|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

deej(at)deej.net

Guest

|

Posted: Fri Nov 05, 2010 9:14 am Post subject: cylinder woes Posted: Fri Nov 05, 2010 9:14 am Post subject: cylinder woes |

|

|

My 1975 AA1B with the standard O235 with approx 1400 hours SMOH is in

for annual, and after sending my cylinders away due to leaks detected it

turns out that 3 of them have cracks in the cylinder heads. The shop

said the cost of repair was approx $1100 each, so it doesn't make sense

to do this since new ones are close to the same price.

Recommendations as to where to buy new cylinder assemblies? I have an

extremely limited budget so cost is a factor.

Part of me is wondering if it is worth putting this much money into the

plane.

How much is an AA1B worth that needs to have 3 cylinders replaced?

How much is one worth with 4 new cylinder assemblies with about 1400

SMOH, 3200 hours total time airframe?

Thanks,

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Fri Nov 05, 2010 9:44 am Post subject: cylinder woes Posted: Fri Nov 05, 2010 9:44 am Post subject: cylinder woes |

|

|

The TBO is 2400 hours. RIght? Put all new cylinders on it and fly it for another 1000 hours without worrying about when the last one will fail. I'm a firm believer in new cylinders at mid time.

Dave White's AA1B needed new cylinders. We happened to get a set of cylinders from Ken at Lycon with 10 hours on them. They had been prepped for a race engine and not used. Dave paid $4000 for them with all the custom work already done. With 50 hours on them, compressions are 79/80 and the plane runs nice.

From: Dj Merrill <deej(at)deej.net>

To: teamgrumman-list(at)matronics.com

Sent: Fri, November 5, 2010 9:45:35 AM

Subject: cylinder woes

--> TeamGrumman-List message posted by: Dj Merrill <deej(at)deej.net (deej(at)deej.net)>

My 1975 AA1B with the standard O235 with approx 1400 hours SMOH is in

for annual, and after sending my cylinders away due to leaks detected it

turns out that 3 of them have cracks in the cylinder heads. The shop

said the cost of repair was approx $1100 each, so it doesn't make sense

to do this since new ones are close to the same price.

Recommendations as to where to buy new cylinder assemblies? I have an

extremely limited budget so cost is a factor.

Part of me is wondering if it is worth putting this much money into the

plane.

How much is an AA1B worth that needs to have 3 cylinders replaced?

How much is one worth with 4 new cylinder assemblies with about

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

curt_johnson(at)sbcglobal

Guest

|

Posted: Fri Nov 05, 2010 10:03 am Post subject: cylinder woes Posted: Fri Nov 05, 2010 10:03 am Post subject: cylinder woes |

|

|

I paid $19,900 for a '73 with about 1280 TT and 100 STOH.

Curt

On 11/5/2010 9:45 AM, Dj Merrill wrote:

| Quote: |

My 1975 AA1B with the standard O235 with approx 1400 hours SMOH is in

for annual, and after sending my cylinders away due to leaks detected it

turns out that 3 of them have cracks in the cylinder heads. The shop

said the cost of repair was approx $1100 each, so it doesn't make sense

to do this since new ones are close to the same price.

Recommendations as to where to buy new cylinder assemblies? I have an

extremely limited budget so cost is a factor.

Part of me is wondering if it is worth putting this much money into the

plane.

How much is an AA1B worth that needs to have 3 cylinders replaced?

How much is one worth with 4 new cylinder assemblies with about 1400

SMOH, 3200 hours total time airframe?

Thanks,

-Dj

|

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Fri Nov 05, 2010 3:24 pm Post subject: cylinder woes Posted: Fri Nov 05, 2010 3:24 pm Post subject: cylinder woes |

|

|

On 11/5/2010 1:34 PM, Gary Vogt wrote:

| Quote: | The TBO is 2400 hours. RIght? Put all new cylinders on it and fly it

for another 1000 hours without worrying about when the last one will

fail. I'm a firm believer in new cylinders at mid time.

|

Hi Gary,

I'd love to, but unfortunately I'm not rich. New Lyc cyls are about

$1600 each, so that's over $6k for 4 new cyls, not including labor.

