|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Davidcripps

Joined: 09 Aug 2021

Posts: 40

|

Posted: Tue Jan 03, 2023 5:10 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Tue Jan 03, 2023 5:10 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

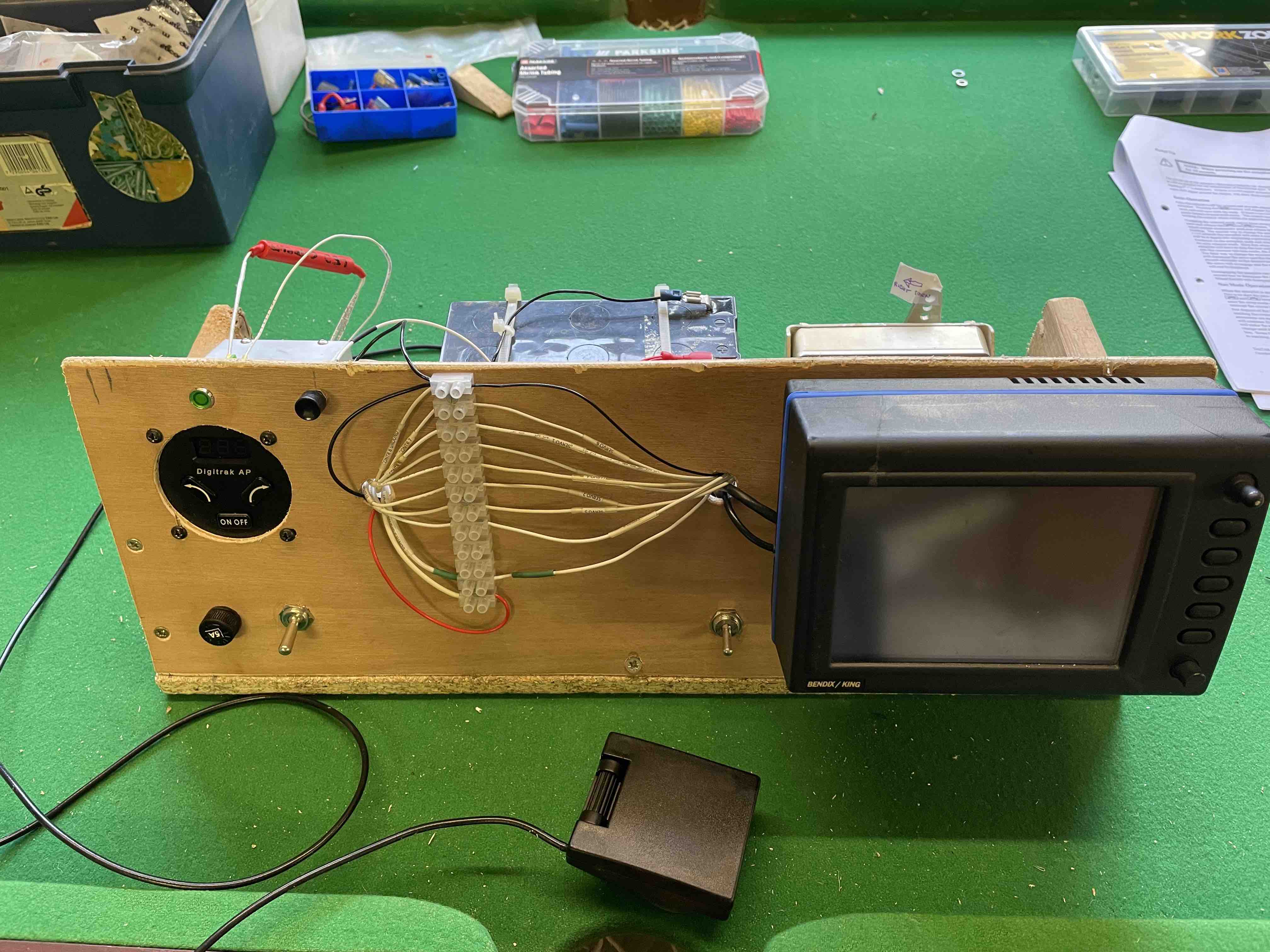

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com <mailto:owner-europa-list-server(at)matronics.com> on behalf of alanb(at)dpy01.co.uk <mailto:alanb(at)dpy01.co.uk>> wrote:

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad

| Quote: | On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net <mailto:ami-mcfadyean(at)talktalk.net>> wrote:

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF.

|

s.com/Navigator?Europa-List>

ion>

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

536.76 KB |

| Viewed: |

3493 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 220

|

Posted: Tue Jan 03, 2023 7:15 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Tue Jan 03, 2023 7:15 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

David,

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.

iv). The Europa needs quite a high torque setting (10 or 12 from memory, which can on hot days plus a high 'activity' setting result in servo overheating and shutdown if you have a trigear with 'heated'/unventilated fuselage tunnel and depending where the servo is mounted).

The pilot stick force required to overcome maximum torque will be applied without even thinking about it and in any case there is a necked brass shear pin (comprising a modified 6-32 brass instrument mounting screw) in the servo arm that can be easily sheared (even without knowing it, and then you wonder why the AP is not tracking!). I agreed with LAA to replace this with a (necked) stainless steel pin in order to provide a little more strength and haven't sheared it since.

