this measurement.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

111.42 KB |

| Viewed: |

10025 Time(s) |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Wed May 06, 2020 5:17 pm Post subject: Re: DC clamp meter Posted: Wed May 06, 2020 5:17 pm Post subject: Re: DC clamp meter |

|

|

Bob, I cannot imagine how to go about doing the voltmeter method with an electrical dependent engine running...hence my plan...

Once batteries are charged my normal inflight electrical load is approx 20 amps when not using pitot heat. This is consistent with my predicted load analysis. I have a dual ECU electrically dependent engine which requires approx 13 amps to keep me flying (derived from the engine manufacturer's chart). By shutting down one ECU and a few other items I can safely continue flight and recover to an airfield or suitable airstrip (day VMC) with about the same electrical load of 13 amps.

My plan was to test each battery separately with a 15 amp load (hence the need for a DC clamp meter) and see how long I got energy from the battery before the voltages dropped off below 10V (ECU/engine quitting time) or the EarthX BMS shuts down due to over discharge. As I've already got a few flying seasons on the batteries, I can only compare my discharge amp-hrs to the battery specs and then use the 80% factor for battery changeout.

Does this sound like a reasonable way to do a meaningful capacity check? It does to me, but what the heck may I be missing? Seems like the hardest thing to do will be rigging up the resistive dummy load (open for ideas) so I can consistently do the load test per battery year to year.

Thanks again for the insight and ideas!!

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

gilles(at)elixir-aircraft

Guest

|

Posted: Wed May 06, 2020 5:41 pm Post subject: DC clamp meter Posted: Wed May 06, 2020 5:41 pm Post subject: DC clamp meter |

|

|

Le 07/05/2020 à 03:17, blues750 a écrit :

| Quote: |

Bob, I cannot imagine how to go about doing the voltmeter method with an electrical dependent engine running...hence my plan...

Once batteries are charged my normal inflight electrical load is approx 20 amps when not using pitot heat. This is consistent with my predicted load analysis. I have a dual ECU electrically dependent engine which requires approx 13 amps to keep me flying (derived from the engine manufacturer's chart).

|

Performing actual voltage and current measurements at cruise power would

be interesting.

It can safely be done on the ground.

FWIW,

--

Best regards,

Gilles

http://contrails.free.fr

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri May 08, 2020 6:04 pm Post subject: DC clamp meter Posted: Fri May 08, 2020 6:04 pm Post subject: DC clamp meter |

|

|

| Quote: | | Does this sound like a reasonable way to do a meaningful capacity check? It does to me, but what the heck may I be missing? Seems like the hardest thing to do will be rigging up the resistive dummy load (open for ideas) so I can consistently do the load test per battery year to year.\ |

Okay, got a tighter box around your goal. Probably

doesn't need to be that complicated. You know your

endurance loads to a reasonable degree of accuracy.

The really cool thing about Li batteries is their

very FLAT discharge curve as a consequence of low

internal resistance. This means that energy delivered

to the terminals is relatively constant irrespective

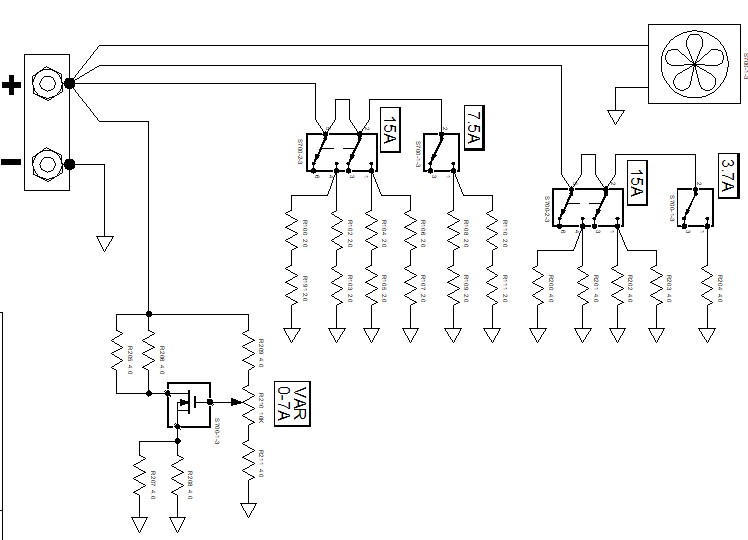

of load. So consider getting some of these.

https://tinyurl.com/ydg62u2r

an order of 5 pcs is about 8 bux delivered to your

door. Mount 4 of these to a chunk of aluminum say

6 x 6 inches or so. .06 or more thick. Space them

out over the surface. Hook all four in parallel

to make a robust, 1.0 ohm resistor.

This resistor connected to one of your batteries

will discharge right at 12.5 amps. Time the interval

to discharge limit with this load.

