|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

vmi67(at)yahoo.com

Guest

|

Posted: Fri Sep 03, 2010 11:42 am Post subject: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 11:42 am Post subject: 601XL fiberglass wingroot fairings |

|

|

Has anyone designed of built a set of glass wingroot fairings for the 601XL?

I saw an old article on the web where someone fabricated a set for a 601HD and am trying to figure out how to do the same for my XL with the different wing.

The rubber gasket fairings are neither very pretty nor particularly effective, especially if you don't have perfectly straight edges.

Jim

N156WT

[quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

psm(at)ATT.NET

Guest

|

Posted: Fri Sep 03, 2010 1:05 pm Post subject: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 1:05 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

Hi Jim,

I had good luck with the rubber gasket approach on the wing/fuselage joint. I used the recommended glue - Locktite Stick'n Seal from Wal*Mart.

I had one area where the trimming I did on the wing skin left a gap between the wing and fuselage. I fixed that by riveting a strip of skin weight (. 025 in my case) aluminum to the wing skin to fill the gap. It was just a matter of shaping the strip to match the fuselage and not worrying about how much overlap it had with the wing skin (of course considering minimum edge distances).

Paul

XL upgrading second wing

From: owner-zenith601-list-server(at)matronics.com [mailto:owner-zenith601-list-server(at)matronics.com] On Behalf Of vmi67(at)yahoo.com

Sent: Friday, September 03, 2010 12:41 PM

To: zenith601-list(at)matronics.com

Subject: 601XL fiberglass wingroot fairings

Has anyone designed of built a set of glass wingroot fairings for the 601XL?

I saw an old article on the web where someone fabricated a set for a 601HD and am trying to figure out how to do the same for my XL with the different wing.

The rubber gasket fairings are neither very pretty nor particularly effective, especially if you don't have perfectly straight edges.

Jim

N156WT

| Quote: | | http://www.matronics.com/Navigator?Zenith601-List |

0123456789

[quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

jaybannist(at)cs.com

Guest

|

Posted: Fri Sep 03, 2010 2:22 pm Post subject: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 2:22 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

Jim,

Yes there was a guy that made fiberglass wing root farings for an HDS. You have to remember that the HD and HDS have no flaps. The flaps make it difficult to incorporate much of a wing root faring for an XL. The guy that made them for his HDS is Klaus Truemper of Dallas and he did a LOT of research into the subject. You might pick his brain to see if he has any ideas about adapting his design for an XL.

Jay Bannister

--

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

daveaustin2(at)primus.ca

Guest

|

Posted: Fri Sep 03, 2010 2:41 pm Post subject: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 2:41 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

I made rigid foam forms on the a/c, coated them with epoxy and then cast the fibreglas fairings with flanges for the wing and fuselage surfaces. Fashioned after the Spitfire wing fairings, going back along the fuse about 14 inches from the wing trailing edge.

They did improve air flow over the horizontal stab. and the elevators

Dave Austin 601HDS 912

[quote][b]

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

chris Sinfield

Joined: 28 Nov 2006

Posts: 270

Location: Sydney Australia

|

Posted: Fri Sep 03, 2010 3:04 pm Post subject: Re: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 3:04 pm Post subject: Re: 601XL fiberglass wingroot fairings |

|

|

Eddie Seve did it to his XL

here is his website page

http://www.mykitlog.com/users/display_log.php?user=eddieseve&project=343&category=0&log=50438&row=46

I forgot to take photos today, as I was so distracted with the fitting and initial test flying with the wing fairings finally fitted. I have yet to collect some worthwhile data, but one thing I can say for certain is that stall speed has been reduced quite dramatically. I did 4 circuits in all, but it was at the wrong time of the day as the thermals where a little rough.

First take off was with half flap and climb seems to have improved but I was getting bounced too much for this to be accurate. In circuit the big thing I noticed was the response of the ailerons is much improved, they are much more in balance with the elevator. Cruse downwind required 200 rpm less to fly at 110lknots; pervious was 2600rpm. Landings, it seems to take a little more effort to slow the plane down and the flair is greatly improved.