I also think that when the servo gets very hot (as above) it's internal voltage regulator starts to shut down (as many are designed to do). Again, there is no way of knowing when this happens until realisation that the AP is not tracking!

v). The LAA will insist upon the stops on the servo, although these stops are not particularly robust and the set up would be better adjusted so that the stops never have to resist the pilot's stick inputs.

Otherwise, the Trutrak system and its dynamics work extremely well and can do a much better job than the pilot, especially in turbulent conditions.

Have you found a setting on your Skymap that allows adjustment of the pre-emptive steering sensitivity (or "turn anticipation")?

Duncan McF. | Quote: | On 03 January 2023 at 13:10 David Cripps <dpc(at)knightonweb.com (dpc(at)knightonweb.com)> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)> on behalf of alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>> wrote:

--> Europa-List message posted by: Alan Burrill <alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>>

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad

| Quote: | On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>> wrote:

--> Europa-List message posted by: D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>>

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF. |

s.com/Navigator?Europa-List>

ion>

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Burrilla

Joined: 25 Apr 2015

Posts: 185

|

Posted: Tue Jan 03, 2023 9:16 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Tue Jan 03, 2023 9:16 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

David

The GPS 196 is only able to output at 0.5Hz i.e. every 2 seconds. I originally used an AVMap EKP-V and that also did 4800 baud and 2 second update. The AP function ok but I did notice some interesting features. It would capture a track by overrunning and then turning back and also on change of direction it would overrun the turning point and then do an S-Type recapture. Once you got used to it it was ok but you defiantly didnât want to be close to airspace when using and expecting it to turn 1 nm from an infringement!

I now use a Garmin 760 and that updates at 1 sec intervals and does pretty much the same thing as there is no pre-emptive turn message so it does the s-turn to capture and change direction.

I assume that you are using Mod 75 from the Europa Club Website?

I didnât install mine so cannot truthfully answer questions on install or stops but certainly all the turns limit to half standard tun rate and I have never had any problems with full deflections and needing to âTake-back-controlâ. That said i do get occasional dropouts in rough Wx and you donât notice until you see that you appear to be driving off track.

Iâd have to investigate the settings for torque etc in my mine, and I need to do it as they are not recorded anywhere so have no reference if they get electronically lost. I I get a chance this week Ill let you know.

Alan

| Quote: | On 3 Jan 2023, at 13:10, David Cripps <dpc(at)knightonweb.com> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Davidcripps

Joined: 09 Aug 2021

Posts: 40

|

Posted: Tue Jan 03, 2023 2:30 pm Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Tue Jan 03, 2023 2:30 pm Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

Thank you for the comprehensive reply, Duncan, and also for the replies from Alan and Peter. I really appreciate the feedback.

It seems that the Skymap III should work OK for us, despite its 0.5Hz data refresh rate. A bit of âhuntingâ shouldnât really be a problem. We hadnât planned to have it fly a full route and navigate itself around turning points. I had thought weâd be manually changing the selected track at each turning point, and then lock the tracking to the new direction required. However, the Skymap III does have a âTurn Anticipationâ feature if we should in the future want it to follow a route, and not overshoot a waypoint. Do most people use it to follow a full track, and make all the waypoint turns?

Good to know about the shear pin in the arm as a last resort! Do you have any drawing of the necked stainless pin that you got the LAA to agree to?

