|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Thu Jun 29, 2023 2:33 am Post subject: Rotax 914 Dyno Test Posted: Thu Jun 29, 2023 2:33 am Post subject: Rotax 914 Dyno Test |

|

|

This was a really interesting video to watch.

https://m.youtube.com/watch?v=lE6Y37GPQqY

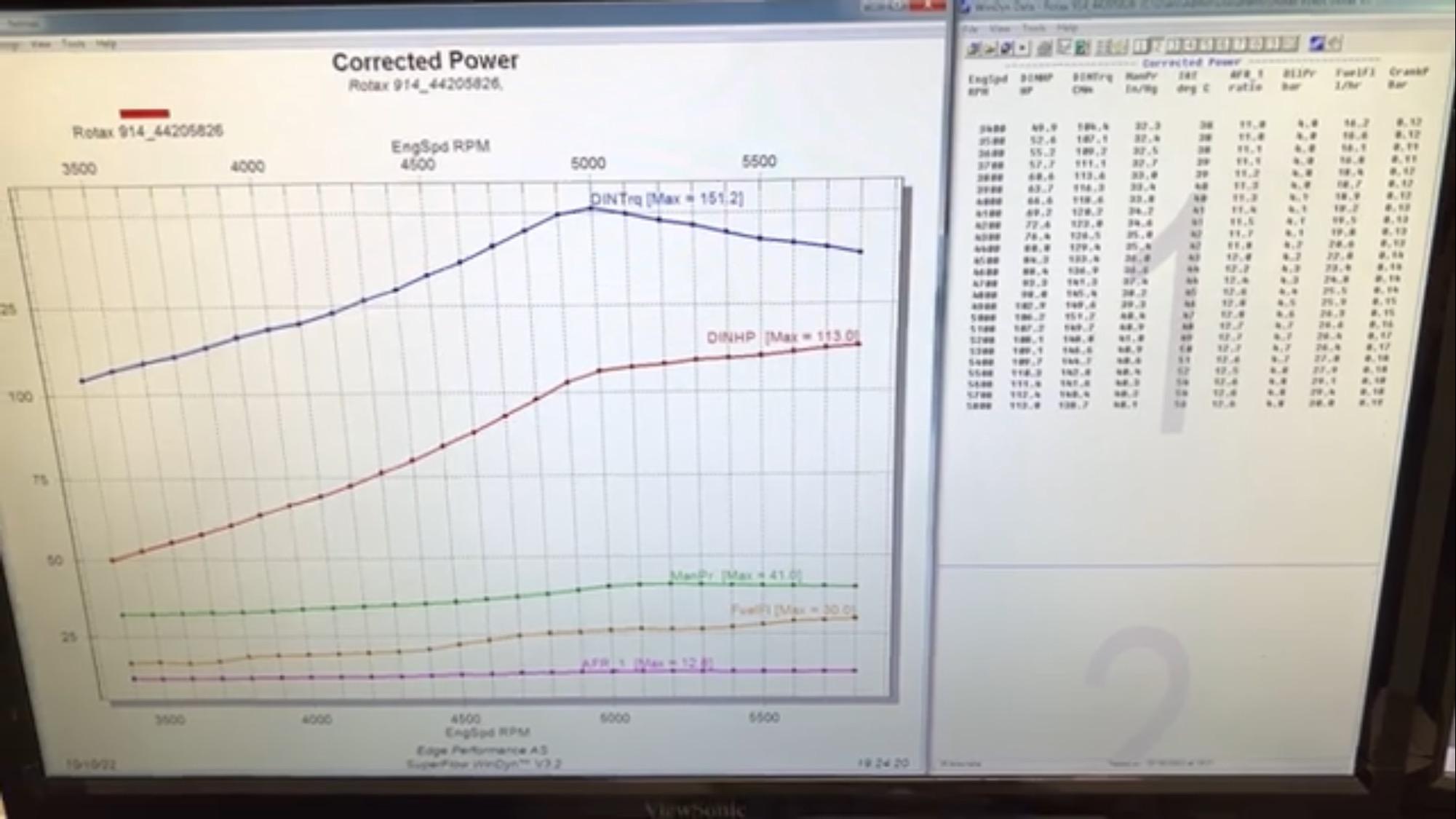

