|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

z601c(at)anemicaardvark.c

Guest

|

Posted: Mon Feb 08, 2010 12:49 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 12:49 pm Post subject: rivet sets |

|

|

All was going semi-well with the mod kit, until I went to set the AD5 (and

AD6) rivets. It seems I've never had a reason to set this size rivet, and

don't have a matching rivet set.

Unless I'm missing something, ATS, Aircraft Spruce, and the others where I

usually buy tools don't seem to have sets this big for rivet guns. Has anyone

found these? If so, where?

TIA.

--

========================================

Jim B. Belcher

BS,MS Physics

A&P/IA

General Radio Telephone Certificate

Instrument Rated Pilot

Retired Aerospace Technical Manager

601XL Builder

========================================

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

Terry Phillips

Joined: 11 Jan 2006

Posts: 346

Location: Corvallis, MT

|

Posted: Mon Feb 08, 2010 1:45 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 1:45 pm Post subject: rivet sets |

|

|

Hi Jim

I'm not sure of the problem, since all suppliers I have looked at have the

rivet sets, e.g.,

http://www.aircraft-tool.com/shop/detail.aspx?PRODUCT_ID 602A&ReturnPage=/shop/search_result.aspx?PageNo=1

shows a rivet gun and sets including 3/16 and 5/32.

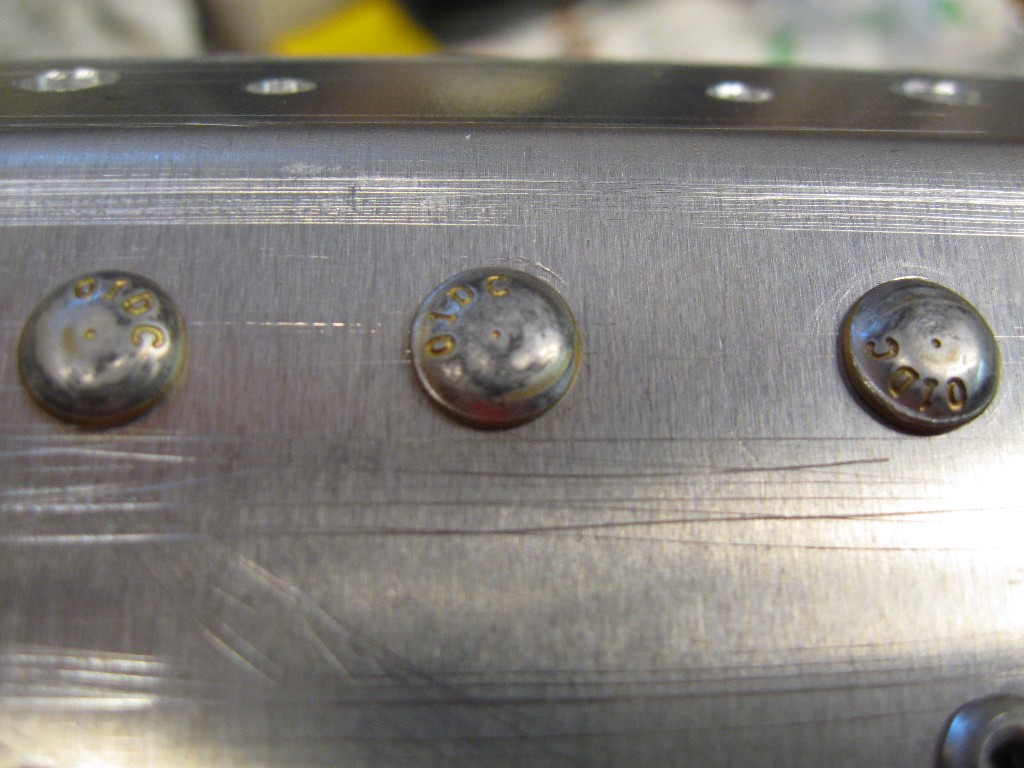

My problem is driving the big rivets w/o mangling the manufactured heads.

The jury is still out, but my practice efforts are pathetic. See attached

photo. I'm sure glad it's not on my spar.

Terry

At 02:47 PM 2/8/2010 -0600, you wrote:

| Quote: | All was going semi-well with the mod kit, until I went to set the AD5 (and

AD6) rivets. It seems I've never had a reason to set this size rivet, and

don't have a matching rivet set.

