|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

alanbikle

Joined: 10 Jan 2006

Posts: 4

|

Posted: Fri Jul 02, 2010 7:42 pm Post subject: Cowl Posted: Fri Jul 02, 2010 7:42 pm Post subject: Cowl |

|

|

Since Deems posted the other day that I had solved the James Cowl high temperature problem by increasing the inlet size I have received several inquiries for more information. I can only assume that there are many others who are experiencing high cylinder and oil temperatures particularly with the James Cowl.

First let me explain my particular setup because each situation is different and your mileage may vary.

I have a new experimental IO-540 built by Lycon with Cold Air Induction 10-1 compression, ported and flow balanced with a single Light Speed Ignition. This translates into a lot more H.P. and HEAT than a stock install.

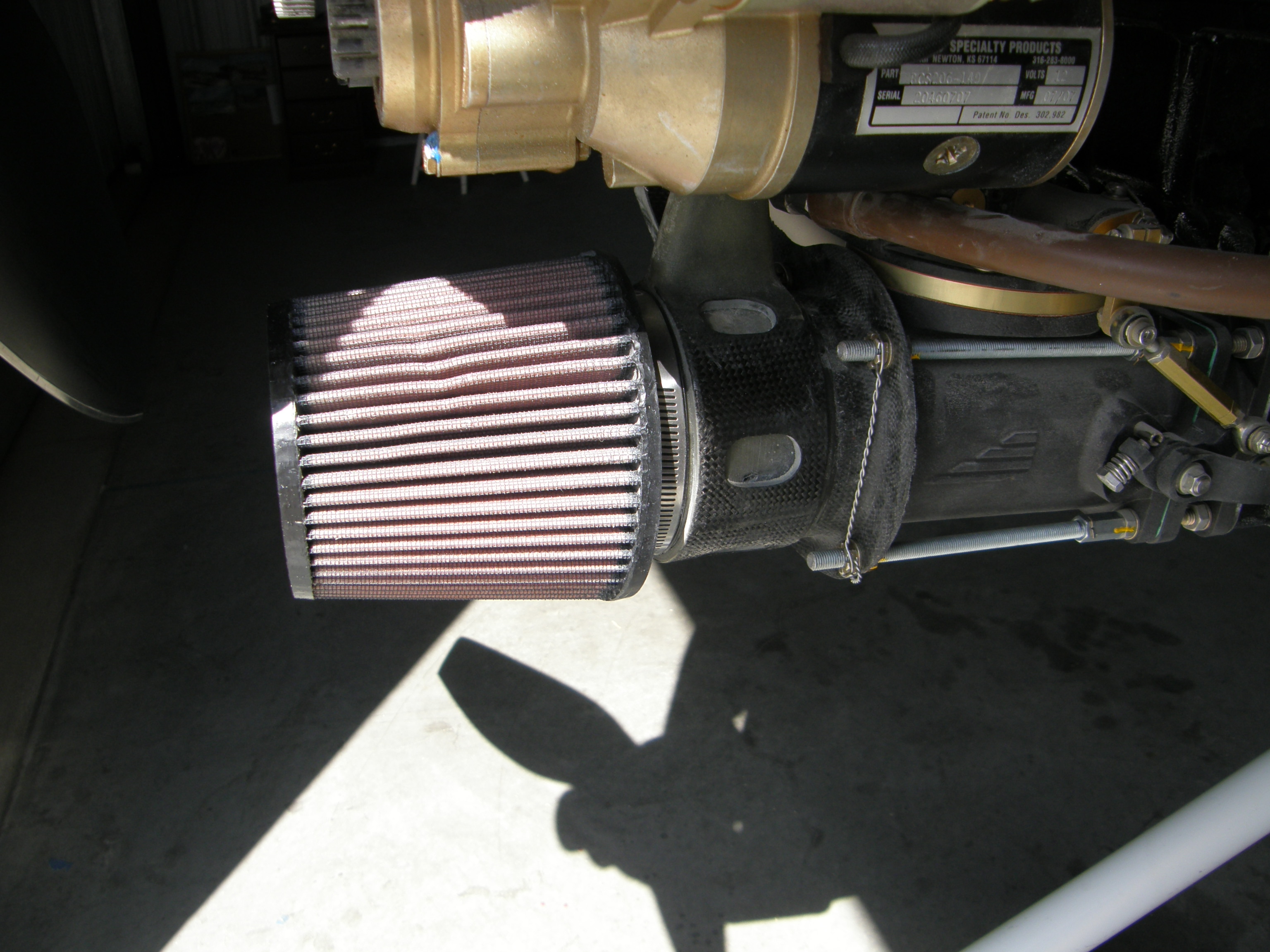

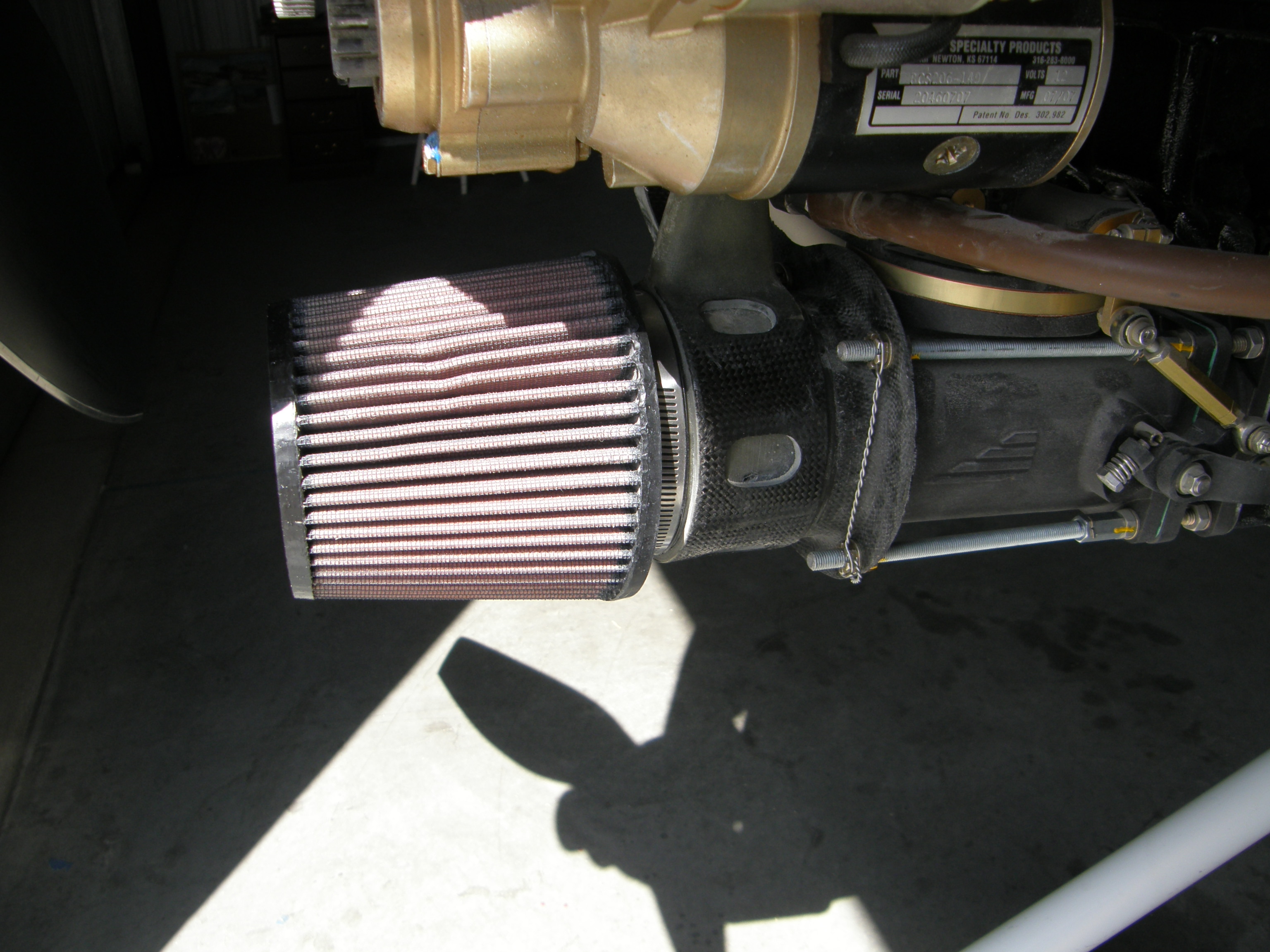

Initial flight tests were performed with a stock James Cowl (4.5" inlets) with my own induction air inlet and filter air box design.

