|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

budyerly@msn.com

Joined: 05 Oct 2019

Posts: 288

Location: Florida USA

|

Posted: Mon Nov 14, 2022 5:21 am Post subject: What did you do with your Europa this week - 08/11/22 Posted: Mon Nov 14, 2022 5:21 am Post subject: What did you do with your Europa this week - 08/11/22 |

|

|

The 80HP 912 was often bought with the 2.27 gearbox to spin a smaller prop a bit faster. Most 912S and 914s have the power to spin a larger prop but need a 2.43 to gear it down.

Way in the past a number of Canadians I knew flying Zodiaks had a 2.27 and were experimenting with prop diameters, pitch and such on only 87 octane fuel. As Will stated I guess the Columbians were doing the same. For an 80 HP engine to spin a larger diameter prop you have to taper the blades way down at the tip because the engine didn’t have the torque. Our Airmaster programming still includes the 2.27 as it is very popular still around the world. The prop spins faster but of course there are some compromises to be made as now the torque from the gearbox is lower.

When I started with the Europa, I worked one of the first monos with a 2.27 gearbox. It would only swing a 62 inch highly tapered WD blade. It did fine. If you install a turbo a 1300 cc engine and run the boost to 5 pounds it will turn a larger prop, but it needs a 2.43 gearbox or the blade still must be very short. But as in my ” Choosing the best prop for your Rotax” article nothing good happens after 67 inches on a Rotax (with a 2.43 gearbox). Even a 2.43 geared 912S can’t swing a wide chord prop over 67 inches and get maximum thrust or acceptable cruise performance. I know some guys have a 75 inch prop but it is disgustingly slow and the pitch barely changes in a constant speed hub. It is OK for STOL but nothing else. Today we have prop blade manufacturers using better aero programs for their propeller blades and cross sections, they have highly tapered “scimitar” tip shapes and greatly reduce the twist at the tip which greatly reduces the tip drag and as a result of the lower tip loading, one can go up to 70 inches fixed pitch but for high cruise or in a constant speed hub, I still find 64-68 inches even on a scimitar blade, is about the max diameter to get the highest cruise speed. (My website https://www.customflightcreations.com has more info and articles.

As for carbs, get over it. If you properly balance the engine tune, the carbs and ignition modules will not shake, and if you use good gas, the carbs will not corrode or clog up. I replaced my carbs about 10 years ago ( I had a scored barrel for some reason (probably some FOD) and I have yet to have to retune them. Clean the bowls, check the floats on a scale (because there are still a few bad ones in the system it appears) clean it up (mine don’t get dirty but do get oily) and reassemble. I don’t pull the fuel lines off the 914 carby, I remove the lines from the regulator as in my troubleshooting guide. I leave the lines and the throttle/choke cables and simply inspect (because the book says to) and look for issues. Normally if I don’t fly often enough, oil from the tubo is slung into the carbs and a bit of carb cleaner removes the oily slimy film. Reinstall and start up. Normally I don’t even have to touch the stops. At 200 hours, I do a full rebuild, it takes me a day because I dunk my carbs in a heated ultrasonic cleaner every two years (I like shiny brass parts), then clean and dry the parts. I put in the new gaskets, I use the new Viton carb bowl gaskets, and like Jim and Eric, I started using the 912 bale clips and light torque on the float bowl bolt gasket. No leaks, no stumble, and in my tome on troubleshooting the Rotax, I set my throttle plate between the two small vent holes and I am ready to start. I have the laptop handy and a very accessible plug for the TCU and I simply check my throttle idle, full, and 100% detent positions. Because I never have to move my cables, I have a small mark on the cables I set them to, and I purge my oil system if necessary and start the engine. Idle will be between 1800-2000 and smooth on start up. After warm up, I adjust the throttle down to 1600 RPM and it is normally quite smooth. I put on my carb balancer gauges and fire up the engine. Check my gauges and move my cables at 2000 RPM (off the stop) fore and aft a bit to see if smoothness improves. It usually doesn’t, and run the engine to 2500, 3500,4000 (mag check), and then 5000. If the needles stay even (and they do) all is well for another few years. Remove the gauges and close it up.