Unless I'm missing something, ATS, Aircraft Spruce, and the others where I

usually buy tools don't seem to have sets this big for rivet guns. Has anyone

found these? If so, where?

TIA.

|

Terry Phillips ZBAGer

ttp44~at~rkymtn.net

Corvallis MT

ZU-601XL/Jab 3300 s .. l .. o .. o .. w build kit - Tail & flaps are done;

Balancing the ailerons and working on the wings

http://www.mykitlog.com/N47TP/

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

70.36 KB |

| Viewed: |

14698 Time(s) |

|

_________________

Terry Phillips

Corvallis, MT

ttp44<at>rkymtn.net

Zenith 601XL/Jab 3300 slow build kit - Tail feathers done; working on the wings. |

|

| Back to top |

|

|

jaybannist(at)cs.com

Guest

|

Posted: Mon Feb 08, 2010 2:43 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 2:43 pm Post subject: rivet sets |

|

|

Jim,

I know that you can get them either at Brown Tool or US Industrial Tool & Supply.

Jay

--

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

DaveG601XL

Joined: 27 Oct 2006

Posts: 351

Location: Cincinnati, Oh

|

Posted: Mon Feb 08, 2010 2:48 pm Post subject: Re: rivet sets Posted: Mon Feb 08, 2010 2:48 pm Post subject: Re: rivet sets |

|

|

Terry,

The only advice I can offer is this:

- FIRM pressure on the rivet gun against the manufacture head. Do not let off on the gun pressure until after you let off on the trigger.

- Hold the gun very perpendicular. Don't eye the shop head during the squeeze, keep attention of the rivet gun side.

- Use a fairly high air pressure. I used 90 psi for the -6's and like 70 for the -5's. You need to get to the point where you can drive a good rivet in around a second of trigger squeeze. Milking them at lower pressure only makes a bad rivet.

- Practice makes perfect. Rivets are cheap, keep on bucking!

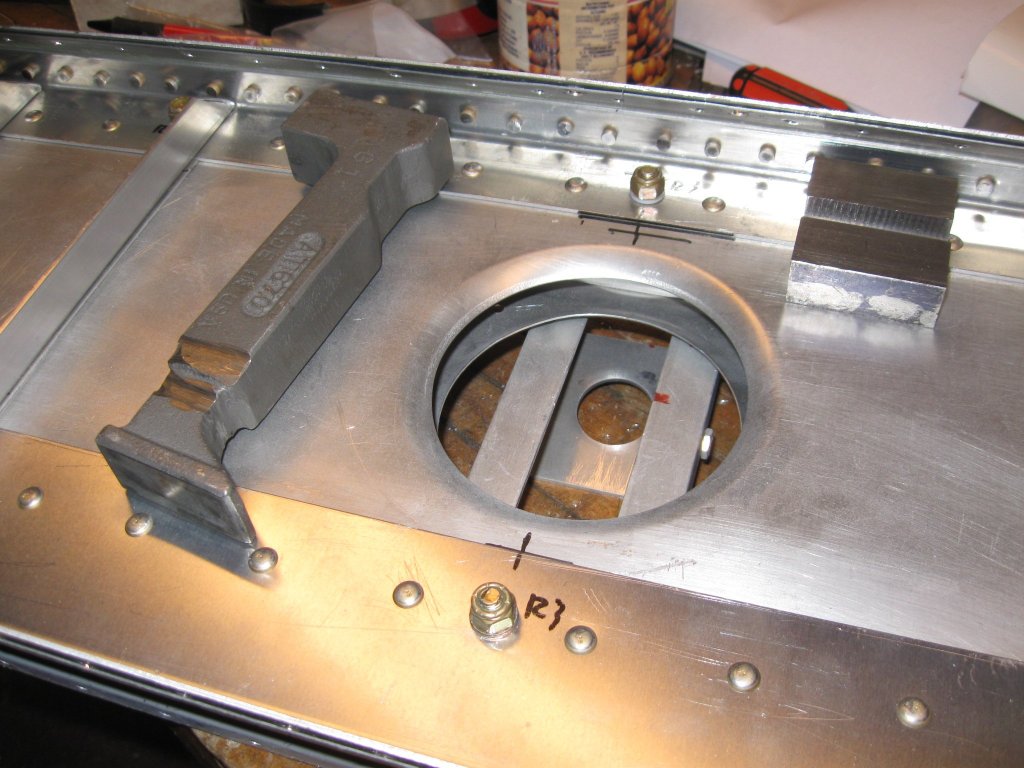

Here is my end result on the center spar. A few cosmetic edge marks are present on the rivet heads and they are acceptable.