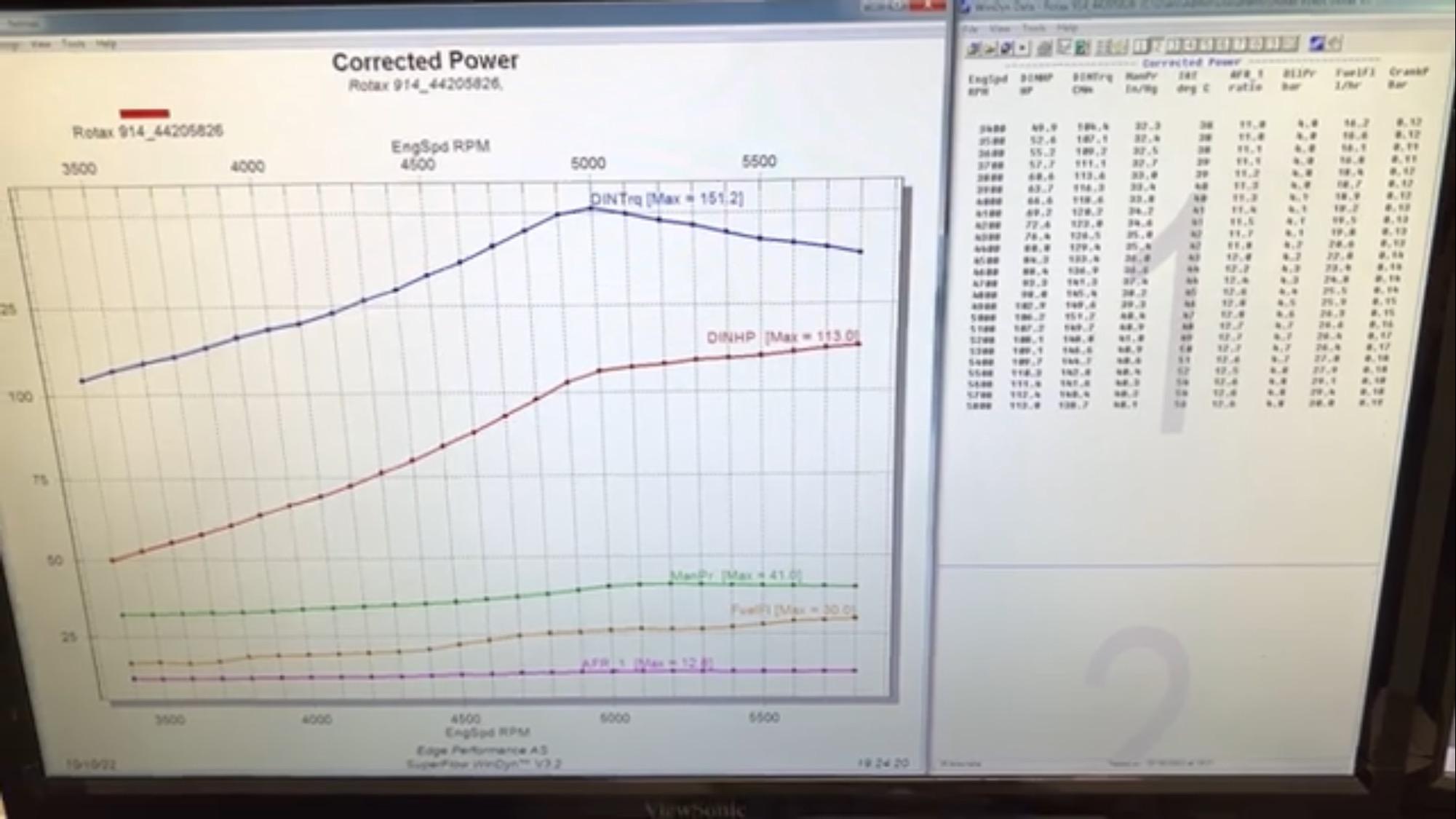

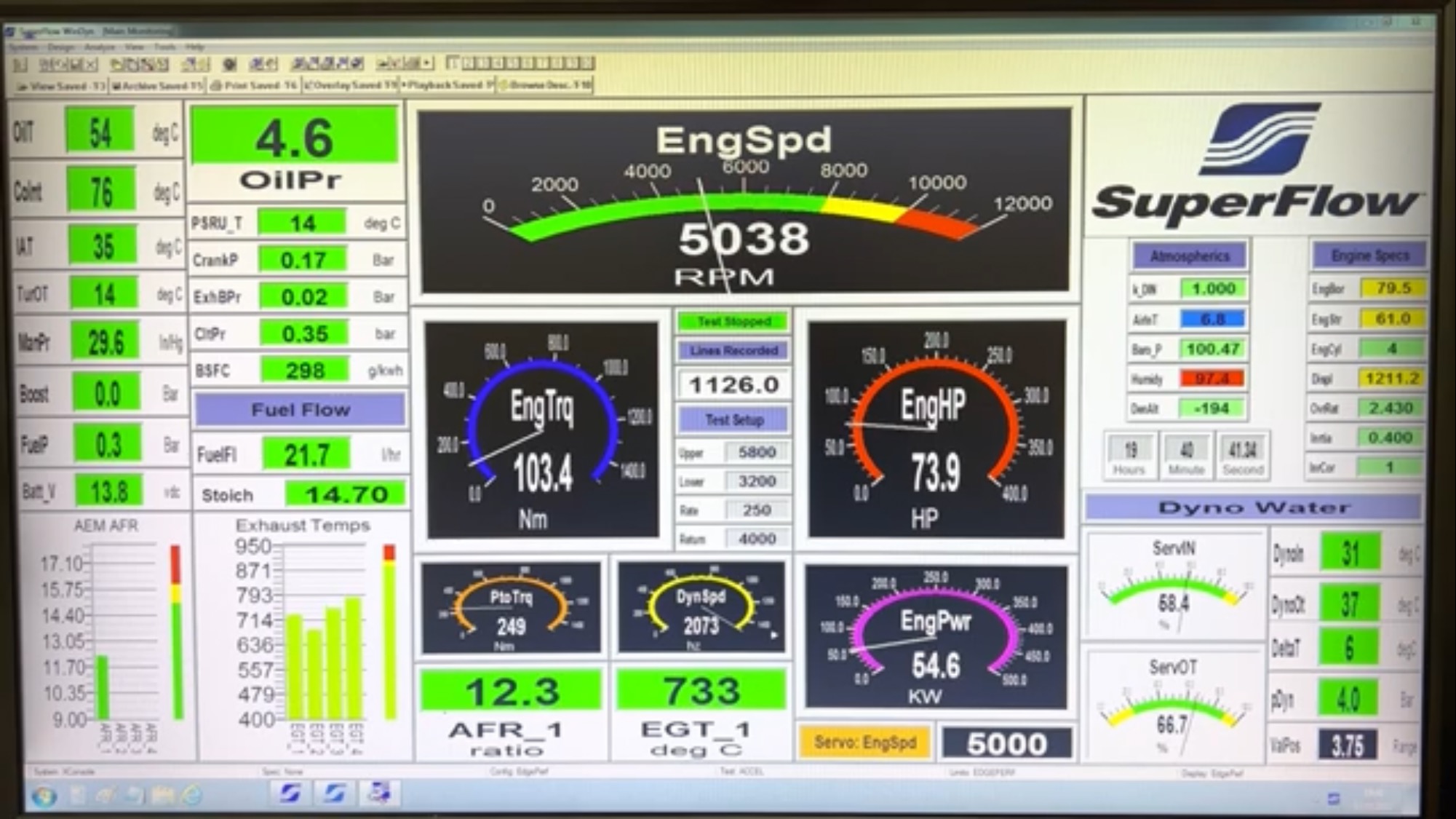

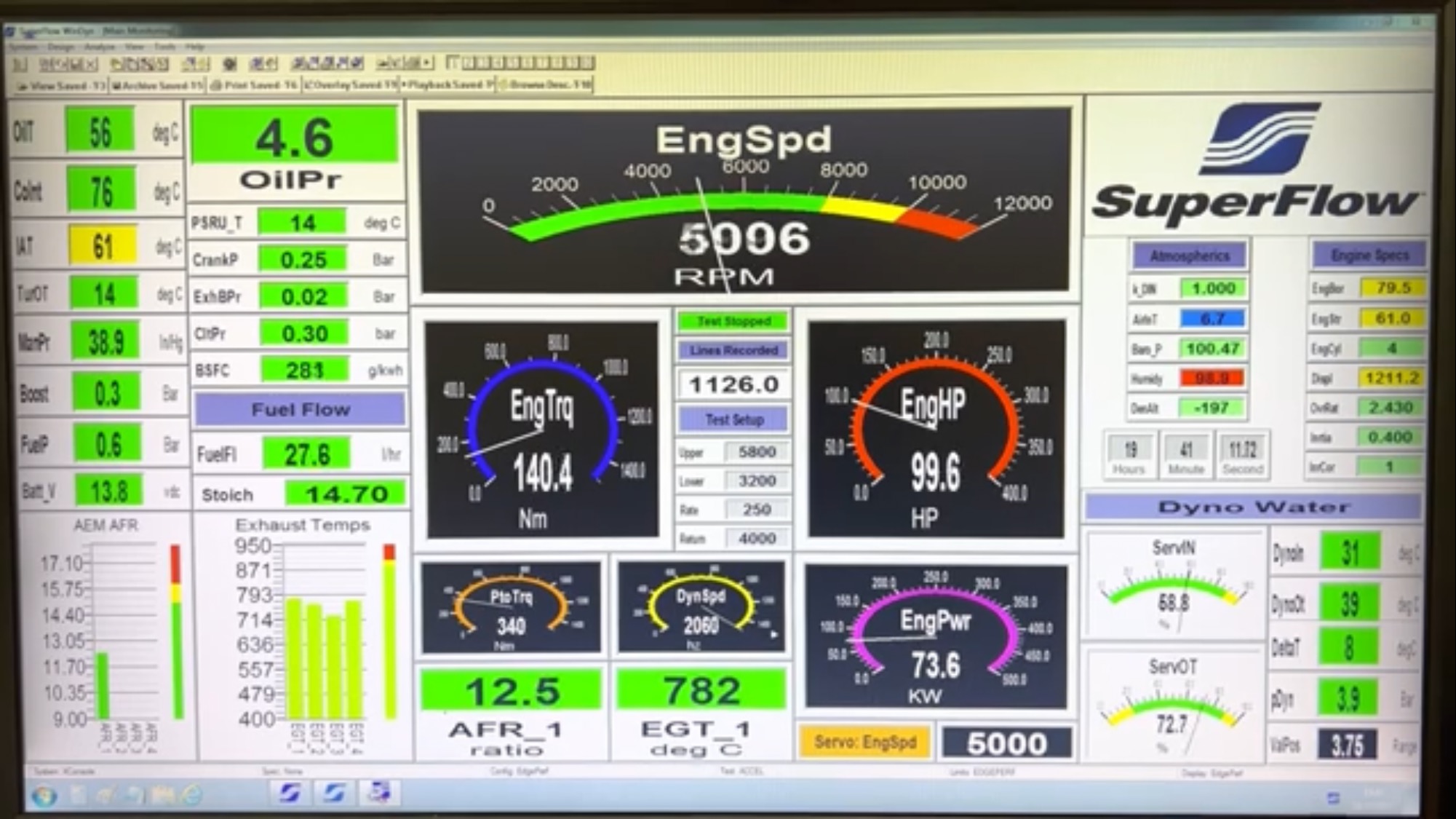

Edge Performance dyno test of a stock Rotax 914 with results.