My initial flight testing resulted in cylinder temps. in the 440 range and oil temps in the 220 range. This was in relatively cool weather (averaging 65 F) so the airplane was basically unusable. I embarked on a flight test program of measuring the differential pressure at seven different locations under the cowl. With knowledge gained I made numerous modifications to the inlets, plenum, inlet ramps and exit ramp, retested and modified retested, etc., etc.. This consumed 27 flight hours and 4 months of work. The induction inlet and filter air box design was not modified since I was seeing 1"+ boost in M.P. with the original design.

The results are very satisfying with cylinder temps. now averaging 350 and oil temps. averaging 180 or below. I have even had to install an oil cooler damper to keep the oil temps. above 180 in cruise. It was all a matter of balancing the inlet area, plenum size, and exit area to achieve the greatest total plenum pressure and greatest differential pressure between the plenum and exit with the minimum inlet size. The final inlet size is 6" diameter which is larger than the stock James inlets but still significantly smaller in area than stock Vans inlets yet I'm effectively and efficiently cooling an engine with 20% more H.P. than stock. The total plenum pressure went from 6" to13" so LOP operation should now be possible without installing turbo rails as many have done.

I mention all this to show it is possible to cool the beast without resorting to unconventional an unsightly options. It is also important to understand that while "size does matter" there is a lot more to it than just increasing the inlet size.

I will be at Arlington and Oshkosh and will be more than happy to discuss any of the particulars. I have attached a few pictures to help show the modifications made and final outcome.

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

1.11 MB |

| Viewed: |

9574 Time(s) |

|

| Description: |

|

| Filesize: |

975.28 KB |

| Viewed: |

9574 Time(s) |

|

| Description: |

|

| Filesize: |

1.09 MB |

| Viewed: |

9574 Time(s) |

|

| Description: |

|

| Filesize: |

1.12 MB |

| Viewed: |

9574 Time(s) |

|

_________________

Alan Bikle

RV-8 sold

RV-10 flying w/400hrs

RV-4 80% complete |

|

| Back to top |

|

|

Robin(at)PaintTheWeb.com

Guest

|

Posted: Fri Jul 02, 2010 10:44 pm Post subject: Cowl Posted: Fri Jul 02, 2010 10:44 pm Post subject: Cowl |

|

|

Alan,

So no change to the outlet area, no under cowl louvers, even cooling across all cylinders?

It sure would be nice to have a mold of that Plenum.

BTW thank you for sharing! Awesome work.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Friday, July 02, 2010 8:32 PM

To: RV-10 list

Subject: Cowl

Since Deems posted the other day that I had solved the James Cowl high temperature problem by increasing the inlet size I have received several inquiries for more information. I can only assume that there are many others who are experiencing high cylinder and oil temperatures particularly with the James Cowl.

First let me explain my particular setup because each situation is different and your mileage may vary.

I have a new experimental IO-540 built by Lycon with Cold Air Induction 10-1 compression, ported and flow balanced with a single Light Speed Ignition. This translates into a lot more H.P. and HEAT than a stock install.

Initial flight tests were performed with a stock James Cowl (4.5" inlets) with my own induction air inlet and filter air box design.

My initial flight testing resulted in cylinder temps. in the 440 range and oil temps in the 220 range. This was in relatively cool weather (averaging 65 F) so the airplane was basically unusable. I embarked on a flight test program of measuring the differential pressure at seven different locations under the cowl. With knowledge gained I made numerous modifications to the inlets, plenum, inlet ramps and exit ramp, retested and modified retested, etc., etc.. This consumed 27 flight hours and 4 months of work. The induction inlet and filter air box design was not modified since I was seeing 1"+ boost in M.P. with the original design.

The results are very satisfying with cylinder temps. now averaging 350 and oil temps. averaging 180 or below. I have even had to install an oil cooler damper to keep the oil temps. above 180 in cruise. It was all a matter of balancing the inlet area, plenum size, and exit area to achieve the greatest total plenum pressure and greatest differential pressure between the plenum and exit with the minimum inlet size. The final inlet size is 6" diameter which is larger than the stock James inlets but still significantly smaller in area than stock Vans inlets yet I'm effectively and efficiently cooling an engine with 20% more H.P. than stock. The total plenum pressure went from 6" to13" so LOP operation should now be possible without installing turbo rails as many have done.

