|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

JonathanMilbank

Joined: 14 Apr 2012

Posts: 391

Location: Aberdeen area

|

Posted: Wed Dec 25, 2024 5:19 pm Post subject: Engine mount bolt loosens Posted: Wed Dec 25, 2024 5:19 pm Post subject: Engine mount bolt loosens |

|

|

This is the fourth time in over 27 years that I'm removing a Rotax 912 from my aircraft to get something attended to. Each time that I've installed an engine in the past, I inserted and tightened the 4 bolts securing the frame to the crankcase without using Loctite or grease. I've always simply tightened them, not using any specific torque setting, but simply tightening them to a degree which seems "plenty enough".

For the first time in over 1500 hours, I've found one bolt which loosened since the last 50 hour inspection. So my question is whether to use Loctite when reinstalling the engine and what number Loctite do you recommend?

My instinct is to use fairly low strength Loctite, in case the next time of engine removal proves to be near impossible to get the bolts out.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 403

|

Posted: Wed Dec 25, 2024 9:39 pm Post subject: Re: Engine mount bolt loosens Posted: Wed Dec 25, 2024 9:39 pm Post subject: Re: Engine mount bolt loosens |

|

|

Consult the Rotax installation manual and use the specified thread lock product.

Alternatively purchase new cap screws and "hardened" washers to required specification that have drilled heads to permit lock wiring.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 222

|

Posted: Thu Dec 26, 2024 3:17 am Post subject: Engine mount bolt loosens Posted: Thu Dec 26, 2024 3:17 am Post subject: Engine mount bolt loosens |

|

|

I think that misses the point, Which was that, despite proper locking, some installations fret the mount against the engine, resulting in bolts coming "loose". I've previously found one on a Pioneer, despite being tight for the preceding several years.

BTW, the combination of Loctite plus the swarf that Rotax leaves down the tapped mounting bolt holes is irremovable without significant risk of galling the threads upon bolt extraction.

Duncan McF.

| Quote: | On 26/12/2024 05:39 GMT Area-51 <goldsteinindustrial(at)gmail.com> wrote:

Consult the Rotax installation manual and use the specified thread lock product.

Alternatively purchase new cap screws and "hardened" washers to required specification that have drilled heads to permit lock wiring.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=515170#515170

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 403

|

Posted: Thu Dec 26, 2024 11:20 am Post subject: Re: Engine mount bolt loosens Posted: Thu Dec 26, 2024 11:20 am Post subject: Re: Engine mount bolt loosens |

|

|

All valid; points noted.

On occasion have found bolt has loosened and departed the airframe leaving three secure in place. Why does the bolt loosen? Vibration and the sum total of heat expansion and contraction cycles of individual components. Check the flat washer used under the cap screw heads; they should be hardened washers under the spring washers.

I now make it a routine item at 25hrs to check the torque on all 4 engine to crankcase frame bolts. Clean the thread well with brake clean and compressed air before refitting. Ensure the spacer block between crankcase and engine frame has been fitted during installation; visual inspection with light and mirror. it cannot come out even if bolt departs the frame.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

budyerly@msn.com

Joined: 05 Oct 2019

Posts: 289

Location: Florida USA

|

Posted: Thu Dec 26, 2024 12:53 pm Post subject: Engine mount bolt loosens Posted: Thu Dec 26, 2024 12:53 pm Post subject: Engine mount bolt loosens |

|

|

All points well made. I found a solution but you won't like it as it is a bit tedious in some cases.

I have found looseness in the following bolts:

The M10 Bolts securing the ring mount to the engine are torqued and many have lock washers on newer airplanes. It is rare but should I find one loose, I use 10 mm Nord-lock wedge locking washers, rather than Loctite 243 alone as called for. Nord-locks are expensive ($25 for 20) but are very secure on steel and work especially well on aluminum. See Granger or Nord-Lock direct. The Rotax Heavy Mx Manual has torque requirements for bolt sizes used and further amplify in the specific installation of components like cylinder head bolts.

The M10 Allen head bolts securing the Engine Mounting Frame to the ring mount using the M10 "Binx" nuts will loosen often. These nuts are particularly frustrating on the 914 near the turbo. I drill the bolt head and use .020 safety wire through the slot in the "Binx" nut back to the hole in the Allen head. This is not hard drilling the Allen head, but I highly recommend proper security of the bolt and cobalt 1/16 inch drill bits for the chore. This is tedious with the engine on but can be done with long pliers and a lot of patience. I may try 10mm Nord-Locks one of these times.

