|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

propellerdesign(at)tele2.

Guest

|

Posted: Mon Oct 26, 2009 4:39 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 4:39 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

What fuel? avgas or mogas? vapor lock at altitude?

why not use a fuel pump bulb on each fed line?

Jan

[quote] ---

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

FlyboyTR

Joined: 04 Nov 2006

Posts: 215

Location: Mobile, Alabama

|

Posted: Mon Oct 26, 2009 5:19 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 5:19 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

My fuel is 100LL. I was wishing I had a squeeze bulb...or something! I have considered installing two of those. However, I have had several fail (no flow) when used in my boats and several of the local Ultralight folks have had engine outs because of the same problem.

Travis

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

www.enotam.net (My Flying Info Website) |

|

| Back to top |

|

|

pwmac(at)sisna.com

Guest

|

Posted: Mon Oct 26, 2009 7:26 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 7:26 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Travis,

I think you have touched on why the engineers of

the KF fuel system used the design of the latest

configuration. This system design has no valve or

filters in the lines from the tank to the header.

Also included by the engineers was the deep sump

header tank behind the seat. All great

improvements in the original KFIII and older design.

Further my best advice is to use the KF design

AND replace all the lines with 3/8" SAE black

elastomer hose. Including the vent line. Further,

have you cleaned your finger strainers? Another source of flow restriction.

You all may ask why and the answer lies with the

surface tension and small pressure that

contributes to the flow of the fuel. This is

very hard to quantify but the theory that is

followed but the KF design is correct by making

the pressure lost in those lines is always

correct and will not have negative aspects.

For plane in construction a tank pressure pitot

that is plumbed under the wing is also a big

improvement since under the wing is where the greatest pressure is.

I know it all about experimenting, however the

physics must be followed for any non standard mods.

Maybe the above will help?

Regards, Paul

============

At 05:52 PM 10/25/2009, you wrote:

| Quote: |

We just returned from an 800 mile trip to our

favorite flying destination, High Valley Resort

in north GA. We developed a fuel flow problem while enroute.

A little history. Two years ago I had a fuel

flow problem (actually on the same trip!) that

was caused by my “new” paper filters

(located between the wing tanks and the header

tank) air locking and not allowing fuel to

flow. We completed the trip using just one

tank. After returning home, I discovered that

if I blew up through the fuel line, causing the

filter to fill with air, it would not gravity

flow! After either sucking on the line ( or

blowing on the gas cap vent tube) to force the

fuel to flow, it would flow without

restriction. This was repeated numerous times,

on both tanks with the exact same results! The

filters had been replaced just prior to this

event. This was also tested with new filters

with the same results. After that, I returned

to using the filters with the glass sight tubes.

OK…present day... I filled both tanks to the

brim prior to our 400 mile, one way,

flight. After about 45 minutes Kathy noticed

there was no fuel in the header tank vent

line. The right tank level was low and the left

one was full (could not see the fuel

level…above the sight gauge). We checked and

both fuel valves were on and we cycled them

several times. I reduced power to the engine

and set it up lean of peak to reduce the fuel

flow. Shortly, fuel appeared in the vent tube

(yes that was a relief!). Fortunately we were

at 9,500’, talking the Atlanta Center and had

an airport with easy gliding distance (which

also provided some peace of mind).

After going back to full cruise power, the fuel

level in the vent line started dropping. We

turned the working tank off, pinched the vent

line so it would force, hopefully, the fuel in

the right tank to be sucked. After a few

seconds, the left tank filter (which was filed

with air) starting showing some fuel movement

and slowly filled about ½ way. I kept the vent

line pinched for about a minute. Fuel flow was

established on the left tank, but still not

enough to fill the vent line. I turned the

right tank back on and the vent line filled. I

closed it again and then slowly opened it to

allow partial flow and kept the fuel level in

the vent line visible for about 30

minutes. After several gallons of fuel was

pulled from the left tank, I opened the right

valve completely and the vent tube

filled. After that fuel flowed from both tanks and was not a problem.

Heading Home… We stopped for fuel while

heading home. This time the same thing

happened, except the tanks were reversed! Right

tank would not flow. We did the same

thing…pinching off the vent line and forcing

the system to “suck” from the non-flowing

tank. Again, this was met with success.

I am at a complete loss! The vent lines on the

gas caps are open (checked with each fill-up and

also with a pipe cleaner, etc). All my flexible

fuel lines are 3/8” marine grade lines (vent

line is ¼” clear Tygon). No lines are

pinched. Once flowing, they flow with no

restriction. There are no loops, etc in any of

the lines. I would appreciate any helpful information regarding this problem!

Also…On the return leg home this

afternoon…My charging system went out! I just

hope it's not “another” alternator coupling/clutch that’s gone bad!

Travis

--------

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 69410#269410

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

propellerdesign(at)tele2.