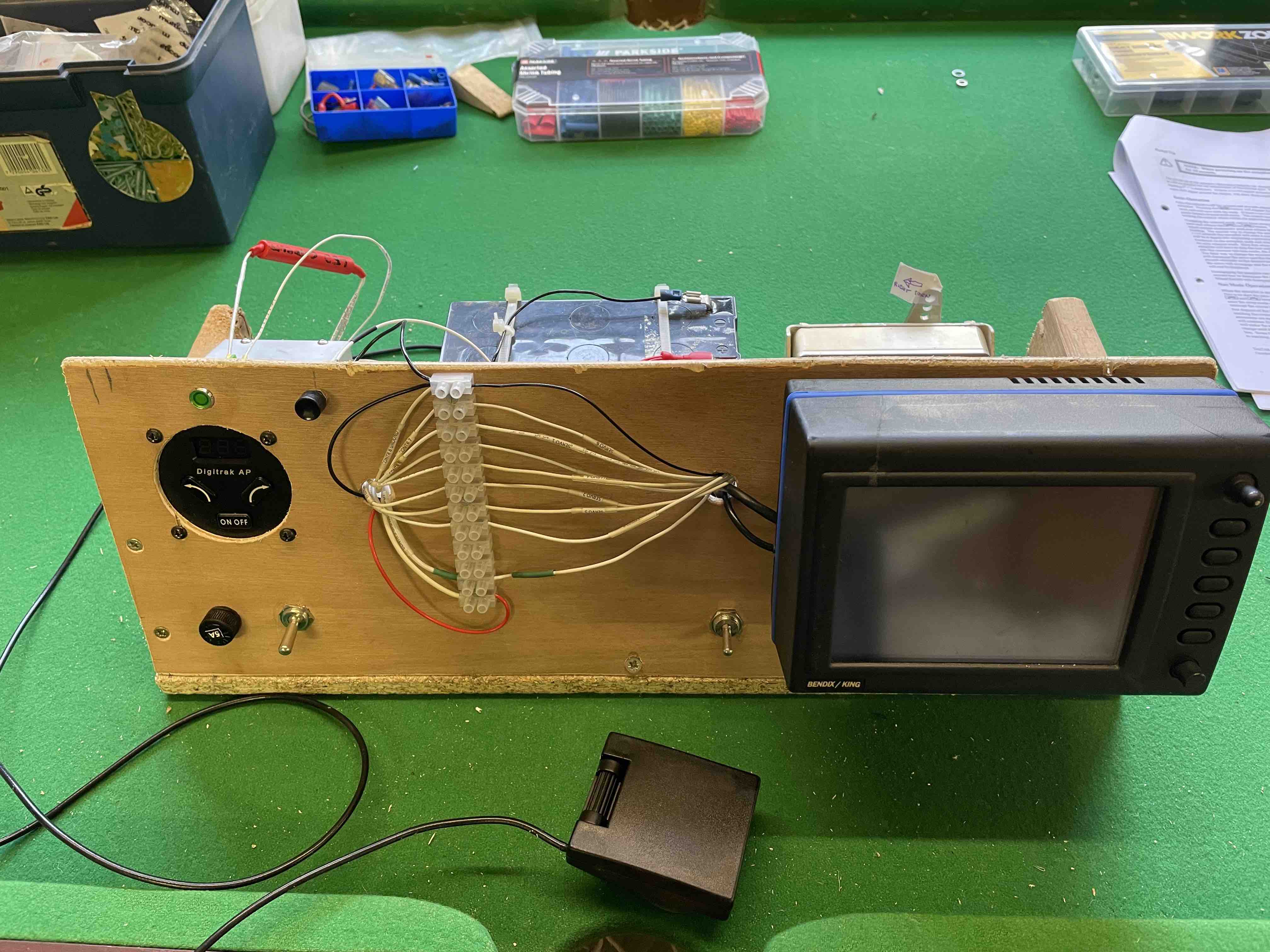

The servo that I have came out of an old Europa and didnât seem to have any physical stops on the servo arm. It did, however, have the extra alloy âclipâ to secure the screw that attaches the arm to the servo. Iâve seen that that clip was an LAA requirement too (see photo). For the physical stops, I did see on another forum something that looked like it would do the job on this servo (may even have been a Trutrak part). Does the LAA specify what these stops should look like or be made of? Should they be set so that the servo arm touches them at the same time as the control column reaches its full deflection (if not, then which stop should âtake priorityâ and be hit first)? Does anyone have a photo of what the stops look like in their setup? I imagine them being mounted on the bolts that attach the servo motor to its mounting frame.

My servo would be mounted under the pax seat per Mod 75, so there is not really any ventilation there. Is it worth adding a little cooling fan to the seat locker to keep the air circulating around the servo?

Many thanks for all the input!

David

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.

iv). The Europa needs quite a high torque setting (10 or 12 from memory, which can on hot days plus a high 'activity' setting result in servo overheating and shutdown if you have a trigear with 'heated'/unventilated fuselage tunnel and depending where the servo is mounted).

The pilot stick force required to overcome maximum torque will be applied without even thinking about it and in any case there is a necked brass shear pin (comprising a modified 6-32 brass instrument mounting screw) in the servo arm that can be easily sheared (even without knowing it, and then you wonder why the AP is not tracking!). I agreed with LAA to replace this with a (necked) stainless steel pin in order to provide a little more strength and haven't sheared it since.

I also think that when the servo gets very hot (as above) it's internal voltage regulator starts to shut down (as many are designed to do). Again, there is no way of knowing when this happens until realisation that the AP is not tracking!

v). The LAA will insist upon the stops on the servo, although these stops are not particularly robust and the set up would be better adjusted so that the stops never have to resist the pilot's stick inputs.

Otherwise, the Trutrak system and its dynamics work extremely well and can do a much better job than the pilot, especially in turbulent conditions.

Have you found a setting on your Skymap that allows adjustment of the pre-emptive steering sensitivity (or "turn anticipation")?

Duncan McF. | Quote: |

On 03 January 2023 at 13:10 David Cripps <dpc(at)knightonweb.com (dpc(at)knightonweb.com)> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)> on behalf of alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>> wrote:

--> Europa-List message posted by: Alan Burrill <alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>>

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad

| Quote: |

On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>> wrote:

--> Europa-List message posted by: D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>>

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF. |

s.com/Navigator?Europa-List>

ion>

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

340.2 KB |

| Viewed: |

3482 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 220

|

Posted: Wed Jan 04, 2023 2:06 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Wed Jan 04, 2023 2:06 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

I'd not seen before the clip on the servo arm; there was an earlier Factory 'fix' of Loctited replacement screws. Later servos have a stud and pinned locknut instead (I guess the stud is held in only by Loctite!).