Good luck,

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

162.35 KB |

| Viewed: |

14690 Time(s) |

|

_________________

David Gallagher

Cincinnati, OH area |

|

| Back to top |

|

|

dsleepy47

Joined: 15 Dec 2007

Posts: 41

|

Posted: Mon Feb 08, 2010 2:50 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 2:50 pm Post subject: rivet sets |

|

|

What weight of bucking bar are you using and what does the shop head look like?

Deems

Your E-mail and MoreGBL/go/201469229/direct/01/' target='_new'>Sign up now. [quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

_________________

dsleepy47

N1491R |

|

| Back to top |

|

|

Terry Phillips

Joined: 11 Jan 2006

Posts: 346

Location: Corvallis, MT

|

Posted: Mon Feb 08, 2010 4:53 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 4:53 pm Post subject: rivet sets |

|

|

Hi Deems

I've tried a variety of things, from a 3.5 lb bucking bar to the face of a

10 lb sledge hammer. I think that the 10 lb sledge worked best. The shop

heads look OK when I hold the bucking bar face normal to the rivet. When

the bucking bar is crooked, the shop heads are pushed sideways.

I've developed a few theories. I'm going to have a helper hold the bucking

bar so I can concentrate better on holding the rivet gun steady. I've been

going through a rivet/drill out cycle that enlarges the holes a bit. I'm

thinking that maybe the holes are too big, and so too much energy is needed

to expand the shank to fill the enlarged hole.

Also, I'm using a well used 3X rivet gun that I bought off Ebay. Maybe it's

just over the hill. Though I have a borrowed 3X rivet gun that is near new,

and it didn't work as well.

Terry

At 05:23 PM 2/8/2010 -0500, you wrote:

| Quote: | What weight of bucking bar are you using and what does the shop head look

like?

Deems

|

Terry Phillips ZBAGer

ttp44~at~rkymtn.net

Corvallis MT

ZU-601XL/Jab 3300 s .. l .. o .. o .. w build kit - Tail & flaps are done;

Balancing the ailerons and working on the wings

http://www.mykitlog.com/N47TP/

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

_________________

Terry Phillips

Corvallis, MT

ttp44<at>rkymtn.net

Zenith 601XL/Jab 3300 slow build kit - Tail feathers done; working on the wings. |

|

| Back to top |

|

|

floyd wilkes

Joined: 11 Jun 2007

Posts: 39

Location: spring branch, tx

|

Posted: Mon Feb 08, 2010 7:18 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 7:18 pm Post subject: rivet sets |

|

|

Terry,

Definitely use a helper. The bucking bar must be normal to the rivet.

If the gun has a regulator on it, make sure it is turned way up. If it was

set for smaller rivets, that setting will not work on the larger ones.

I used a 4X gun turned up to near max and a helper with a 5 lb bucking bar.

Worked very well.

Also, a piece of tape placed on the set will help reduce the smilies.

Floyd Wilkes

--

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

_________________

Floyd Wilkes |

|

| Back to top |

|

|

ggower_99(at)yahoo.com

Guest

|

Posted: Mon Feb 08, 2010 10:25 pm Post subject: rivet sets Posted: Mon Feb 08, 2010 10:25 pm Post subject: rivet sets |

|

|

Hi Terry,

I think your Theory is correct... I am sure you will get better results using an already Trainned rivet gun ....

Saludos

Gary Gower

Still waiting for my Upgrade Kit.

Looking for a good ol' trained rivet gun.

