|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rv10(at)colohan.com

Guest

|

Posted: Mon May 31, 2010 8:52 pm Post subject: Fixing a bad hole... Posted: Mon May 31, 2010 8:52 pm Post subject: Fixing a bad hole... |

|

|

I've reached the horizontal stabilizer in building my RV-10. While drilling the 3/32" holes in the spar doublers for the forward spar, I mucked one of the holes up.

In particular, the drill appears to have slid about 3/32" sideways while drilling, mis-placing the hole by 3/32". Perhaps better explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too large -- you drill it out larger and put an "oops" rivet in it. But what can you do to fix a hole which is misplaced? Is there a good fix for this? Drilling a hole large enough to cover this error would take a rivet larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due to an earlier error that Van's made, and so I'd just need to order some new spar doublers. But I'd like to first learn if I can fix this one.)

Also, while I have your ear -- I made this error while using a brand new Rigid Cobalt drill bit (like this one: http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The bit appears to be able to cut sideways just as well (or even better) than it can drill straight ahead in aluminum. It also takes about 20-30 seconds per hole drilling at 4000rpm (assuming my air drill is making its rated speed) while applying moderate pressure. Is this a known problem with this type of bit, or is my drilling technique off? I've ordered some "aviation" 3/32" bits from Avery, but wanted to know if I should expect it to be easier to drill straight with those bits.

Thanks!

Chris [quote][b]

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

Dale Ensing

Joined: 11 Jan 2006

Posts: 571

Location: Aero Plantation Weddington NC

|

Posted: Tue Jun 01, 2010 4:04 am Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 4:04 am Post subject: Fixing a bad hole... |

|

|

If you are drilling holes for 3/32" rivets, shouldn't you be using a #40 drill and not a 3/32"?

---- Chris Colohan <rv10(at)colohan.com> wrote:

| Quote: | I've reached the horizontal stabilizer in building my RV-10. While drilling

the 3/32" holes in the spar doublers for the forward spar, I mucked one of

the holes up.

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

_________________

Dale Ensing

RV-6A

Aero Plantation

Weddington NC |

|

| Back to top |

|

|

martinaerodrome(at)gmail.

Guest

|

Posted: Tue Jun 01, 2010 4:52 am Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 4:52 am Post subject: Fixing a bad hole... |

|

|

Use pilot point drill bits available at any good hardware store. Don't waste your time at Harbor Freight etc.

Dick Martin

RV8 N233M

the fast one

On Mon, May 31, 2010 at 11:51 PM, Chris Colohan <rv10(at)colohan.com (rv10(at)colohan.com)> wrote:

[quote]I've reached the horizontal stabilizer in building my RV-10. While drilling the 3/32" holes in the spar doublers for the forward spar, I mucked one of the holes up.

In particular, the drill appears to have slid about 3/32" sideways while drilling, mis-placing the hole by 3/32". Perhaps better explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too large -- you drill it out larger and put an "oops" rivet in it. But what can you do to fix a hole which is misplaced? Is there a good fix for this? Drilling a hole large enough to cover this error would take a rivet larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due to an earlier error that Van's made, and so I'd just need to order some new spar doublers. But I'd like to first learn if I can fix this one.)

Also, while I have your ear -- I made this error while using a brand new Rigid Cobalt drill bit (like this one: http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The bit appears to be able to cut sideways just as well (or even better) than it can drill straight ahead in aluminum. It also takes about 20-30 seconds per hole drilling at 4000rpm (assuming my air drill is making its rated speed) while applying moderate pressure. Is this a known problem with this type of bit, or is my drilling technique off? I've ordered some "aviation" 3/32" bits from Avery, but wanted to know if I should expect it to be easier to drill straight with those bits.

Thanks!

Chris

| Quote: |

t="_blank">http://www.matronics.com/Navigator?RV-List

ttp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

rv6(at)grandecom.net

Guest

|

Posted: Tue Jun 01, 2010 5:24 am Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 5:24 am Post subject: Fixing a bad hole... |

|

|

Quoting Richard Martin <martinaerodrome(at)gmail.com>

You might consider a # 8 screw and lock nut.

T Jones

RV9A

| Quote: | Use pilot point drill bits available at any good hardware store. Don't

waste your time at Harbor Freight etc.

Dick Martin

RV8 N233M

the fast one

On Mon, May 31, 2010 at 11:51 PM, Chris Colohan <rv10(at)colohan.com> wrote:

> I've reached the horizontal stabilizer in building my RV-10. While

> drilling the 3/32" holes in the spar doublers for the forward spar, I mucked

> one of the holes up.