Since you have quite a bit of time on these

batteries, you don't have an as-new benchmark

but you now have as-is benchmark.

Maybe the a.h. number isn't really that

useful. Rather, it's time to trip

the discharge limiter. That's pretty close

to your as-is endurance value. When

that number is below design goals, change

the battery.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

racerjerry

Joined: 15 Dec 2009

Posts: 202

Location: Deer Park, NY

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Mon May 11, 2020 4:54 pm Post subject: Re: DC clamp meter Posted: Mon May 11, 2020 4:54 pm Post subject: Re: DC clamp meter |

|

|

Bob, finally able to do the calculation on how you get a 1 OHM equivalent resistor out of the four resistors rated at 4 ohms in parallel along with power dissipation through the resistors...what a blast from the past! Thank you so much for the help and interest. I can't wait to get some data!

Dave (most appreciative novice experimentalist)

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon May 11, 2020 7:20 pm Post subject: DC clamp meter Posted: Mon May 11, 2020 7:20 pm Post subject: DC clamp meter |

|

|

At 07:54 PM 5/11/2020, you wrote:

| Quote: | --> AeroElectric-List message posted by: "blues750" <den_beaulieu(at)yahoo.com>

Bob, finally able to do the calculation on how you get a 1 OHM equivalent resistor out of the four resistors rated at 4 ohms in parallel. What a blast from the past! I'll take your word on the Power rating being suitable!! Thank you so much for the help and interest. I can't wait to get some data!

|

Yup . ..

1

RT = ====================================

1 1 1 1

____ _____ _____ ______

R1 R2 R3 Rx

Rtotal equals the reciprocal of the SUM

of reciprocals of all resistors in the

array . . . no matter how many resistors.

It just so happened that your target current

worked out close to a 1-ohm load . . . so

the array of 4 x 4 ohms works nicely.

The total wattaged needed is much less than

to total ratings of thsoe four resistors.

They're offered as 100W devices . . . but

in practice, they're closer to 50W when

adequately heat-sinked. So the sum total

of the 4 is comfortably good for 200W.

You only need 13A x 13v is 169W.

This bucket-o-resistors technique is

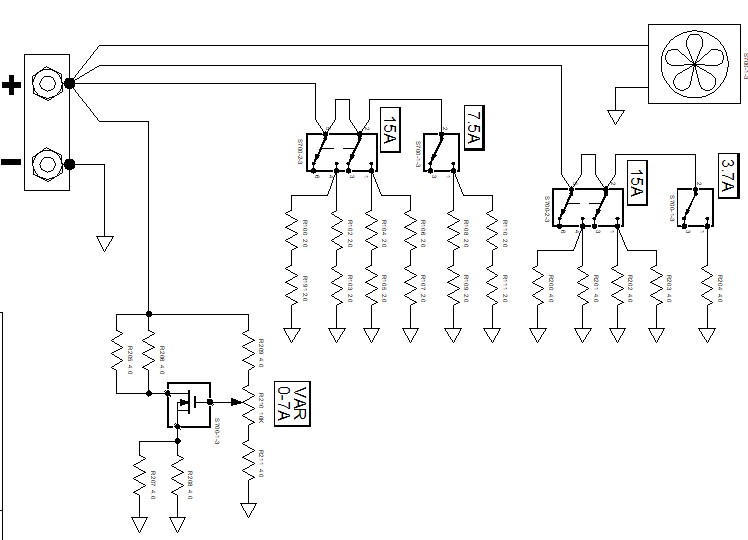

very versatile. For example, a couple

years ago I crafted a portable, 750

watt, variable load bank for the purpose

of airborne cooling tests on alternators.

An array of 21 resistors not unlike the

ones I suggested plus a handful of components

and a fan made for a device that would

offer loads from 0 to approx 50A fan

cooled.

I've used this technique to craft load banks

up to 2800 watts (28v, 100A) . . . with

a lot more resistors and a bigger fan . . .

but knob-adjusted at the control panel.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

140.7 KB |

| Viewed: |

9807 Time(s) |

|

| Description: |

|

| Filesize: |

62.41 KB |

| Viewed: |

9807 Time(s) |

|

|

|

| Back to top |

|

|

blues750

Joined: 06 Jun 2015

Posts: 56

|

Posted: Wed May 13, 2020 10:02 am Post subject: Re: DC clamp meter Posted: Wed May 13, 2020 10:02 am Post subject: Re: DC clamp meter |

|

|

Bob, that's pretty clever. In my case how "fancy" should I go? For connections to the load from the battery, I was thinking of simply using two leads of #10 wire with alligator clips on both ends and having an inline fuseholder on one lead with a 15A fuse. Or...do I fabricate a switched/fused platform, with ring terminals for connections, etc? User preference?

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|