|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

GrummanDude

Joined: 15 Jan 2006

Posts: 926

Location: Auburn, CA

|

Posted: Fri Apr 24, 2009 3:20 pm Post subject: Cowling: Percent power. How to calculate? Posted: Fri Apr 24, 2009 3:20 pm Post subject: Cowling: Percent power. How to calculate? |

|

|

Please read and make comments and recommendations if you have any

additional information.

OK, so, the FAA has been working on the paperwork submitted by myself

and the DER for the last month or so. There seems to be a hitch in the

giddy-up: I used the POH to compute percent power for a 30°F OAT, 5000

feet, and 10.8 gph for 75% power. (Note: altimeter setting was 29.84

at 120 MSL with an OAT on the ground of 52°F)

Problem 1: The POH I used is not an FAA approved document.

Apparently, the FAA wants the equivalent computation

based on the charts in the Lycoming Engine handbook. They could not

tell me if the handbook was or was not FAA approved. It isn't marked

as such.

Problem 2: The Lycoming Engine handbook itself.

The problem is, based on feedback from LyCon Engine

Rebuilder's engine/performance specialist, that the charts in the

Lycoming handbook are built from full throttle operation with a

constant speed propeller used to limit RPM at a given manifold

pressure.

I've researched articles from the Lycoming website. Specifically,

"Lycoming Flyer." Case in point: From Lycoming Flyer, General

Operation, page 22-23 (Note: material in "quotes" is quoted from the

Lycoming Flyer article.)

"As an example, the standard fixed pitch propeller supplied with an

aircraft may allow the engine to dev

elop 180 horsepower at 2700 RPM at

full throttle, in flight at sea level, with a standard temperature. The

Lycoming O-360-A Series normally aspirated engine illustrates this

example."

For the test plane used (65 inch pitch), we could easily exceed 2700

rpm in level flight at 5000 feet. Therefore, we had to reduce manifold

pressure (throttle) just to maintain engine operation below the 2700

rpm redline. (Note: the 65 inch pitch propeller is the maximum pitch

certified for this engine/plane combination)

"Next, let us assume that this same engine/propeller combination is

operated at 75% power with a “best economy” fuel/air mixture setting.

Again, assume sea level and standard temperature to simplify and

standardize the discussion.

75% power will require about 2450 RPM with a brake-specific fuel

consumption of .435 pounds per brake horsepower hour. Also, 75% of the

180 rated horsepower is equal to 135 horsepower. Fuel usage at this

power and mixture setting will be 58.7 pounds per hour or 9.8 gallons

per hour."

Again, this is based on sea level operation. At 5000 feet, more

throttle is required, i.e., fuel flow, to obtain 75% power. The only

tool available to the owner/operator of the plane is the POH. So, now

what?

"With this information as background, it is easy to see that setting a

desired power with a fixed-pitch propeller can only be accomplished if

the pilot has a chart tha

t applies to the specific

aircraft/engine/propeller combination. Although the power chart for a

new aircraft may come from data obtained by test flying with a

calibrated torque meter, a fairly accurate chart can be derived for any

fixed-pitch propeller and engine combination. Briefly, this is done by

finding the maximum available RPM at any particular altitude and

applying data from the propeller load curve.

To conclude, the purpose of this article is to make readers more aware

of some operational aspects of the fixed-pitch propeller. Usually, it

is only necessary to accept the material provided by the airframe

manufacturer and to use the engine/propeller as directed."

As quoted by Lycoming in their own reference, "the airframe

manufactures data should be used. "

========================

Gary

PS, any feedback is welcome.

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

_________________

Gary

AuCountry Aviation

Home of Team Grumman |

|

| Back to top |

|

|

jamey

Joined: 10 Jan 2006

Posts: 124

|

Posted: Mon Apr 27, 2009 10:32 pm Post subject: Cowling: Percent power. How to calculate? Posted: Mon Apr 27, 2009 10:32 pm Post subject: Cowling: Percent power. How to calculate? |

|

|

I certainly don't have any personal experience with this sort of issue but you might try the following. Contact GAMI/Tornado Alley as they have several performance-enhancing STCs for a variety of aircraft and they know more about engines than just about anyone. They should know what percent power numbers the FAA will find acceptable and how to prepare them.