I mention all this to show it is possible to cool the beast without resorting to unconventional an unsightly options. It is also important to understand that while "size does matter" there is a lot more to it than just increasing the inlet size.

I will be at Arlington and Oshkosh and will be more than happy to discuss any of the particulars. I have attached a few pictures to help show the modifications made and final outcome.

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

Barry

Joined: 16 Sep 2008

Posts: 108

|

Posted: Sat Jul 03, 2010 5:27 am Post subject: Cowl Posted: Sat Jul 03, 2010 5:27 am Post subject: Cowl |

|

|

Alan great job of fixing a problem alot of us have. If you plan on selling the mod, put me down for one.

Barry Marz

18735 Baseleg AVE.

FT. Myers, Fl 33917

239-567-2271

blalmarz(at)embarqmail.com (blalmarz(at)embarqmail.com)

[quote][b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

alanbikle

Joined: 10 Jan 2006

Posts: 4

|

Posted: Sat Jul 03, 2010 6:56 am Post subject: Cowl Posted: Sat Jul 03, 2010 6:56 am Post subject: Cowl |

|

|

I experimented with increasing and decreasing the outlet area but settled on the original area of 69sq. in. No noticeable gain on increasing the outlet and negative results with both pressure and cooling with reducing the outlet. I experienced the same results with increasing and decreasing the inlet size. I have come to the conclusion that an exit area slightly larger than inlet area works best on the 10. I am aware of some 2 place Vans that successfully employ smaller exit area than inlet area but I would guess that there inlets are simply larger than needed. Once again I think its a balancing act to get enough volume (pounds of air) over the cylinders to cool the engine without over doing it and creating excess drag. Tony Bingelis book quoted that the rule of thumb for inlet sizing is to multiply H.P. x .35. I think that is larger than necessary. A stock RV-10 with 260 H.P. has a inlet to H.P. ratio of .29 a stock RV-8 of .27. With proper balancing and a high volume plenum I was able to reduce that that ratio to .17 on my 10.

No louvers etc. and all cylinders run within 20 F of each other and I have done no work to improve on that. Increasing the volume of the plenum helped considerably with even cooling.

Alan Bikle

AIRFLOW TECHNOLOGY

Salinas, CA. 93905

Tel: 831-320-0193

Fax: 831-771-0833

From: Robin Marks <Robin(at)painttheweb.com>

To: rv10-list(at)matronics.com

Sent: Fri, July 2, 2010 11:11:12 PM

Subject: RE: Cowl

Alan,

So no change to the outlet area, no under cowl louvers, even cooling across all cylinders?

It sure would be nice to have a mold of that Plenum.

BTW thank you for sharing! Awesome work.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Friday, July 02, 2010 8:32 PM

To: RV-10 list

Subject: Cowl

Since Deems posted the other day that I had solved the James Cowl high temperature problem by increasing the inlet size I have received several inquiries for more information. I can only assume that there are many others who are experiencing high cylinder and oil temperatures particularly with the James Cowl.

First let me explain my particular setup because each situation is different and your mileage may vary.

I have a new experimental IO-540 built by Lycon with Cold Air Induction 10-1 compression, ported and flow balanced with a single Light Speed Ignition. This translates into a lot more H.P. and HEAT than a stock install.

Initial flight tests were performed with a stock James Cowl (4.5" inlets) with my own induction air inlet and filter air box design.

My initial flight testing resulted in cylinder temps. in the 440 range and oil temps in the 220 range. This was in relatively cool weather (averaging 65 F) so the airplane was basically unusable. I embarked on a flight test program of measuring the differential pressure at seven different locations under the cowl. With knowledge gained I made numerous modifications to the inlets, plenum, inlet ramps and exit ramp, retested and modified retested, etc., etc.. This consumed 27 flight hours and 4 months of work. The induction inlet and filter air box design was not modified since I was seeing 1"+ boost in M.P. with the original design.