I did a few more landings with various stages of flap and it feels like a different plane.

Last landing was no flap and this one blew me away, previously the aircraft would stop flying at around 35knots, this now seems to have drop by a good 8knots or so (I'll need to do lots more landings to confirm this, but it was great, even when the stall did occur it still wanted to keep flying. This would have to have been my best landing to date and I now have 36 happy hours on the airframe.

Next week I'll post some photos, the fairings look fairly ugly in primer at the moment; I'll also gather some data in nice smooth early morning air.

and finally here they are

http://www.mykitlog.com/users/display_log.php?user=eddieseve&project=343&category=0&log=56146&row=31

Chris

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

dgraham7(at)TWCNY.RR.COM

Guest

|

Posted: Fri Sep 03, 2010 4:49 pm Post subject: 601XL fiberglass wingroot fairings Posted: Fri Sep 03, 2010 4:49 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

I am hoping that someone will design and sell a set of wing root fairings

for the 601 HDS. I don't have the time or skill. I would think that it would be a money-maker.

Regards,

Damien

N48TK

[quote] ---

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

daveaustin2(at)primus.ca

Guest

|

Posted: Sat Sep 04, 2010 5:44 am Post subject: 601XL fiberglass wingroot fairings Posted: Sat Sep 04, 2010 5:44 am Post subject: 601XL fiberglass wingroot fairings |

|

|

Att. is a pic of my 601 with the fairings - not a closeup, but you can see them.

Dave Austin

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

46.25 KB |

| Viewed: |

20140 Time(s) |

|

|

|

| Back to top |

|

|

naumuk(at)windstream.net

Guest

|

Posted: Sat Sep 04, 2010 5:54 am Post subject: 601XL fiberglass wingroot fairings Posted: Sat Sep 04, 2010 5:54 am Post subject: 601XL fiberglass wingroot fairings |

|

|

Dave-

Did you re-paint your plane?

Bill

do not archive

---

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

daveaustin2(at)primus.ca

Guest

|

Posted: Sat Sep 04, 2010 9:23 am Post subject: 601XL fiberglass wingroot fairings Posted: Sat Sep 04, 2010 9:23 am Post subject: 601XL fiberglass wingroot fairings |

|

|

Bill,

That is an old picture. Re-painted off-white three years ago. I think you saw it.

Dave

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

Louie928

Joined: 15 Nov 2009

Posts: 32

Location: Mosier, OR USA

|

Posted: Mon Sep 13, 2010 4:21 pm Post subject: Re: 601XL fiberglass wingroot fairings Posted: Mon Sep 13, 2010 4:21 pm Post subject: Re: 601XL fiberglass wingroot fairings |