--- On Mon, 2/8/10, Terry Phillips <ttp44(at)rkymtn.net> wrote:

[quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

Afterfxllc(at)aol.com

Guest

|

Posted: Tue Feb 09, 2010 3:04 am Post subject: rivet sets Posted: Tue Feb 09, 2010 3:04 am Post subject: rivet sets |

|

|

Terri

Something tells me the small piece you are practicing with is to hard to hold while riveting. I would suggest clamping the piece in a vise then hold pressure at all times on the head of the rivet use your body weight if you have to. hold the bucking bar against the rivet but let it bounce slightly as you squeeze the trigger. You get smiley faces because the rivet gun bounced on the rivet head from either removing the bucking bar before you stopped the gun or you didn't hold pressure on the head. Just like flying when you get it you will know it.

BTW if you are using a 3 x gun it will just take longer to set the rivets but it can be done. A 4 x makes a world of difference.

Jeff

[quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

DaveG601XL

Joined: 27 Oct 2006

Posts: 351

Location: Cincinnati, Oh

|

Posted: Tue Feb 09, 2010 4:25 am Post subject: Re: rivet sets Posted: Tue Feb 09, 2010 4:25 am Post subject: Re: rivet sets |

|

|

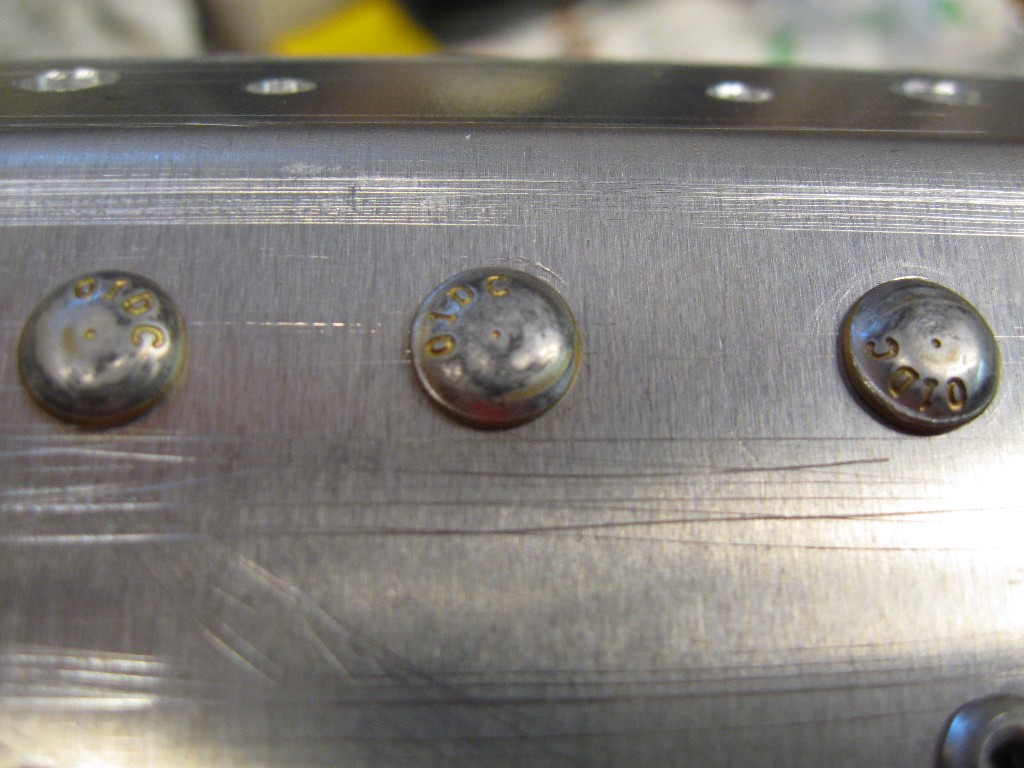

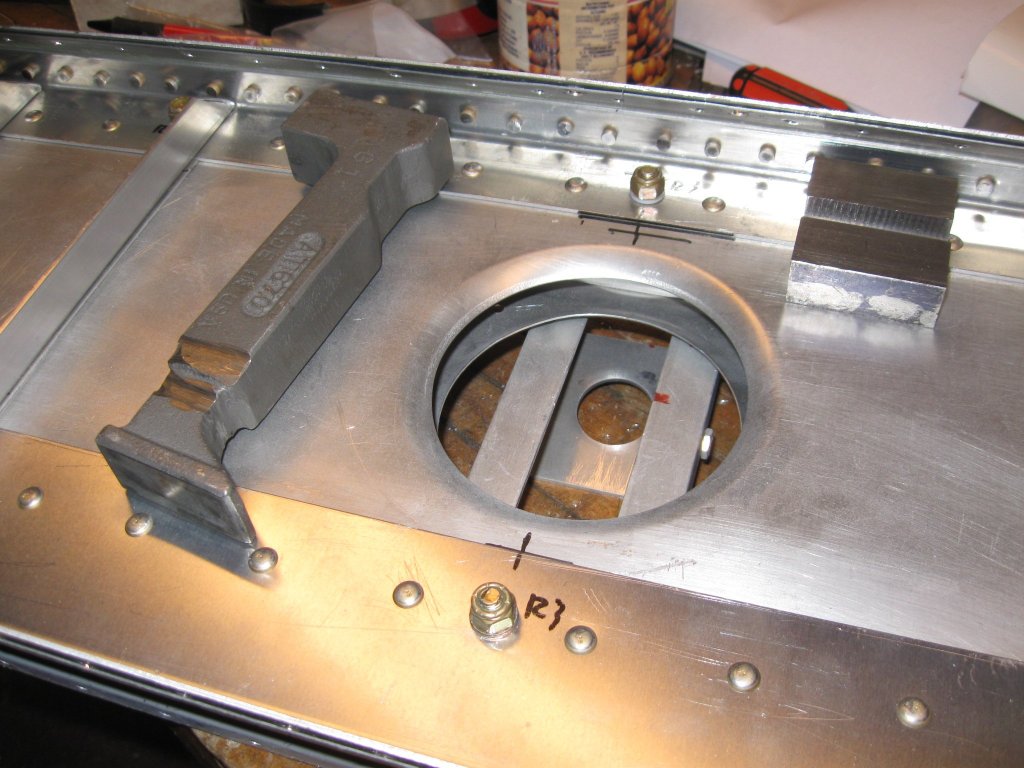

