|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

paul.the.aviator(at)gmail

Guest

|

Posted: Mon Mar 30, 2009 6:48 pm Post subject: 914 Waste gate servo mounting position question Posted: Mon Mar 30, 2009 6:48 pm Post subject: 914 Waste gate servo mounting position question |

|

|

Hi All,

I am attempting to "shoe horn" in a second Grand Rapids EFIS screen into my panel which is turning into an mechanical challenge. It is pretty much looking like I am going to have to move it to the outside of the firewall. I know a few folks have done this and provided cooling with a blast tube. I was wondering if anyone had some photographs and best practices to share.

Thanks, Paul

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ptag.dev(at)tiscali.co.uk

Guest

|

Posted: Tue Mar 31, 2009 12:30 am Post subject: 914 Waste gate servo mounting position question Posted: Tue Mar 31, 2009 12:30 am Post subject: 914 Waste gate servo mounting position question |

|

|

Hi! Paul

I have no photos at present but have installed mine on the P1 foot well with the Ignition regulator both in an insulated lightweight box unsealed to the firewall to allow circulating cooling air to escape. I have a 1” dia. Hose picking up intake air from well in front of the radiator with a little permanent position flap “catching” air to the box.

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.) I took some crude temperature tests early days and in flight they were generally less than 30 deg but on shutdown without top cowl service doors closed they never reach more than 37deg approx. Obviously opening the doors immediately defrays the cowling heat quicker as does parking into wind.

Regards

Bob Harrison.G-PTAG

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rob(at)hyperion-ef.com

Guest

|

Posted: Tue Mar 31, 2009 8:08 am Post subject: 914 Waste gate servo mounting position question Posted: Tue Mar 31, 2009 8:08 am Post subject: 914 Waste gate servo mounting position question |