I think at this point I'm just going to post an ad asking $12k for it

as-is, and see if I get any interest.

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Fri Nov 05, 2010 3:24 pm Post subject: cylinder woes Posted: Fri Nov 05, 2010 3:24 pm Post subject: cylinder woes |

|

|

On 11/5/2010 1:34 PM, Gary Vogt wrote:

| Quote: | The TBO is 2400 hours. RIght? Put all new cylinders on it and fly it

for another 1000 hours without worrying about when the last one will

fail. I'm a firm believer in new cylinders at mid time.

|

Hi Gary,

I'd love to, but unfortunately I'm not rich. New Lyc cyls are about

$1600 each, so that's over $6k for 4 new cyls, not including labor.

I think at this point I'm just going to post an ad asking $12k for it

as-is, and see if I get any interest.

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Fri Nov 05, 2010 3:31 pm Post subject: cylinder woes Posted: Fri Nov 05, 2010 3:31 pm Post subject: cylinder woes |

|

|

Alternatively, if someone knows of where I might find 4 used cylinders

that have been inspected by a qualified shop, and are ready to bolt on

and go, I might be interested in that option as well.

Thanks,

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Fri Nov 05, 2010 3:47 pm Post subject: cylinder woes Posted: Fri Nov 05, 2010 3:47 pm Post subject: cylinder woes |

|

|

this place is real good for rebuilding and / or having cylinders ready to go with rings fitted:

http://dbaircraftengines.com/_wsn/page3.html

[quote] ---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Sat Nov 06, 2010 2:05 pm Post subject: cylinder woes Posted: Sat Nov 06, 2010 2:05 pm Post subject: cylinder woes |

|

|

-L2C cylinders are listed at a few hundred dollars cheaper than the

-C2C cylinders. What is the difference between them? Can -L2C

cylinders be used on the -C2C engine in the AA1B?

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Sun Nov 07, 2010 7:00 am Post subject: cylinder woes Posted: Sun Nov 07, 2010 7:00 am Post subject: cylinder woes |

|

|

The case has to be split and machined to accept the larger through bolts

that the -L2C engine uses. Part of the mod is you get different pistons

that raise the CR to 8.5 which improves both power and fuel efficiency. Not

much more expensive to install an O-320 engine and have a real performance

gain!

Cliff

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

andy747(at)charter.net

Guest

|

Posted: Sun Nov 07, 2010 7:23 am Post subject: cylinder woes Posted: Sun Nov 07, 2010 7:23 am Post subject: cylinder woes |

|

|

same subject....on Barnstormers this morning there is an O-235 with 1000

hours complete with accessories for 5K. Don't know if it is the right

series but there are deals like this out there. You could buy one, install

it, sell your engine as a core and then sell the accessories, ending up

getting most of your money back. I know, I know, you are putting out front

money but the end result is a quicker source than a second job even if you

have to borrow the up front cost....

Andy Thomas

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyv35b(at)minetfiber.com

Guest

|

Posted: Sun Nov 07, 2010 7:39 am Post subject: cylinder woes Posted: Sun Nov 07, 2010 7:39 am Post subject: cylinder woes |

|

|

Pretty incredible when the core charge on an O-235-L2/C engine is $12K

---

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Mon Nov 08, 2010 5:30 am Post subject: Cylinder woes Posted: Mon Nov 08, 2010 5:30 am Post subject: Cylinder woes |

|

|

Dj:

Not True... Lycoming Cylinders are about $1100 each and you can get other brands for $890 each.

And if you are building a Glastar, you should have the tool knowledge to replace the cylinders yourself. Just get an A&P to LQQK over your shoulder. Give him $400 for his knowledge.

Barry

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Mon Nov 08, 2010 6:54 am Post subject: Cylinder woes Posted: Mon Nov 08, 2010 6:54 am Post subject: Cylinder woes |

|

|

On 11/08/2010 08:15 AM, FLYaDIVE wrote:

| Quote: | Not True... Lycoming Cylinders are about $1100 each and you can get

other brands for $890 each.

|

Hi Barry,

I'd greatly appreciate it if you would share with me where I can get

O-235-C2C cylinders for $1100. The cheapest I have been able to find

them is $1472 at Air Power. I'm still hoping to find 3 used, rebuilt

cylinders for less than that, though.