If you allow “Joe Bag of Doughnuts” mechanic that only can recognize a Rotax because of the valve covers, you may have carb issues. Hence, learn to do the maintenance on the engine or find a good Rotax repairman. If you don’t have one locally, learn how to maintain the engine.

Best Regards,

Bud Yerly

From: owner-europa-list-server(at)matronics.com <owner-europa-list-server(at)matronics.com> On Behalf Of Brian Phillips

Sent: Monday, November 14, 2022 3:05 AM

To: europa-list(at)matronics.com

Subject: Re: Europa-List: Re: What did you do with your Europa this week - 08/11/22

Bud,

Thanks very much for your explanations below, a great read and very illuminating. I didn't realize you had done work with Jason Parker. Agree with everything you have said. The 914's running upward of 60" MP, effectively doubling their mas flow, I can't see how they would not ping, blow head gaskets and hole pistons, scary stuff.

On your first line, you mention 2.27, i'm assuming a simple typo and meant 2.43. As the weight of the 914 is pretty much the same as the 912Is, and based on your numerous advice, a 914 is the go if I can put up with those silly carby things. I spent many years playing with Holleys, I thought I was over ever having to rebuild of fault find these things : )

Cheers

Brian Phillips

On 14/11/2022 5:17 am, Bud Yerly wrote:

[quote]

Let me try to shed some light here from experience. The cost to performance issue has been around since airplanes became accepted as a “necessary” part of higher speed transportation.

First: Propellers fly on torque. The reason the 2.27 gearbox was better for the Columbians was the wide chord Warp Blade requires too much torque in comparison to the 914, hence the 912 (80HP) even with lower normalized boost hasn’t sufficient torque to pull a wide chord Warp at full power. Had narrower chord blade been selected, fixed or constant speed prop, these issues change a lot. Too many for this level of discussion. At sea level manifold pressure with no losses the 80HP Rotax cannot turn a fixed 64 inch Wide Chord WD prop set for a 5000 RMP WOT much beyond about 5200 RPM. Takeoff suffers. Therefore, WD and others have smaller diameter or narrow chord blades to match to the 80HP Rotax. So, if I turbo normalize the 80 HP engine to 30 or even 35 inches, the engine/prop combination becomes a compromise of changes. Either the pitch has to be changed to decrease torque, the boost and therefore mixtures, jetting, fuel grade, and gearbox ratio has to be tweaked to make the engine “runnable” within the narrower torque range of engine with a now smaller or narrower prop.

Second: Looking at the cruise speed difference doesn’t tell the whole story but in fact it does. In high altitude operations, a turbo or supercharging is essential to regain sea level performance or perhaps a bit more. The back yard mechanics tweaked and tinkered to get a truck turbo and custom hand built components and jetting to get around the higher cost of the stock 914 due to rather onerous taxation in Columbia or as I did, just tinkering. Turbo normalization, prop and gearbox selection (but not optimization) led to a workable boost to allow reasonable performance for takeoff, climb and some additional cruise at altitude. However, without optimized waste gate control, you loose efficiency and power in cruise to gain takeoff. So, a turbo normalized 912 vs a 914 may only be 10 knots, but it is more than that. If you desire to optimize takeoff, climb, and cruise, then a more refined means of turbo waste gate control is necessary. That means a computer, or at least a circuit card with a application. Will did a great job of describing his build situation compromises in his last email. For him, it was his choice of compromises. He knew what had worked in Columbia to meet his basic requirements/compromises.

Third: The Columbian conversion and the Italian chap (Vz Power) with the bolt on turbo or even the “Big Bore” conversions are all interesting experiments in getting around the Austrian overpriced 914. After all, the TCU control of a wastegate is not rocket science and a stock Garret turbo is only $500. But you have to look at the cost to long term maintenance and parts availability issues also. In my working with Jason Parker on a degraded Predator Drone engine, we put a stock Garett Turbo, a waste gate dashpot and an SDS fuel injection on a 2015 9XX Rotax stronger block (now stock on all Rotax engines). Jason removed the cylinders/heads, installed forged pistons, worked fuel mapping and boost control to get a very workable engine for about $15000 less than a 914 and a lot less than a 915. However, who got paid back for investing in all this work. Not I, as I didn’t ask for any, but Jason lost 3 years of his life (but was hired to a lucrative position in defense) for all his work. About 25 engines were modified and very quickly sold. Half of them however were tinkered with by “knowledgeable amateurs/experimenter” and eventually blew up cylinders and pistons when tweaked to 60 inches of MP for superb takeoff and climb. When you modify an existing engine for more power, you always trade off something.