|

|

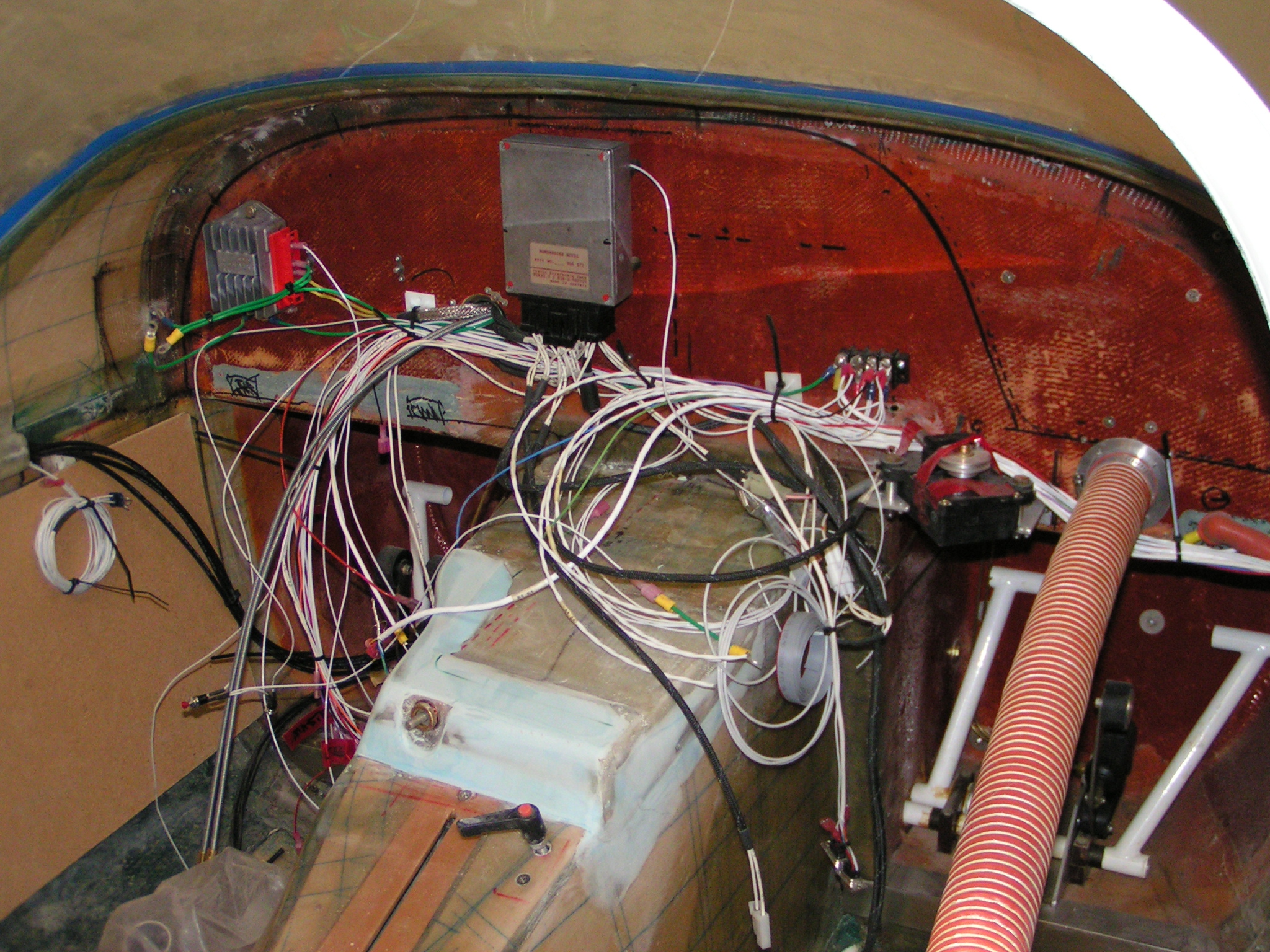

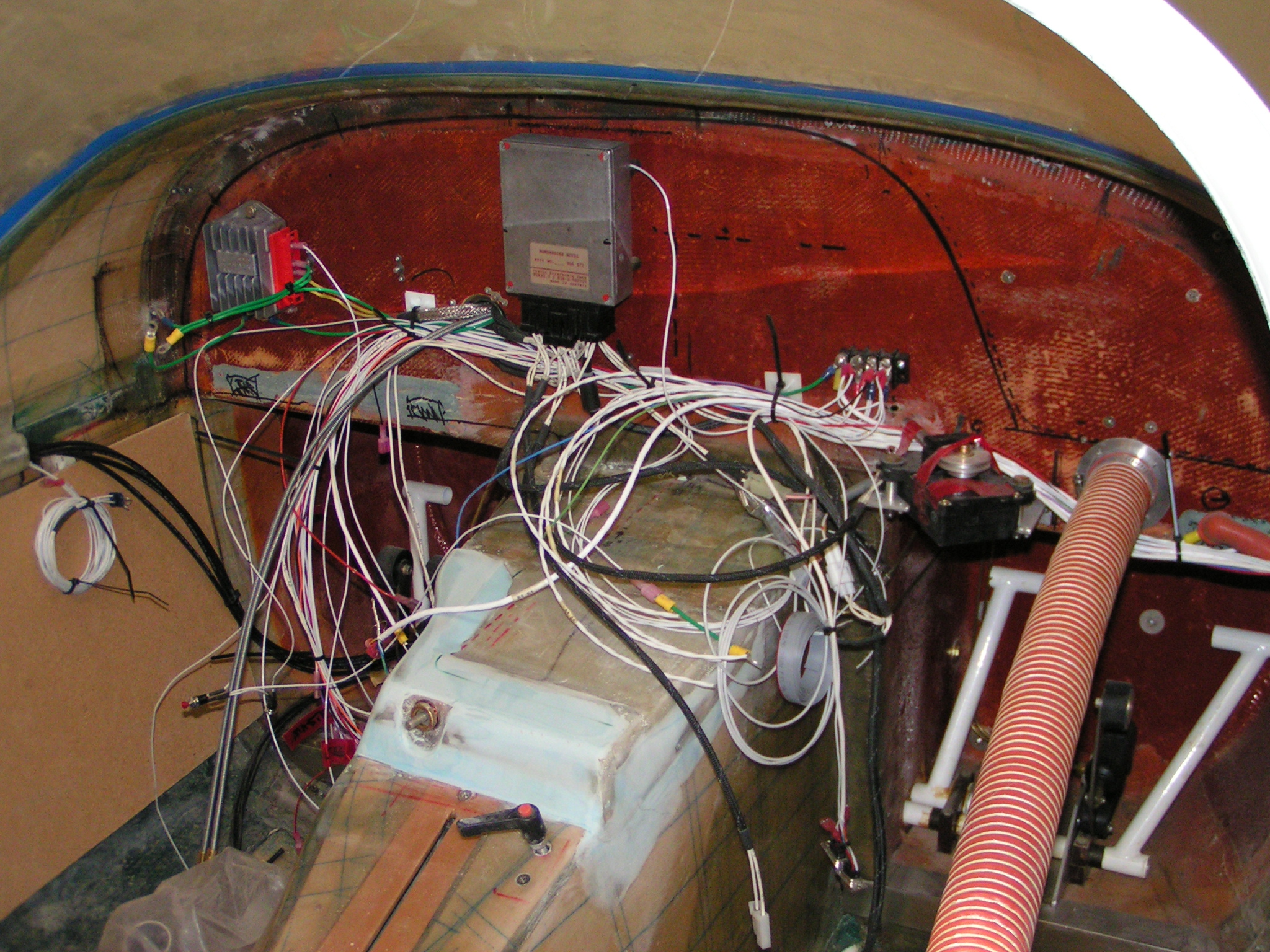

There is room, just barely, for the waste gate servo to mount on the cabin side of the firewall – see the attached photo. In this somewhat (OK, more than somewhat) cluttered image, the servo is just to the left of the SCAT tube. Note the black outline drawn on the firewall to indicate the instrument panel molding features. The red tape on the servo is holding some loose components in place.

In order to facilitate this mounting location I fabricated an aluminum bracket; the plan view is shown in the attached pdf file. The bracket was made from a piece of aluminum channel (with one leg removed) since an appropriate angle 90 degree shape was not conveniently available. Other stock would also be suitable.

Best regards,

Rob Housman

Irvine, CA

Europa XS Tri-Gear

A070

Airframe complete

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Paul McAllister

Sent: Monday, March 30, 2009 7:44 PM

To: europa-list(at)matronics.com

Subject: 914 Waste gate servo mounting position question

Hi All,

I am attempting to "shoe horn" in a second Grand Rapids EFIS screen into my panel which is turning into an mechanical challenge. It is pretty much looking like I am going to have to move it to the outside of the firewall. I know a few folks have done this and provided cooling with a blast tube. I was wondering if anyone had some photographs and best practices to share.

Thanks, Paul | Quote: | | http://www.matronics.com/Navigator?Europa-List |

0123456789

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

1.51 MB |

| Viewed: |

5601 Time(s) |

|

| Description: |

|

Download |

| Filename: |

Turbo_servo_mount.pdf |

| Filesize: |

12.19 KB |

| Downloaded: |

292 Time(s) |

|

|

| Back to top |

|

|

kevann(at)gotsky.com

Guest

|