It would appear that running the 914 at 5500rpm and 5800rpm produces less HP Economy and Torque than running at 5000rpm due to the ECU opening the wastegate as post turbo IAT increases.

Off-Boost numbers at 5000rpm also are indicative of 912 80hp performance at 5000rpm.

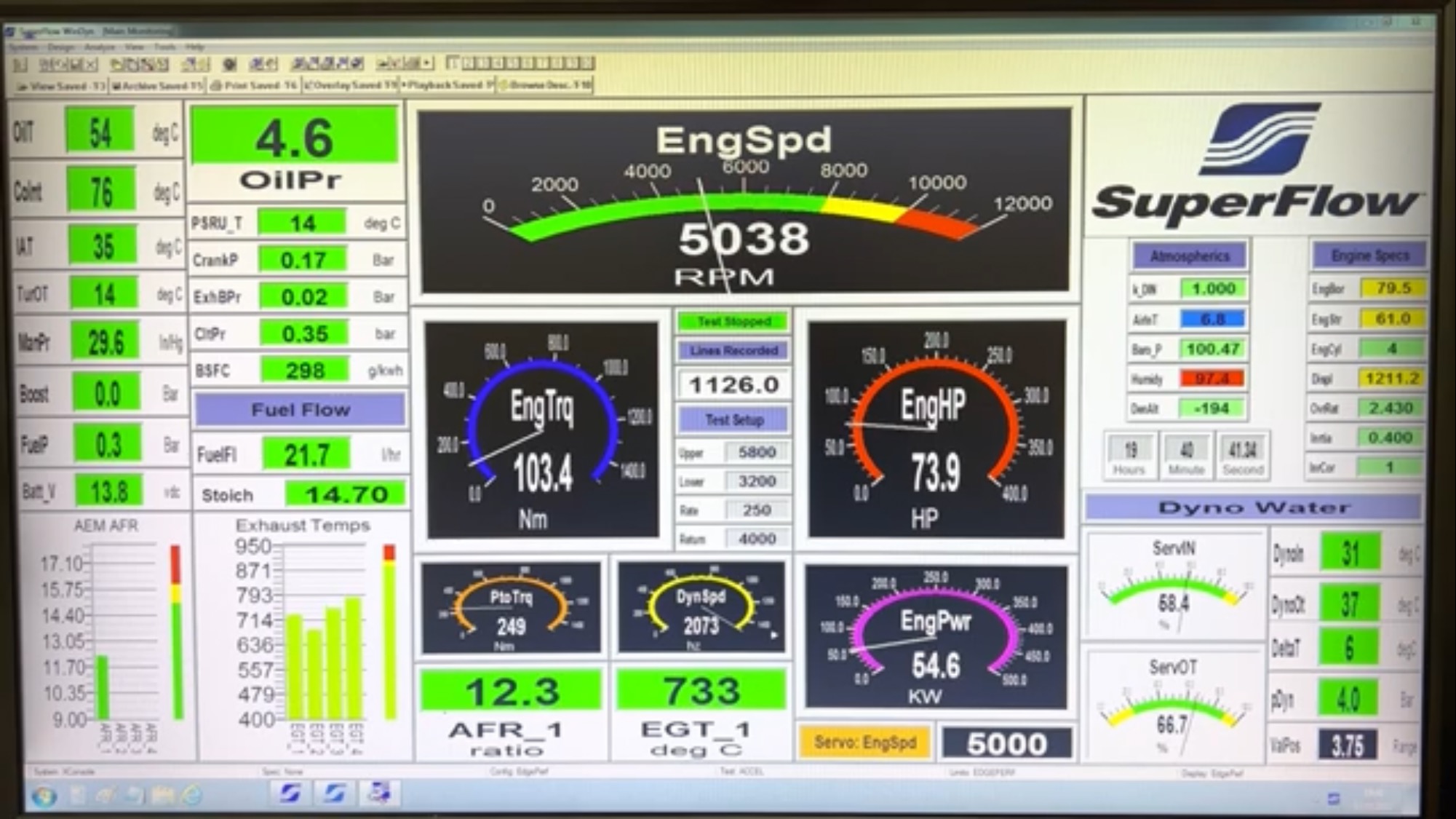

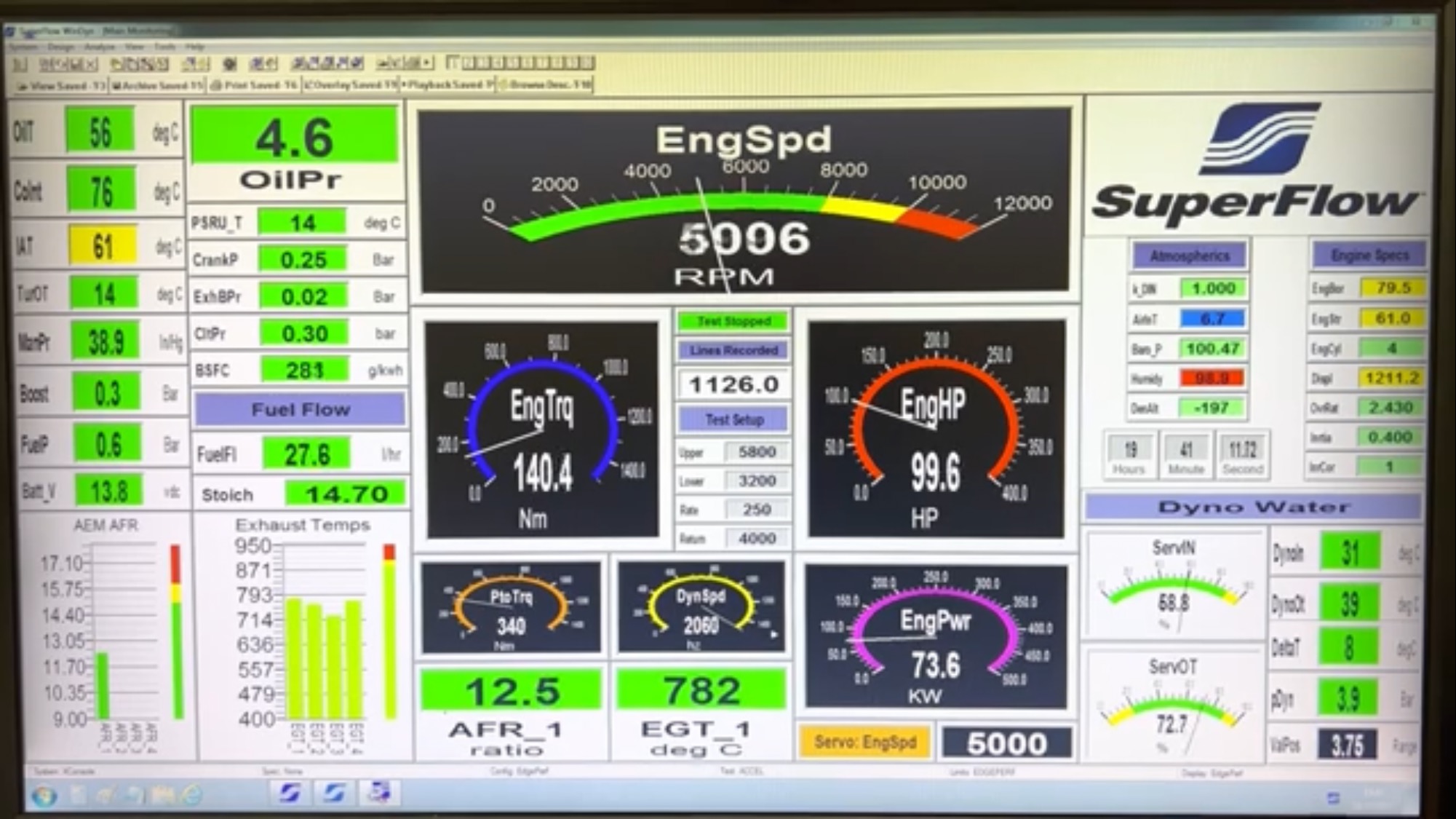

The PTO Torque (orange readout) above AFR is available torque at the propeller shaft, and Dyno Speed (yellow readout) above EGT is the propeller shaft RPM.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

245.04 KB |

| Viewed: |

5069 Time(s) |

|

| Description: |

|

| Filesize: |

381.47 KB |

| Viewed: |

5069 Time(s) |

|

| Description: |

|

| Filesize: |

376.93 KB |

| Viewed: |

5069 Time(s) |

|

Last edited by Area-51 on Sun Jul 02, 2023 10:35 pm; edited 1 time in total |

|

| Back to top |

|

|

dmac7

Joined: 05 Apr 2019

Posts: 48

Location: Canada

|

Posted: Sun Jul 02, 2023 8:51 am Post subject: Re: Rotax 914 Dyno Test Posted: Sun Jul 02, 2023 8:51 am Post subject: Re: Rotax 914 Dyno Test |

|

|

Thing's are not always as they first appear, fortunately. As one Youtube reply would suggest. He also had a high IAT of 92C but after isolating his inlet from the exhaust/turbo heat his IAT dropped to 42C...so maybe you don't need that intercooler after all. The devil is often in the details...details we learn about later.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