>

> In particular, the drill appears to have slid about 3/32" sideways while

> drilling, mis-placing the hole by 3/32". Perhaps better explained through

> pictures:

> http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

>

> http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

>

> http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

>

> http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

>

> So I know how to fix a hole when you make it slightly too large -- you

> drill it out larger and put an "oops" rivet in it. But what can you do to

> fix a hole which is misplaced? Is there a good fix for this? Drilling a

> hole large enough to cover this error would take a rivet larger than 1/8"...

>

> (At worst, I can just replace the spar -- I have a spare, due to an earlier

> error that Van's made, and so I'd just need to order some new spar doublers.

> But I'd like to first learn if I can fix this one.)

>

> Also, while I have your ear -- I made this error while using a brand new

> Rigid Cobalt drill bit (like this one:

> http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The bit

> appears to be able to cut sideways just as well (or even better) than it can

> drill straight ahead in aluminum. It also takes about 20-30 seconds per

> hole drilling at 4000rpm (assuming my air drill is making its rated speed)

> while applying moderate pressure. Is this a known problem with this type of

> bit, or is my drilling technique off? I've ordered some "aviation" 3/32"

> bits from Avery, but wanted to know if I should expect it to be easier to

> drill straight with those bits.

>

> Thanks!

>

> Chris

>

> *

>

> *

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

john_s_bright(at)yahoo.co

Guest

|

Posted: Tue Jun 01, 2010 6:43 am Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 6:43 am Post subject: Fixing a bad hole... |

|

|

It's only one hole of tens... not a structural issue... you could do your best with an oops rivet and move on. Is it a cosmetic issue with the skin? You don't show the skin... is the skin bungled-up also? You could fill around it on the exterior skin cosmetically with pro-seal when you mix it for the tanks.

I like the 135 degree split points. IMO cobalt or TiN or whatever does not matter to us with this aluminum. Split points have less tendency to walk than 118 degree non split points but they will still walk. All drills make triangular holes in thin sheet metal.

I use an electric drill that spins maybe 2,400 rpm and I go thru skin and doubler in 1 or 2 seconds. I don't know what's going on with 20-30 seconds but something is wrong.

Thanks,

John Bright

o:757-864-2305

c:757-812-1909

From: Chris Colohan <rv10(at)colohan.com>

To: rv-list(at)matronics.com

Sent: Tue, June 1, 2010 12:51:12 AM

Subject: Fixing a bad hole...

I've reached the horizontal stabilizer in building my RV-10. While drilling the 3/32" holes in the spar doublers for the forward spar, I mucked one of the holes up.

In particular, the drill appears to have slid about 3/32" sideways while drilling, mis-placing the hole by 3/32". Perhaps better explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too large -- you drill it out larger and put an "oops" rivet in it. But what can you do to fix a hole which is misplaced? Is there a good fix for this? Drilling a hole large enough to cover this error would take a rivet larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due to an earlier error that Van's made, and so I'd just need to order some new spar doublers. But I'd like to first learn if I can fix this one.)

Also, while I have your ear -- I made this error while using a brand new Rigid Cobalt drill bit (like this one: http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The bit appears to be able to cut sideways just as well (or even better) than it can drill straight ahead in aluminum. It also takes about 20-30 seconds per hole drilling at 4000rpm (assuming my air drill is making its rated speed) while applying moderate pressure. Is this a known problem with this type of bit, or is my drilling technique off? I've ordered some "aviation" 3/32" bits from Avery, but wanted to know if I should expect it to be easier to drill straight with those bits.

Thanks!

Chris

[quote][b]

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

dave.saylor.aircrafters(a

Guest

|

Posted: Tue Jun 01, 2010 9:41 am Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 9:41 am Post subject: Fixing a bad hole... |

|

|

You could countersink the mis-drilled hole and put a flush rivet in it, under the skin. Then using the pre-drilled skin as a template, drill the correct hole in the spar, and continue on. I'd think that one repair on the spar wouldn't have much if any effect on the overall strength. If you're concerned about the strength of the spar cap you could put a doubler under the existing row of rivets that picked up 6-8 holes.

Dave Saylor

AirCrafters LLC

140 Aviation Way

Watsonville, CA 95076

831-722-9141 Shop

831-750-0284 Cell

On Tue, Jun 1, 2010 at 8:20 AM, Chris Colohan <rv10(at)colohan.com (rv10(at)colohan.com)> wrote:

[quote] This is a slightly unusual assembly in the RV-10.