Posted: Tue Mar 31, 2009 8:27 am Post subject: 914 Waste gate servo mounting position question Posted: Tue Mar 31, 2009 8:27 am Post subject: 914 Waste gate servo mounting position question |

|

|

Or you might consider mounting on the front of the passenger footwell inside the cold air intake housing for the 914. I mounted my rotax regulator there and wish I had considered mounting the servo there as well.No hose or box needed. I mounted the servo per the manual on the tunnel where it is hard to get at and I made a box cover to keep instrument wires clear.

Kevin

just past 50 hours on N211KA

[quote] ---

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

budyerly(at)msn.com

Guest

|

Posted: Tue Mar 31, 2009 3:36 pm Post subject: 914 Waste gate servo mounting position question Posted: Tue Mar 31, 2009 3:36 pm Post subject: 914 Waste gate servo mounting position question |

|

|

<?xml:namespace prefix="v" /><?xml:namespace prefix="o" /><![endif]--> Paul,

Contact Jerry Hope...He has pictures of the installation he did with me.

email: herebitty(at)embarqmail.com (herebitty(at)embarqmail.com)

Made a little bump in the left side of the panel.

Bud Yerly

[quote] ---

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

acrojim7534(at)YAHOO.COM

Guest

|

Posted: Wed Apr 01, 2009 4:08 am Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 4:08 am Post subject: 914 Waste gate servo mounting position question |

|

|

I am from the school of thought, that if the engine needs something to function (ie wastgate servo) that it needs to be where it can be checked, as needed, replaced if necessary, without having to access it from behind the panel.

I installed the servo on the top of the passenger side of the footwell. We have 800 hours on this installation, and at this point in time there have been no problems. I am able to system check the servo each time I have the cowling off. When and if I need to work on, or replace the servo or cable it will just a matter of removing the cowl.