Guest

|

Posted: Mon Oct 26, 2009 8:10 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 8:10 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

ok

I have had the same bulb on my Yamaha outboard engine for 35 year, still no

problem, but sure it isn't 100LL.

about the vent line they must go from top of header to top of wing tank! (I

guess)

and fuel line go from bottom of wing tank to bottom of header tank?

what about the tank vents? are they faced forward? on top of the wings there

is a suction so a bent tube facing into the airstreams isn't wrong.

paper filter can "clog" by water, when the paper is wet from water fuel

isn't coming throe.

We hade some problem just like this on our aeronca, with a small wing tank

that will feed the main tank forward of the dash.

Jan

---

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

ruebd(at)skymail.csus.edu

Guest

|

Posted: Mon Oct 26, 2009 8:13 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 8:13 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Travis:

Why do you use filtration at that point in the system? Is it because you have shut off valves there and you figured that you might as well? The closer upward toward the tank level, the less head pressure there is, so the restriction of a filter even if quite low will bother the flow.

On my plane with the same engine as you have, the filter is up forward just ahead of the pump. I have not other filters, but of course, the final filter is in your fuel distributor.

I guess I would think that a squeeze bulb would be needed if you have filters high in the system, but considering that now you have a possible leak source in the cockpit, I would feel better not having any bulb/filters in the cabin.

I also use 100LL and find that it is quite clean. Out here in Ca. in the summer which is a long time we do not have much rain, so I must admit that we tend at least I do to not worry much about water.

I should think that you would get good results as I do by not having any filters in the cabin and having one up forward. The one that I have is a metal finger style screen approx 3-1/2 inches long. It gives me the sense that it is of a semi fine mesh, and because of its size and location seems to work just fine. I service it at annual, it is not glass, so one cannot see what is happening, but where it is, I think the alloy housing is the best choice. I definitely would not feel good about a glass one there, mounted just in front of the engine case.

On the topic of alternator coupling problems, I see by looking in the logs that my coupling was changed at a fairly low time, but I have not had problems, and have assumed that the 'new one' may have been an improved version, but from what I read here, it seems not the case. I seem to recall that they are quite pricey, being over $1k. I now have 760 hours on everything, so the new one seems to be there for the long haul on my plane, and I had forgotten to worry about it until I read this thread. Why would you change alternators? Is there more than one model that fits to the engine case like the stock one? Or do you do an adaption? Is the 'light weight' one you refer to the same output current? The drive setup on this engine for the alternator has always impressed me as one the cool design features of the engine, but this is assuming one doesn't need to change drive couplings like one would belts; especially at their cost. Can this change be done with the engine mounted?

Duane, N24ZM IO240B4B, Clark Lydic Performance Propeller

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

FlyboyTR

Joined: 04 Nov 2006

Posts: 215

Location: Mobile, Alabama

|

Posted: Mon Oct 26, 2009 10:04 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Mon Oct 26, 2009 10:04 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

My fuel configuration has remained virtually unchanged from the way is was when I purchased the Vixen from the builder. Yep...vent line from top of header tank to the top of the right wing tank. My fuel caps have the vent tube that is welded to the top of the cap. They both face forward and I blow through them each time I add fuel. They have also been checked with a pipe cleaner to ensure something wasn't hiding inside!

My system has 4 filters. One on each fuel line from the wing tanks to the header tank, a larger sintered type (aluminum housing) filter just after the fuel leaves the header tank and the same filter again just before the fuel enters the engine driven fuel pump. The only changes I have made were replacing the in-line fuel valves with a "higher" flow valve than was originally installed. In September, during my conditional inspection, I replaced the filter elements (which flowed freely).

Duane,...my Purolator filters are located rather high. ...Hadn't thought about that. After purchasing the plane 07/06, I replaced all the flexible fuel line. I did move the valves and filters higher (closer to the tank) to help protect them. Just guessing...the bottom of each filter is probably about 6" below the wing tank.

Today I noted that my fuel lines (from the tanks to the header) do have some horizontal component to them (behind the seat)...not completely flat or uphill. I can shorten those lines to make the flow as vertical as possible.

Odd thing is...the fuel problem is not consistent. It does seem to occur more frequently when I fill the fuel tanks "completely" up...but not always. It can be one tank...then the other...that has the flow problem.

I don't remember checking the finger strainers in the tank. I will check those, just in case!