|

|

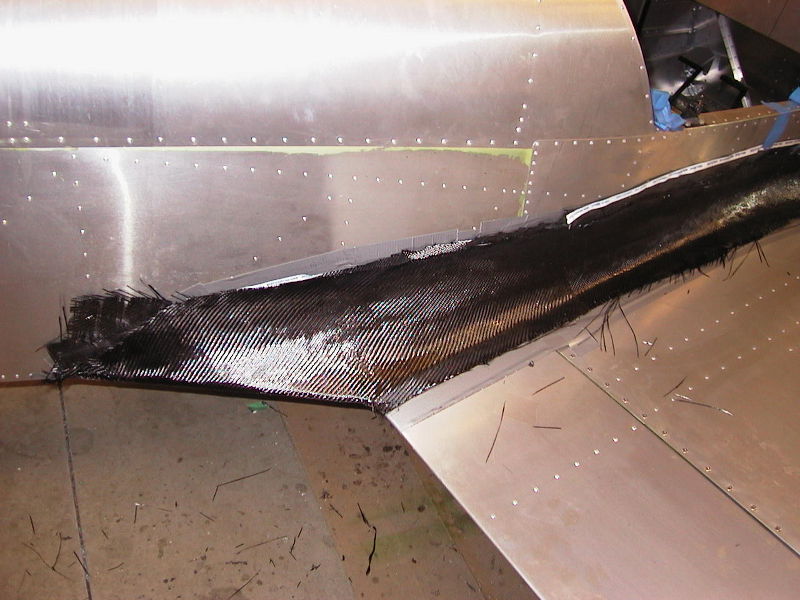

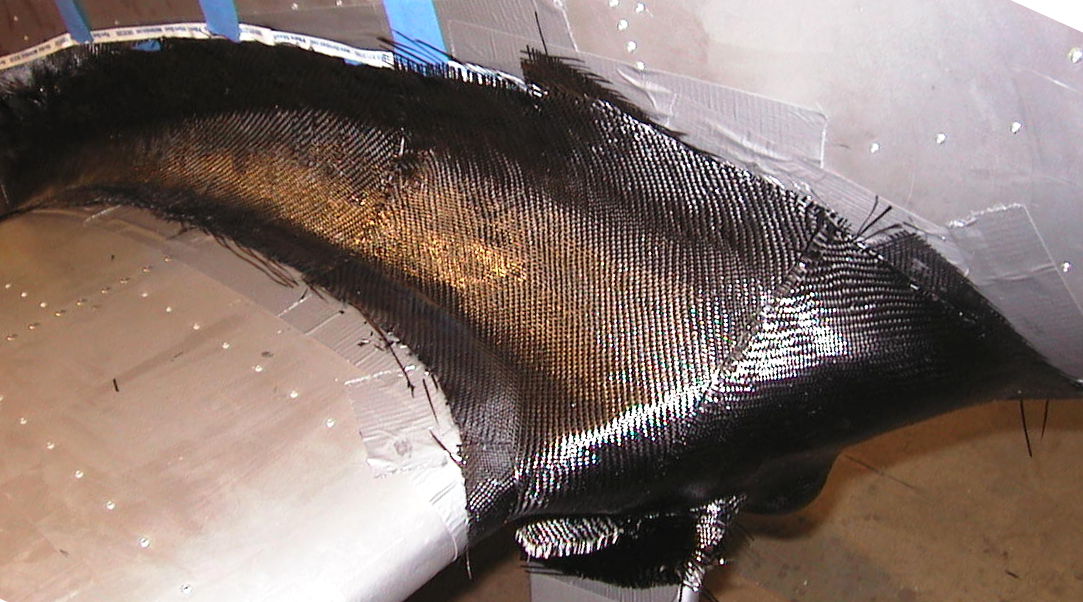

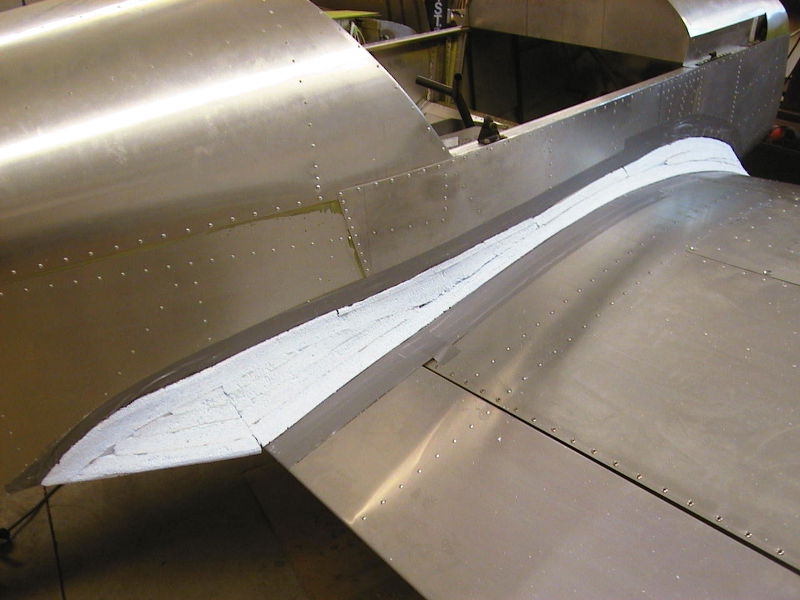

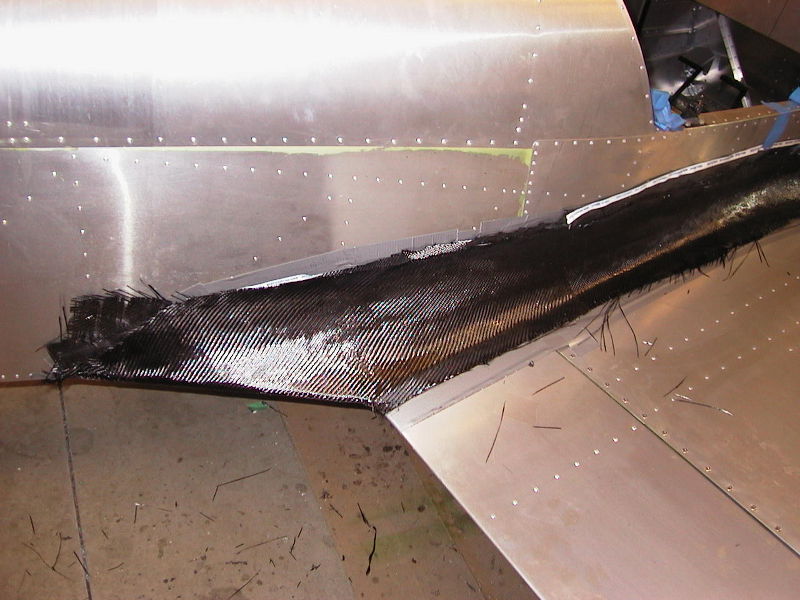

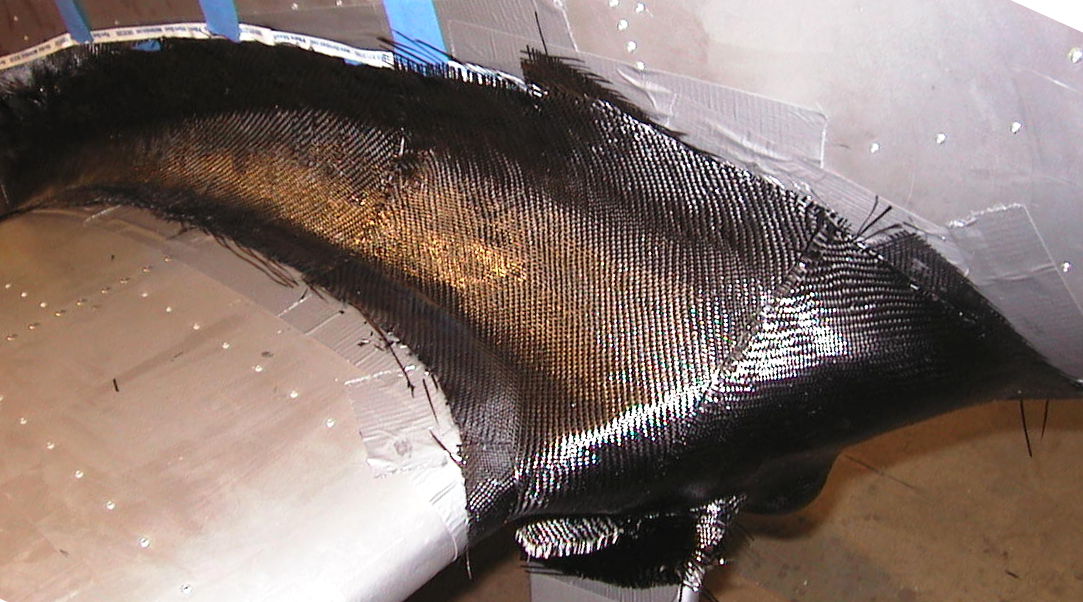

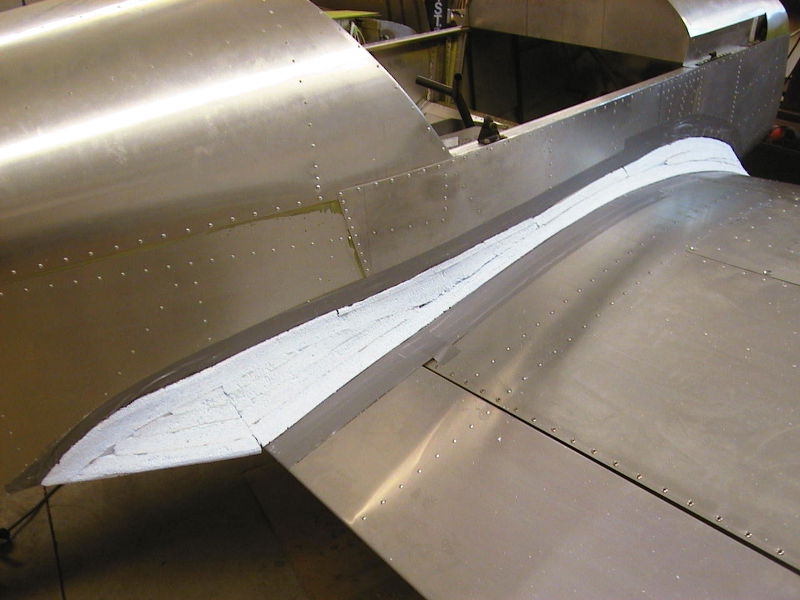

I'm fabricating top and bottom fairings for my 601 XL. The airplane isn't finished yet, but from an aerodynamic point, it is evident that the fairings should help quite a bit. It doesn't take a huge amount of specialized skill, but does take more time than I expected. I fastened 1" thick foam sheets (the foam that the QB kit was packed in) to the airframe with double sided tape. That type foam isn't the best for forms because it isn't very dense, but it was available and I had no other use for it. Additional sheets were stuck to existing sheets with double sided tape or small dabs of epoxy adhesive. The foam was shaped with Stanley Sureform files, sandpaper, hot wire foam cutter, electric chainsaw, etc. Irregularities, and gaps, were filled with modeling clay. Then, I coated the foam with epoxy for stiffness. After