The spar comes pre-drilled with undersized holes in the flange. The doubler comes with no holes.

You clamp the doubler on the spar, and drill through the existing spar flange holes and through the doubler with a 3/32" drill. When you later assemble the whole thing with the skin in place, you match drill everything (including the skin) with a #40 drill.

So for this hole I've messed up the spar flange and doubler, and now have a misplaced hole to go under my pre-drilled skin (which I have not touched yet). I was hoping to find a solution which does not involve: (a) drilling another hole right next to the first mistake, since that would weaken the spar flange, or (b) making my skin look ugly. I fear this solution doesn't exist...

Chris

On Tue, Jun 1, 2010 at 4:58 AM, <densing(at)carolina.rr.com (densing(at)carolina.rr.com)> wrote:

| Quote: | If you are drilling holes for 3/32" rivets, shouldn't you be using a #40 drill and not a 3/32"?

---- Chris Colohan <rv10(at)colohan.com (rv10(at)colohan.com)> wrote:

> I've reached the horizontal stabilizer in building my RV-10. While drilling

> the 3/32" holes in the spar doublers for the forward spar, I mucked one of

> the holes up.

t="_blank">http://www.matronics.com/Navigator?RV-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Tue Jun 01, 2010 12:22 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 12:22 pm Post subject: Fixing a bad hole... |

|

|

Also, you need a drill with a good teasing trigger that you can start

very slow, and only after the drill bit has started, run the speed up

high. Chicago Pneumatics makes a good one that Avery sells for around

$125, and there are the Sioux drills for about double that.

On 6/1/2010 7:43 AM, John Bright wrote:

| Quote: | It's only one hole of tens... not a structural issue... you could do

your best with an oops rivet and move on. Is it a cosmetic issue with

the skin? You don't show the skin... is the skin bungled-up also? You

could fill around it on the exterior skin cosmetically with pro-seal

when you mix it for the tanks.

I like the 135 degree split points. IMO cobalt or TiN or whatever does

not matter to us with this aluminum. Split points have less tendency

to walk than 118 degree non split points but they will still walk. All

drills make triangular holes in thin sheet metal.

I use an electric drill that spins maybe 2,400 rpm and I go thru skin

and doubler in 1 or 2 seconds. I don't know what's going on with 20-30

seconds but something is wrong.

Thanks,

John Bright

o:757-864-2305

c:757-812-1909

------------------------------------------------------------------------

*From:* Chris Colohan <rv10(at)colohan.com>

*To:* rv-list(at)matronics.com

*Sent:* Tue, June 1, 2010 12:51:12 AM

*Subject:* Fixing a bad hole...

I've reached the horizontal stabilizer in building my RV-10. While

drilling the 3/32" holes in the spar doublers for the forward spar, I

mucked one of the holes up.

In particular, the drill appears to have slid about 3/32" sideways

while drilling, mis-placing the hole by 3/32". Perhaps better

explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too large -- you

drill it out larger and put an "oops" rivet in it. But what can you

do to fix a hole which is misplaced? Is there a good fix for this?

Drilling a hole large enough to cover this error would take a rivet

larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due to an

earlier error that Van's made, and so I'd just need to order some new

spar doublers. But I'd like to first learn if I can fix this one.)

Also, while I have your ear -- I made this error while using a brand

new Rigid Cobalt drill bit (like this one:

http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The

bit appears to be able to cut sideways just as well (or even better)

than it can drill straight ahead in aluminum. It also takes about

20-30 seconds per hole drilling at 4000rpm (assuming my air drill is

making its rated speed) while applying moderate pressure. Is this a

known problem with this type of bit, or is my drilling technique off?

I've ordered some "aviation" 3/32" bits from Avery, but wanted to

know if I should expect it to be easier to drill straight with those bits.

Thanks!