For most of my rivets, I used the rivet set that is on the left of the attached picture. I bought it from Aircraft Spruce. I think it weighs a couple pounds. For the center spar top rivets, it was a little tight getting to the underside shop heads. I grabbed a piece of steel I had laying in the shop and it worked great. It only weighs a 1/2 pound or so. It is on the right side of the picture. I did have to hold it a lot tighter since it was lighter.

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

133.93 KB |

| Viewed: |

14635 Time(s) |

|

_________________

David Gallagher

Cincinnati, OH area |

|

| Back to top |

|

|

Geoff Heap

Joined: 12 Jan 2006

Posts: 266

Location: Lindenwold, New Jersey

|

Posted: Tue Feb 09, 2010 5:28 am Post subject: Re: rivet sets Posted: Tue Feb 09, 2010 5:28 am Post subject: Re: rivet sets |

|

|

Again. When you let go the trigger on the rivet gun, you should still have a lot of pressure on the rivet. Its easy to think you are safe to ease off at the same time but you 'll get a smile every time....Geoff

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

dsleepy47

Joined: 15 Dec 2007

Posts: 41

|

Posted: Tue Feb 09, 2010 3:32 pm Post subject: Re: rivet sets Posted: Tue Feb 09, 2010 3:32 pm Post subject: Re: rivet sets |