Exhaust nuts on the 912S are frustrating and difficult to safety wire. However, I have had luck when the whole stud comes off with the nut to simply buy new nuts, remove the old corroded nuts, clean the stud threads inspect and if good reinstall with Loctite 243 on the head side (the Loctite will fail with heat but...) Secure the stud and allow the Loctite to cure overnight. I then install the new nuts, and I will peen the nut lightly if the prong ends are not grabbing well. On one aircraft a customer drilled the 8mm bolts through the corner for 0.020" safety wire. Very secure, but I have found my proper install and if necessary,peening of "sloppy fitting exhaust nuts" (as tolerances are not what they used to be) to be quite effective. Exhaust vibration on the 912S is demanding on the exhaust system. Pay attention to springs, the sealing points and look for soot. I've written on this in the past and still find satisfaction with exhaust sealant and lapping my joints. Springs require some silicone down the outside and just in case I still put a loop of safety wire down through the springs to keep everything secure.

Never use a Nylock nuts forward of the firewall. In high heat they melt, and after exposure for a few years under the hood, will tend to fail. Lock washers, Nord-Locks or safety wire are best. I find Nut plates and MS210 squeeze nuts hold up extremely well over time. Squeeze nuts, MS210 type, are very good unless reused, then proper re-peening will suffice for a temporary fix for lack of a new nut on hand.

This is why I do a 25 hour oil change and inspection. Use Torque Seal on your nuts to determine if they have loosened. That way the inspection is quite fast. If a bolt or nut has loosened apply a fix as stated above and then Torque Seal Again. Your airplane may look like a bunch of orange or yellow dots on all the bolts, but a stitch in time saves 9 as they say.

Best Regards,

Bud Yerly

From: owner-europa-list-server(at)matronics.com <owner-europa-list-server(at)matronics.com> on behalf of Area-51 <goldsteinindustrial(at)gmail.com>

Sent: Thursday, December 26, 2024 2:20 PM

To: europa-list(at)matronics.com <europa-list(at)matronics.com>

Subject: Re: Engine mount bolt loosens

--> Europa-List message posted by: "Area-51" <goldsteinindustrial(at)gmail.com>

All valid; points noted.

On occasion have found bolt has loosened and departed the airframe leaving three secure in place. Why does the bolt loosen? Vibration and the sum total of heat expansion and contraction cycles of individual components. Check the flat washer used under the cap screw heads; they should be hardened washers under the spring washers.

I now make it a routine item at 25hrs to check the torque on all 4 engine to crankcase frame bolts. Clean the thread well with brake clean and compressed air before refitting. Ensure the spacer block between crankcase and engine frame has been fitted during installation; visual inspection with light and mirror. it cannot come out even if bolt departs the frame.

Read this topic online here:

https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fforums.matronics.com%2Fviewtopic.php%3Fp%3D515173%23515173&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132634723%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=nyXVKOq2lcf0w03vR2xUA%2BXTKgFfxpRcgjijK5lyEf4%3D&reserved=0

===========

st Email Forum -

pa-List" data-auth="NotApplicable"> https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fwww.matronics.com%2FNavigator%3FEuropa-List&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132651474%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=Yj%2Fw1aYLUHTCadXWflFfhvkN1zVgoY%2BiCfTPs3FVfWs%3D&reserved=0

===========

p; - MATRONICS WEB FORUMS -

="NotApplicable">https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fforums.matronics.com%2F&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132668403%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=TCioi00KtQxPgO3AP1YiW7XXYaQVJZ1VMaIRjfv3vyI%3D&reserved=0

===========

p; - NEW MATRONICS LIST WIKI -

="NotApplicable">https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fwiki.matronics.com%2F&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132684663%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=oE4Yes8%2F3pU1mOYLCNuvcWTSoTnI2jv8wq87I1QGNBQ%3D&reserved=0

===========

p; - List Contribution Web Site -

p; -Matt Dralle, List Admin.

a-auth="NotApplicable"> https://na01.safelinks.protection.outlook.com/?url=https%3A%2F%2Fmatronics.com%2Fcontribution&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132702270%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=%2BBBDNz%2F87c4un0O2fXMyi5STRcofJ4sQ1EON2%2BiMHBw%3D&reserved=0

===========

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

Posted: Thu Dec 26, 2024 4:10 pm Post subject: Engine mount bolt loosens Posted: Thu Dec 26, 2024 4:10 pm Post subject: Engine mount bolt loosens |

|

|

On the classic all those bolts are safety wired. Yours aren’t? Shouldn’t be missing bolts with safety wires and inspections….. no?

