|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Jun 22, 2021 7:48 pm Post subject: Archer style wingtip antenna fabrication questions Posted: Tue Jun 22, 2021 7:48 pm Post subject: Archer style wingtip antenna fabrication questions |

|

|

At 12:03 PM 6/22/2021, you wrote:

| Quote: | I have an Archer wingtip comm� antenna I intend to install in one wingtip (can always add a 1/4 wave whip if needed), and I'm thinking about building the nav version detailed in Bob's 'Antennas & Feedlines chapter for the other wingtip (figure 13-12 in my document).

How critical is the material for the .032" x .8" x 3.25" bakelite insulator that forms what I'm guessing is a matching capacitor? Does the bakelite participate in any way in operation, or is it simply a way to get a fixed air gap?

Bakelite in that 'thinness' doesn't seem to be available without paying more for shipping than the 3-postage-stamp size needed would cost. What about� substituting something like the thin HDPE cutting board stock, available at discount stores? Two layers would be about .034" thick.� |

It IS critical . . . yes it forms the dielectric

for a capacitor used to series resonate the feeder

strut.

Bob must have conducted experiments to optimize

the characteristics of that capacitor with respect

to the matching strut for optimal mid-band impedance

match.

If it were my project, I'd use ANY available dielectric

material and conduct experiments over a ground plane

on the table to achieve (1) antenna resonance and

(2) best match to the feed line.

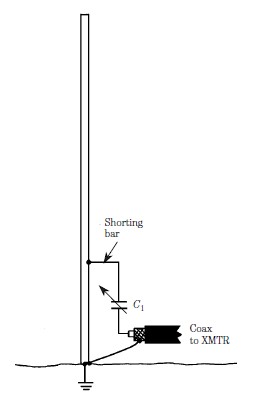

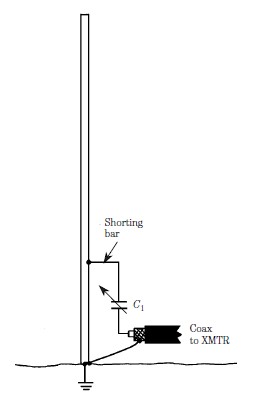

When I was a kid, a 'gamma match' was commonly

used to bring a feed line and antenna radiator

into functional harmony. The attached figure

illustrates an adjustable feeder strut paired

with a variable capacitor to feed a grounded

quarter-wave antenna.

My 10M, 2-element beam had such a feature that

was tuned with the aid of an SWR bridge. Today,

a vector network analyzer is the instrument

of choice and can cost less than a good SWR

meter.

After getting close on the bench, you can

confirm on the airplane to see if 'tweeking'

is called for. I've had readers assemble the

Archer wing tip antennas per drawings but found

it useful to trim dimensions per measured results.

Bob . . .

Un impeachable logic: George Carlin asked, "If black boxes

survive crashes, why don't they make the whole airplane

out of that stuff?"

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

7.94 KB |

| Viewed: |

1504 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Jun 23, 2021 8:30 am Post subject: Archer style wingtip antenna fabrication questions Posted: Wed Jun 23, 2021 8:30 am Post subject: Archer style wingtip antenna fabrication questions |

|

|

| Quote: |

If any dielectric is worth a shot, I think I'll try my flexible cutting board idea for a start. I've got a pack of them on the shelf, left over from another project (bearing surface for the round top tube of an aluminum hangar door). Package says 43% HDPE/57% EVA, and it's ~0.017" thick, so 2 layers will be pretty close in thickness, at least. How critical is tuning, for a receive-only Nav antenna? I do have a NanoVNA; I just need to learn how to use it.  |

The reason that any dielectric can be considered is

based on the physics of capacitors. The value of a

capacitor is proportional to area of the 'plates',

space between the plates, and dielectric constant

of the material.

Here's a comprehensive tutorial on the topic:

http://www.phys.uri.edu/gerhard/PHY204/slides8-phy204.pdf

In cases like this, one can estimate the value

of any particular capacitor fabrication with

the goal of duplicating Bob Archer's design

goals. It would be REALLY nice if we had

an Archer Original to measure the value of

his productions.

| Quote: | | Thanks for the offer on the dielectric, but let me give the cutting board a shot first. |

No problem. I thought about the cutting sheets

too but wondered if their flexibility might

compromise the mechanical integrity of Bob's

original design goal. But we're in experimental

waters here.

| Quote: | BTW, since this is a Nav antenna and can lie flat on the bottom of the wingtip,

I'm thinking I may try aluminum flashing (~0.008"), and slightly 'break' the

edges to stiffen it. Any issues with that, if width/length dimensions are maintained? |

Skin effects for current flow due to operating

frequency tell us that thickness of a conductor

has no practical influence on performance. It's

surface area and then only to a depth of .001"

or so. The primary concern for materials selection

are conductivity (aluminum and copper are good)

and mechanical robustness suited to the environment.

Bob's antennas were no more 'robust' than needed to

avoid falling apart or breaking.

Bob . . .

Un impeachable logic: George Carlin asked, "If black boxes

survive crashes, why don't they make the whole airplane

out of that stuff?"

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|