My hat is off to those attempting to improve the internal combustion piston engine. Pratt and Whitney, Rolls Royce, and others developed wonderfully complex hydromechanical control systems to increase engine power and in some cases longevity and many other manufacturers capitalized on that from the 1930’s to the 50’s until the demise of the high powered piston aircraft engine. The internal combustion piston engine was left as a necessary evil mired in inefficiency and relegated to mass produced autos. But then, about 20 years ago computer/digital systems became cheap and available. Toyota’s TRD division, Ford’s Racing, Mercedes and BMW as well as other motor divisions have developed wonderfully powerful and more efficient engines. Today modern electronic controls finally bring these dinosaur piston engines into greater efficiency. Supercharging and Turbo-super-charging can be electronically controlled with the fuel injection to prevent untrained operators from blowing them up and produced an automobile engine that is high powered and yet a reliable daily use vehicle. However, more power means the more your inspection and installation requirements go up, improved cooling, higher octane fuel types and improved electronic “sensoring” to keep it all running flawlessly. Luckily, we don’t push our autos to the extreme we push our aircraft engines. (Although I did leave a Porsche 4 seater in the dirt with my 495 HP pickup truck from the stoplight a few months ago which was great fun for a couple of old guys, but he will never forget to be in “sport mode” again if he sees me.. )

In the many compromises we make in building an aircraft, never forget that the engine and prop are the powerplant. The engine supplies torque to the torque converter (propeller) and if you are smart, a variable pitch propeller. This prop choice allows one to take every bit of power the engine can produce for takeoff, and climb, then power down to 75% and run a few thousand hours with the prop pulling full power out of the available HP and Torque for cruise also. HP is the rate of work, torque is the twisting force and the twisting force/RPM is what is important for cruise. The 914 has reasonably optimized all these and with a constant speed (or variable pitch (with higher pilot work load)) prop is not only more efficient, but is mechanically more reliable than a fixed or mechanically controlled wastegate. Is it perfect, no, is it overpriced, yes, and am I frustrated with their turbo rebuild fiasco of a repair program, absolutely (a turbo only costs about $400 to rebuild and Rotax wants you to replace it for $8000, that is just plain greedy”). Do I like turbo normalization (30 inches), yes, do I like more boost absolutely, but at what cost and reliability?

For me, I’ll stick with my 914 because I can get parts, it is easy to troubleshoot from the TCU to the carbs and frankly just plugs onto the front of my Europa. Is it as nice an engine as the high tech 915, no way, but the extra stuff on the 915 doesn’t really suit my aircraft or pocketbook. Performance wise, if I want to suck on oxygen and fly at 17,500 MSL to get 160 Kts. Vs 143 at 10,000 feet ish, it is worth it for me to stick to the 914 rather than upgrade and change everything on the FWF to match a different engine, then rebalance the aircraft. My drag curve goes much more vertical above 140 Knots and frankly, the only advantage of the 915 is rate of climb (that’s HP or rate of work) but my top cruise increase is going to be less spectacular for all that work, extra weight and fuel burn. Ah compromises!