Travis

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

www.enotam.net (My Flying Info Website) |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Oct 28, 2009 10:16 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 10:16 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Duane and Travis-

I just measured my Purolator glass filters, and they are

12" (vertical measurement) from the bottoms of the wing tanks to the

tops of the filters. The fuel lines go through a ball valve

(installed for servicing the filters, and for shutting off a tank for

various reasons in-flight) and then the filters, and then to the

header tank. I have another similar filter just after the main fuel

(ball) valve. I had originally installed this one to catch any crap

that might get past the the other two, and not settle down in the

header tank (my "gascolator"), but now it's there to protect my

Northstar F210 fuel flow meter (which works great, by the way). The

last filter in my system is inside the Rotec TBI, and is called by

them, a "last chance" filter. Not including the last chance filter,

my system, (which is 95% 5/16" automotive fuel lines...30R7...and 5%

3/8" lines) flows over 13 gallons per hour, which is over *twice*

what is recommended for the maximum take-off fuel requirements for my

engine. Larger engines of course will require more fuel flow than

this, hence the 3/8" fuel lines that some builders use. So I'm having

trouble with the suggestion to avoid the glass filters (or any) at

that point, Duane. I'll admit that I got the idea for the location

from viewing another Kitfox, but in all the hours I've flown, I've

had no problem with their location, or any fuel flow through them,

admitting that they are 6" lower than Travis' location.

One thing about the Purolator glass filters, is that they should be

assembled and installed correctly. I just looked at some extras that

I have in the hangar, and it is possible to assemble them such that

the incoming fuel goes directly into the middle of the filter

cartridge, OUT through it, and then out the exit end of the filter.

This would reduce the capacity of the filter to hold junk by having

the *inside* of the filter cartridge trap the junk. The proper way is

for the fuel to flow into the "IN" end of the filter, surround the

filter medium, and go into it, leaving the junk trapped on the

outside of the cartridge where it is visible. I just changed my

filter cartridges a couple of weeks ago, and this was the first time

in three years of flying (800+ hours) that I've even had the filters

apart. Because I could *see* them, I knew their condition, and

because periodic checks of fuel flow RIGHT AT the point of connection

to the (then) Bing carb, or more recently the Rotec TBI, I knew the

whole system was flowing like it should for my application. My only

problem is making sure that there's enough fuel IN the tanks to

ensure that there will be flow OUT of the tanks. : )

And by the way, the Mr. Gasket version of the Purolator glass filters

leaves a lot to be desired. The NAPA ones seem to be OK from what I

see, comparing them to Purolators. The Mr. Gasket ones have plastic

"selective-size" fittings which screw into the end caps, and I don't

like them much. Try to get the ones that have the one-piece end caps.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 803.7 hrs

Countdown to 1000 hrs--197 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

On Oct 26, 2009, at 2:04 PM, FlyboyTR wrote:

| Quote: |

My fuel configuration has remained virtually unchanged from the way

is was when I purchased the Vixen from the builder. Yep...vent

line from top of header tank to the top of the right wing tank. My

fuel caps have the vent tube that is welded to the top of the cap.

They both face forward and I blow through them each time I add

fuel. They have also been checked with a pipe cleaner to ensure

something wasn't hiding inside!

My system has 4 filters. One on each fuel line from the wing tanks

to the header tank, a larger sintered type (aluminum housing)

filter just after the fuel leaves the header tank and the same

filter again just before the fuel enters the engine driven fuel

pump. The only changes I have made were replacing the in-line fuel

valves with a "higher" flow valve than was originally installed.

In September, during my conditional inspection, I replaced the

filter elements (which flowed freely).

Duane,...my Purolator filters are located rather high. ...Hadn't

thought about that. After purchasing the plane 07/06, I replaced

all the flexible fuel line. I did move the valves and filters

higher (closer to the tank) to help protect them. Just

guessing...the bottom of each filter is probably about 6" below the

wing tank.

Today I noted that my fuel lines (from the tanks to the header) do

have some horizontal component to them (behind the seat)...not

completely flat or uphill. I can shorten those lines to make the

flow as vertical as possible.

Odd thing is...the fuel problem is not consistent. It does seem to

occur more frequently when I fill the fuel tanks "completely"

up...but not always. It can be one tank...then the other...that

has the flow problem.

I don't remember checking the finger strainers in the tank. I will

check those, just in case!

Travis

--------

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 69517#269517

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

FlyboyTR

Joined: 04 Nov 2006

Posts: 215

Location: Mobile, Alabama

|

Posted: Wed Oct 28, 2009 10:44 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 10:44 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Lynn,

My glass filters are the ones with the metal fittings on each end (not the plastic ones). You're right...there is a big difference in quality. My fuel flow is correct and flows to the "bowl", through the filter, then out the bottom.

A six inch difference in filter height isn't much...but when considering the limited head pressure, I'm sure 6" makes a considerable difference.

At present I'm going to do four things (I'll do all of this while everything is torn apart for the new alternator coupling)  : :

1, Lower the filters as low as safely possible and still visible,

2, Shorten the fuel lines to remove as much horizontal component as possible,

3, Replace the fuel cap gaskets (not leaking...but are hard,

4, Inspect the finger strainers.

I really like having a visual check of the fuel flow in the glass filters. Without that, if you had a fuel issue, you wouldn't have any idea which side was the problem...or where to start troubleshooting.