Chris

*

*

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

HCRV6(at)comcast.net

Guest

|

Posted: Tue Jun 01, 2010 12:22 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 12:22 pm Post subject: Fixing a bad hole... |

|

|

Chris,

However you fix this oops, save yourself a lot of headaches in the future by ordering a dozen or so #40 and #30 (for AN4 rivets) drill bits from Avery or Cleveland Tool. Do not use fractional drill bits for aircraft rivets. A sharp #40 drill should take no more than about 5 seconds to go thru that flange.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

Rick Galati

Joined: 10 Jan 2006

Posts: 91

Location: Lake St. Louis MO.

|

Posted: Tue Jun 01, 2010 1:30 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 1:30 pm Post subject: Fixing a bad hole... |

|

|

Chris,

I see at least two ways of addressing that particular problem:

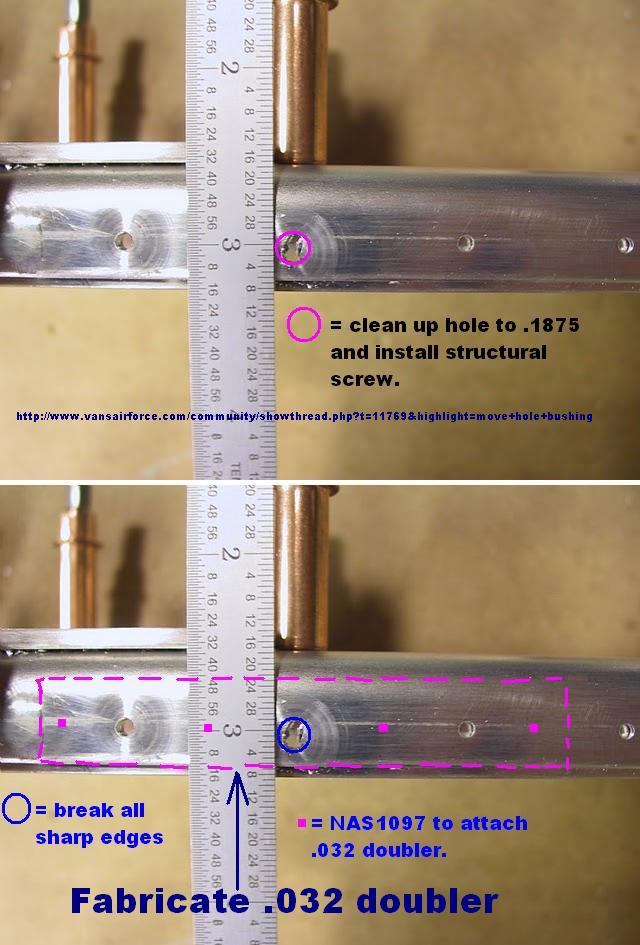

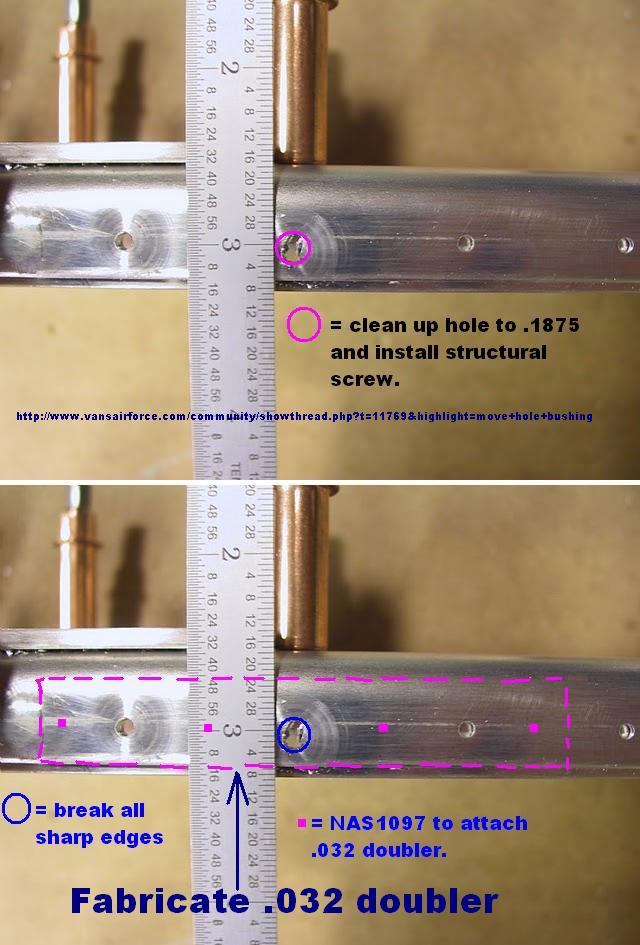

First fix option: You could "pull" the hole over and clean it up although I suspect it may need to go up to .1875 to do that perfectly. Then after dimpling, the hole would require an AD6 rivet or more likely....a structural screw. The problem is you likely do not possess the proper tooling to clean up the hole and even if you did, any 3/16" fastener would stand out like a sore thumb among all those AD3 rivets. Still, here is a link to "builders tip" I once wrote that describes the technique of "pulling" or moving a hole over:

http://www.vansairforce.com/community/showthread.php?t=11769&highlight=move+hole+bushing