Just my two cents worth, no slam intended.

Jim Brown

--- On Tue, 3/31/09, Rob Housman <rob(at)hyperion-ef.com> wrote:

| Quote: |

From: Rob Housman <rob(at)hyperion-ef.com>

Subject: RE: 914 Waste gate servo mounting position question

To: europa-list(at)matronics.com

Date: Tuesday, March 31, 2009, 4:04 PM

There is room, just barely, for the waste gate servo to mount on the cabin side of the firewall – see the attached photo. In this somewhat (OK, more than somewhat) cluttered image, the servo is just to the left of the SCAT tube. Note the black outline drawn on the firewall to indicate the instrument panel molding features. The red tape on the servo is holding some loose components in place.

In order to facilitate this mounting location I fabricated an aluminum bracket; the plan view is shown in the attached pdf file. The bracket was made from a piece of aluminum channel (with one leg removed) since an appropriate angle 90 degree shape was not conveniently available. Other stock would also be suitable.

Best regards,

Rob Housman

Irvine, CA

Europa XS Tri-Gear

A070

Airframe complete

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Paul McAllister

Sent: Monday, March 30, 2009 7:44 PM

To: europa-list(at)matronics.com

Subject: 914 Waste gate servo mounting position question

Hi All,

I am attempting to "shoe horn" in a second Grand Rapids EFIS screen into my panel which is turning into an mechanical challenge. It is pretty much looking like I am going to have to move it to the outside of the firewall. I know a few folks have done this and provided cooling with a blast tube. I was wondering if anyone had some photographs and best practices to share.

Thanks, Paul

| Quote: |

http://www.matronics.com/Navigator?Europa-List

|

0123456789

|

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

mikenjulie.parkin(at)btin

Guest

|

Posted: Wed Apr 01, 2009 8:32 am Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 8:32 am Post subject: 914 Waste gate servo mounting position question |

|

|

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.)

Regards

Bob Harrison.G-PTAG

Bob,

That statement is just not correct. In flight, there is a noticeable flow of hot air from the gills – obviously aiding the flow of cooling air across the cylinders. Perhaps that is why you have had cooling issues on Jabiru and Rotax.

Regards,

Mike

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

terrys(at)cisco.com

Guest

|

Posted: Wed Apr 01, 2009 9:47 am Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 9:47 am Post subject: 914 Waste gate servo mounting position question |

|

|

We spent nearly a year looking into and fixing our cooling problems. We installed temperature probes throughout the engine compartment and performed data logging on those temps, as well as engine parameters (rpm, MP, oil pressure, oil and water temps, CHTs, and fuel flow). Each parameter was sampled once every 2 seconds during flight and downloaded to a lap-top after the flight. We found that the gills allowed the upper cowl inlet air to escape without contributing much to engine cooling. After closing them off, we found no significant rise in upper cowl temps, but with a noticeable improvement in lower cowl temps. Closing off the area between the foot wells was the final fix that made the temps come down, from a max of 450 deg F inside the cowl to a max of 250 deg F.

Regards,

Terry Seaver

A135 / N135TD

XS monowheel with 912S

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 9:31 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.)

Regards

Bob Harrison.G-PTAG

Bob,

That statement is just not correct. In flight, there is a noticeable flow of hot air from the gills – obviously aiding the flow of cooling air across the cylinders. Perhaps that is why you have had cooling issues on Jabiru and Rotax.

Regards,

Mike | Quote: | | http://www.matronics.com/Navigator?Europa-List |

0123456789

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

mikenjulie.parkin(at)btin

Guest

|

Posted: Wed Apr 01, 2009 10:24 am Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 10:24 am Post subject: 914 Waste gate servo mounting position question |

|

|

Terry,

While I acknowledge your comments and development. My comments where based on my experience with a monowheel AND on Andy Draper’s comments on the original Europa development with G-YURO. Plainly there are variable issues with individual aircraft. I have the Graham Singleton firewall fitted to my aircraft and have never had any problems apart from the Evans stuff seeming to push the cooling system past its capability. However, what exactly do you mean by ‘closing off the area between the footwells’. Is this a problem that the Singleton firewall avoids?