Choose wisely to meet your requirements. Everyone has a different flying mission for their aircraft. The stock 912S (100HP) is a nice option for the Europa for a lower altitude performer. The UL engine is gaining popularity (I’m still not completely sure why, as the performance increases with most planes isn’t showing up in cruise performance, and prop performance to match at this time is being worked out). It is a well engineered product though and impressive. But is it as maintainable over time. Time will tell. Although Airmaster has attacked that faster spinning UL issue in an attempt to match the engine power/torque to a propeller, as of today, results are encouraging. The faster spinning UL has only about the same torque as the Rotax 9 series. The higher power meant more cooling issues, higher octane fuel (100LL is best) and it appears that the engine can’t be lugged down to lower RPMs most likely due to detonation, hence the faster spinning engine (pump) must be electronically leaned for efficiency and hence cooling rears its ugly head. The UL 350 series engine develops max torque (330nm or 230Ft/lbs.) at about 23-2400 RPM which is 100 HP at sea level but at about 25L/Hr. or 6.6 GPH. Note the fall off of torque as RPM increases. The gearbox makes a difference in how hard you pull the RPM down vs using the fuel to prevent detonation by running a bit richer. That is not a great leap over the 912iS or even the 912S in cruise speed, at and the UL is at a higher fuel burn. At altitude though the HP drops significantly an any normally aspirated engine and on the 350iS and 912iS as the fuel burn goes down to about 17L/Hr. or 4.5 GPH. Not bad and comparable to the Rotax 912iS and 912S with a HacMan leaning kit. Since 2018, UL is continuing to solve all these issues as they attempt to overcome the inefficiencies of the dinosaur horizontally opposed air cooled engine issues in aircraft through fuel mapping, compression ratio, and timing controls. Good on them. Rotax was forced to catch up. And did they do it well. Well, that remains to be seen.

The 914 like the 912/912S fits the cowl FWF package without major issue (you got to do the cooling work though). Extra power means extra heat to dissipate. The UL teething issues are mostly from poor cowl design or execution in my opinion which will take time and money to iron out (why cowl flaps are not used by manufacturers I cannot explain). Too bad as they really need an efficient cowl design for cruise to get rid of the heat in cruise and cowl flaps in climb to cool properly at low speed and high power. In my opinion, the airframe manufacturers seem to be indifferent to higher power engines cooling needs and settle for all but the most basic lower power engines requirements (i.e. it costs them money and time and besides, the actual money is in the stock airplane from a sales point of view).

Research is 90% of your time in selecting an airframe and powerplant. I prefer to go fly in a similarly equipped aircraft I am considering to build, as I can copy or just assemble IAW the manual and achieve an acceptable aircraft that will meet or exceed my expectations without worry of reliability, longevity, or parts supply. As Ira Rampil told me “Better is the enemy of Good”. One has to raise the issues of cost, time, talent and services needed to go from good to better.

Just my opinion and observations!

Best Regards,

Bud Yerly

From: owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <owner-europa-list-server(at)matronics.com> (owner-europa-list-server(at)matronics.com) On Behalf Of William Daniell

Sent: Sunday, November 13, 2022 8:42 AM

To: europa-list(at)matronics.com (europa-list(at)matronics.com)

Subject: Re: Europa-List: Re: What did you do with your Europa this week - 08/11/22

Yup - the original 2.27:1 wouldnt make the revs with the airmaster even in Guaymaral at 8500. My previous plane a ICP Savannah with an Ivo had no problem with the 2.27 gearbox. I had the ivo with the narrow blades. The 914 gearbox is 2.43:1.

Theres a lot of experience with this conversion in Colombia - they even claim they turbo-ed the 912 before rotax. It could be true - you never know with Colombia. But in any case I wasnt the pioneer. It’s a well understood process. The chap who did it for me turned up all the required components with nicely welded stainless exhausts etc installed them and fired up the motor. Worked ever since no faffing about.

In any case a 914 would have probably been the way to go but Im a cheapskate. Or rather it would have cost me the price plus another 15% import tax raising the price to almost USD40k. What with labor and parts my current engine cost USD25k.

You dont have to mess with the TCU and it retains the mechanical fuel pump (you need an electric pump as well). The mech pump will just about keep you flying at 22” MAP.

On Sun, Nov 13, 2022 at 00:58 Brian Phillips <barp99(at)gmail.com (barp99(at)gmail.com)> wrote:

[quote]

Thanks for that Will. Clearly you know what you are doing as you have been running it since 2006. Can I ask, why do you need to change the gearbox ratio?

Once you installed the turbo system, did you have to adjust or replace it to get it to absorb the power available at higher altitudes?

Cheers,

Brian Phillips.

On 13/11/2022 12:33 am, William Daniell wrote:

[quote]

I use up to 36” although lots of people in Colombia go up to 40”. So yes pretty much the same boost as a 914.

If you use a stock 912 you have to add the turbo system and airbox exhaust etc as you would expect. And also the oil system to feed the turbo none of which is unexpected. A bigger main jet is normal. However the gochta is that you need to change the gearbox ratio and I put in a slipper clutch. All of this can actually be done in a day (the exhaust and airbox are made beforehand.)