Cheers

PeteZ

| Quote: | On Dec 26, 2024, at 4:00 PM, Bud Yerly <budyerly(at)msn.com> wrote:

All points well made. I found a solution but you won't like it as it is a bit tedious in some cases.

I have found looseness in the following bolts:

The M10 Bolts securing the ring mount to the engine are torqued and many have lock washers on newer airplanes. It is rare but should I find one loose, I use 10 mm Nord-lock wedge locking washers, rather than Loctite 243 alone as called for. Nord-locks are expensive ($25 for 20) but are very secure on steel and work especially well on aluminum. See Granger or Nord-Lock direct. The Rotax Heavy Mx Manual has torque requirements for bolt sizes used and further amplify in the specific installation of components like cylinder head bolts.

The M10 Allen head bolts securing the Engine Mounting Frame to the ring mount using the M10 "Binx" nuts will loosen often. These nuts are particularly frustrating on the 914 near the turbo. I drill the bolt head and use .020 safety wire through the slot in the "Binx" nut back to the hole in the Allen head. This is not hard drilling the Allen head, but I highly recommend proper security of the bolt and cobalt 1/16 inch drill bits for the chore. This is tedious with the engine on but can be done with long pliers and a lot of patience. I may try 10mm Nord-Locks one of these times.

Exhaust nuts on the 912S are frustrating and difficult to safety wire. However, I have had luck when the whole stud comes off with the nut to simply buy new nuts, remove the old corroded nuts, clean the stud threads inspect and if good reinstall with Loctite 243 on the head side (the Loctite will fail with heat but...) Secure the stud and allow the Loctite to cure overnight. I then install the new nuts, and I will peen the nut lightly if the prong ends are not grabbing well. On one aircraft a customer drilled the 8mm bolts through the corner for 0.020" safety wire. Very secure, but I have found my proper install and if necessary,peening of "sloppy fitting exhaust nuts" (as tolerances are not what they used to be) to be quite effective. Exhaust vibration on the 912S is demanding on the exhaust system. Pay attention to springs, the sealing points and look for soot. I've written on this in the past and still find satisfaction with exhaust sealant and lapping my joints. Springs require some silicone down the outside and just in case I still put a loop of safety wire down through the springs to keep everything secure.

Never use a Nylock nuts forward of the firewall. In high heat they melt, and after exposure for a few years under the hood, will tend to fail. Lock washers, Nord-Locks or safety wire are best. I find Nut plates and MS210 squeeze nuts hold up extremely well over time. Squeeze nuts, MS210 type, are very good unless reused, then proper re-peening will suffice for a temporary fix for lack of a new nut on hand.

This is why I do a 25 hour oil change and inspection. Use Torque Seal on your nuts to determine if they have loosened. That way the inspection is quite fast. If a bolt or nut has loosened apply a fix as stated above and then Torque Seal Again. Your airplane may look like a bunch of orange or yellow dots on all the bolts, but a stitch in time saves 9 as they say.

Best Regards,

Bud Yerly

From: owner-europa-list-server(at)matronics.com <owner-europa-list-server(at)matronics.com> on behalf of Area-51 <goldsteinindustrial(at)gmail.com>

Sent: Thursday, December 26, 2024 2:20 PM

To: europa-list(at)matronics.com <europa-list(at)matronics.com>

Subject: Re: Engine mount bolt loosens

--> Europa-List message posted by: "Area-51" <goldsteinindustrial(at)gmail.com>

All valid; points noted.

On occasion have found bolt has loosened and departed the airframe leaving three secure in place. Why does the bolt loosen? Vibration and the sum total of heat expansion and contraction cycles of individual components. Check the flat washer used under the cap screw heads; they should be hardened washers under the spring washers.

I now make it a routine item at 25hrs to check the torque on all 4 engine to crankcase frame bolts. Clean the thread well with brake clean and compressed air before refitting. Ensure the spacer block between crankcase and engine frame has been fitted during installation; visual inspection with light and mirror. it cannot come out even if bolt departs the frame.