Regards,

Mike

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Terry Seaver (terrys)

Sent: 01 April 2009 18:46

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

We spent nearly a year looking into and fixing our cooling problems. We installed temperature probes throughout the engine compartment and performed data logging on those temps, as well as engine parameters (rpm, MP, oil pressure, oil and water temps, CHTs, and fuel flow). Each parameter was sampled once every 2 seconds during flight and downloaded to a lap-top after the flight. We found that the gills allowed the upper cowl inlet air to escape without contributing much to engine cooling. After closing them off, we found no significant rise in upper cowl temps, but with a noticeable improvement in lower cowl temps. Closing off the area between the foot wells was the final fix that made the temps come down, from a max of 450 deg F inside the cowl to a max of 250 deg F.

Regards,

Terry Seaver

A135 / N135TD

XS monowheel with 912S

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 9:31 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.)

Regards

Bob Harrison.G-PTAG

Bob,

That statement is just not correct. In flight, there is a noticeable flow of hot air from the gills – obviously aiding the flow of cooling air across the cylinders. Perhaps that is why you have had cooling issues on Jabiru and Rotax.

Regards,

Mike | Quote: | | http://www.matronics.com/Navigator?Europa-List http://forums.matronics.com http://www.matronics.com/contribution |

01234567890123456789

No virus found in this incoming message.

Checked by AVG - www.avg.com

04/01/09 06:06:00

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

terrys(at)cisco.com

Guest

|

Posted: Wed Apr 01, 2009 1:10 pm Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 1:10 pm Post subject: 914 Waste gate servo mounting position question |

|

|

Hi Mike,

Our cooling problem was temps reaching 450 deg F in the lower engine cowl, near the exhaust. The heat melted tie wraps into drops of nylon, took the temper out of the springs holding the exhaust on, and caused damage to the cowl itself. We first found that the gills were allowing air to escape without cooling much of anything. After closing them off, we found that the cooling air was coming in the upper inlets, crossing across the top of the engine and then going down the back of the engine, between the foot wells, bypassing the cylinders and the exhaust area. Closing off the area behind the engine, between the foot wells, forced the air to act like it does in a conventional air cooled installation. It forced the air to pass around the cylinders, top to bottom, and then to pass around the exhaust, before exiting the lower, rear, of the cowl.

After the two changes mentioned above, the max in-cowl temps dropped to 250 deg F, and our oil temp in the climb dropped 20 deg F, from 240 deg F to 220 deg F (100 deg F ambient at 12,000+ feet density altitude).

The key to our changes was to treat the engine as you would an air cooled aircraft engine (the Rotax cylinders are, after all, air cooled). Bring air into the top of the cowl, force it down around the cylinders with ducting/baffles, past the exhaust, to finally exit the lower rear of the cowl.

After making these changes we carefully monitored the temps at the top of the cowl, near the ignition and carbs, to make sure we had not negatively affected their cooling. Those temps remained barely above ambient, only a few degrees different than before.

Regards,

Terry

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 11:22 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

Terry,

While I acknowledge your comments and development. My comments where based on my experience with a monowheel AND on Andy Draper’s comments on the original Europa development with G-YURO. Plainly there are variable issues with individual aircraft. I have the Graham Singleton firewall fitted to my aircraft and have never had any problems apart from the Evans stuff seeming to push the cooling system past its capability. However, what exactly do you mean by ‘closing off the area between the footwells’. Is this a problem that the Singleton firewall avoids?

Regards,

Mike

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Terry Seaver (terrys)

Sent: 01 April 2009 18:46

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

We spent nearly a year looking into and fixing our cooling problems. We installed temperature probes throughout the engine compartment and performed data logging on those temps, as well as engine parameters (rpm, MP, oil pressure, oil and water temps, CHTs, and fuel flow). Each parameter was sampled once every 2 seconds during flight and downloaded to a lap-top after the flight. We found that the gills allowed the upper cowl inlet air to escape without contributing much to engine cooling. After closing them off, we found no significant rise in upper cowl temps, but with a noticeable improvement in lower cowl temps. Closing off the area between the foot wells was the final fix that made the temps come down, from a max of 450 deg F inside the cowl to a max of 250 deg F.

Regards,

Terry Seaver

A135 / N135TD

XS monowheel with 912S

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 9:31 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.)

Regards

Bob Harrison.G-PTAG

Bob,

That statement is just not correct. In flight, there is a noticeable flow of hot air from the gills – obviously aiding the flow of cooling air across the cylinders. Perhaps that is why you have had cooling issues on Jabiru and Rotax.