I have a manual waste gate in this engine but in the previous one I had a simple wastegate controller like a car

I flown with this engine since 2006 never had an issue.

The turbo is from a Renault diesel van - made by mitisubishi

Nitrile gaskets on the carbs are necessary otherwise they suck air at altitude.

On Fri, Nov 11, 2022 at 23:16 Brian Phillips <barp99(at)gmail.com (barp99(at)gmail.com)> wrote:

[quote]

Thanks for that Pete, good to know. As you say, too few accumulated hours to build reliable predictability. At least the big bore kit does not need any changes to crank, which is essentially the same as the 914 with the same output. The lighter than standard pistons may even reduce crank stresses.

I did look at the Viking options, I could be wrong but I seem to remember belt drive issues, recessed valves & delivery issues. I believe the crank fillets are smaller on auto engines compared to A/C engines, and with the 100% duty factor can cause cracks, not sure if this applies to the suby though. I do have an EJ25 in my road car, 200K miles, no problems, great engine.

William, your Columbian turbo does interest me, I remember you used a Mitsubishi turbo. Do you use it to normalize or do you actually add a bit more boost in?

Cheers,

Brian Phillips.

On 11/11/2022 10:30 pm, Pete wrote:

[quote]

My experience conversing with Edge’s principal over the years, fwiw, is that he is chock full of confidence, many good ideas but peppered with some critical bad ones -which he will not acknowledge, and lets his customers “prove him wrong”. And some have (ex: cracked/failed welded crank). Too few accumulated hours to tease out all that pepper.

Same syndrome as Jan at viking (although Jan even lacks the engineering basics).

Difficult to watch.

Cheers,

PeteZ

<![if !supportLineBreakNewLine]> <![endif]> [quote]

On Nov 11, 2022, at 6:13 AM, Brian Phillips <barp99(at)gmail.com> (barp99(at)gmail.com) wrote:

Bud, thanks very much for your well laid out advice below, much appreciated, your background knowledge never ceases to amaze me.

You have talked me out of the 915, the thought of doing all the retrofit work, along with the weight issues, its just not worth it, and I would never finish it. I am still interested in the 912Is, & was thinking about the Edge 1484cc big bore kit. Your comments below about some of the US based big bore kits has got me thinking again. 10.5:1 CR does seem a little high, combined with no detonation detection feedback loop, does sound a bit risky. Edge performance don't play with the Rotax FI software, they supply a fuel pressure reg that increases the rail pressure, so the pump/s are working harder, again an added risk. Add to that limited operational history, makes the 914 look an even better outcome. As you say, 20,000 compromises flying in close formation.

Cheers,

Brian Phillips.

On 11/11/2022 4:34 am, Bud Yerly wrote:

[quote]

Pete, as you are most aware and Brian you are learning fast:

Weight is the enemy of an airplane. Especially the Europa, as it is a very compact aircraft. If I add 15 horsepower, but it moves the CG forward, requires a prop extension and a constant speed prop, the CG is going to be somewhere around the spinner. Now we move the battery back, run longer heavier cables and as much more to the rear as possible such as autopilots, ELTs, etc. to counterbalance the nose. The weight just keeps going up. The Europa XS is 100 pounds heavier than the equivalent Europa Classic even with the XS fuselage module and firewall forward. The 912 80 HP is not a spectacular performer but will give 30 ANMPG at low altitude or with a leaning device at altitudes up to about 10,000 feet. Cruise is in the 120-130 knot range. The 912S raised the cruise about 5 knots more. The 914 doubles the climb rate, ups cruise to at least 140-145 knot range at the same 25 ANMPG as the 912S on a tricycle gear aircraft of course. The mono is faster and lighter of course.