The results are very satisfying with cylinder temps. now averaging 350 and oil temps. averaging 180 or below. I have even had to install an oil cooler damper to keep the oil temps. above 180 in cruise. It was all a matter of balancing the inlet area, plenum size, and exit area to achieve the greatest total plenum pressure and greatest differential pressure between the plenum and exit with the minimum inlet size. The final inlet size is 6" diameter which is larger than the stock James inlets but still significantly smaller in area than stock Vans inlets yet I'm effectively and efficiently cooling an engine with 20% more H.P. than stock. The total plenum pressure went from 6" to13" so LOP operation should now be possible without installing turbo rails as many have done.

I mention all this to show it is possible to cool the beast without resorting to unconventional an unsightly options. It is also important to understand that while "size does matter" there is a lot more to it than just increasing the inlet size.

I will be at Arlington and Oshkosh and will be more than happy to discuss any of the particulars. I have attached a few pictures to help show the modifications made and final outcome.

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Alan Bikle

RV-8 sold

RV-10 flying w/400hrs

RV-4 80% complete |

|

| Back to top |

|

|

Robin(at)PaintTheWeb.com

Guest

|

Posted: Mon Jul 05, 2010 8:27 am Post subject: Cowl Posted: Mon Jul 05, 2010 8:27 am Post subject: Cowl |

|

|

Alan,

The photos really helped (along with your explanation). Rather than visit you and have you de-cowl the plane for me (I hate taking on & off a painted cowl for almost no reason) I will hold off and chat with you at OSH. I will be there Monday evening to Friday at noon camping with the RV-10 group.

One more question. Are your wheel pants stock? The look more narrow than stock to me.

Have a great week & good trip to Arlington.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Saturday, July 03, 2010 7:55 AM

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Subject: Re: Cowl

I experimented with increasing and decreasing the outlet area but settled on the original area of 69sq. in. No noticeable gain on increasing the outlet and negative results with both pressure and cooling with reducing the outlet. I experienced the same results with increasing and decreasing the inlet size. I have come to the conclusion that an exit area slightly larger than inlet area works best on the 10. I am aware of some 2 place Vans that successfully employ smaller exit area than inlet area but I would guess that there inlets are simply larger than needed. Once again I think its a balancing act to get enough volume (pounds of air) over the cylinders to cool the engine without over doing it and creating excess drag. Tony Bingelis book quoted that the rule of thumb for inlet sizing is to multiply H.P. x .35. I think that is larger than necessary. A stock RV-10 with 260 H.P. has a inlet to H.P. ratio of .29 a stock RV-8 of .27. With proper balancing and a high volume plenum I was able to reduce that that ratio to .17 on my 10.

No louvers etc. and all cylinders run within 20 F of each other and I have done no work to improve on that. Increasing the volume of the plenum helped considerably with even cooling.

Alan Bikle

AIRFLOW TECHNOLOGY

Salinas, CA. 93905

Tel: 831-320-0193

Fax: 831-771-0833

From: Robin Marks <Robin(at)painttheweb.com (Robin(at)painttheweb.com)>

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Sent: Fri, July 2, 2010 11:11:12 PM

Subject: RE: Cowl

Alan,

So no change to the outlet area, no under cowl louvers, even cooling across all cylinders?

It sure would be nice to have a mold of that Plenum.

BTW thank you for sharing! Awesome work.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Friday, July 02, 2010 8:32 PM

To: RV-10 list

Subject: Cowl

Since Deems posted the other day that I had solved the James Cowl high temperature problem by increasing the inlet size I have received several inquiries for more information. I can only assume that there are many others who are experiencing high cylinder and oil temperatures particularly with the James Cowl.

First let me explain my particular setup because each situation is different and your mileage may vary.

I have a new experimental IO-540 built by Lycon with Cold Air Induction 10-1 compression, ported and flow balanced with a single Light Speed Ignition. This translates into a lot more H.P. and HEAT than a stock install.

Initial flight tests were performed with a stock James Cowl (4.5" inlets) with my own induction air inlet and filter air box design.

My initial flight testing resulted in cylinder temps. in the 440 range and oil temps in the 220 range. This was in relatively cool weather (averaging 65 F) so the airplane was basically unusable. I embarked on a flight test program of measuring the differential pressure at seven different locations under the cowl. With knowledge gained I made numerous modifications to the inlets, plenum, inlet ramps and exit ramp, retested and modified retested, etc., etc.. This consumed 27 flight hours and 4 months of work. The induction inlet and filter air box design was not modified since I was seeing 1"+ boost in M.P. with the original design.