Second fix option: This fix is what I would be inclined to do, because in the end you can install a regular AD3 rivet in the bad hole as if it never existed. Using a pattern file or similar, clean up the bad hole in the spar so no sharp edges exist. Then fabricate an .032 doubler of a given length. You could install that doubler by simply picking up a number of existing holes in the spar OR you could fabricate it as shown in the second picture by riveting it in place using a total of four NAS1097 rivets through the spar and doubler. Then later, when the skin is clecoed into place, use the subject hole location on the match hole skin to drill through the doubler. The over-sized spar hole would be effectively ignored. Care must be taken to insure whatever dimpling you do to the spar is effective. Done properly, nobody but you will ever know.

Rick Galati

RV-6A

RV-8

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

| Description: |

|

| Filesize: |

83.62 KB |

| Viewed: |

7462 Time(s) |

|

|

|

| Back to top |

|

|

rv10(at)colohan.com

Guest

|

Posted: Tue Jun 01, 2010 1:36 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 1:36 pm Post subject: Fixing a bad hole... |

|

|

I have a bunch of these numbered bits from Avery -- but the in this one place the instructions call for drilling to 3/32" when you assemble the spar and doublers, and then match drilling up to #40 when you have the skins in place.

I've now ordered some fractional aviation bits from Avery, and so when I redo this I'll have the right tools.

Chris

On Tue, Jun 1, 2010 at 1:15 PM, <HCRV6(at)comcast.net (HCRV6(at)comcast.net)> wrote:

[quote]Chris,

However you fix this oops, save yourself a lot of headaches in the future by ordering a dozen or so #40 and #30 (for AN4 rivets) drill bits from Avery or Cleveland Tool. Do not use fractional drill bits for aircraft rivets. A sharp #40 drill should take no more than about 5 seconds to go thru that flange.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

rv10(at)colohan.com

Guest

|

Posted: Tue Jun 01, 2010 1:40 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 1:40 pm Post subject: Fixing a bad hole... |

|

|

I have the Avery drill -- the issue here is not that I started the hole in the wrong place, but that once the hole started through one piece of aluminum the bit managed to expand the hole sideways into a giant oval instead of drilling through the next piece. It acted more like a router than a drill.

After the messages on this list and off -- I've ordered new HS-1013 doublers from Van's, and will use this with my spare spar to redo the whole thing the right way.

Chris

On Tue, Jun 1, 2010 at 1:16 PM, Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)> wrote:

[quote] --> RV-List message posted by: Kelly McMullen <kellym(at)aviating.com (kellym(at)aviating.com)>

Also, you need a drill with a good teasing trigger that you can start very slow, and only after the drill bit has started, run the speed up high. Chicago Pneumatics makes a good one that Avery sells for around $125, and there are the Sioux drills for about double that.

On 6/1/2010 7:43 AM, John Bright wrote:

| Quote: | It's only one hole of tens... not a structural issue... you could do your best with an oops rivet and move on. Is it a cosmetic issue with the skin? You don't show the skin... is the skin bungled-up also? You could fill around it on the exterior skin cosmetically with pro-seal when you mix it for the tanks.

I like the 135 degree split points. IMO cobalt or TiN or whatever does not matter to us with this aluminum. Split points have less tendency to walk than 118 degree non split points but they will still walk. All drills make triangular holes in thin sheet metal.

I use an electric drill that spins maybe 2,400 rpm and I go thru skin and doubler in 1 or 2 seconds. I don't know what's going on with 20-30 seconds but something is wrong.

Thanks,

John Bright

o:757-864-2305

c:757-812-1909

------------------------------------------------------------------------

*From:* Chris Colohan <rv10(at)colohan.com (rv10(at)colohan.com)>

*To:* rv-list(at)matronics.com (rv-list(at)matronics.com)

*Sent:* Tue, June 1, 2010 12:51:12 AM

*Subject:* Fixing a bad hole...

I've reached the horizontal stabilizer in building my RV-10. While drilling the 3/32" holes in the spar doublers for the forward spar, I mucked one of the holes up.

In particular, the drill appears to have slid about 3/32" sideways while drilling, mis-placing the hole by 3/32". Perhaps better explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too large -- you drill it out larger and put an "oops" rivet in it. But what can you do to fix a hole which is misplaced? Is there a good fix for this? Drilling a hole large enough to cover this error would take a rivet larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due to an earlier error that Van's made, and so I'd just need to order some new spar doublers. But I'd like to first learn if I can fix this one.)