Regards,

Mike | Quote: | | http://www.matronics.com/Navigator?Europa-List http://forums.matronics.com http://www.matronics.com/contribution |

0123456789

No virus found in this incoming message.

Checked by AVG - www.avg.com

04/01/09 06:06:00 0123456789 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

0 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

1 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

2 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

3 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

4 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

5 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

6 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

7 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

8 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

9

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

terrys(at)cisco.com

Guest

|

Posted: Wed Apr 01, 2009 1:11 pm Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 1:11 pm Post subject: 914 Waste gate servo mounting position question |

|

|

Hi Mike,

I forgot to mention that we also have the Singleton firewall, although we have since gone back to the standard stainless firewall in the lower half. This allows easier inspection of the motor mounts, etc.

Terry

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 11:22 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

Terry,

While I acknowledge your comments and development. My comments where based on my experience with a monowheel AND on Andy Draper’s comments on the original Europa development with G-YURO. Plainly there are variable issues with individual aircraft. I have the Graham Singleton firewall fitted to my aircraft and have never had any problems apart from the Evans stuff seeming to push the cooling system past its capability. However, what exactly do you mean by ‘closing off the area between the footwells’. Is this a problem that the Singleton firewall avoids?

Regards,

Mike

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Terry Seaver (terrys)

Sent: 01 April 2009 18:46

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

We spent nearly a year looking into and fixing our cooling problems. We installed temperature probes throughout the engine compartment and performed data logging on those temps, as well as engine parameters (rpm, MP, oil pressure, oil and water temps, CHTs, and fuel flow). Each parameter was sampled once every 2 seconds during flight and downloaded to a lap-top after the flight. We found that the gills allowed the upper cowl inlet air to escape without contributing much to engine cooling. After closing them off, we found no significant rise in upper cowl temps, but with a noticeable improvement in lower cowl temps. Closing off the area between the foot wells was the final fix that made the temps come down, from a max of 450 deg F inside the cowl to a max of 250 deg F.

Regards,

Terry Seaver

A135 / N135TD

XS monowheel with 912S

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 9:31 AM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

I do not have the “gills” open (left them closed since it has been established that they were a development item providing little cooling benefit on shut down(positioned too low) and are now a “leftover” item.)

Regards

Bob Harrison.G-PTAG

Bob,

That statement is just not correct. In flight, there is a noticeable flow of hot air from the gills – obviously aiding the flow of cooling air across the cylinders. Perhaps that is why you have had cooling issues on Jabiru and Rotax.

Regards,

Mike | Quote: | | http://www.matronics.com/Navigator?Europa-List http://forums.matronics.com http://www.matronics.com/contribution |

0123456789

No virus found in this incoming message.

Checked by AVG - www.avg.com

04/01/09 06:06:00 0123456789 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

0 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

1 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

2 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

3 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

4 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

5 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

6 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

7 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

8 | Quote: | | http://www.matronics.com/Navigator?Europa-List |

9

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ptag.dev(at)tiscali.co.uk

Guest

|

Posted: Wed Apr 01, 2009 2:40 pm Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 2:40 pm Post subject: 914 Waste gate servo mounting position question |

|

|

Mike …Andy Draper said originally the gills were there for heat escaping on shut down. He did tests during flight and they were practically none effective.

On shut down they are below the hot air collecting in the cowl top and are not as effective as opening the service access doors. However probably provide some escape route if parked into wind.

On the Jabiru the whole downward cooling principle made it necessary to have all alternative outlets above the engine blanked and so keeping the cowl top internal pressure high. My 914 has the barrel hood fitted also demanding downward flowing air. I don’t have Rotax cooling issues with the small diverter flap in the lower cowl to boost prop wash into the radiator when ground running. (The modified lower cowl radiator entrance however could have been about 4” lower.