The control column stops should take priority, as the servo stops are probably too light to limit enthusiastic control movements by the pilot, but should at least contain a runaway servo or some other breakage in the servo. I might have some spare stops (if I can find them). The stops are half-visible and annotated 'F' in the photo at: TruTrak-RV10-Roll-Installation-Guide.pdf (bendixking.com)

The shear pin is merely a 6-32 screw with a short part of its length (where this crosses the interface between the mating arm and hub) necked and polished to the roots of the screw thread.

My own servo is mounted towards the back of the Europa 'tunnel' and connects to a horn bolted to the rear end of the roll torque tube. This area used to get hot under certain situations via heat from the stainless firewall and no tunnel ventilation. Subsequently a 'fire blanket' (two thin layers of woven Kevlar with thin fibreglass loft insulation sandwiched between, rather like Orkotek) placed on the back of the firewall enabled cooler temperatures. I've not heard of the standard under-seat servo location getting too hot.

Duncan McF. | Quote: | On 03 January 2023 at 22:30 David Cripps <dpc(at)knightonweb.com> wrote:

Thank you for the comprehensive reply, Duncan, and also for the replies from Alan and Peter. I really appreciate the feedback.

It seems that the Skymap III should work OK for us, despite its 0.5Hz data refresh rate. A bit of âhuntingâ shouldnât really be a problem. We hadnât planned to have it fly a full route and navigate itself around turning points. I had thought weâd be manually changing the selected track at each turning point, and then lock the tracking to the new direction required. However, the Skymap III does have a âTurn Anticipationâ feature if we should in the future want it to follow a route, and not overshoot a waypoint. Do most people use it to follow a full track, and make all the waypoint turns?

Good to know about the shear pin in the arm as a last resort! Do you have any drawing of the necked stainless pin that you got the LAA to agree to?

The servo that I have came out of an old Europa and didnât seem to have any physical stops on the servo arm. It did, however, have the extra alloy âclipâ to secure the screw that attaches the arm to the servo. Iâve seen that that clip was an LAA requirement too (see photo). For the physical stops, I did see on another forum something that looked like it would do the job on this servo (may even have been a Trutrak part). Does the LAA specify what these stops should look like or be made of? Should they be set so that the servo arm touches them at the same time as the control column reaches its full deflection (if not, then which stop should âtake priorityâ and be hit first)? Does anyone have a photo of what the stops look like in their setup? I imagine them being mounted on the bolts that attach the servo motor to its mounting frame.

My servo would be mounted under the pax seat per Mod 75, so there is not really any ventilation there. Is it worth adding a little cooling fan to the seat locker to keep the air circulating around the servo?

Many thanks for all the input!

David

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.

iv). The Europa needs quite a high torque setting (10 or 12 from memory, which can on hot days plus a high 'activity' setting result in servo overheating and shutdown if you have a trigear with 'heated'/unventilated fuselage tunnel and depending where the servo is mounted).

The pilot stick force required to overcome maximum torque will be applied without even thinking about it and in any case there is a necked brass shear pin (comprising a modified 6-32 brass instrument mounting screw) in the servo arm that can be easily sheared (even without knowing it, and then you wonder why the AP is not tracking!). I agreed with LAA to replace this with a (necked) stainless steel pin in order to provide a little more strength and haven't sheared it since.

I also think that when the servo gets very hot (as above) it's internal voltage regulator starts to shut down (as many are designed to do). Again, there is no way of knowing when this happens until realisation that the AP is not tracking!

v). The LAA will insist upon the stops on the servo, although these stops are not particularly robust and the set up would be better adjusted so that the stops never have to resist the pilot's stick inputs.

Otherwise, the Trutrak system and its dynamics work extremely well and can do a much better job than the pilot, especially in turbulent conditions.

Have you found a setting on your Skymap that allows adjustment of the pre-emptive steering sensitivity (or "turn anticipation")?

Duncan McF. | Quote: |

On 03 January 2023 at 13:10 David Cripps <dpc(at)knightonweb.com (dpc(at)knightonweb.com)> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)> on behalf of alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>> wrote:

--> Europa-List message posted by: Alan Burrill <alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>>

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad

| Quote: |

On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>> wrote:

--> Europa-List message posted by: D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>>

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF. |

s.com/Navigator?Europa-List>

ion>

|

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Davidcripps

Joined: 09 Aug 2021

Posts: 40

|

Posted: Wed Jan 04, 2023 4:22 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Wed Jan 04, 2023 4:22 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

Thanks very much for this extra info, Duncan.

If you can find that spare stop that would be great. I had seen a picture similar to the one you sent of the stops in another aircraft application.

Following your comments about the shear pin, I think this is the small brass screw located just above the main central cross-head screw that holds the control arm onto the servo in the photo Iâve attached here? I looked at mine more closely and saw that the head of that brass screw appeared to be slightly loose and with some tapping I could get the screw head to drop out of the arm. If that is the shear pin youâre referring to then it appears mine is already sheared! However, the arm doesnât show any tendency to rotate on the hub? I guess the cross-head screw is holding it onto the hub pretty firmly, but I can see that the arm could potentially rotate against the hub without the pin being there (since there is no positive locking mechanism against rotation), but the cross-head screw would need to be looser than it currently is for rotation of the arm to be possible. Should the arm be free to rotate against the hub without the pin there? Question also now is how to get the threaded bit out and the pin replaced?!