Read this topic online here:

https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fforums.matronics.com%2Fviewtopic.php%3Fp%3D515173%23515173&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132634723%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=nyXVKOq2lcf0w03vR2xUA%2BXTKgFfxpRcgjijK5lyEf4%3D&reserved=0

===========

st Email Forum -

pa-List" data-auth="NotApplicable"> https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fwww.matronics.com%2FNavigator%3FEuropa-List&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132651474%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=Yj%2Fw1aYLUHTCadXWflFfhvkN1zVgoY%2BiCfTPs3FVfWs%3D&reserved=0

===========

p; - MATRONICS WEB FORUMS -

="NotApplicable">https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fforums.matronics.com%2F&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132668403%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=TCioi00KtQxPgO3AP1YiW7XXYaQVJZ1VMaIRjfv3vyI%3D&reserved=0

===========

p; - NEW MATRONICS LIST WIKI -

="NotApplicable">https://na01.safelinks.protection.outlook.com/?url=http%3A%2F%2Fwiki.matronics.com%2F&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132684663%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=oE4Yes8%2F3pU1mOYLCNuvcWTSoTnI2jv8wq87I1QGNBQ%3D&reserved=0

===========

p; - List Contribution Web Site -

p; -Matt Dralle, List Admin.

a-auth="NotApplicable"> https://na01.safelinks.protection.outlook.com/?url=https%3A%2F%2Fmatronics.com%2Fcontribution&data=05%7C02%7C%7C3854b21b979b4feb2c5508dd25e2c73f%7C84df9e7fe9f640afb435aaaaaaaaaaaa%7C1%7C0%7C638708378132702270%7CUnknown%7CTWFpbGZsb3d8eyJFbXB0eU1hcGkiOnRydWUsIlYiOiIwLjAuMDAwMCIsIlAiOiJXaW4zMiIsIkFOIjoiTWFpbCIsIldUIjoyfQ%3D%3D%7C0%7C%7C%7C&sdata=%2BBBDNz%2F87c4un0O2fXMyi5STRcofJ4sQ1EON2%2BiMHBw%3D&reserved=0

===========

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Burrilla

Joined: 25 Apr 2015

Posts: 187

|

Posted: Sat Jan 04, 2025 2:09 am Post subject: Engine mount bolt loosens Posted: Sat Jan 04, 2025 2:09 am Post subject: Engine mount bolt loosens |