I haven't found any other brands for this engine. I'm told that ECI

doesn't make them for this particular engine, and Superior doesn't seem

to be making cylinder assemblies at all right now as far as I can tell.

What other brands are there, and where can I find out about them? If I

can get brand new cylinder assemblies for $890 I'd be very tempted to do it.

Thanks!

| Quote: |

And if you are building a Glastar, you should have the tool knowledge to

replace the cylinders yourself. Just get an A&P to LQQK over

your shoulder. Give him $400 for his knowledge.

|

I could probably do it, but I'd rather my A&P do the engine work and

have me look over his shoulder so I can learn. I've gotten pretty good

at riveting and am okay at fiberglass work, but since I've never touched

the internals of an engine I'll defer to him since this is one area I

don't want to mess up...

Thanks,

-Dj

--

Dj Merrill - N1JOV

Glastar Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Please use Netiquette Guidelines http://tools.ietf.org/html/rfc1855

Kindly TRIM your email replies and post AFTER the relevant text

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Mon Nov 08, 2010 11:00 am Post subject: Cylinder woes Posted: Mon Nov 08, 2010 11:00 am Post subject: Cylinder woes |

|

|

Barry, I don't know why you have such a hard-on for Lycoming cylinders, they are much better cylinders. No ADs to start with. I've talked to Ken at Lycon about the various cylinders. From his perspective, they are the best and they make the most power. Building 500 engines a year, including racers and air show planes, he should know. You can pay less for a cylinder, but that's what you'll get: less.

Since the labor costs the same to remove and replace a $200 overhauled cylinder as it does to replace an $1100 new cylinder, the only advantage is, you won't have to replace the new cylinder in a hundred hours.

Oh, good, I feel a story coming on . . . .

A few years back, I had a customer with a new, to her, 1976 Tiger. Her primary reason for picking this plane was that it had an overhauled engine. Yep, only 125 hours since complete overhaul. The compressions were in the low to mid 70s. It leaked oil at the case parting line. And, in flight, it felt very weak.

Fast forward 2 years and 175 hours. Compressions were low 40s on 2 cylinders and the other two were mid 60s. "It still feels like it's flying fine." she would tell me. "The guys in Pali, (her vernacular for Palo Alto) told me I must have stuck rings. They said I should soak the cylinders in Mouse Milk and then (some other solvent I can't remember)."

So, for 2 weeks, I kept they cylinders full and pulled the engine through a full four cycles everyday. Then refilled, repeated, then refilled. What the hell, I charged her an hour a day for 2 weeks. It was her choice. I just couldn't convince her that the engine did not really get a real overhaul. She kept insisting, "It only has 300 hours since major overhaul!"

After 2 weeks, there was no change in the compressions. I ran the engine and high speed taxied it for an hour. Checked again. No change. (oh, by-the-way, these were the instructions the guys in Palo Alto wanted me to follow. It was her money.)