Posted: Sun Jul 02, 2023 9:32 am Post subject: Rotax 914 Dyno Test Posted: Sun Jul 02, 2023 9:32 am Post subject: Rotax 914 Dyno Test |

|

|

Indeed.

Many of his vids/posts are a bit misleading/partial truths. ( like him claiming he could fit his forged single piece crank with bolted rods in the stock case.....not)

Cheers

PeteZ

On Sun, Jul 2, 2023, 12:58 p.m. dmac7 <dmac7(at)outlook.com (dmac7(at)outlook.com)> wrote:

| Quote: | --> Europa-List message posted by: "dmac7" <dmac7(at)outlook.com (dmac7(at)outlook.com)>

Thing's are not always as they first appear, fortunately. As one Youtube reply would suggest. He also had a high IAT of 92C but after isolating his inlet from the exhaust/turbo heat his IAT dropped to 42C...so maybe you don't need that intercooler after all. The devil is often in the details...details we learn about later.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=511021#511021

===========

pa-List" rel="noreferrer noreferrer" target="_blank">http://www.matronics.com/Navigator?Europa-List

===========

FORUMS -

eferrer noreferrer" target="_blank">http://forums.matronics.com

===========

WIKI -

errer noreferrer" target="_blank">http://wiki.matronics.com

===========

b Site -

-Matt Dralle, List Admin.