The results are very satisfying with cylinder temps. now averaging 350 and oil temps. averaging 180 or below. I have even had to install an oil cooler damper to keep the oil temps. above 180 in cruise. It was all a matter of balancing the inlet area, plenum size, and exit area to achieve the greatest total plenum pressure and greatest differential pressure between the plenum and exit with the minimum inlet size. The final inlet size is 6" diameter which is larger than the stock James inlets but still significantly smaller in area than stock Vans inlets yet I'm effectively and efficiently cooling an engine with 20% more H.P. than stock. The total plenum pressure went from 6" to13" so LOP operation should now be possible without installing turbo rails as many have done.

I mention all this to show it is possible to cool the beast without resorting to unconventional an unsightly options. It is also important to understand that while "size does matter" there is a lot more to it than just increasing the inlet size.

I will be at Arlington and Oshkosh and will be more than happy to discuss any of the particulars. I have attached a few pictures to help show the modifications made and final outcome.

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

ator to browse[/b][/quote] /b>[/quote] 10-List">http://www.matronics.com/Navigator?RV10-List[/b]===================[/quote] ="http://forums.matronics.com">http://forums.matronics.com[/b][/quote] =====================[/b][/quote]

= --> http://w===[/b] [b]

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

|

|

| Back to top |

|

|

alanbikle

Joined: 10 Jan 2006

Posts: 4

|

Posted: Mon Jul 05, 2010 6:23 pm Post subject: Cowl Posted: Mon Jul 05, 2010 6:23 pm Post subject: Cowl |

|

|

Robin,

The wheel pants are my own design and are low profile pressure recover pants. I will be marketing them as a high quality low drag option for those builders that are looking to upgrade and have had enough fun with fiberglass. The pants will be delivered in a nearly finished condition essentially eliminating all glass work and grinding. They include a pre-installed axle bracket that greatly simplifies installation. You simply attach the pant to the stock Vans axle nut which locates the pants height, roll, and longitudinal position. All that is left is setting the yaw and pitch and drilling four holes into the inboard bracket to fix them in place. I have included a few photos.

See you in OSHKOSH!

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

Fax: 831-771-0833

From: Robin Marks <Robin(at)PaintTheWeb.com>

To: rv10-list(at)matronics.com

Sent: Mon, July 5, 2010 9:20:15 AM

Subject: RE: Cowl

Alan,

The photos really helped (along with your explanation). Rather than visit you and have you de-cowl the plane for me (I hate taking on & off a painted cowl for almost no reason) I will hold off and chat with you at OSH. I will be there Monday evening to Friday at noon camping with the RV-10 group.

One more question. Are your wheel pants stock? The look more narrow than stock to me.

Have a great week & good trip to Arlington.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Saturday, July 03, 2010 7:55 AM

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Subject: Re: Cowl

I experimented with increasing and decreasing the outlet area but settled on the original area of 69sq. in. No noticeable gain on increasing the outlet and negative results with both pressure and cooling with reducing the outlet. I experienced the same results with increasing and decreasing the inlet size. I have come to the conclusion that an exit area slightly larger than inlet area works best on the 10. I am aware of some 2 place Vans that successfully employ smaller exit area than inlet area but I would guess that there inlets are simply larger than needed. Once again I think its a balancing act to get enough volume (pounds of air) over the cylinders to cool the engine without over doing it and creating excess drag. Tony Bingelis book quoted that the rule of thumb for inlet sizing is to multiply H.P. x .35. I think that is larger than necessary. A stock RV-10 with 260 H.P. has a inlet to H.P. ratio of .29 a stock RV-8 of .27. With proper balancing and a high volume plenum I was able to reduce that that ratio to .17 on my 10.

No louvers etc. and all cylinders run within 20 F of each other and I have done no work to improve on that. Increasing the volume of the plenum helped considerably with even cooling.

Alan Bikle

AIRFLOW TECHNOLOGY

Salinas, CA. 93905

Tel: 831-320-0193

Fax: 831-771-0833

From: Robin Marks <Robin(at)painttheweb.com (Robin(at)painttheweb.com)>

To: rv10-list(at)matronics.com (rv10-list(at)matronics.com)

Sent: Fri, July 2, 2010 11:11:12 PM

Subject: RE: Cowl

Alan,

So no change to the outlet area, no under cowl louvers, even cooling across all cylinders?

It sure would be nice to have a mold of that Plenum.