Fingerstrainers.... does the strainer come out with the fitting? I have seen strainers that were integral to the tank and non-removable.

Again, thanks to everyone for all the help and suggestions. I really look forward to moving past this problem.

Travis

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

www.enotam.net (My Flying Info Website) |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Oct 28, 2009 11:11 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 11:11 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

My tanks have the finger strainers screwed right into the tank

itself....no step-down bushing is there on mine. The strainer sleeves

will come out with the fitting, if they're like mine. If yours has

two brass "fittings" at that location, it is because there is a brass

bushing that is meant to remain in the tank, and the finger strainer

itself. Removing the smaller of the two fittings and you'll have the

entire finger strainer in your hand. I removed mine a couple weeks

ago and found nothing trapped on it after three years of flying.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 803.7 hrs

Countdown to 1000 hrs--197 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

On Oct 28, 2009, at 2:44 PM, FlyboyTR wrote:

| Quote: |

Lynn,

My glass filters are the ones with the metal fittings on each end

(not the plastic ones). You're right...there is a big difference

in quality. My fuel flow is correct and flows to the "bowl",

through the filter, then out the bottom.

A six inch difference in filter height isn't much...but when

considering the limited head pressure, I'm sure 6" makes a

considerable difference.

At present I'm going to do four things (I'll do all of this while

everything is torn apart for the new alternator coupling)  : :

1, Lower the filters as low as safely possible and still visible,

2, Shorten the fuel lines to remove as much horizontal component as

possible,

3, Replace the fuel cap gaskets (not leaking...but are hard,

4, Inspect the finger strainers.

I really like having a visual check of the fuel flow in the glass

filters. Without that, if you had a fuel issue, you wouldn't have

any idea which side was the problem...or where to start

troubleshooting.

Fingerstrainers.... does the strainer come out with the fitting? I

have seen strainers that were integral to the tank and non-removable.

Again, thanks to everyone for all the help and suggestions. I

really look forward to moving past this problem.

Travis

--------

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 69873#269873

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Oct 28, 2009 11:25 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 11:25 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Oops, I goofed! My finger strainer is the largest of the two fittings

at the finger strainer location....the smallest is the fuel fitting

itself. (I forgot about the fuel line fitting) The largest is the

strainer, and there is no "bushing" on mine. Sorry 'bout that.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 803.7 hrs

Countdown to 1000 hrs--197 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

do not archive

On Oct 28, 2009, at 3:09 PM, Lynn Matteson wrote:

| Quote: |

My tanks have the finger strainers screwed right into the tank

itself....no step-down bushing is there on mine. The strainer

sleeves will come out with the fitting, if they're like mine. If

yours has two brass "fittings" at that location, it is because

there is a brass bushing that is meant to remain in the tank, and

the finger strainer itself. Removing the smaller of the two

fittings and you'll have the entire finger strainer in your hand. I

removed mine a couple weeks ago and found nothing trapped on it

after three years of flying.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 803.7 hrs

Countdown to 1000 hrs--197 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

FlyboyTR

Joined: 04 Nov 2006

Posts: 215

Location: Mobile, Alabama

|

Posted: Wed Oct 28, 2009 11:36 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 11:36 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Lynn,

Thanks! Shouldn't be a problem to check!

Travis

| Lynn Matteson wrote: | Oops, I goofed! My finger strainer is the largest of the two fittings

at the finger strainer location....the smallest is the fuel fitting

itself. (I forgot about the fuel line fitting) The largest is the

strainer, and there is no "bushing" on mine. Sorry 'bout that.

Lynn Matteson

|

[/quote]

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

www.enotam.net (My Flying Info Website) |

|

| Back to top |

|

|

lcfitt(at)sbcglobal.net

Guest

|

Posted: Wed Oct 28, 2009 7:24 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Wed Oct 28, 2009 7:24 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

I am a bit curious (maybe confused is a better word) here talking about head

height to the filters. It seems to me that if there were nothing below the

filter, this would be an accurate term. However, the fuel system remains

closed to the level of the header tank where it is vented and it would seem

to me that the total head of this system would be the height from the fuel

level in the tank to the level of the vent in the header tank. This would

be the same if it was six inch pipe, 3.8" tubing, no filters or valves or

lots of stuff in line. Granted the filters and valves and bends in the line

cause some resistance to fuel flow, but the head remains the same regardless

of what is in the line.

The weight of the fuel below the filter will suck on the fuel in the filter

as well as the fuel in above the filter pushing it down. This is how

siphons work.

Correct me if this idea is all wet.

