|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

johnbright

Joined: 14 Dec 2011

Posts: 165

Location: Newport News, VA

|

Posted: Tue May 12, 2020 9:19 am Post subject: crimp multiple wires into one terminal Posted: Tue May 12, 2020 9:19 am Post subject: crimp multiple wires into one terminal |

|

|

Hi Bob,

I've seen how you crimp four 22 awg wires into one red (18-22AWG) PIDG terminal and I wonder if this is OK with larger wires and wires of different gages. http://www.aeroelectric.com/articles/multiplewires/multiplewires.html

I'm thinking for example to put a 10 awg and a 4 awg together to save stack height on a contactor or battery stud.

Thanks,

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

John Bright, RV-6A, at FWF, O-360

Z-101 single batt dual alt SDS EM-5-F.

john_s_bright@yahoo.com, Newport News, Va

N1921R links |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue May 12, 2020 11:26 am Post subject: crimp multiple wires into one terminal Posted: Tue May 12, 2020 11:26 am Post subject: crimp multiple wires into one terminal |

|

|

At 12:19 PM 5/12/2020, you wrote:

| Quote: | --> AeroElectric-List message posted by: "johnbright" <john_s_bright(at)yahoo.com>

Hi Bob,

I've seen how you crimp four 22 awg wires into one red (18-22AWG) PIDG terminal and I wonder if this is OK with larger wires and wires of different gages. http://www.aeroelectric.com/articles/multiplewires/multiplewires.html

I'm thinking for example to put a 10 awg and a 4 awg together to save stack height on a contactor or battery stud. |

The car-guys do it all the time . . . well . . .

not exactly 'crimped' but it's common to bring

two (or more), largely different gage wires into the same

termination.

You have two design goals:

(1) gas-tight connection between conductor

stranding and the terminal's wire grip barrel.

(2) insulation support to minimize flexing

of the stress riser represented by the

transition from solid (in the grip) to

stranded (in the insulation).

The article I posted about 25 years ago

is still an excellent approach to your

mission:

https://tinyurl.com/ct36xen

This technique is much less critical of

wire/terminal/tool sizing. With the stuff-n-

solder technique, your wire grip can be

quite tight on stranding. In fact, you

purposely 'wedge' the stranding until they

are tight.

Then fill voids in the grip with solder.

Step (1) done.

Finish up with one, perhaps two heat-shrink

sleeves over the terminal and wire to provide

some environmental protection and add mechanical

support. Step (2) done.

I'd stay with welding cable for the really

fat wires . . . tefzel is okay for the smaller

stuff.

Post some pictures of what you end up with.

The fat-wire article could stand to be updated

to include the process you've asked about.

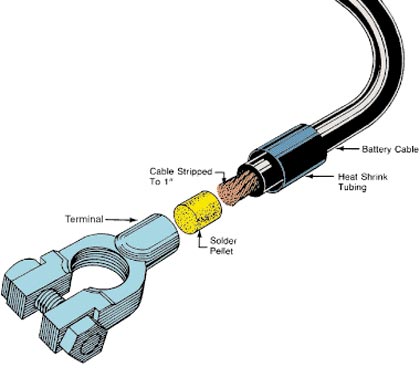

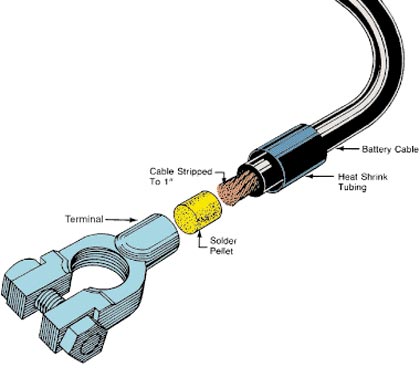

By the way, while surfing for a picture

of a two-wire battery cable, I found what

appears to be an aftermarket product for

replacing battery-post terminal-ends with

. . . who wuda thunk it . . . SOLDERED

attachement.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

15.37 KB |

| Viewed: |

3105 Time(s) |

|

| Description: |

|

| Filesize: |

16.8 KB |

| Viewed: |

3105 Time(s) |

|

|

|

| Back to top |

|

|

johnbright

Joined: 14 Dec 2011

Posts: 165

Location: Newport News, VA

|

Posted: Thu May 14, 2020 7:14 pm Post subject: Re: crimp multiple wires into one terminal Posted: Thu May 14, 2020 7:14 pm Post subject: Re: crimp multiple wires into one terminal |

|

|

Thanks for the detailed reply Bob.

I'm not far enough along yet but whenever I do get some photos I will post them. Another lister, Jeff Parker, is the one with the issue at present of not having enough stack height on either a battery or contactor stud. Jeff and I have been collaborating on implementing Z-101 onto our respective aircraft with SDS electronic injection and ignition.

Interestingly, Jeff was speaking with a jet aircraft repair technician who mentioned the solder pellet method of attaching a fat wire to a fat lug. This fellow recommended from his experience to crimp after soldering. (Bob responded to this to say don't crimp after soldering, ref http://forums.matronics.com/viewtopic.php?t=16775418&view=previous)

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

John Bright, RV-6A, at FWF, O-360

Z-101 single batt dual alt SDS EM-5-F.

john_s_bright@yahoo.com, Newport News, Va

N1921R links |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|