="noreferrer noreferrer" target="_blank">https://matronics.com/contribution

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Sun Jul 02, 2023 10:43 pm Post subject: Re: Rotax 914 Dyno Test Posted: Sun Jul 02, 2023 10:43 pm Post subject: Re: Rotax 914 Dyno Test |

|

|

Thought it was interesting re' how the ECU bleeds off boost as IAT increases.

Wondering if this is experienced by end users not running intercooler.

Also provides turbo timing data.

Didn't know about one piece crank; have thought about it though for a minute and decided split crank is a much better deal.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 796

|

Posted: Mon Jul 03, 2023 9:21 am Post subject: Re: Rotax 914 Dyno Test Posted: Mon Jul 03, 2023 9:21 am Post subject: Re: Rotax 914 Dyno Test |

|

|

Hi Group

What I find interesting on the 914 is with the throttle about 1/2" or less, the airbox pressure is greater than 44"! When setting up 914 with TCU software, I found that 1/2" or less the wastegate is closed. Then remains opened from about 1" to 3" (this is with the engine not running:

https://www.cps-parts.com/cps/pdf/d05240.pdf

See page 7-10 for airbox pressure graph.

Boy, if the airbox is going to blow off, who would have thunk that it just may have a better chance of doing so near idle with over 44" and probably more vibration than at war emergency power (115% power, 100% throttle) which only has a tad bit more than 40" or at 100% continuous power that has only a tad bit more than 36".

See page 5-4 for MP from 55% to 115% power.

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Mon Jul 03, 2023 4:51 pm Post subject: Re: Rotax 914 Dyno Test Posted: Mon Jul 03, 2023 4:51 pm Post subject: Re: Rotax 914 Dyno Test |

|

|

It's highly probable the manifold graph referred to in fig 6, p76, is referencing the max MAP baseline which drops dramatically at engine startup.

The wastgate rests at full open position when the engine is not operating and/or the wasgate switch on the instrument panel is switched off.

Turbo timing occurs at 46% throttle, with boosting available upward of 3000rpm.

Apart from Line Maintenance lubrication, unless you really have a total understanding of what you are doing I wouldn't recommend fiddling with any of the turbo controlling components.

Unlike a Supercharger a Turbo has the capability to runaway and bust the engine in a split second.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 796

|

Posted: Mon Jul 03, 2023 6:29 pm Post subject: Re: Rotax 914 Dyno Test Posted: Mon Jul 03, 2023 6:29 pm Post subject: Re: Rotax 914 Dyno Test |

|

|

Hi Area 51

Graph 6 on page 7-10 is in fact airbox pressure, not manifold pressure. That would be the pressure before it gets to the carbs. The wastegate is in fact fully closed at idle position and up to about up to 1/2" advanced. There is turbo pressure even at idle and because the butterfly is mostly closed and whatever pressure there is can't escape thus airbox pressure increases, it increases the airbox pressure to 44" as per graph. When the engine is off and you move throttle to idle, the wastegate closes. Then you advance it to about 1/2" it opens. Net increase of power over straight 912 doesn't start to occur till about half throttle.

The old TCU had a airbox temperature intervention temperature of 160F, the newer style TCU 190F. Even with new style TCU, if for whatever reason you are going to trust that your 914 is going to be making boost HP and not 912 normally aspirated HP, and your life is going to depend on that, Rotax suggests a DO 178 B take off. See page 3-11 in Operators manual. In other words, move the wastegate to the closed position (which you can do by placing the throttle lever to less than 1/2" advancement) then turnoff your TCU. Now you have a closed wastegate. One needs to be extremely careful doing this, you can easily exceed maximum boost. That said, if you advance slowly and select maximum boost using the throttle, you can limit boost pressure. Just like at idle where airbox pressure is way up and manifold pressure is way down, doing a DO 178B take off airbox pressure will be way up and you are limiting manifold pressure with throttle. At high power settings this is not something you want to do for a very long time as it's hard on the turbo. But to clear those 50 foot trees taking off downwind from a short field (which you should probably not be doing in the first place) but if you ever do that or something where you don't the turbo to quit when you can't abort, best eliminate uncommanded removal of turbo boost.

Ron P.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Mon Jul 03, 2023 9:09 pm Post subject: Re: Rotax 914 Dyno Test Posted: Mon Jul 03, 2023 9:09 pm Post subject: Re: Rotax 914 Dyno Test |

|

|

In that case the Wastegate switch referred to above is the TCU switch component, and the Nominal Airbox pressure (2atm) would be residual from the compressor function at 1600rpm-2000rpm. As soon as the throttle is cracked this pressure drops suddenly as the compressor has no capacity yet to supply enough volume to maintain boost pressure.