Ask for George Braly if he's available and feel free to mention I (a customer of one of their TATurbo conversions) suggested you contact them. Tim Roehl may also be able to help you.

That'd be who I'd call to ask about such things.

Best,

Jamey

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Tue Apr 28, 2009 4:12 am Post subject: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 4:12 am Post subject: Cowling: Percent power. How to calculate? |

|

|

Hi Gary,

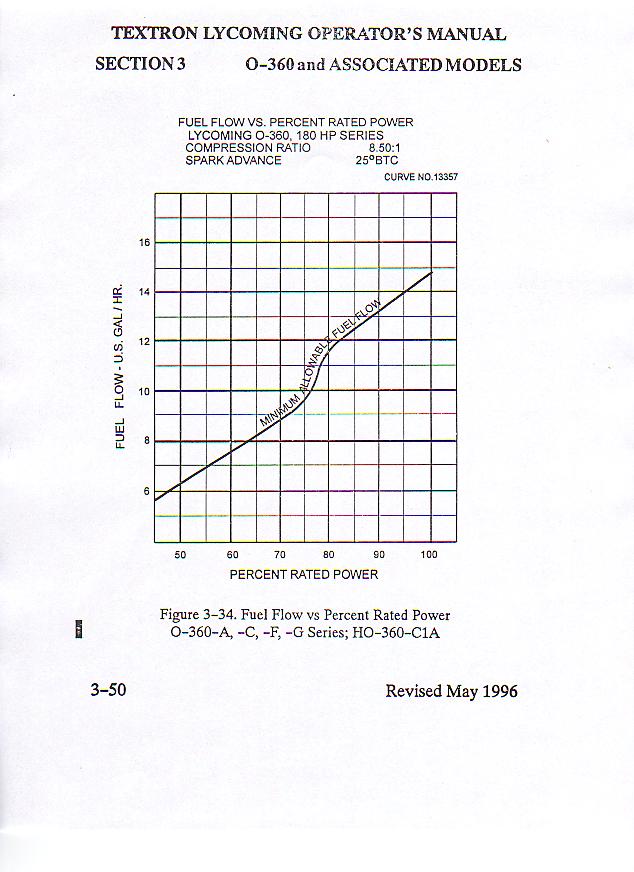

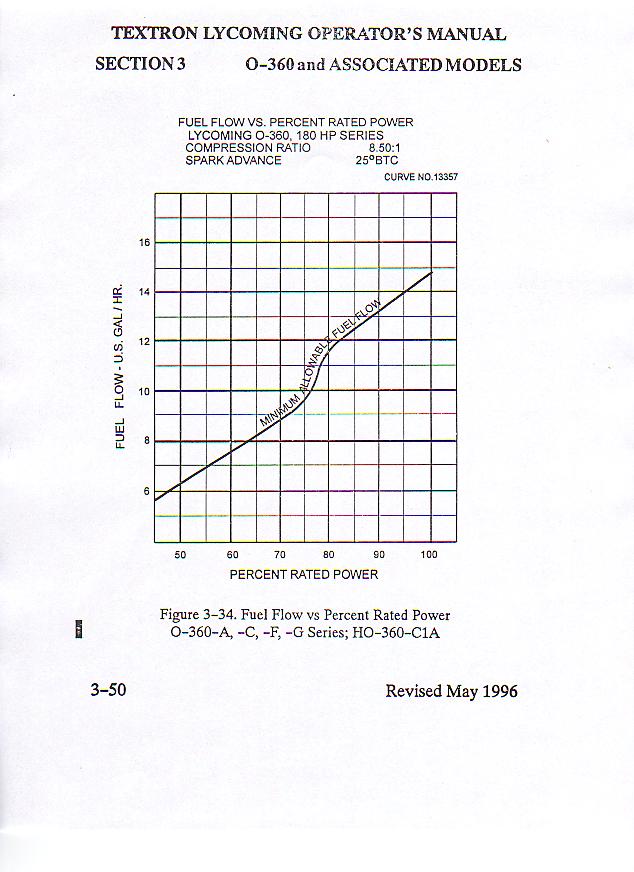

I didn't really understand what you needed when I first read your email. I guess I'm a little slooow but after rereading it a few times I have something for you that might help. The Lycoming Operators Handbook gives Figure 3-34 for determining power in flight. It replaces the Figure 3-2 in earlier manuals that I think you were referring to. Anyway Figure 3-34 is Fuel Flow VS Percent Rated Power. From there you can determine HP from your fuel flow.

Attached Figure 3-34

Best Regards,

ned

[quote] ---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

69.87 KB |

| Viewed: |

5199 Time(s) |

|

|

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Tue Apr 28, 2009 6:32 am Post subject: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 6:32 am Post subject: Cowling: Percent power. How to calculate? |

|

|

The full throttle curve in Fig 3-2 is for engines with CS props and the propeller load curve is for a prop that is pitched to result in full throttle at 2700 rpm. Any other situation would be a different curve. Fig. 3-34 is for O-360-A4D, -F engines (don't know what the difference is but they should be very similar. Notice on this curve that the fuel flow makes a jog between 75 and 80% power. The upper portion is a rich mixture, probably best power, and the lower portion is a lean mixture, or best economy. If you are at peak on LOP the fuel flow will be relative and a fixed % or power but on the rich side the fuel flow can be all over the place depending on where you are on the curve, i.e., how rich.