|

|

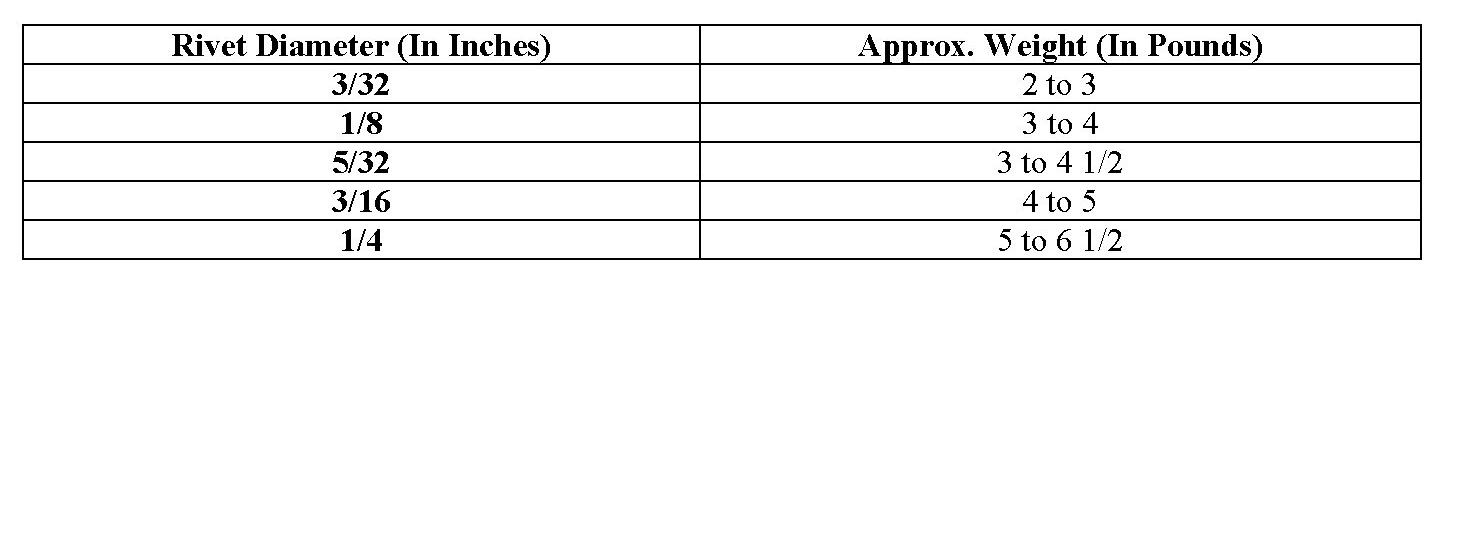

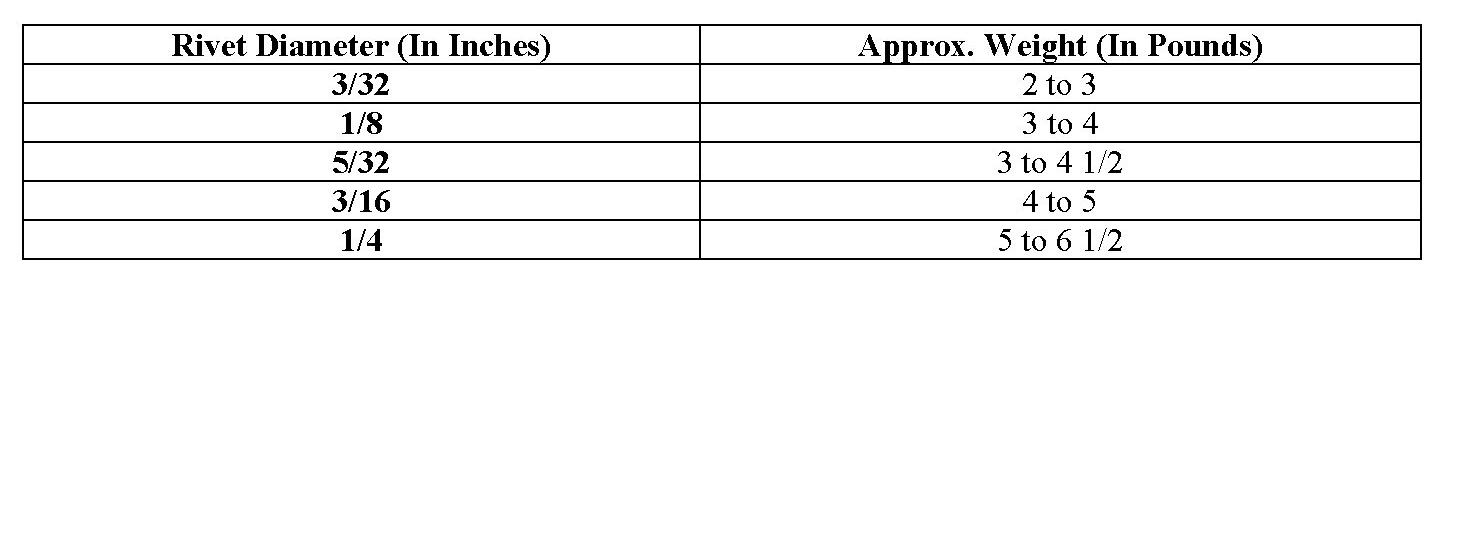

Here is a chart of rivet size to bucking bar weight. With the right size gun, bucking bar and the right air pressure it should take 3 to 5 strokes of the gun to form the shop head. It looks like you are driving it way too long.