Regards

Bob H G-PTAG

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

mikenjulie.parkin(at)btin

Guest

|

Posted: Wed Apr 01, 2009 10:11 pm Post subject: 914 Waste gate servo mounting position question Posted: Wed Apr 01, 2009 10:11 pm Post subject: 914 Waste gate servo mounting position question |

|

|

Bob and Terry,

I must say that I find the subject of Europa cooling most baffling (pardon the pun). G-JULZ is constructed absolutely ‘bog standard’ apart from the addition of the Singleton firewall. My 914 engine pre-dates the later ducting and stuff that is fitted around the cylinders. You may recall that I had the cooling issues in Switzerland some years back which prompted me to lower the oil cooler from behind the radiator. Since then my problem has been getting the engine up to temperature to take-off – particularly in winter. It is true that the Evans coolant had an adverse effect such that in a sustained climb during the summer the engine temperature climbed quickly such that I had to level off early to control the temperatures. I think that the heat transfer properties of the Evans being less than that of water/glycol was enough to push the cooling system beyond its capability on a hot day. I am just completing the modification paperwork for my cowl flap which may or may not have any effect – certainly these days – trying to keep the engine temperatures up particularly in the cruise is the main problem. CHT and Oil temperatures circa 60-70 degs C are not unusual once established in the cruise. It is curious that some people have major cooling issues and other people don’t. Perhaps I am missing something. I have just fitted a water temperature gauge which might help identify any problems. In light of Terry’s experience, I will be watching the whole thing much more carefully.

Regards,

Mike

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ptag.dev(at)tiscali.co.uk

Guest

|

Posted: Thu Apr 02, 2009 12:47 am Post subject: 914 Waste gate servo mounting position question Posted: Thu Apr 02, 2009 12:47 am Post subject: 914 Waste gate servo mounting position question |

|

|

Hi! Mike

Yes we all find that the cooling problem solving is a black art . The only positive thing I gained from my Jabiru 3300 was to understand that on a completely air cooled installation (excepting the oil cooler of course) the top of cowl has to have pressure maintained to push hot air down (against physics … hot air rises!) and so away. My Rotax installation has the third cooling air intake hole linked to the fiberglass hood forcing air down through the barrels not unlike the damn Jabiru! The authorities said NOT to cut that hole out on a 914, I am so pleased that I did.

I’m pretty sure I would concur with Terry about closing off the rear of the engine down between the foot wells, all goes to achieve overall cooling at the scource…the guts of engine…by improving the down draught. Air flirting over the top isn’t slow enough to pick up any therms !

Regards

Bob H G-PTAG

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

terrys(at)cisco.com

Guest

|

Posted: Thu Apr 02, 2009 8:35 am Post subject: 914 Waste gate servo mounting position question Posted: Thu Apr 02, 2009 8:35 am Post subject: 914 Waste gate servo mounting position question |

|

|

Mike,

We have not seen similar problems on 914 installations, which are different from the 912S. The key to look for are the spark plug wire marker bands. On ours, the ones on the lower plugs quickly shriveled up to a very thin, dark brown band that could no longer be read. If yours are still yellow and readable, you do not have the kind of cooling issue we had.

Having said that all installations are not the same, I still believe our measurements gave a very strong indication that the gills are counterproductive to engine cooling in flight.

Regards,

Terry Seaver

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Mike Parkin

Sent: Wednesday, April 01, 2009 11:08 PM

To: europa-list(at)matronics.com

Subject: RE: 914 Waste gate servo mounting position question

Bob and Terry,

I must say that I find the subject of Europa cooling most baffling (pardon the pun). G-JULZ is constructed absolutely ‘bog standard’ apart from the addition of the Singleton firewall. My 914 engine pre-dates the later ducting and stuff that is fitted around the cylinders. You may recall that I had the cooling issues in Switzerland some years back which prompted me to lower the oil cooler from behind the radiator. Since then my problem has been getting the engine up to temperature to take-off – particularly in winter. It is true that the Evans coolant had an adverse effect such that in a sustained climb during the summer the engine temperature climbed quickly such that I had to level off early to control the temperatures. I think that the heat transfer properties of the Evans being less than that of water/glycol was enough to push the cooling system beyond its capability on a hot day. I am just completing the modification paperwork for my cowl flap which may or may not have any effect – certainly these days – trying to keep the engine temperatures up particularly in the cruise is the main problem. CHT and Oil temperatures circa 60-70 degs C are not unusual once established in the cruise. It is curious that some people have major cooling issues and other people don’t. Perhaps I am missing something. I have just fitted a water temperature gauge which might help identify any problems. In light of Terry’s experience, I will be watching the whole thing much more carefully.

Regards,

Mike | Quote: | | http://www.matronics.com/Navigator?Europa-List |

0123456789

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|