Best regards

David

I'd not seen before the clip on the servo arm; there was an earlier Factory 'fix' of Loctited replacement screws. Later servos have a stud and pinned locknut instead (I guess the stud is held in only by Loctite!).

The control column stops should take priority, as the servo stops are probably too light to limit enthusiastic control movements by the pilot, but should at least contain a runaway servo or some other breakage in the servo. I might have some spare stops (if I can find them). The stops are half-visible and annotated 'F' in the photo at: TruTrak-RV10-Roll-Installation-Guide.pdf (bendixking.com)

The shear pin is merely a 6-32 screw with a short part of its length (where this crosses the interface between the mating arm and hub) necked and polished to the roots of the screw thread.

My own servo is mounted towards the back of the Europa 'tunnel' and connects to a horn bolted to the rear end of the roll torque tube. This area used to get hot under certain situations via heat from the stainless firewall and no tunnel ventilation. Subsequently a 'fire blanket' (two thin layers of woven Kevlar with thin fibreglass loft insulation sandwiched between, rather like Orkotek) placed on the back of the firewall enabled cooler temperatures. I've not heard of the standard under-seat servo location getting too hot.

Duncan McF. | Quote: |

On 03 January 2023 at 22:30 David Cripps <dpc(at)knightonweb.com> wrote:

Thank you for the comprehensive reply, Duncan, and also for the replies from Alan and Peter. I really appreciate the feedback.

It seems that the Skymap III should work OK for us, despite its 0.5Hz data refresh rate. A bit of âhuntingâ shouldnât really be a problem. We hadnât planned to have it fly a full route and navigate itself around turning points. I had thought weâd be manually changing the selected track at each turning point, and then lock the tracking to the new direction required. However, the Skymap III does have a âTurn Anticipationâ feature if we should in the future want it to follow a route, and not overshoot a waypoint. Do most people use it to follow a full track, and make all the waypoint turns?

Good to know about the shear pin in the arm as a last resort! Do you have any drawing of the necked stainless pin that you got the LAA to agree to?

The servo that I have came out of an old Europa and didnât seem to have any physical stops on the servo arm. It did, however, have the extra alloy âclipâ to secure the screw that attaches the arm to the servo. Iâve seen that that clip was an LAA requirement too (see photo). For the physical stops, I did see on another forum something that looked like it would do the job on this servo (may even have been a Trutrak part). Does the LAA specify what these stops should look like or be made of? Should they be set so that the servo arm touches them at the same time as the control column reaches its full deflection (if not, then which stop should âtake priorityâ and be hit first)? Does anyone have a photo of what the stops look like in their setup? I imagine them being mounted on the bolts that attach the servo motor to its mounting frame.

My servo would be mounted under the pax seat per Mod 75, so there is not really any ventilation there. Is it worth adding a little cooling fan to the seat locker to keep the air circulating around the servo?

Many thanks for all the input!

David

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.

iv). The Europa needs quite a high torque setting (10 or 12 from memory, which can on hot days plus a high 'activity' setting result in servo overheating and shutdown if you have a trigear with 'heated'/unventilated fuselage tunnel and depending where the servo is mounted).

The pilot stick force required to overcome maximum torque will be applied without even thinking about it and in any case there is a necked brass shear pin (comprising a modified 6-32 brass instrument mounting screw) in the servo arm that can be easily sheared (even without knowing it, and then you wonder why the AP is not tracking!). I agreed with LAA to replace this with a (necked) stainless steel pin in order to provide a little more strength and haven't sheared it since.

I also think that when the servo gets very hot (as above) it's internal voltage regulator starts to shut down (as many are designed to do). Again, there is no way of knowing when this happens until realisation that the AP is not tracking!

v). The LAA will insist upon the stops on the servo, although these stops are not particularly robust and the set up would be better adjusted so that the stops never have to resist the pilot's stick inputs.

Otherwise, the Trutrak system and its dynamics work extremely well and can do a much better job than the pilot, especially in turbulent conditions.

Have you found a setting on your Skymap that allows adjustment of the pre-emptive steering sensitivity (or "turn anticipation")?

Duncan McF. | Quote: |

On 03 January 2023 at 13:10 David Cripps <dpc(at)knightonweb.com (dpc(at)knightonweb.com)> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)> on behalf of alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>> wrote:

--> Europa-List message posted by: Alan Burrill <alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>>

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad | Quote: |

On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>> wrote:

--> Europa-List message posted by: D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>>

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF. |

s.com/Navigator?Europa-List>

ion>

|

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

359.97 KB |

| Viewed: |

3478 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 220

|

Posted: Wed Jan 04, 2023 7:55 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Wed Jan 04, 2023 7:55 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

With a failed pin, there would now be no shear connection between the servo hub and the arm other than friction. So, given enough torque it will slip, and it must have slipped at some point otherwise the pin wouldn't be sheared. The earlier servos had a nylon washer under the crosshead screw to help it slip!

I guess if you take off the arm, the remains of the shear pin may be projecting from the hub sufficiently to get a grip on it.

Duncan mcF. | Quote: | On 04 January 2023 at 12:21 David Cripps <dpc(at)knightonweb.com> wrote:

Thanks very much for this extra info, Duncan.