Of course you (Gary) have a special situation that changes the relevance of either of these curves! Probably the best curve to use (for FAA purposes) would be Fig. 3-17 provided you have a MP gauge and use that along with RPM, pressure alt. and OAT to determine % power. It is with an MA4-5 carb but there should not be any significant difference with the HA-6.

I don't know where you came up with .435 BSFC.� Fig. 3-2 shows the best BSFC to be about .46 lb/hp-hr at 2350 rpm on the propeller load curve. I don't think you can get that low on any 8.5:1 CR Lycoming engine unless you have FI or a pressure carb under the most ideal conditions.

Cliff

[quote] ---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Tue Apr 28, 2009 7:39 am Post subject: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 7:39 am Post subject: Cowling: Percent power. How to calculate? |

|

|

Gil and Cliff,

I must be missing some paperwork. I just don't see what you guys are basing your assumption upon. If you have more data I sure wuold like to see it. Could you send it to me?

The Fig3-34 in my copy of the manual clearly states it is for O-360-A series engines along with several other series. Why are you limitining it to the O-360-A4D, -F?

The Lycoming Engine Operators manual says

Page 3-7

1) "maintain mixture control in "Full Rich" position for rated ....maximum cruise powers (above approximately 75%)."

2) "Operate the engine at maximum power mixture for performance cruise powers and at best economy mixture for economy cruise power, unless otherwise specified in the airplane owners manual."

Page 3-9:

3) 2. LEANING TO FLOWMETER "Lean to applicable fuel-flow tables or lean to indicator marked for correct fuel flow for each power setting."

Page 3-50 Figure 3-34 Fuel Flow VS. Percent Rated Power for the O-360-A Series (which by my assumption must include the A4K in the Tiger)

The logic of the manual seems clear:

A) Figure 3-34 is based on the above specified leaning practices and is meant to be used in conjunction with Leaning based on Page 3-9 LEANING TO FLOWMETER.

B) Figure 3-34 takes into account whether you are at best economy or power and it is based on the leaning instructions given on page 3-7. Notice Lycomings use of the term "approximately" and how that is reflected on the figure in the change you noted from 75 - 80% power.