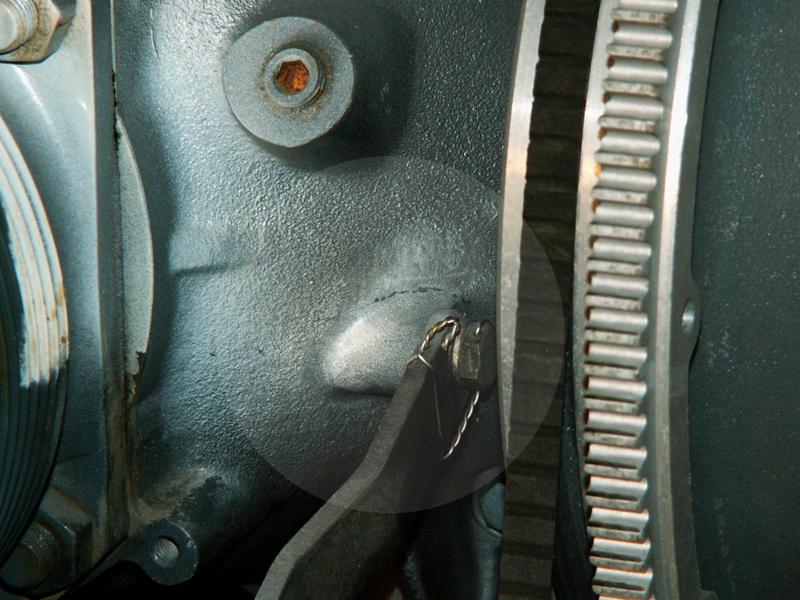

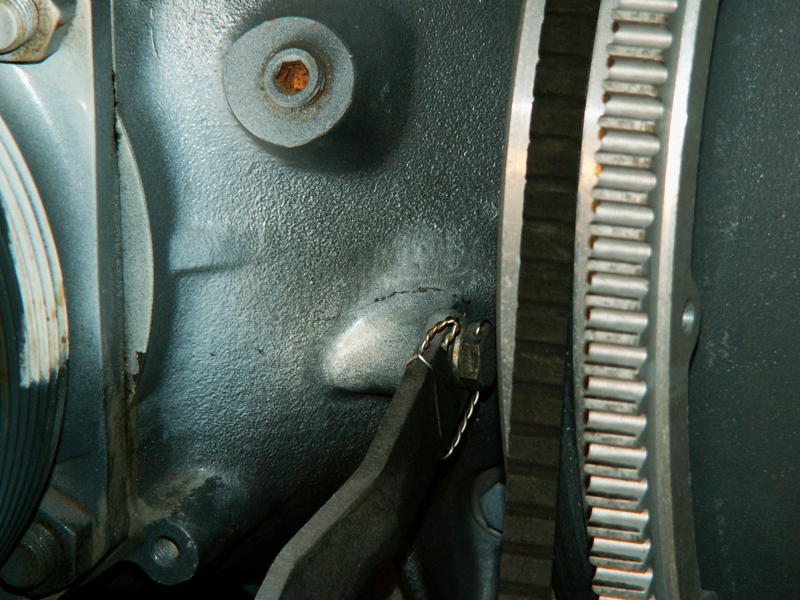

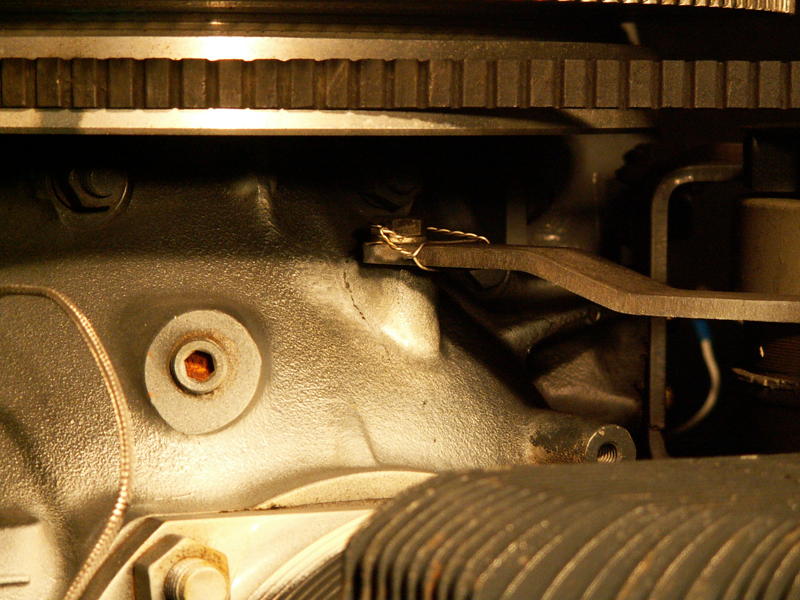

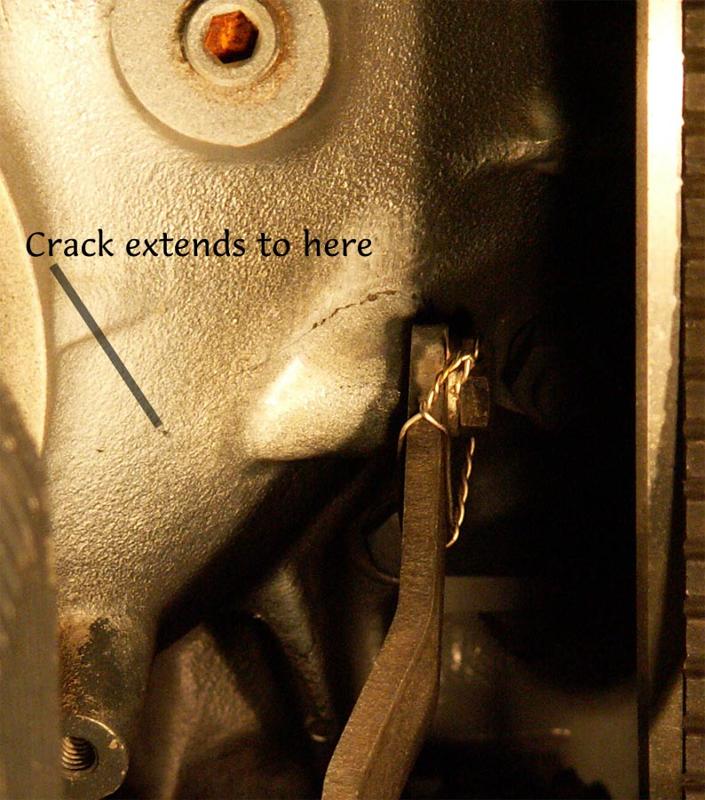

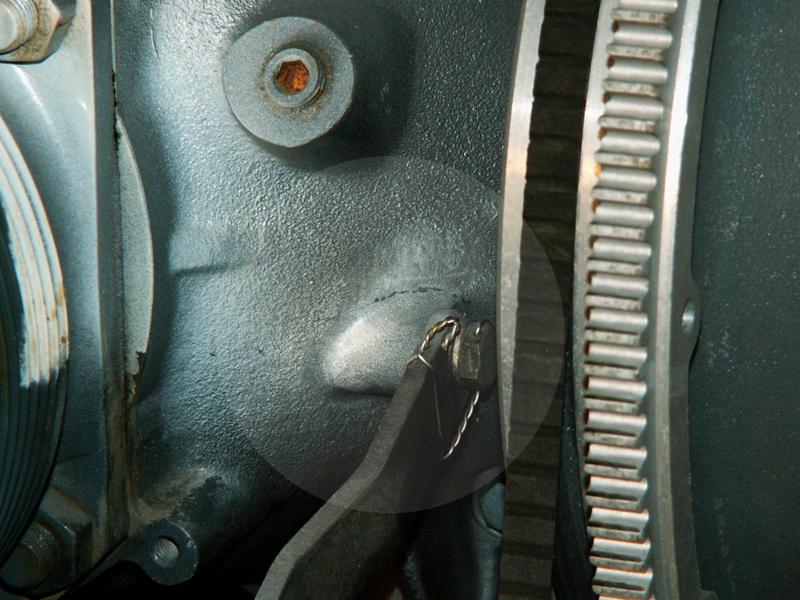

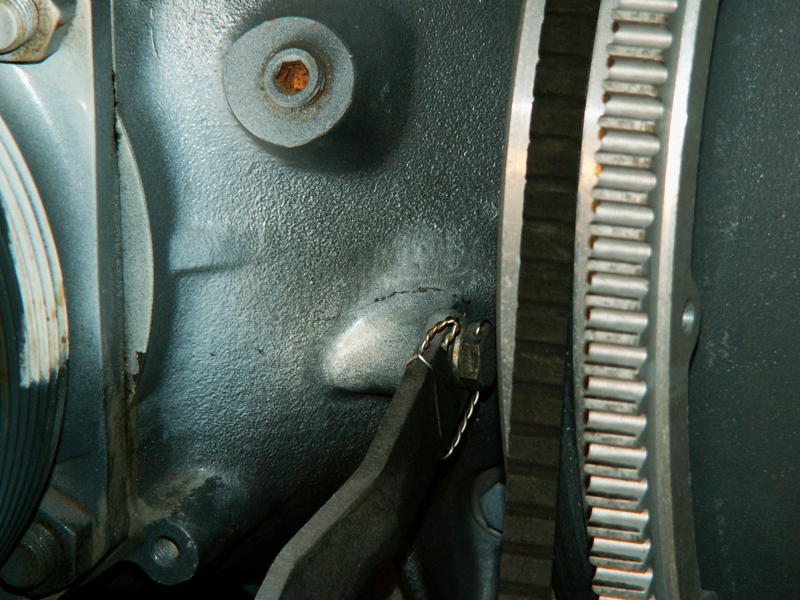

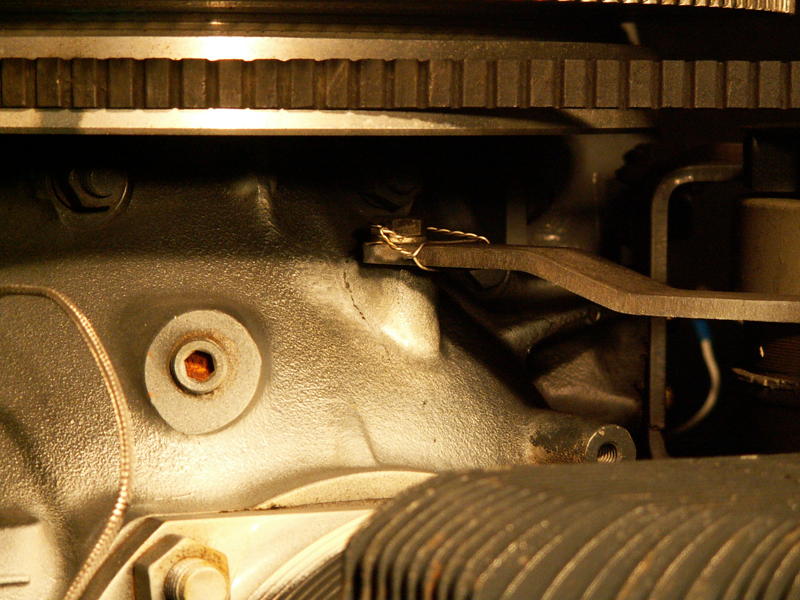

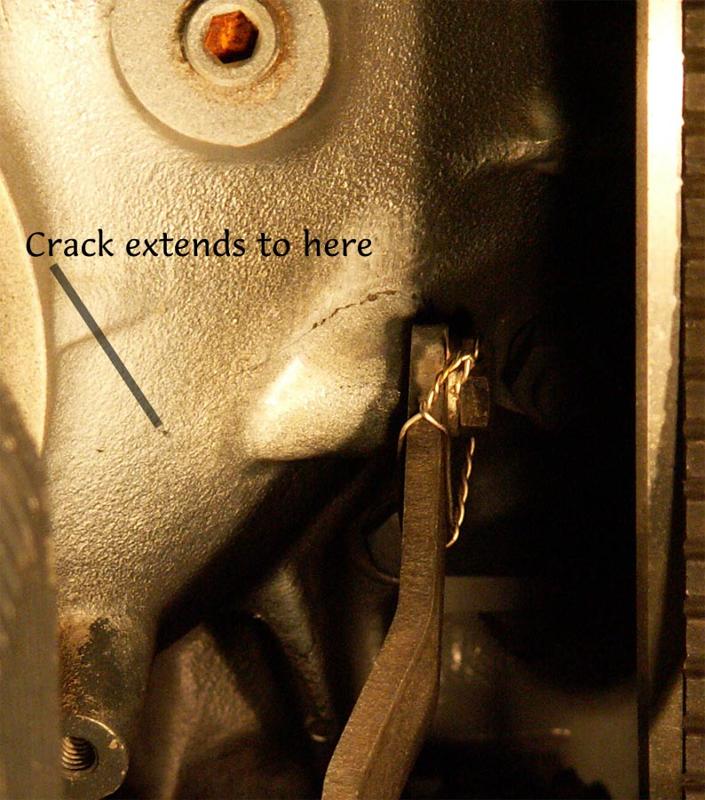

I pulled the cylinders to send them to LyCon. The block was cracked at the alternator mounting boss. Over the last year, when she brought it in for an oil change, I thought there was a lot of oil. (I had changed the #4 oil drain back tube the oil change prior because it was corroded through and leaking a lot. I thought that was the source of the oil).

When I called her and told her that her engine block was cracked she responded with, "How can that be? It only has 300 hours since major overhaul." I got her a deal on an overhauled engine directly from Lycoming for under $19,000. Her response, "The guys in Pali said I can have the block welded for a couple of hundred dollars." So, I put her plane back together and sent her on her way.