If you can find that spare stop that would be great. I had seen a picture similar to the one you sent of the stops in another aircraft application.

Following your comments about the shear pin, I think this is the small brass screw located just above the main central cross-head screw that holds the control arm onto the servo in the photo Iâve attached here? I looked at mine more closely and saw that the head of that brass screw appeared to be slightly loose and with some tapping I could get the screw head to drop out of the arm. If that is the shear pin youâre referring to then it appears mine is already sheared! However, the arm doesnât show any tendency to rotate on the hub? I guess the cross-head screw is holding it onto the hub pretty firmly, but I can see that the arm could potentially rotate against the hub without the pin being there (since there is no positive locking mechanism against rotation), but the cross-head screw would need to be looser than it currently is for rotation of the arm to be possible. Should the arm be free to rotate against the hub without the pin there? Question also now is how to get the threaded bit out and the pin replaced?!

Best regards

David

I'd not seen before the clip on the servo arm; there was an earlier Factory 'fix' of Loctited replacement screws. Later servos have a stud and pinned locknut instead (I guess the stud is held in only by Loctite!).

The control column stops should take priority, as the servo stops are probably too light to limit enthusiastic control movements by the pilot, but should at least contain a runaway servo or some other breakage in the servo. I might have some spare stops (if I can find them). The stops are half-visible and annotated 'F' in the photo at: TruTrak-RV10-Roll-Installation-Guide.pdf (bendixking.com)

The shear pin is merely a 6-32 screw with a short part of its length (where this crosses the interface between the mating arm and hub) necked and polished to the roots of the screw thread.

My own servo is mounted towards the back of the Europa 'tunnel' and connects to a horn bolted to the rear end of the roll torque tube. This area used to get hot under certain situations via heat from the stainless firewall and no tunnel ventilation. Subsequently a 'fire blanket' (two thin layers of woven Kevlar with thin fibreglass loft insulation sandwiched between, rather like Orkotek) placed on the back of the firewall enabled cooler temperatures. I've not heard of the standard under-seat servo location getting too hot.

Duncan McF. | Quote: |

On 03 January 2023 at 22:30 David Cripps <dpc(at)knightonweb.com> wrote:

Thank you for the comprehensive reply, Duncan, and also for the replies from Alan and Peter. I really appreciate the feedback.

It seems that the Skymap III should work OK for us, despite its 0.5Hz data refresh rate. A bit of âhuntingâ shouldnât really be a problem. We hadnât planned to have it fly a full route and navigate itself around turning points. I had thought weâd be manually changing the selected track at each turning point, and then lock the tracking to the new direction required. However, the Skymap III does have a âTurn Anticipationâ feature if we should in the future want it to follow a route, and not overshoot a waypoint. Do most people use it to follow a full track, and make all the waypoint turns?

Good to know about the shear pin in the arm as a last resort! Do you have any drawing of the necked stainless pin that you got the LAA to agree to?

The servo that I have came out of an old Europa and didnât seem to have any physical stops on the servo arm. It did, however, have the extra alloy âclipâ to secure the screw that attaches the arm to the servo. Iâve seen that that clip was an LAA requirement too (see photo). For the physical stops, I did see on another forum something that looked like it would do the job on this servo (may even have been a Trutrak part). Does the LAA specify what these stops should look like or be made of? Should they be set so that the servo arm touches them at the same time as the control column reaches its full deflection (if not, then which stop should âtake priorityâ and be hit first)? Does anyone have a photo of what the stops look like in their setup? I imagine them being mounted on the bolts that attach the servo motor to its mounting frame.

My servo would be mounted under the pax seat per Mod 75, so there is not really any ventilation there. Is it worth adding a little cooling fan to the seat locker to keep the air circulating around the servo?

Many thanks for all the input!

David

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.

iv). The Europa needs quite a high torque setting (10 or 12 from memory, which can on hot days plus a high 'activity' setting result in servo overheating and shutdown if you have a trigear with 'heated'/unventilated fuselage tunnel and depending where the servo is mounted).

The pilot stick force required to overcome maximum torque will be applied without even thinking about it and in any case there is a necked brass shear pin (comprising a modified 6-32 brass instrument mounting screw) in the servo arm that can be easily sheared (even without knowing it, and then you wonder why the AP is not tracking!). I agreed with LAA to replace this with a (necked) stainless steel pin in order to provide a little more strength and haven't sheared it since.

I also think that when the servo gets very hot (as above) it's internal voltage regulator starts to shut down (as many are designed to do). Again, there is no way of knowing when this happens until realisation that the AP is not tracking!

v). The LAA will insist upon the stops on the servo, although these stops are not particularly robust and the set up would be better adjusted so that the stops never have to resist the pilot's stick inputs.

Otherwise, the Trutrak system and its dynamics work extremely well and can do a much better job than the pilot, especially in turbulent conditions.

Have you found a setting on your Skymap that allows adjustment of the pre-emptive steering sensitivity (or "turn anticipation")?