As I learned on modifying the 914 to fuel injection. Customers moved the boost up to get more power but complained it burned more fuel. The only advantage was more power with less reliability. Fuel burn was basically the same at 31 inches and 5000 RPM. So, what did I gain? Slightly more power for climb but more heat to dissipate, a bigger radiator and shallow climb was necessary to cool. BTU requirements are the same for the same amount of power at the same fuel air ratio and varies little with displacement. Aircraft engines run at constant RPMs like a marine engines, so a carb is just as good as fuel injection except for altitude performance of a normally aspirated engine with no leaning. The Bing stops leaning after about 3500 feet in the normally aspirated engine. So, an after market leaning system is necessary for the high altitude flyers to improve fuel efficiency of the 912/912S. The Rotax 914 is ideal for higher altitude operations and frankly ideal for the Europa but at a higher cost. I believe the 914 totally transformed the Europa into a great airplane. Reliability of the 914 is now as good as the 912S but as we all know, there are techniques and inspections required to keep it running like new.

Normally a 912 through the 914 will go 1000 hours with only carb maintenance/oil changes. Overspeed of the engine is an issue many ignore. The valves can and do contact the piston if oversped. Prop strikes are ignored also by many STOL operators and taildragger/mono.

I do a top overhaul at about 500-600 hours (gearbox, clean up the valves, inspect the rings/cylinders) and press on. Repeat at 1000 hours and the engine is good to 1500 hours. The cleanup of the valves restores compression to like new or better than new and is really a surprise when a 914 burps after only about 5 blades of rotation.

I have no experience with the latest Edge Performance engines, but I do with the so called "Big Bore" engines done here in the States some years ago. They do put out more power. But for how long? Over the years the stock Rotax 100 HP 912S (especially the new blocks) last and last. Most of the Big Bores were back in after as short as 200 hours. But we have many cowboys here in the States that just want more power but won't pay for it to get power and reliability. I was around for the first of these Big Bore mods. As Edge Performance has found out, the crank shaft, and many other formally robust Rotax parts are now under more stress and required "upgrade". This costs money. My hats off to them, as they have at least backed their engines. In their defense, some of our “cowboys” here in the States are running regular car fuel. This causes detonation for sure. I can’t fix stupid!

If you need more power keep in mind in general you will need more gas, gain weight, reduce reliability, increase inspection requirements, require greater cooling mass, and of course add cost. An airplane is 20,000 compromises flying in close formation. If you change one thing, you affect 20 others. Choose wisely.

Example: Charts are scare still for the 915.

5000 RPM wide open throttle 87 KW or about 115 HP (10-20 more than the 914 depending on MP and TCU.) Fuel flow 27 L/hr or 7.1GPH.

A 20 HP increase on N12AY (Trigear) yields a cruise speed increase of nearly 10-13 Kts above 10,000 feet which is better than most.

However, the range in Air Nautical Mile per Gallon does not increase it decreases from about 25 ANMPG to 20 ANMPG.

The Europa drag goes up beyond 140 Knots by a cube root for the trigear. The mono is much better at still basically a square root curve. More horsepower doesn’t give me impressive efficiency or speed.

The 914 fits easily in the Europa XS, will cool, accepts a constant speed prop without issue or added extensions, has a reasonable fuel burn and will get you to 10,000 feet in about 11-13 minutes in a cruise climb. I can put out 70 to 95 horsepower continuous for cruise (typically 140-145 for a trigear) or max speed. Both the 912S/iS and Big Bore require the same octane fuel as the 914 so no advantage. The 914 turbo takes care of most of the issues with density altitude, it allows the Bing to work ideally from cruise to max continuous from the surface to service ceiling (which is well above 25,000 which is our human physiological limit without cabin pressurization). We know how to maintain it, the TCU has been modified and I can setup, troubleshoot or simply run a data dump from my laptop running Windows 7 through 10 without a special dongle. I don’t have Windows 11 yet, but it should work also. Carbs are easy to balance, and the installation manual is easy to follow. Always follow the engine installation manual in conjunction with the airframe firewall forward manual .

The 915 was never designed to fit a standard Rotax engine mount and does not fit most experimental aircraft firewall forwards. Extensive work is necessary to retrofit the 915 to a 912/914 airframe. The 915 is unmaintainable but for plugs and oil change without a “buds” system for the average owner to tell you what it’s doing but the troubleshooting manual is a bit sparce. Much study and patience is needed as the 915 goes through its teething issues. It runs lean on the ground like the 912iS and will overheat easily during an extended taxi out. Automatic systems means you the pilot lose control. Many 912iS owners hate the power drop off and find economy only comes through lower power. They have found fuel burn is the same for the same speed after an engine change from the S to the iS. The 915 has a similar issue with the power requirements. It is not like hopping into your BMW tubo and everything works. It is still like the 1980’s first gen fuel injection and turbo mods. Today it all works flawlessly in our autos, but with larger cooling requirements and components taking up more space under the hood. The 915 is not quite a plug and play engine electrically either. Look at Sling and their learning curve. The 4 place needs 140-150 HP. The two place not so much. Guys are looking hard at the difference.