Also, while I have your ear -- I made this error while using a brand new Rigid Cobalt drill bit (like this one: http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The bit appears to be able to cut sideways just as well (or even better) than it can drill straight ahead in aluminum. It also takes about 20-30 seconds per hole drilling at 4000rpm (assuming my air drill is making its rated speed) while applying moderate pressure. Is this a known problem with this type of bit, or is my drilling technique off? I've ordered some "aviation" 3/32" bits from Avery, but wanted to know if I should expect it to be easier to drill straight with those bits.

Thanks!

Chris

*

*

|

===========

get="_blank">http://www.matronics.com/Navigator?RV-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

[b]

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

carl.froehlich(at)verizon

Guest

|

Posted: Tue Jun 01, 2010 4:09 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 4:09 pm Post subject: Fixing a bad hole... |

|

|

The way I approach these kind of problems:

<![if !supportLists]>1. <![endif]>If you can drill it out to 1/8”, then do so and use a 1/8” rivet. No one will ever see the one or two 1/8” rivets in the sea of 3/32” rivets.

<![if !supportLists]>2. <![endif]>If after drilling out the screw up the hole it too large, then just get a replacement part from Van’s. The parts are cheap – especially when you think about flying this plane for 20-30 years and every time you look at the tail you wonder if you should have replace the part or not.

Carl Froehlich

RV-8A (550 hrs)

RV-10 (systems install)

From: owner-rv-list-server(at)matronics.com [mailto:owner-rv-list-server(at)matronics.com] On Behalf Of Chris Colohan

Sent: Tuesday, June 01, 2010 5:29 PM

To: rv-list(at)matronics.com

Subject: Re: Fixing a bad hole...

I have a bunch of these numbered bits from Avery -- but the in this one place the instructions call for drilling to 3/32" when you assemble the spar and doublers, and then match drilling up to #40 when you have the skins in place.

I've now ordered some fractional aviation bits from Avery, and so when I redo this I'll have the right tools.

Chris

On Tue, Jun 1, 2010 at 1:15 PM, <HCRV6(at)comcast.net (HCRV6(at)comcast.net)> wrote:

Chris,

However you fix this oops, save yourself a lot of headaches in the future by ordering a dozen or so #40 and #30 (for AN4 rivets) drill bits from Avery or Cleveland Tool. Do not use fractional drill bits for aircraft rivets. A sharp #40 drill should take no more than about 5 seconds to go thru that flange.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Tue Jun 01, 2010 7:42 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 7:42 pm Post subject: Fixing a bad hole... |

|

|

I agree with this approach. Done properly, there should be no strength

compromise. You can also slightly countersink the underside of the bad

hole, to give the shop head a better grip.

In fact, I know there are a number of RV 10 wings that have this sort of

repair where the plans call for one single lug nut plate in the middle

of a bunch of two lug nut plates. Before long you will learn how to

efficiently repair your mistakes, the plan mistakes, the QB facility

mistakes, etc. In fact, fixing mistakes is one of the better skills you

acquire as you move along.

There are some who say you should just pick a finger to drill through,

with a small bit, so it isn't a surprise when it happens. Since I had

already done that long ago working on the motorhome type of RV, I

figured I didn't need to repeat the experience. ;-p

On 6/1/2010 10:35 AM, Dave Saylor wrote:

| Quote: | You could countersink the mis-drilled hole and put a flush rivet in

it, under the skin. Then using the pre-drilled skin as a template,

drill the correct hole in the spar, and continue on. I'd think that

one repair on the spar wouldn't have much if any effect on the overall

strength. If you're concerned about the strength of the spar cap you

could put a doubler under the existing row of rivets that picked up

6-8 holes.

Dave Saylor

AirCrafters LLC

140 Aviation Way

Watsonville, CA 95076

831-722-9141 Shop

831-750-0284 Cell

On Tue, Jun 1, 2010 at 8:20 AM, Chris Colohan <rv10(at)colohan.com

<mailto:rv10(at)colohan.com>> wrote:

This is a slightly unusual assembly in the RV-10.

The spar comes pre-drilled with undersized holes in the flange.

The doubler comes with no holes.

You clamp the doubler on the spar, and drill through the existing

spar flange holes and through the doubler with a 3/32" drill.

When you later assemble the whole thing with the skin in place,

you match drill everything (including the skin) with a #40 drill.