|

|

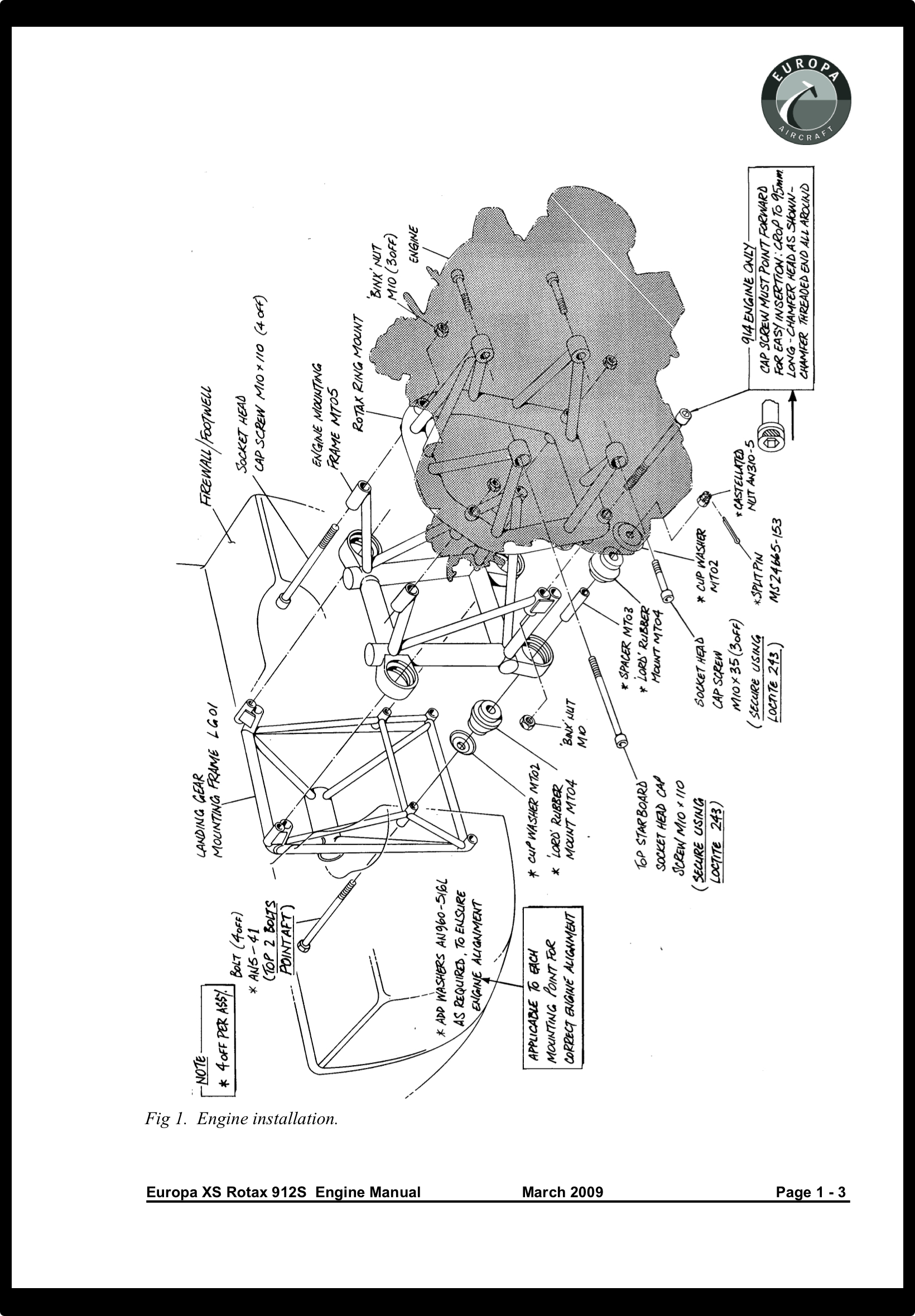

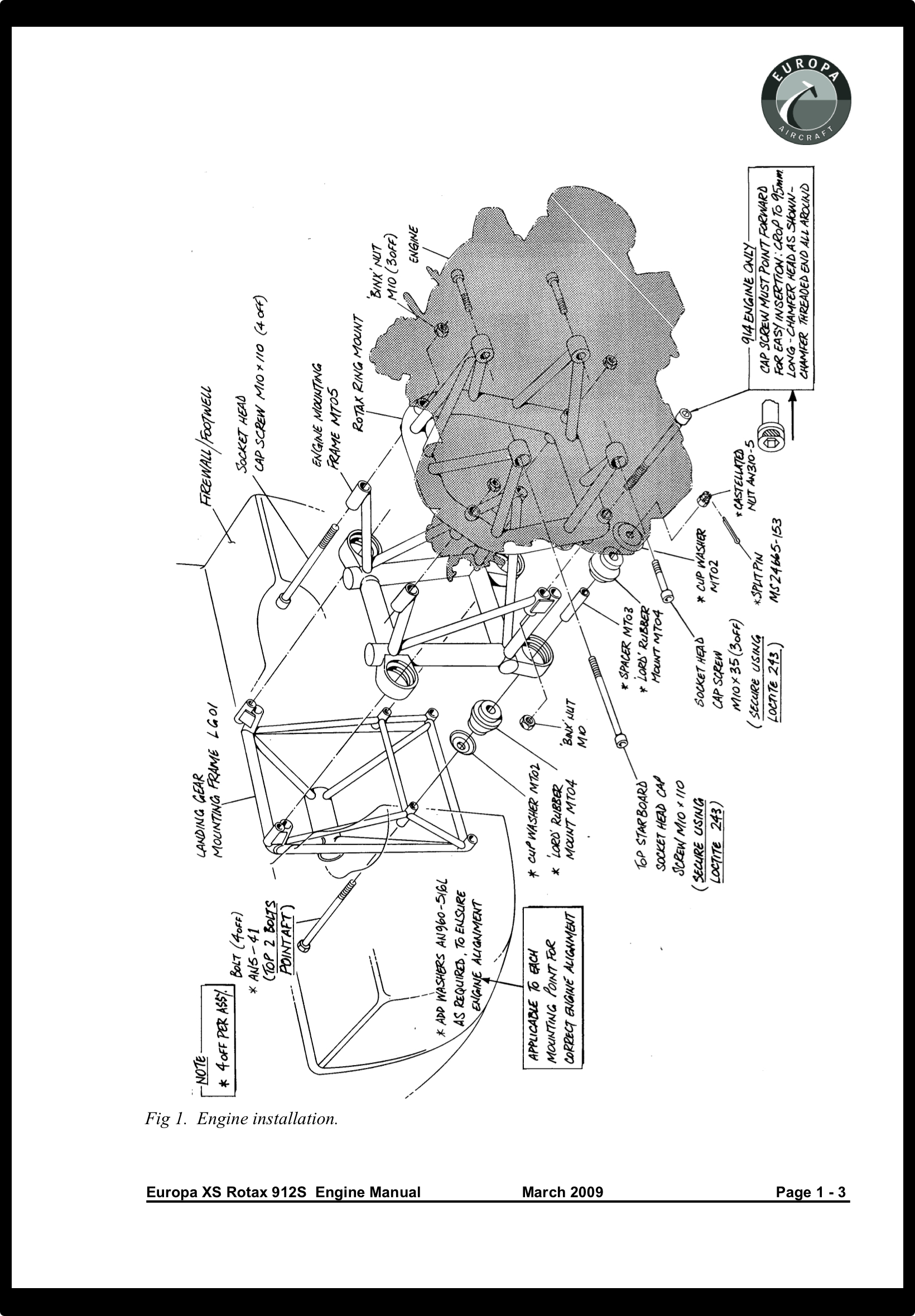

A good start to answering you question is the Europa Engine Installation Manual.

Alan Burrill

Sent from my iPad

| Quote: | On 26 Dec 2024, at 01:21, JonathanMilbank <jdmilbank(at)yahoo.co.uk> wrote:

This is the fourth time in over 27 years that I'm removing a Rotax 912 from my aircraft to get something attended to. Each time that I've installed an engine in the past, I inserted and tightened the 4 bolts securing the frame to the crankcase without using Loctite or grease. I've always simply tightened them, not using any specific torque setting, but simply tightening them to a degree which seems "plenty enough".

For the first time in over 1500 hours, I've found one bolt which loosened since the last 50 hour inspection. So my question is whether to use Loctite when reinstalling the engine and what number Loctite do you recommend?

My instinct is to use fairly low strength Loctite, in case the next time of engine removal proves to be near impossible to get the bolts out.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=515168#515168

====================================

|

====================================

====================================

====================================

====================================

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

1.01 MB |

| Viewed: |

223 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 222

|

Posted: Sun Jan 05, 2025 2:07 am Post subject: Engine mount bolt loosens Posted: Sun Jan 05, 2025 2:07 am Post subject: Engine mount bolt loosens |

|

|

I used Loctite 243 on my four bolts. When the engine came out 700 hours/20 years later, one of the four bolt holes had to be helicoiled for reuse!