You need to get comfortable hitting them hard and quick. Assuming you have the correct size set that should work.

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

53.58 KB |

| Viewed: |

14593 Time(s) |

|

_________________

dsleepy47

N1491R |

|

| Back to top |

|

|

Terry Phillips

Joined: 11 Jan 2006

Posts: 346

Location: Corvallis, MT

|

Posted: Wed Feb 10, 2010 12:25 am Post subject: rivet sets Posted: Wed Feb 10, 2010 12:25 am Post subject: rivet sets |

|

|

Many, many thanks to all who responded. I think I'm seeing light at the end of the tunnel.

Post Mortem: I believe that I had a combination of factors fouling up my riveting. - As Jeff says, it is vital that the piece be securely fixed. I thought I had done this with the jig, as shown in the photo 409. But I think that I was wrong. I now believe that the structure probably rocked backward with every blow from rivet gun, but the dynamics were such that the next rivet gun blow struck before the rivet rocked back under the set. The reult was a smashing of the bottom of the mfg'd rivet head.

- In trying to keep control of the rivet gun with one hand while I held the bucking bar with the other, I found that by reducing the air pressure to ~50 psi, I had better luck keeping the gun on the rivet.

- But, at this low pressure, my "well used" 3X gun probably required at least 5 seconds (and way too many impacts) to form the shop head. After 5 seconds of pounding, the mfg's head softened from compressive heating, and deformed easily (I produced some really awful mfg'd heads)!. It was probably impossible to drive the 3/16 rivets reliably with this low pressure because it just took too long.

- And, it required more skill that I have to hold the rivet gun steady in one hand and the bucking bar in the other while driving the rivet, so the rivet set moved around and obliterated the mfg'd head.

Pretty grim. So, I have made a much simpler jig to hole the practice bar, just 2-2x4's with a slot on the edge to clear the rivets, bolted to the edge of my table. With this design, there is negligible lever arm to flex and bend under the rivet gun impact, see photo 415. My helper was not available today, so, for practice, I screwed a piece of 1/8" x 1" steel scrap to the back edge of the 2x4 with a 3/16" hole for a rivet, also shown in photo 415. Then I could put a rivet through the hole and practice riveting with full compressor pressure.

It was fairly easy to hold the rivet gun in place with both hands and avoid mangling the mfg'd head. If I kept pounding long enough, the head would soften and deform. The force of the rivet gun was easily enough to drive the steel into the 2x4, resulting in a significant bend in the metal after a while.

When my helper returns tomorrow, I'll try the new practice setup on the practice bar.

One question--my heaviest bucking bar weighs 3 lb, 12 oz, probably heavy enough. But, who sells 5 lb bucking bars?

Thanks again to all you who answered.

Terry

At 05:34 AM 2/9/2010 -0500, you wrote:

| Quote: | Terri

Something tells me the small piece you are practicing with is to hard to hold while riveting. I would suggest clamping the piece in a vise then hold pressure at all times on the head of the rivet use your body weight if you have to. hold the bucking bar against the rivet but let it bounce slightly as you squeeze the trigger. You get smiley faces because the rivet gun bounced on the rivet head from either removing the bucking bar before you stopped the gun or you didn't hold pressure on the head. Just like flying when you get it you will know it.

BTW if you are using a 3 x gun it will just take longer to set the rivets but it can be done. A 4 x makes a world of difference.

Jeff

|

Terry Phillips ZBAGer

ttp44~at~rkymtn.net

Corvallis MT

ZU-601XL/Jab 3300 s .. l .. o .. o .. w build kit - Tail & flaps are done;

Balancing the ailerons and working on the wings

http://www.mykitlog.com/N47TP/

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

65.8 KB |

| Viewed: |

14576 Time(s) |

|

| Description: |

|

| Filesize: |

63.15 KB |

| Viewed: |

14576 Time(s) |

|

_________________

Terry Phillips

Corvallis, MT

ttp44<at>rkymtn.net

Zenith 601XL/Jab 3300 slow build kit - Tail feathers done; working on the wings. |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|