The Torque performance figures in the Rotax Op' manual do not match the Edge Performance results due to differences in wastgate function. The Edge Performance run shows full MAP of 41 from 5000rpm upward while the Rotax figures state MAP of 31 at 5000rpm. Timing the turbo for full boost at 5000rpm extracts the engine's full Torque curve potential. Approx 105hp at 5000rpm v's 74hp. Whether or not the engine can sustain this level of thermal loading while using an intercooler is another matter. EGT and CHT readings would indicate yes or no. Keep in mind these performance figures are under full load WOT and the pitched propeller may or may not actually request this amount of power under real flight conditions.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rparigoris

Joined: 24 Nov 2009

Posts: 796

|

Posted: Tue Jul 04, 2023 10:22 am Post subject: Re: Rotax 914 Dyno Test Posted: Tue Jul 04, 2023 10:22 am Post subject: Re: Rotax 914 Dyno Test |

|

|

Hi Area 51

Yes you turn off the power to the TCU to lock the waste-gate servo in whatever position it happens to be in. There is a normally closed momentary switch in series with the waste-gate, it's used to reset the TCU if boost pressure is rising and dropping. Maximum off of switch is 5 seconds, see page 4-3. Note around 108% power the enrichment kicks in and the boost begins to rise rapidly to war emergency power (115%), best stay out of this range to keep things stable, so I plan to use 100% or 115%,see page 7-10.

As far as idle airbox pressure, looking at figure 6 on page 7-10, Rotax by using the throttle position sensor, closes the wastegate between 0 and 10% of throttle movement (they are using 115% movement). It's not just the cracking of butterfly off of idle, it's the TCU opening the wastegate when the lever is at 10%. 10% equates to just about 1/2" in the throttle slot. The opening of the wastegate is why there is such a large drop in airbox pressure, not more opening of the carb butterfly. I'm thinking perhaps the reason Rotax closes the wastegate, is to prevent carb ice if the airbox was at ambient pressure with butterfly very closed??? Then looking at figure 6, they open the wastegate from 10% to a little under 50%.

You were not comparing apples with apples when you said the 914 can only make 74hp at 5,000 rpm. You were probably looking at performance data for CS prop page 5-4. That shows a 75% (that is of 100%) setting of 31" and 5,000 rpm. 31" is not the maximum MF pressure, it just happens to be what is required for 75%.

If you look at Manifold Pressure graph page 5-2 and Performance graph for standard conditions page 5-2, you will see that 100% continuous manifold pressure and 5,000 rpm produces just under 90 horse power. Using 115% manifold pressure and 5,000 rpm, horse power is just under 100hp.

For a DO178 B take off, If the TCU seems to be working, the manual has you have the TCU on, then set to 115% power (always checking to make sure you are not going to exceed maximum boost pressure), then turn off TCU. If the TCU isn't working properly, personally I would just leave the wastegate opened till I could fix it, but if I really needed to have some extra power, close wastegate then turn off TCU and CAREFULLY add throttle and take off, then open wastegate and turn off TCU. Again using the throttle butterfly to limit boost can be done, but you really need to be careful and only do it for a short period of time as it's hard on the turbo. BTW, a fun note, I owned a 1983 Volvo GLT 50 (245) turbo wagon with a 2.1 liter 4 cylinder. It had the identical Garette turbo the 914 has! I used to tow a 15' high profile Hot Air Balloon trailer, set up an old american auto anti dieseling solenoid and set it to 29.92" of manifold pressure. If going uphill I would just drop gears. Got over 350K on that turbo, then the clutch began to slip. Many folks blew up the air cooled turbos. I bought the car new and installed a factory intercooler. Supposedly with intercooler installed, would instead of raising ambient temperature 145F, it would only raise it 45F. Now while still maintaining the the factory guarantee, they made a controlled leak between the wastegate and manifold (it was vacuum operated wastegate). What they did was have a counter, when you got to 3,750rpm the leak would open and give you more boost. It worked great. Many would just put a fish tank bleed valve to make a leak, I was not too much a fan. With 914 new style TCU, maximum MP is 39". I imagine if you really wanted you could make a controlled leak at the airbox pressure sensor. Best to use 100ll or really high octane fuel and probably have an intercooler and bump up an inch or 2. I think crankshafts may start to move? Perhaps could TIG together? For me, I'm leaving things stock with no intercooler. That said, Rotax even with new style airbox that has a less touchy enrichment "hand in breeze" to create a higher than airbox pressure to enrich things over 108% power, asks that if you install an intercooler, check each cylinder at war emergency power and make sure it's making enough Carbon Monoxide. I have a carbon monoxide tool and plan to test my carbon monoxide one cylinder at a time. They give you a minimum amount of carbon monoxide they want for the leanest cylinder. Ron

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

erichdtrombley(at)juno.co

Guest

|

Posted: Wed Jul 05, 2023 7:18 am Post subject: Rotax 914 Dyno Test Posted: Wed Jul 05, 2023 7:18 am Post subject: Rotax 914 Dyno Test |

|

|

Hello all,

Having flown my Europa Monowheel, powered by an early 914 for over 20 years, I find this discussion interesting. I initially installed my engine with an intercooler, however after a few years I removed it, rationalizing that it was unnecessary since 100% power is all that I ever use for takeoff, and I cruise at 75% power. I figured it was just extra weight and so out it came. Unfortunately, at the time I was not monitoring airbox temp as my engine monitor wasn’t that sophisticated.