Duncan McF. | Quote: |

On 03 January 2023 at 13:10 David Cripps <dpc(at)knightonweb.com (dpc(at)knightonweb.com)> wrote:

So, I've slowly been making some progress on this, having mocked up the whole system out of the aircraft. I have now been able to test it in the workshop and yesterday in a car (it needed to be moving to get a track signal). See attached photo. However, I now have a couple more questions/observations!

i) It seems that the Skymap III that I used in these tests works in terms of making the servo move and display a track on the Trutrak, so that's progress! However, I note from the Skymap manual that it only gives its GPS info every 2 seconds, rather than the once every second that the Trutrak recommends to avoid 'wandering'. Peter, in your post you mentioned that you were using a Skymap III - have you ever had a problem with this (assuming your A/P is the Trutrak Digitrak too)? Alan, is the Garmin 196 that you've mentioned as suitable, able to be set to give data at the 'once per second' rates, as from the manual it seems it may too default to once every 2 seconds?

ii) I noticed when testing in the car, that when the track that was displayed in the Trutrak was close to what we were actually tracking (as read from the Skymap), that the servo was more or less static, and moved in the correct direction when there was a small deviation between what was set on the Trutrak and what we were tracking. However, because our roads are not straight, there were frequently occasions when the actual track from the Skymap was miles away from that set on the Trutrak. In that situation the servo went a bit crazy and rotated its arm by many more degrees than it could ever do in the plane. Is this to be expected in this rather 'offline' mode? I can imagine that when the Trutrak senses that its control input is not creating the sort of aircraft track change that it had expected, that it just moves the servo even further in order to try to get aircraft to do something?

iii) Clearly my mock-up does not provide any sort of 'force feedback' to the servo control arm (ie the arm is completely free to rotate as it likes). In an aircraft, would this be taken care of by aerodynamic feedback via the aileron torque tube? What happens to the servo when it reaches the full movement that the aileron would allow (the point when the control column hits its roll stops)?

iv) I can imagine that I wouldn't want the servo ever applying full aileron to create a turn as that would make for a very violent manoeuvre! I see that there are settings that can be adjusted in the Trutrak set-up menus that control activity level and also control maximum torque. What values have people set in theirs? I note that when I have set the recommended value of 12 for the torque, it is almost impossible to override the servo arm when the A/P is engaged (though I appreciate that with no control column attached the leverage I can apply to the servo arm with my fingers is very low. I also appreciate that normally if one wanted to override the A/P you would disengage it first).

v) Lastly (for now!) has anyone fitted physical 'stops' to the servo body that the servo arm would hit to ensure that the servo can never try to move the pushrod beyond the point where full aileron is applied?

Apologies for all the questions but I want to make sure it is really working correctly before I contort myself to fit it into the aircraft itself!

Best regards

David

On 19/11/2022, 16:26, "Alan Burrill" <owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com) <mailto:owner-europa-list-server(at)matronics.com (owner-europa-list-server(at)matronics.com)> on behalf of alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>> wrote:

--> Europa-List message posted by: Alan Burrill <alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk) <mailto:alanb(at)dpy01.co.uk (alanb(at)dpy01.co.uk)>>

Ok Iâve had a. Ha ce to fly mine with the GPS feed off.

As Duncan says below the display drops to show -|â|- but maintains the track last set or you are holding when you switch it on.

The are no heading digits on the display so you will need use your compass/DI to show that.

If you press the left or right â¤µï¸ buttons then you can alter the track the AP is following either left or right and a number appears which if you press the button you can increase or decrease after the AP locks on the numbers disappear and you have the -|â|- on the display.

Useful if you have a GPS failure but wouldnât want that as normal mode of operation so my suggestion is you need a GPS feed with the right NEMA message set to get the most out of the AP and the ability for it to follow a track you have programmed in is a bonus.

One word of caution, I have come across some GPS that donât put out any messages, even the position message for driving a Transponder ADS-B output, unless there is a track in the GPS. That was how some of the older version worked, GARMIN 430 and possible the early AVMAP were guilty of that.

Hope that helps.

Alan

Sent from my iPad | Quote: |

On 10 Nov 2022, at 10:52, D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>> wrote:

--> Europa-List message posted by: D McFadyean <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net) <mailto:ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>>

Digitrak only needs basic positional information from the GPS on a regular basis. It will use this information to fly the track that has been set on the Digitrak.

If a route is programmed in to the GPS, it will fly that too (with different commands being set at the Digitrak control head to enable this), so long as the GPS is also putting out the crosstrack error signal; not all of them do.

Duncan McF. |

s.com/Navigator?Europa-List>

ion>

|

|

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Davidcripps

Joined: 09 Aug 2021

Posts: 40

|

Posted: Wed Jan 04, 2023 8:48 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz Posted: Wed Jan 04, 2023 8:48 am Post subject: Trutrak AP with Garmin GPS 18x 5Hz |

|

|

Thanks, Duncan.

I have removed the arm now (and the crosshead screw does indeed have a nylon washer under it). I note the LAA requirement that this screw needs Loctiting when it is put back in, as well as the screw retaining clip refitting over it.

I can see that the shaft of the brass pin has broken below the surface of the hub so unfortunately there is nothing to grab onto. However, I also notice that there are two other similar screw holes in the hub which could be used instead, by rotating the hub through 120deg. Perhaps this is a deliberate design to give a chance of doing an in-field replacement of a sheared pin in order to get it working again, enabling the removal of the old pin stub to be done at a later time.