BTW thank you for sharing! Awesome work.

Robin

From: owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com) [mailto:owner-rv10-list-server(at)matronics.com (owner-rv10-list-server(at)matronics.com)] On Behalf Of Alan Bikle

Sent: Friday, July 02, 2010 8:32 PM

To: RV-10 list

Subject: Cowl

Since Deems posted the other day that I had solved the James Cowl high temperature problem by increasing the inlet size I have received several inquiries for more information. I can only assume that there are many others who are experiencing high cylinder and oil temperatures particularly with the James Cowl.

First let me explain my particular setup because each situation is different and your mileage may vary.

I have a new experimental IO-540 built by Lycon with Cold Air Induction 10-1 compression, ported and flow balanced with a single Light Speed Ignition. This translates into a lot more H.P. and HEAT than a stock install.

Initial flight tests were performed with a stock James Cowl (4.5" inlets) with my own induction air inlet and filter air box design.

My initial flight testing resulted in cylinder temps. in the 440 range and oil temps in the 220 range. This was in relatively cool weather (averaging 65 F) so the airplane was basically unusable. I embarked on a flight test program of measuring the differential pressure at seven different locations under the cowl. With knowledge gained I made numerous modifications to the inlets, plenum, inlet ramps and exit ramp, retested and modified retested, etc., etc.. This consumed 27 flight hours and 4 months of work. The induction inlet and filter air box design was not modified since I was seeing 1"+ boost in M.P. with the original design.

The results are very satisfying with cylinder temps. now averaging 350 and oil temps. averaging 180 or below. I have even had to install an oil cooler damper to keep the oil temps. above 180 in cruise. It was all a matter of balancing the inlet area, plenum size, and exit area to achieve the greatest total plenum pressure and greatest differential pressure between the plenum and exit with the minimum inlet size. The final inlet size is 6" diameter which is larger than the stock James inlets but still significantly smaller in area than stock Vans inlets yet I'm effectively and efficiently cooling an engine with 20% more H.P. than stock. The total plenum pressure went from 6" to13" so LOP operation should now be possible without installing turbo rails as many have done.

I mention all this to show it is possible to cool the beast without resorting to unconventional an unsightly options. It is also important to understand that while "size does matter" there is a lot more to it than just increasing the inlet size.

I will be at Arlington and Oshkosh and will be more than happy to discuss any of the particulars. I have attached a few pictures to help show the modifications made and final outcome.

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

ator to browse /b> 10-List">http://www.matronics.com/Navigator?RV10-List | Quote: | | =================== |

="http://forums.matronics.com">http://forums.matronics.com =====================

= --> http://w===

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

| Description: |

|

| Filesize: |

1.06 MB |

| Viewed: |

9512 Time(s) |

|

| Description: |

|

| Filesize: |

922.56 KB |

| Viewed: |

9512 Time(s) |

|

| Description: |

|

| Filesize: |

1.19 MB |

| Viewed: |

9512 Time(s) |

|

_________________

Alan Bikle

RV-8 sold

RV-10 flying w/400hrs

RV-4 80% complete |

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Mon Jul 05, 2010 7:39 pm Post subject: Cowl Posted: Mon Jul 05, 2010 7:39 pm Post subject: Cowl |

|

|

Alan, Is that a 6:00X6 tire or the Vans supplied 15x600X6 tire? I like

the concept of narrower tires and wheel pants, if the drag is same or less.

On 7/5/2010 7:15 PM, Alan Bikle wrote:

| Quote: | Robin,

The wheel pants are my own design and are low profile pressure recover

pants. I will be marketing them as a high quality low drag option for

those builders that are looking to upgrade and have had enough fun

with fiberglass. The pants will be delivered in a nearly

finished condition essentially eliminating all glass work and

grinding. They include a pre-installed axle bracket that greatly

simplifies installation. You simply attach the pant to the stock Vans

axle nut which locates the pants height, roll, and longitudinal

position. All that is left is setting the yaw and pitch and drilling

four holes into the inboard bracket to fix them in place. I have

included a few photos.

See you in OSHKOSH!

Alan Bikle

AIRFLOW TECHNOLOGY

1586 Moffett Street Ste. E

Salinas, CA. 93905

Tel: 831-320-0193

Fax: 831-771-0833

|

| | - The Matronics RV10-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV10-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|