That changed when I installed my Dynon Skyview with a very capable engine monitor. I found that the airbox temperature was as high as 170 F which exceeded the intervention temperature (160 F) for my early motor. So, I reinstalled the intercooler which knocked the airbox temp down to 132 F max.

Considering the new TCU has an intervention temperature of 190 F, the installation of an intercooler may not be necessary. YMMV.

Lastly, regarding the DO 178 B takeoff. I believe the english translation of the operating manual my be incorrect. The description of the DO 178 B takeoff is correct, stating that the takeoff is performed with a “deactivated servo motor” of the TCU. This makes sense considering Rotax requires a double pole, single throw switch be installed to isolate the servo motor should the engine be unable to maintain a steady RPM at high power settings. However, the steps listed to perform the DO 178 B instruct you to turn off the TCU. I believe this is an error, as doing so would cause the TCU to perform a self test upon being turned back on, which would cycle the waste-gate, something you would not want to happen while in flight. Rather, I believe the manual intended to say that you should deactivate (isolate) the servo motor with the above reference switch while keeping the TCU on. In this manner, when the servo motor is turned back on, the TCU will not recycle the waste-gate, but will adjust the waste-gate as necessary based on the current throttle position.

Looking forward to seeing everyone at OSH later this month,

Erich

N28ET Classic Mono 914

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

budyerly@msn.com

Joined: 05 Oct 2019

Posts: 288

Location: Florida USA

|

Posted: Wed Jul 05, 2023 10:29 am Post subject: Rotax 914 Dyno Test Posted: Wed Jul 05, 2023 10:29 am Post subject: Rotax 914 Dyno Test |

|

|

Eric you are spot on.

In 2010 I put the TLR46 TCU on my old Rotax 914 and I didn't see the airbox temp on my thermocouple go above 140 C so that told me I didn't need any intercooler as we did on the Jason Parker modified 914. His engine had a simple vacuum dashpot turbo control, so the boost came on later as RPM increased).

Personally, I use full turbo for takeoff to check it works as advertised, more than actually needing the power for takeoff. My inlet temp was measured by a thermocouple clamped to the plenum for my tests originally. (I don't have a probe in the engine although there is a port.) I was more concerned about heat during the extended climb at max continuous and my CHTs and found TOT was not a factor with the new TCU in 90 F degree summer heat.

In the Parker engines I would put a bag of ice on the intercooler and found that could make a huge difference but in fact we needed a larger intercooler, the width of the engine, to be effective without ice on the slower planes. The flow of air in these small turbos is not that great and the mass of the cooler was more important as a temperature dissipater on hot California desert days than the inlet and discharge. That is just my opinion down here in hot Florida. We every day fliers don't race the other fast glass planes like in the very early 2000's at Sun n Fun to fool with the turbo. We want to fly safe and efficiently, or we wouldn't own the Europa. (They told me the Eclipse would win because they wired open the wastegate to get the factory Europa mono's by a couple knots.)

In general: Use good gas, go to full turbo for takeoff and pull it back when safely airborne and leave it in max continuous for the climb is all most Europa owners need to do. Where the TCU places the turbo wastegate is information not needed to fly or worry about the old TCU temperature anti knock waste gate limiter but its nice to know and that is what data logging is good for. The charts in the book are good enough for a reference. I would recommend , just prior to annual, wash the bird, bring your laptop along and hook it up on the D sub you put in the cockpit for your TLR 46 recording. Go fly: Record the data at start for a few seconds, then hit L to stop log, then hit L again and record takeoff, transition to climb and then hit L to stop, then L again to turn on log for passing 5000MSL, and go into cruise at 5500 MSL (East Coast and 7500 Western mountains may be better) and let the engine stabilize at cruise, trim it up, and enjoy the flight. At cruise, record into your camera or on paper, the trim, rig, your desired aircraft upgrades, deficiencies, malfunctions, analyze your stall and slow flight for feel, stall recognition and reaction then land and take the data home. Break it down, prepare your inspection checklist, gather parts, and then go to the hangar/workshop/garage and take care of mx business.

The stock 914 installation per the manual is adequate with some attention to the ducting. Because the power output (BTUs) are higher on the 914, watch your cylinder temps with the new engine on extended climbs. Climb at 90-100 Kts will help on break-in of a new engine. Set your plane up for good recording. Dynon, Grand Rapids, and of course the famous Rotax recording methods are good things to build into your plane and assist you in flight testing as you will find data recording to be time consuming and distracting. Let the computers do their thing and you fly the airplane, clear for traffic, concentrate on good airmanship in flight, the pattern and landing.

Just my opinion,

Bud Yerly

Custom Flight

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 397

|

Posted: Thu Jul 06, 2023 2:15 am Post subject: Re: Rotax 914 Dyno Test Posted: Thu Jul 06, 2023 2:15 am Post subject: Re: Rotax 914 Dyno Test |

|

|

That's sound advise; just set it all up as factory advise, and just fly the plane and let the computer do the rest. Guess what? It will work as required 🤷🏼♂️

Personally, my view toward turbo charging is not to increase go fast performance, but just for atmospheric compensation at altitude.

Is that a typo re' Eclipse, wouldn't they of wired the wast gate shut?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|