Lowell Fitt

Cameron Park, CA

Second Build Model IV-1200 R-912 UL

Prepping the right wing for covering

---

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Thu Oct 29, 2009 4:54 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 4:54 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Beats me, Lowell, I'm no engineer (can't carry that burden), but I

think you're right. I've always thought of head pressure being like

you said, from the top of the fluid to the bottom. But what's to say

that you can't measure along the way from top to bottom to determine

a "head" pressure at any given point? Seems sensible to me, but like

I said I'm no engineer....I quit that school when the math got to

lookin' like Greek. : )

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 803.7 hrs

Countdown to 1000 hrs--197 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

On Oct 28, 2009, at 11:13 PM, Lowell Fitt wrote:

| Quote: |

<lcfitt(at)sbcglobal.net>

I am a bit curious (maybe confused is a better word) here talking

about head height to the filters. It seems to me that if there

were nothing below the filter, this would be an accurate term.

However, the fuel system remains closed to the level of the header

tank where it is vented and it would seem to me that the total head

of this system would be the height from the fuel level in the tank

to the level of the vent in the header tank. This would be the

same if it was six inch pipe, 3.8" tubing, no filters or valves or

lots of stuff in line. Granted the filters and valves and bends in

the line cause some resistance to fuel flow, but the head remains

the same regardless of what is in the line.

The weight of the fuel below the filter will suck on the fuel in

the filter as well as the fuel in above the filter pushing it

down. This is how siphons work.

Correct me if this idea is all wet.

Lowell Fitt

Cameron Park, CA

Second Build Model IV-1200 R-912 UL

Prepping the right wing for covering

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

ruebd(at)skymail.csus.edu

Guest

|

Posted: Thu Oct 29, 2009 6:57 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 6:57 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Lowell:

Head pressure is much more valuable to the analysis of the problem then head vacuum. There is no source of vacuum in our systems. When the fuel tank is low and the item we are talking about (filter)is mounted high in the system there is very little head pressure to urge the fluid to flow. When the tank is full, approximately 4" more. And there is no vacuum on the bottom of the filter to initiate flow. If the column of fuel in the lines is not solid, in other words there is some air in the line below the filter, then you have the worst case scenario for the initiation of flow through the filter, which has resistance due to the surface tension of the fluid through the mesh holes and the debris collected.

The fluid 'Pulling' on the outflow side of the system does not necessarily do the trick, which is why we are talking about this. It would take a more significant vacuum on the outside than would be caused by opening our fuel valve in the cockpit. The system we are analyzing here is a gravity actuated system and can be schematically represented by a fluid column of the height involved. Due to gravity and column height head pressure is generated. With no restrictions whatsoever it can be represented as being from the top of the fuel in the tank to the level of the carburetor or engine pump inlet.

When the lines are of sufficient diameter capillary action can be ignored; especially with a low viscosity fluid, such as 100LL. Car gas is slightly more viscous due to the remaining oil in it. The theory that our systems is based on presents fuel to the low portion of the system due to gravity enabled head, and nothing else, and does not plan on any resistance higher than the 1/4" or 5/16" i.d. lines. ANYTHING that presents a barrier placed in this initial path will cause a resistance to the flow and the higher in the system that it is placed the greater the resistance effect due to the diminishment of the head available as you move up in the system.

Unlike with the siphon set up that works for a limited height, by the way, you do not have the initiating vacuum to rely on to initiate flow in our systems. When you suck on the siphon hose, you first establish a head if you want the flow to continue after sucking.

So now we can see why it is not good to place anything that has resistance high in the system used in our Kitfoxes. When turned on, a valve is essentially the same as a line, so it causes no problem beyond adding two more connections.

Simply put, do not add any filters to our system higher than the ones that are included in the design as they add resistance to flow where you really do not want it.

I admit that I have not yet seen the finger filter at the tank outlet, but expect to see that the mesh chosen is large enough and the area also large enough so that they can be expected to work for long periods without cleaning, but I now will be looking at them regularly, at least with a light and mirror.

Duane Rueb

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

Tom Jones

Joined: 12 Mar 2006

Posts: 752

Location: Ellensburg, WA

|

Posted: Thu Oct 29, 2009 7:05 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 7:05 am Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

I think the head pressure is the same as long as the fuel is flowing. If it stops for some reason...unporting a tank...a filter high on the line close to the tank may make getting the flow started again a problem.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Tom Jones

Classic IV

503 Rotax, 72 inch Two blade Warp

Ellensburg, WA |

|

| Back to top |

|

|

matronics(at)bob.brennan.

Guest

|

Posted: Thu Oct 29, 2009 7:37 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 7:37 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Good explanation Duane, but there is one term that keeps coming up in this

thread that I can't say I understand completely - many talk about their wing

tank becoming "unported" in flight, which I understand as no-more-flow, but

what can cause this "unporting" and is it unrecoverable in flight?

I have a KF2 with the main tank in my lap and a reserve tank in the wing - I

know that getting the fuel to flow from the reserve on the ground doesn't

always work but in the air the fuel cap has a tube facing into the airflow

which provides enough pressure to push any fuel out of that tank easily. I

don't understand why later systems with header tanks have this "unported"

problem.