Any ideas how to remove that stub? I have some screw extractors but theyâre much too big.

Also, do you know where I can obtain replacement pins? You probably made your own when you switched to the stainless screws? If I do the same with a brass or stainless 6-32 screw is there a defined amount of âneckingâ required so that it shears at an appropriate shear force?

David

With a failed pin, there would now be no shear connection between the servo hub and the arm other than friction. So, given enough torque it will slip, and it must have slipped at some point otherwise the pin wouldn't be sheared. The earlier servos had a nylon washer under the crosshead screw to help it slip!

I guess if you take off the arm, the remains of the shear pin may be projecting from the hub sufficiently to get a grip on it.

Duncan mcF. | Quote: |

On 04 January 2023 at 12:21 David Cripps <dpc(at)knightonweb.com> wrote:

Thanks very much for this extra info, Duncan.

If you can find that spare stop that would be great. I had seen a picture similar to the one you sent of the stops in another aircraft application.

Following your comments about the shear pin, I think this is the small brass screw located just above the main central cross-head screw that holds the control arm onto the servo in the photo Iâve attached here? I looked at mine more closely and saw that the head of that brass screw appeared to be slightly loose and with some tapping I could get the screw head to drop out of the arm. If that is the shear pin youâre referring to then it appears mine is already sheared! However, the arm doesnât show any tendency to rotate on the hub? I guess the cross-head screw is holding it onto the hub pretty firmly, but I can see that the arm could potentially rotate against the hub without the pin being there (since there is no positive locking mechanism against rotation), but the cross-head screw would need to be looser than it currently is for rotation of the arm to be possible. Should the arm be free to rotate against the hub without the pin there? Question also now is how to get the threaded bit out and the pin replaced?!

Best regards

David

I'd not seen before the clip on the servo arm; there was an earlier Factory 'fix' of Loctited replacement screws. Later servos have a stud and pinned locknut instead (I guess the stud is held in only by Loctite!).

The control column stops should take priority, as the servo stops are probably too light to limit enthusiastic control movements by the pilot, but should at least contain a runaway servo or some other breakage in the servo. I might have some spare stops (if I can find them). The stops are half-visible and annotated 'F' in the photo at: TruTrak-RV10-Roll-Installation-Guide.pdf (bendixking.com)

The shear pin is merely a 6-32 screw with a short part of its length (where this crosses the interface between the mating arm and hub) necked and polished to the roots of the screw thread.

My own servo is mounted towards the back of the Europa 'tunnel' and connects to a horn bolted to the rear end of the roll torque tube. This area used to get hot under certain situations via heat from the stainless firewall and no tunnel ventilation. Subsequently a 'fire blanket' (two thin layers of woven Kevlar with thin fibreglass loft insulation sandwiched between, rather like Orkotek) placed on the back of the firewall enabled cooler temperatures. I've not heard of the standard under-seat servo location getting too hot.

Duncan McF. | Quote: |

On 03 January 2023 at 22:30 David Cripps <dpc(at)knightonweb.com> wrote:

Thank you for the comprehensive reply, Duncan, and also for the replies from Alan and Peter. I really appreciate the feedback.

It seems that the Skymap III should work OK for us, despite its 0.5Hz data refresh rate. A bit of âhuntingâ shouldnât really be a problem. We hadnât planned to have it fly a full route and navigate itself around turning points. I had thought weâd be manually changing the selected track at each turning point, and then lock the tracking to the new direction required. However, the Skymap III does have a âTurn Anticipationâ feature if we should in the future want it to follow a route, and not overshoot a waypoint. Do most people use it to follow a full track, and make all the waypoint turns?

Good to know about the shear pin in the arm as a last resort! Do you have any drawing of the necked stainless pin that you got the LAA to agree to?

The servo that I have came out of an old Europa and didnât seem to have any physical stops on the servo arm. It did, however, have the extra alloy âclipâ to secure the screw that attaches the arm to the servo. Iâve seen that that clip was an LAA requirement too (see photo). For the physical stops, I did see on another forum something that looked like it would do the job on this servo (may even have been a Trutrak part). Does the LAA specify what these stops should look like or be made of? Should they be set so that the servo arm touches them at the same time as the control column reaches its full deflection (if not, then which stop should âtake priorityâ and be hit first)? Does anyone have a photo of what the stops look like in their setup? I imagine them being mounted on the bolts that attach the servo motor to its mounting frame.

My servo would be mounted under the pax seat per Mod 75, so there is not really any ventilation there. Is it worth adding a little cooling fan to the seat locker to keep the air circulating around the servo?

Many thanks for all the input!

David

i). The Trutrak will work on a Europa at 0.5Hz update frequency (i.e. every 2 seconds). Sometimes the AP will hunt gently (yesterday was a case in point, but there were sites yesterday that were GPS-jamming as well, so that might have been a cause' or possibly I have a too low torque setting than optimal in order to limit servo overheating). If too many options of output data are requested in the GPS NMEA output setup then there won't be enough time to output all that data within a faster update period; the GPS set will normally tell you if this is going to be the case.

iii). The servo does not care about torque feedback. The servo will provide a force (torque) only up to the maximum value that has been preselected.