I still think this was a combination of residual swarf and Loctite in the depths of the hole that allowed the bolt to pick up. I was lucky to get the bolt out at all. Anyway, they didn't come loose in service.

Duncan McF.

| Quote: | On 04/01/2025 10:08 GMT Alan Burrill <alanb(at)dpy01.co.uk> wrote:

A good start to answering you question is the Europa Engine Installation Manual.

Alan Burrill

Sent from my iPad

> On 26 Dec 2024, at 01:21, JonathanMilbank <jdmilbank(at)yahoo.co.uk> wrote:

>

>

>

> This is the fourth time in over 27 years that I'm removing a Rotax 912 from my aircraft to get something attended to. Each time that I've installed an engine in the past, I inserted and tightened the 4 bolts securing the frame to the crankcase without using Loctite or grease. I've always simply tightened them, not using any specific torque setting, but simply tightening them to a degree which seems "plenty enough".

>

> For the first time in over 1500 hours, I've found one bolt which loosened since the last 50 hour inspection. So my question is whether to use Loctite when reinstalling the engine and what number Loctite do you recommend?

>

> My instinct is to use fairly low strength Loctite, in case the next time of engine removal proves to be near impossible to get the bolts out.

>

>

>

>

> Read this topic online here:

>

> http://forums.matronics.com/viewtopic.php?p=515168#515168

>

>

>

>

>

>

====================================

====================================

====================================

====================================

====================================

>

>

>

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|