that was cured, I covered it with duct tape and made sure the duct tape was extended a few inches outside of the fairing area so no epoxy would get on the skin. Epoxy doesn't stick to duct tape, but some mold release on the tape helps with de-molding. Mold release can be paste wax, or even spray on cooking oil, or Pledge furniture wax. Thanks to Jake Reyna for the duct tape covering of the foam idea. It's a good solution.

Cut the glass or carbon fiber cloth to shape leaving plenty of excess on the edges. I put a coat of resin on the form using a small roller or brush. Lay the cloth over the form and work the cloth into the epoxy on the surface. Use more epoxy if you have to for wet through, but not too much. If you use a brush, cut off about 1/3rd of the length of the bristles so they are stiffer. Push the cloth into the epoxy with short vertical jabs called "stippling". There shouldn't be so much resin that it puddles, and the weave should show. I used three three layers of 6 oz/sq yd carbon fiber twill cloth. Glass cloth is less expensive, but heavier and not as stiff. It's likely you can't make the layup in one piece as it gets quite unwieldy. Overlap the separate pieces by about 1 1/2". Leave the layup on the mold until the epoxy has fully cured. This might be a couple of days. De-mold by starting on an edge by working a putty knife under and edge and getting it lifted. At first it will appear to come off with difficulty, but after some has broken loose, it's likely the part will fall off. Making a part from a male mold as I've described will leave a somewhat uneven and rough surface. Depending how you want to finish the fairing will determine how it's made smooth. If painting, use a lightweight filler made from epoxy and microballoons (glass beads). You could use lightweight polyester body filler too. Then sand and paint. I made mine from carbon fiber cloth and intend to leave it natural. I painted on another coat of epoxy to fill the weave and sanded most of that off. Another coat of epoxy and more sanding using finer grit. I'll finish with urethane automotive paint clear coats for UV protection with sanding between coats.