C) EVEN IF YOU DON'T AGREE WITH THE ABOVE

For the purposes of certification I would argue that Figure 3-34 gives the manufactures data as concerns percentage power based upon fuel flow when the engine is operated by the manufacures stated practices. I would also argue that ALL the test flights whereby data was derived for the certification of the "cowling" were operated in strict compliance with the engine manufacures practices as stated in the manufactures manual and therefore the manufacture provided data ie Figure 3-34 and ALL the flight test derived data is authoritative and accurate. I would also make it clear that the Lycoming Operators Manual States on Page 2 that it is APPROVED BY FAA and because it is APPROVED BY FAA that there is no question as to the applicability or validity of the data contained therein to answer the current question / requirement posed by the FAA

D) I understand what you, Gary stated in PROBLEM 2.

I learned about that during my MT prop arguements with those that argued going from 2500 to 2700rpm was going to get some additional 16 or 32 hp depending upon who was reading what curve...if the correct curve is used one finds that only 6hp is gained.

I would not be concerned with PROBLEM 2. If for some reason you don't like or cannot use the argument above based upon figure 3-34 then pick another figure from the operators manual and make the same argument of logic proposed in C) above.

Figure 3-34 gives the right engineering answer as far as Lycoming data for power. The other figures may or may not give the right answer...BUT it doesn't matter. What you need is to answer the FAA. They don't care what or whether it's based upon right they just want it from an FAA APPROVED source even if it's BS. Focus on giving them what they want and not on what you'd like them to know!

Best Regards,

ned

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

az_gila

Joined: 17 Jun 2006

Posts: 99

Location: Tucson, AZ

|

Posted: Tue Apr 28, 2009 8:00 am Post subject: Re: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 8:00 am Post subject: Re: Cowling: Percent power. How to calculate? |

|

|

Gary.... what was the manifold pressure reading at the 5000 ft measurement point of your first post?

My DA calculator says the 5000 ft at 30 F was a DA of 4400 ft - for future power chart look-ups...

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

Last edited by az_gila on Tue Apr 28, 2009 8:05 am; edited 1 time in total |

|

| Back to top |

|

|

Phil(at)ReliantAir.com

Guest

|

Posted: Tue Apr 28, 2009 8:04 am Post subject: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 8:04 am Post subject: Cowling: Percent power. How to calculate? |

|

|

Gary, the link to the Benchmark website might help. It has downloadable software for calculating the HP of the 0-360 lycoming. It extrapolates from the Lycoming sea level power charts. http://www.seqair.com/benchmark/index.html

P. J. Kelsey

Vice President/Co-owner

ReliantAir

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Tue Apr 28, 2009 8:09 am Post subject: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 8:09 am Post subject: Cowling: Percent power. How to calculate? |

|

|

Gary,

If you don't care about certification delays and you want to show your local FAA guys how stupid they are, then you can make the argument that what you have already calculated for them IS APPROVE BY FAA because the guidance you followed is THE FAA APPROVED POH. THE Lycoming POH tells one to use the AIRFRAME POH as follows from the quote below...so tell The FAA tards that what you did is already blessed I mean APPROVED by the FAA by default and cram it down their throats...or do it as discussed previously ...

Page 3-7

2) "Operate the engine at maximum power mixture for performance cruise powers and at best economy mixture for economy cruise power, *******unless otherwise specified in the airplane owners manual."******

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

az_gila

Joined: 17 Jun 2006

Posts: 99

Location: Tucson, AZ

|

Posted: Tue Apr 28, 2009 9:05 am Post subject: Re: Cowling: Percent power. How to calculate? Posted: Tue Apr 28, 2009 9:05 am Post subject: Re: Cowling: Percent power. How to calculate? |

|

|

Gary... if I read this chart correctly, and you had 25 inches of manifold pressure, then you were just over 160 HP at 2700 rpm.

gil A

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

Download |

| Filename: |

lyc-power001.pdf |

| Filesize: |

629.59 KB |

| Downloaded: |

312 Time(s) |

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|