In summary, the Europa was designed for about 100HP engines of light weight. It is fast and efficient for a 100HP 500 pound payload airplane. More weight makes the induced drag go up. The mono airframe was not designed to go faster than about 170 KTAS at 20,000 feet at an empty weight of 900 pounds. If you go above 900 pounds empty weight, the plane gets sluggish, speed drops and range is decreased. In the States, a 1000 mile per day range airplane is essential for getting around west of the Mississippi river. For my snow birds coming from Canada to Florida for the winter, they need that range also. Frankly, a bigger engine makes for shorter hops, less payload, and a longer day. More horsepower is not as important as more torque. Torque turns the prop, HP just makes it spin up faster.

Keep it light, keep it simple, and it will be a trouble-free steed with stock components. Work on drag reduction and keeping the weight down. Not by slapping more horsepower, weight, complexity, and cost on a very small airframe.

Just my thoughts….

Best Regards,

Bud Yerly

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Mon Nov 14, 2022 11:23 am Post subject: Re: What did you do with your Europa this week - 08/11/22 Posted: Mon Nov 14, 2022 11:23 am Post subject: Re: What did you do with your Europa this week - 08/11/22 |

|

|

That's so true; Joe Dougnuts is always ready to screw up a well balanced set of carbi's... Lost count of how many times customers would come back with their SU and Stromberg setups complaining the engine is running rough again... so first thing i would always ask is "who messed with the mixtures?", Joe Doughnuts was always reliably the last person to "tune up" the engine... 🦦

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Mon Nov 14, 2022 11:35 am Post subject: Re: What did you do with your Europa this week - 08/11/22 Posted: Mon Nov 14, 2022 11:35 am Post subject: Re: What did you do with your Europa this week - 08/11/22 |

|

|

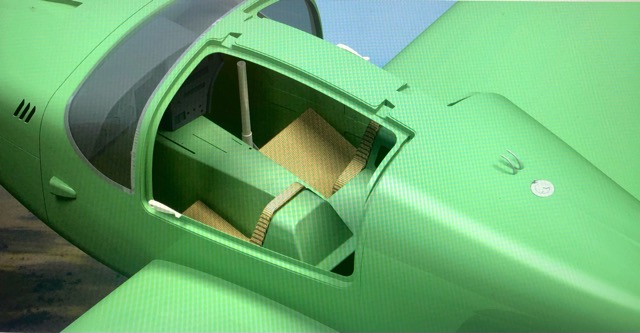

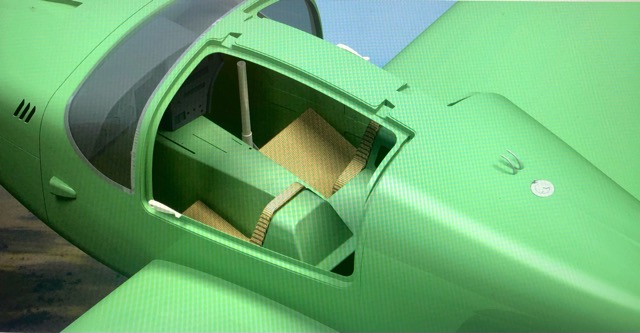

More flight time in the digital tube... door frames are finally done and installed; starting to look like a finished aircraft... Doors should be a fairly fast process now with all the root surfaces having been drafted... enough modelled data now to run some aero analysis on a twin departed door scenario. So far this task has been the most challenging to resolve and has been almost 100% sequential spline and surface development all the way through eight complete rebuild iterations. In comparison the instrument panel took just three complete iterations to resolve and was in itself an epic journey.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

62.38 KB |

| Viewed: |

872 Time(s) |

|

| Description: |

|

| Filesize: |

53.62 KB |

| Viewed: |

870 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|