Polyester resin could be used instead of epoxy. Epoxy doesn't shrink like polyester does, and epoxy is a much better adhesive than polyester. I used epoxy that is good to over well over 200 deg F since the top fairings will be out in the sun. I used epoxy system 2000 from Fiberglast. http://www.fibreglast.com/ They have hardeners in 20 min, 60 min, and 120 min setting time. Epoxy resins are available from other sources that will work too.

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

| Description: |

|

| Filesize: |

84.24 KB |

| Viewed: |

20055 Time(s) |

|

| Description: |

|

| Filesize: |

136.97 KB |

| Viewed: |

20055 Time(s) |

|

| Description: |

| Right wing front fairing covering gear attachment. TD gear. |

|

| Filesize: |

86.65 KB |

| Viewed: |

20055 Time(s) |

|

| Description: |

| Top fairing mold nearly done |

|

| Filesize: |

64.21 KB |

| Viewed: |

20055 Time(s) |

|

| Description: |

| Top fairing form construction |

|

| Filesize: |

69.55 KB |

| Viewed: |

20055 Time(s) |

|

| Description: |

| Under wing fairing form covered with duct tape. |

|

| Filesize: |

57.7 KB |

| Viewed: |

20055 Time(s) |

|

_________________

Louis W. Ott

601XL-B Corvair |

|

| Back to top |

|

|

naumuk(at)windstream.net

Guest

|

Posted: Tue Sep 14, 2010 1:43 pm Post subject: 601XL fiberglass wingroot fairings Posted: Tue Sep 14, 2010 1:43 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

Louis-

Kudos for a very good description of the process.

Bill

---

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

|

|

| Back to top |

|

|

mhubel

Joined: 05 Sep 2009

Posts: 141

|

Posted: Tue Sep 14, 2010 4:55 pm Post subject: 601XL fiberglass wingroot fairings Posted: Tue Sep 14, 2010 4:55 pm Post subject: 601XL fiberglass wingroot fairings |

|

|

Louis,

Did you ever think of making a blow molded plastic part instead?

Given that this is not structural, that might be a way someone could

make these in some small quantity if the group is interested.

On 09/14/2010 5:39 PM, Bill Naumuk wrote:

[quote]

<naumuk(at)windstream.net>

Louis-

Kudos for a very good description of the process.

Bill

---

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

_________________

Mark Hubelbank

N708HU

CH601XL

Jabiru 3300

Rotec TBI 40-3 carb

Sensenich ground adj prop.

240 hr TAF

Pictures at photo.hubbles.com |

|

| Back to top |

|

|

Louie928

Joined: 15 Nov 2009

Posts: 32

Location: Mosier, OR USA

|

Posted: Tue Sep 14, 2010 11:17 pm Post subject: Re: 601XL fiberglass wingroot fairings Posted: Tue Sep 14, 2010 11:17 pm Post subject: Re: 601XL fiberglass wingroot fairings |

|

|

I have thought of making female molds from the fairings I have and make CF layups from those. The finished surface would be a lot smoother and they would be lighter weight. I guess blow molds could be made too. I'd have to think a while about how to do that. I think it would just take too much time to make it worthwhile. I've been through that making some rear fender molds for my car, and that was a lot simpler. I have sold a few sets. Right now, I have to get this little 601 finished and flying.

http://www.performance928.com/cgi-bin/page_display.cgi?page_nav_name=rearfenderuir&pass_parent=1128

http://www.performance928.com/cgi-bin/page_display.cgi?page_nav_name=fendermoldM9o

[quote="mhubel"]Louis,

Did you ever think of making a blow molded plastic part instead?

Given that this is not structural, that might be a way someone could

make these in some small quantity if the group is interested.

On 09/14/2010 5:39 PM, Bill Naumuk wrote:

| Quote: |

<naumuk>

Louis-

Kudos for a very good description of the process.

Bill

--- |

| | - The Matronics Zenith601-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith601-List |

|

_________________

Louis W. Ott

601XL-B Corvair |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|