Thanks in advance for any explanations...

Bob Brennan - N717GB

ELSA Repairman, inspection rated

1991 UK Model 2 ELSA Kitfox taildragger

Rotax 582 with 3 blade GSC prop

Wrightsville Pa

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

lcfitt(at)sbcglobal.net

Guest

|

Posted: Thu Oct 29, 2009 11:10 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 11:10 am Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

Bob and all,

I guess what precipitated my original post and what may answer Bob's

question is the configuration I had in my original build Model IV. It had

the glass Purelator filters just below the tanks and and a tad behind the

doors. There were no valves so I carried some light plastic clamps so I

could clamp off the lines if I needed to for any reason.

In 900 hours of flight, I had no problems what-so-ever. The lines were

5/16" id and as Don Smythe suggested, I was very careful of the run of the

lines to the header tank.

As many have reported, I did have uneven fuel flow on long flights, but

became convinced that it was because of the tendency of all. and I repeat

all, Kitfox pilots to fly in a slightly uncoordinated manner with one wing

low on the more boring portions of the three and four hour flights.

I did intentionally umport my tanks once on a long decent from the ridges of

the Sierras to home as I was on the bottom fourth of the tank capacity and

with the early aft positioned pick-up on the wing tanks, they rose above the

level of the fuel in the tanks. I watched this unfold through the

transparent vent line and the Purelator filters. Once the low fuel

indicator began to flash, I raised the nose to level flight and fuel began

to flow gain, the lights went out and I proceeded home. I landed with six

gallons in each tank.

One more thought, my wife tells me we need more fuel for the lawnmower - Yes

she allows me to allow her to undertake that task routinely. I plan on

buying five gallons. Then as is the practice, I will transfer half to

another tank so she will not have to tote the full five to the lawnmower. I

plan on siphoning the gas this time to do a little bit of Don Smything

(sorry Don) and with a Purelator filter in the line, I plan doing it two

stages, one with the filter in the upward portion of the line - negative

head, and one with the filter in the downword portion and see if I can tell

a difference in the fuel flow. Any takers on what the results might be.

Lowell

---

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Thu Oct 29, 2009 3:25 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Thu Oct 29, 2009 3:25 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

The following refers to the Kitfox IV that I built, and may not be

the same on a KF2.

The unporting refers to not having any fuel AT the fuel tank outlet.

What causes it is having low fuel, and maybe pointing the plane down,

as in a descent to land. Under this condition, or any condition where

the fuel runs away from the fuel tank outlet, the tank is said to be

"unported." Is it *recoverable* in flight? Yes, IF you bring the nose

of the aircraft up to level (if the tank is only *moderately* low of

fuel), or above level (if the tank is *fairly* low on fuel.) The

terms moderately and fairly are what you have to decide for yourself.

The main thing is to get the nose up so what fuel is left runs back

to the outlet port and starts to flow downward. Something that I

noticed with my Jabiru-powered plane is that the header tank is at

about the same elevation in level flight as the fuel metering device.

If I let the header tank get below a certain level in fuel capacity

(because I'm descending with low fuel in the wing tanks, and they

have unported), and then point the plane up so as to let the

remaining fuel in the wing tanks rush back towards the ports, I may

have just put my header tanks' supply of fuel below the point where

the fuel will (gravity) flow into the fuel metering device. I don't

care to have to practice this, but I'm thinking that by porpoising

the plane *just* the right amount, that I can cause the header tank

to refill...plane pointing up....and then level off to let that fuel

(gravity) flow to the engine. When I recently had an occasion/need to

do this, a field came into view before I could do any more than about

one "up-then-level" cycle, and I *decided* to land instead of pushing

my luck on my untested theory. : )

Another way to unport the tank is to be banking with a low fuel

supply. A bank to the left with low fuel (a subjective term) on board

will/may unport the left wing tank, while the right wing tank

supplies ALL the fuel that the engine requires. If you bank long

enough, the right tank becomes empty...for example...and the low fuel

light comes on, so you level the plane, or even go to a right bank,

hoping the left tank will hurry up and fill the header tank and you

can continue on to a refueling station. If the left tank allows the

fuel to flow quickly enough, the engine catches, and you can fly

towards the nearest J.C. Penney for some new skivvies....and ya might

just wanna get some fuel while you're at it.

That's unporting from a practitioners (been there, done that) point

of view. It's not the header tank that becomes

unported....USUALLY....it's the fuel tanks. Your situation, Bob,

would require you to study the flow of the fuel and see what you

should do if you too, have a brain fart and need to rely on some

aerial gymnastics.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 804.3 hrs

Countdown to 1000 hrs--196 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

On Oct 29, 2009, at 11:24 AM, Bob Brennan wrote:

| Quote: |

<matronics(at)bob.brennan.name>

what can cause this "unporting" and is it unrecoverable in flight?