So for this hole I've messed up the spar flange and doubler, and

now have a misplaced hole to go under my pre-drilled skin (which I

have not touched yet). I was hoping to find a solution which does

not involve: (a) drilling another hole right next to the first

mistake, since that would weaken the spar flange, or (b) making my

skin look ugly. I fear this solution doesn't exist...

Chris

On Tue, Jun 1, 2010 at 4:58 AM, <densing(at)carolina.rr.com

<mailto:densing(at)carolina.rr.com>> wrote:

If you are drilling holes for 3/32" rivets, shouldn't you be

using a #40 drill and not a 3/32"?

---- Chris Colohan <rv10(at)colohan.com

<mailto:rv10(at)colohan.com>> wrote:

> I've reached the horizontal stabilizer in building my RV-10.

While drilling

> the 3/32" holes in the spar doublers for the forward spar, I

mucked one of

> the holes up.

*

t="_blank">http://www.matronics.com/Navigator?RV-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution *

*

*

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Tue Jun 01, 2010 7:47 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 7:47 pm Post subject: Fixing a bad hole... |

|

|

Personally, I have found that #41 drills make for a snugger fit dimpled

hole. I use either the drill bit for new holes, or #41 chucking reamer

to enlarge the pre-punched holes. The reamer both makes it unlikely you

will get a hole where it isn't supposed to be, and leaves a smoother

edge that needs less de-burring.

Most of my skins were probably pre-punched to #42, and won't accept

dimple die, but with #41 the dimple die fits perfectly.

On 6/1/2010 1:15 PM, HCRV6(at)comcast.net wrote:

[quote] Chris,

However you fix this oops, save yourself a lot of headaches in the

future by ordering a dozen or so #40 and #30 (for AN4 rivets) drill

bits from Avery or Cleveland Tool. Do not use fractional drill bits

for aircraft rivets. A sharp #40 drill should take no more than about

5 seconds to go thru that flange.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1705

Location: Sun Lakes AZ

|

Posted: Tue Jun 01, 2010 8:00 pm Post subject: Fixing a bad hole... Posted: Tue Jun 01, 2010 8:00 pm Post subject: Fixing a bad hole... |

|

|

Sounds like your drill bit was either bent, or not installed straight in

the drill. You shouldn't get that kind of wobble from a drill bit.

You can keep a few pieces of scrap to test a drill bit on before doing

critical parts, and to fine tune your rivet gun pressures before driving

any that will look bad if not driven right.

Don't feel bad. I know one or two people that misread the instructions

and misdrilled those doublers, needing to obtain new ones. When you get

into wings and fuselage you will forget all those minor speed bumps on

the tail.

On 6/1/2010 2:27 PM, Chris Colohan wrote:

| Quote: | I have the Avery drill -- the issue here is not that I started the

hole in the wrong place, but that once the hole started through one

piece of aluminum the bit managed to expand the hole sideways into a

giant oval instead of drilling through the next piece. It acted more

like a router than a drill.

After the messages on this list and off -- I've ordered new HS-1013

doublers from Van's, and will use this with my spare spar to redo the

whole thing the right way.

Chris

On Tue, Jun 1, 2010 at 1:16 PM, Kelly McMullen <kellym(at)aviating.com

<mailto:kellym(at)aviating.com>> wrote:

<mailto:kellym(at)aviating.com>>

Also, you need a drill with a good teasing trigger that you can

start very slow, and only after the drill bit has started, run the

speed up high. Chicago Pneumatics makes a good one that Avery

sells for around $125, and there are the Sioux drills for about

double that.

On 6/1/2010 7:43 AM, John Bright wrote:

It's only one hole of tens... not a structural issue... you

could do your best with an oops rivet and move on. Is it a

cosmetic issue with the skin? You don't show the skin... is

the skin bungled-up also? You could fill around it on the

exterior skin cosmetically with pro-seal when you mix it for

the tanks.

I like the 135 degree split points. IMO cobalt or TiN or

whatever does not matter to us with this aluminum. Split

points have less tendency to walk than 118 degree non split

points but they will still walk. All drills make triangular

holes in thin sheet metal.

I use an electric drill that spins maybe 2,400 rpm and I go

thru skin and doubler in 1 or 2 seconds. I don't know what's

going on with 20-30 seconds but something is wrong.

Thanks,

John Bright

o:757-864-2305

c:757-812-1909

------------------------------------------------------------------------

*From:* Chris Colohan <rv10(at)colohan.com <mailto:rv10(at)colohan.com>>

*To:* rv-list(at)matronics.com <mailto:rv-list(at)matronics.com>

*Sent:* Tue, June 1, 2010 12:51:12 AM

*Subject:* Fixing a bad hole...