I have a KF2 with the main tank in my lap and a reserve tank in the

wing - I

know that getting the fuel to flow from the reserve on the ground

doesn't

always work but in the air the fuel cap has a tube facing into the

airflow

which provides enough pressure to push any fuel out of that tank

easily. I

don't understand why later systems with header tanks have this

"unported"

problem.

Thanks in advance for any explanations...

Bob Brennan - N717GB

ELSA Repairman, inspection rated

1991 UK Model 2 ELSA Kitfox taildragger

Rotax 582 with 3 blade GSC prop

Wrightsville Pa

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

FlyboyTR

Joined: 04 Nov 2006

Posts: 215

Location: Mobile, Alabama

|

Posted: Sat Oct 31, 2009 12:07 pm Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Sat Oct 31, 2009 12:07 pm Post subject: Re: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

OK, I have made changes to the fuel filter locations and reduced the extra hose to allow for a more direct flow to the header tank.

I also installed an on/off valve in the header tank vent line. If by chance the system air-locks...at least now I can close the vent line and force the system to pull from the tanks, rather than sucking air.

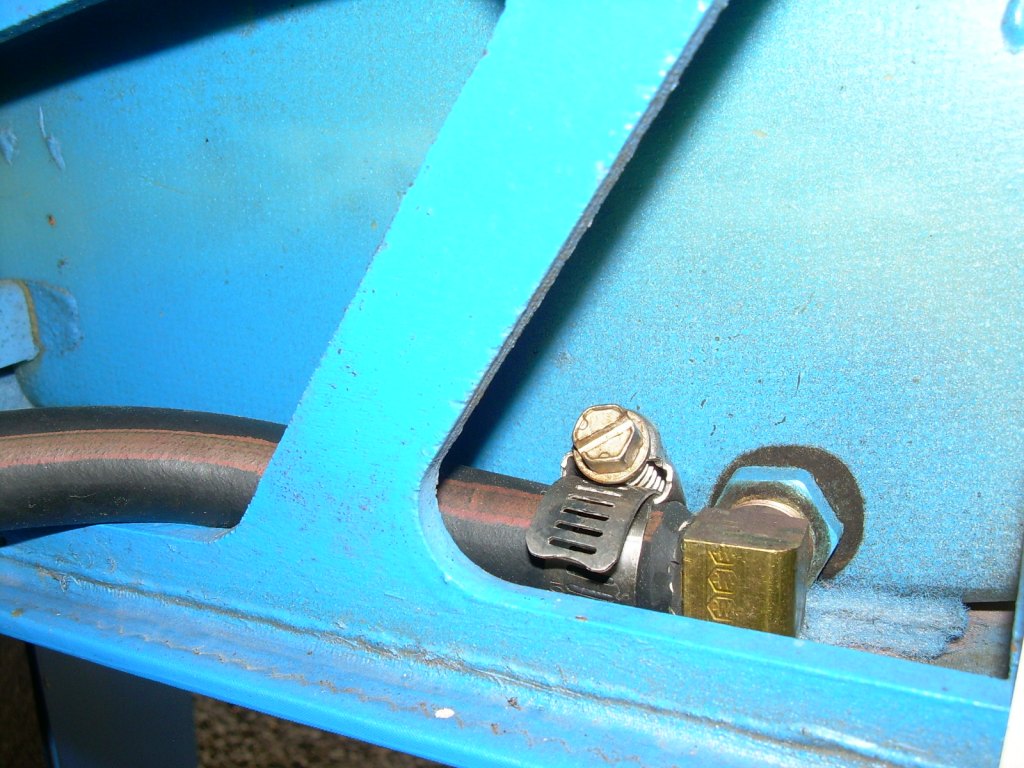

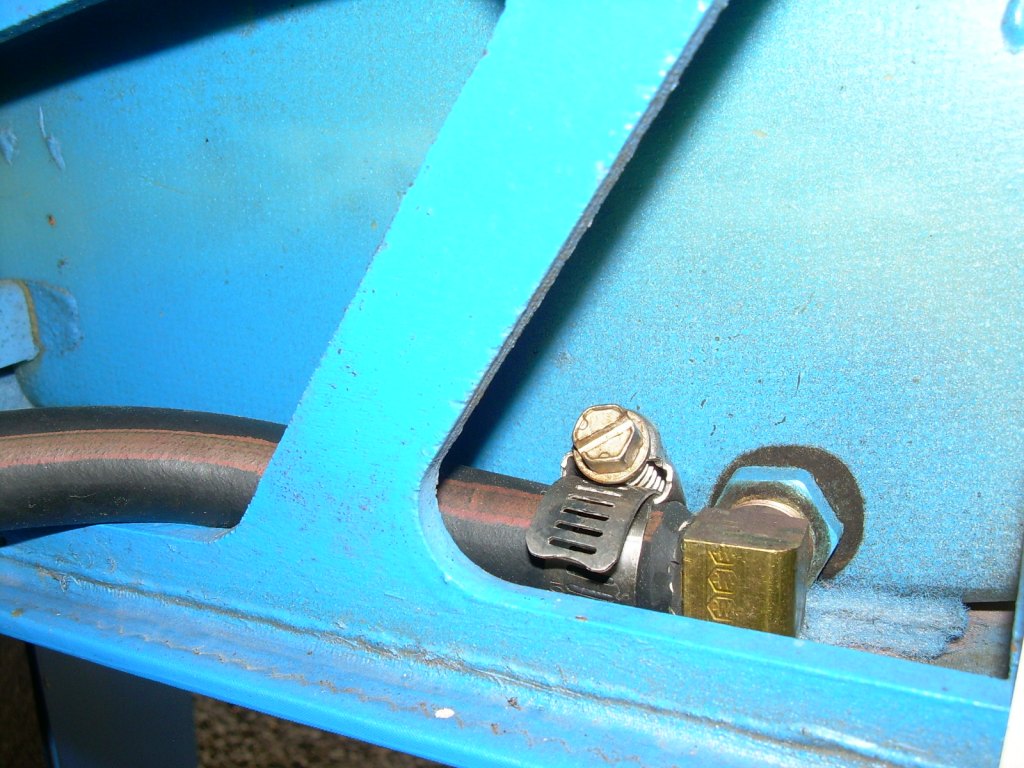

I folded the wing to check the finger strainers. I was unable to remove the 90 fitting (see picture). To do do would mean I would have to cut the fabric in the bottom of the wing. Any suggestions? does this look like the KF setup?

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

| Description: |

| Left wing tank: The fuel line travels upwards from tank outlet, over the end rib and then down. Comments? |

|

| Filesize: |

209.04 KB |

| Viewed: |

16534 Time(s) |

|

| Description: |

| 90 Degee fitting. Unable to remove without cutting wing fabric. |

|

| Filesize: |

196.58 KB |

| Viewed: |

16534 Time(s) |

|

| Description: |

| View from rear. Both fuel supply lines, location of filters, cut-off valves and valve on vent line. |

|

| Filesize: |

220.66 KB |

| Viewed: |

16534 Time(s) |

|

| Description: |

| Left wing tank supply. Filter was previously located directly under the fuel valve (red knob). Move to lowest possible location. |

|

| Filesize: |

220.33 KB |

| Viewed: |

16534 Time(s) |

|

_________________

Travis Rayner

Mobile, AL

Skystar Vixen, N-789DF

Continental IO-240, Prince P-Tip Prop

ADI-II Autopilot

AnyWhereMap Navigation with weather

www.enotam.net (My Flying Info Website) |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Sat Oct 31, 2009 1:31 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) Posted: Sat Oct 31, 2009 1:31 pm Post subject: Fuel Flow Problems, Again! (Vixen, Series-5) |

|

|

I would use a Dremel tool and cut off the "bent" part of the fitting,

remove the fitting and replace it with a straight fitting if at all

possible.

It looks to me like the tank outlet in your number "210" photo is

several inches more forward than my Model IV, but maybe that's

standard for the Vixen. The IV instructions had me cutting a notch in

the rib (my tank outlet is at the very rear of the tank) so that a

straight fitting could be screwed straight into the finger strainer

fitting. Looks like they went with a center-feed tank in those models.

Some folks just don't think far enough ahead when they are building,

as to allow for servicing the plane down the road, and your builder

was probably one of those. Maybe the instructions called for a 90-

degree fitting....if so, then the instructions didn't think far

enough ahead in my sometimes not very humble opinion. Ok, I'll quit

griping. How about cutting the 90-degree portion of the fitting off

*just* a little bit so you can rotate the fitting out of the finger

strainer. Maybe you just need to depress the fabric a little

bit....possibly laying a length of thin plastic under the fitting

where it would rub on the fabric every time it rotated towards the

bottom as you remove it.

When I suggested cutting off some of the "bent" portion of the

fitting, I recall that some of these fittings have more than

necessary length, and can be shortened. I would look for the "bulb-

ended" fittings rather than the "barbed" fittings. In my experience,

the bulb-ended are shorter than the barb-ended fittings, and will

allow for removal of the hose without totally destroying the hose.

I can't understand why your system would suck air....it pulls from

the bottom (or very near the bottom) of the header tank, doesn't it?

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 804.3 hrs

Countdown to 1000 hrs--196 to go

Sensenich 62"x46" Wood prop

Electroair direct-fire ignition system

Rotec TBI-40 injection

Status: flying (and learning)

On Oct 31, 2009, at 4:07 PM, FlyboyTR wrote:

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|