I've reached the horizontal stabilizer in building my RV-10.

While drilling the 3/32" holes in the spar doublers for the

forward spar, I mucked one of the holes up.

In particular, the drill appears to have slid about 3/32"

sideways while drilling, mis-placing the hole by 3/32".

Perhaps better explained through pictures:

http://picasaweb.google.com/lh/photo/YZEMcGR7IQ7RKKSRLDgTIKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/eN0TsDBeAFqGoRwnEt8-s6Iqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/e83Ltq54S8AOdpT-fXhSuKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

http://picasaweb.google.com/lh/photo/JklKOOxA-qYDu9BtPMZJeKIqw9YRHPUJIjz5HHlTjwc?feat=directlink

So I know how to fix a hole when you make it slightly too

large -- you drill it out larger and put an "oops" rivet in

it. But what can you do to fix a hole which is misplaced? Is

there a good fix for this? Drilling a hole large enough to

cover this error would take a rivet larger than 1/8"...

(At worst, I can just replace the spar -- I have a spare, due

to an earlier error that Van's made, and so I'd just need to

order some new spar doublers. But I'd like to first learn if

I can fix this one.)

Also, while I have your ear -- I made this error while using a

brand new Rigid Cobalt drill bit (like this one:

http://www.ridgid.com/Tools/332-Cobalt-Drill-Bit/EN/index.htm). The

bit appears to be able to cut sideways just as well (or even

better) than it can drill straight ahead in aluminum. It also

takes about 20-30 seconds per hole drilling at 4000rpm

(assuming my air drill is making its rated speed) while

applying moderate pressure. Is this a known problem with this

type of bit, or is my drilling technique off? I've ordered

some "aviation" 3/32" bits from Avery, but wanted to know if I

should expect it to be easier to drill straight with those bits.

Thanks!

Chris

*

*

===========

get="_blank">http://www.matronics.com/Navigator?RV-List

===========

http://forums.matronics.com

===========

le, List Admin.

="_blank">http://www.matronics.com/contribution

===========

*

*

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

pitts_pilot(at)bellsouth.

Guest

|

Posted: Wed Jun 02, 2010 4:43 am Post subject: Fixing a bad hole... Posted: Wed Jun 02, 2010 4:43 am Post subject: Fixing a bad hole... |

|

|

Of all the rhetoric this thread has generated, I find the suggestion of

making the hole 'clean' to accept a rivet .... put one in, and then use

the skin as a guide to redrill the hole .... with a good bit. As Kelly

said in a previous post .... fixing (not replacing) an oops will become

a common skill.

Linn

Kelly McMullen wrote:

| Quote: |

Sounds like your drill bit was either bent, or not installed straight

in the drill. You shouldn't get that kind of wobble from a drill bit.

You can keep a few pieces of scrap to test a drill bit on before

doing critical parts, and to fine tune your rivet gun pressures before

driving any that will look bad if not driven right.

Don't feel bad. I know one or two people that misread the instructions

and misdrilled those doublers, needing to obtain new ones. When you

get into wings and fuselage you will forget all those minor speed

bumps on the tail.

|

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

HCRV6(at)comcast.net

Guest

|

Posted: Wed Jun 02, 2010 8:35 pm Post subject: Fixing a bad hole... Posted: Wed Jun 02, 2010 8:35 pm Post subject: Fixing a bad hole... |

|

|

And to repeat myself, dump the fractional drill bits and get some decent #40 (or #41 doesn't really matter) and #30 aircraft split point bits from Avery or Cleveland.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

rv10(at)colohan.com

Guest

|

Posted: Wed Jun 02, 2010 9:06 pm Post subject: Fixing a bad hole... Posted: Wed Jun 02, 2010 9:06 pm Post subject: Fixing a bad hole... |

|

|

I took your advice and ordered new bits from Avery Sunday night when I ordered the replacement parts. Hopefully they arrive before next weekend...

Thanks!

Chris

On Wed, Jun 2, 2010 at 9:29 PM, <HCRV6(at)comcast.net (HCRV6(at)comcast.net)> wrote:

[quote] And to repeat myself, dump the fractional drill bits and get some decent #40 (or #41 doesn't really matter) and #30 aircraft split point bits from Avery or Cleveland.

Harry Crosby

RV-6 N16CX, 692 hours

---

| | - The Matronics RV-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?RV-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|