A year later she flew to Auburn for a fly-in. I asked about the engine. Turns out, during the tear down to get at the crack, they found bent rods, a bad cam, bad lifters, and the crank was scored. Oh, yea, all of the cylinders were so badly cracked they couldn't be repaired. Putting the engine back together cost her . . . . . drum roll . . . . $19,000. And 6 months.

When she called for an annual, I had to reply with, "I would love to work on your plane but, I'm not the right mechanic for you. Have the guys in Pali work on your plane."

Bottom line: You get what you pay for.

From: FLYaDIVE <flyadive(at)gmail.com>

To: teamgrumman-list(at)matronics.com

Sent: Mon, November 8, 2010 5:15:27 AM

Subject: Cylinder woes

Dj:

Not [quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Mon Nov 08, 2010 4:15 pm Post subject: Cylinder woes Posted: Mon Nov 08, 2010 4:15 pm Post subject: Cylinder woes |

|

|

Hi Gary:

I don't know if I am being that unreasonable when it comes to Lycoming. They are the Fathers of the industry and my thoughts just keep telling me they should be much further on in development and quality then they are. It always seems it is the lawyers that hold back the development.

Things like the Oil Pump Gears... How many Millions did that cost aviation. Not them... ME the little guy had to foot that bill.

And remember how much ware there was in the aluminum gear? I still have mine and NONE is the answer. Then you may recall there was the sinted gear for the oil pump. Well, any engineer I know would NEVER even suggest such a thing.

And lets not forget the rocker arm ... An INTAKE and an EXHAUST and don't you mix them up... Oil will be squirting the wrong direction when it comes to the EXHAUST and YES, I lost a cylinder because of that. NO! ! ! I WAS NOT THE ONE THAT INSTALLED THEM INCORRECTLY. Paperwork indicated it was Lycoming, that did the last work on the engine. Yes, I know the paperwork could very easily be wrong.

I eliminated the mix up on rockers completely - I made ALL the rockers EXHAUST rockers. I understand Lycoming did that also?

There are other AD's that luckily I escaped only after pulling the cowl off to check part numbers and serial numbers; others did not escape so cheaply.

I would not say I have a hard-on from them. Quite the opposite. They make me go limp.

I believe in Competition, I believe in keeping the work right here in the USA. I also like to support the underdog and if you think of it. The underdog has an advantage. They can learn from Lycoming. I really liked the idea that Superior had and did with hard-coat anodizing the fin area of the cylinders. No Paint to hold heat in. Better casting without flashing.

And I am still waiting for more oil to be delivered to the heads.

Gary, I respect your knowledge and all your experimentation. So it is NOT a personal thing between you and I. AND from your experience I am learning. It is just that Lycoming has not given me the Warm & Fuzzy feeling, only a lighter wallet. I am NOT totally against Lycoming, maybe with your teachings I may see things in a different light.

==========

I feel you can learn many things from stories. I also enjoy your stories.

My first thought was WHO did the overhaul?

The people at Palo Alto or Lycoming?

My second thought was: She is fixating on the numbers and not the situation. Everyone would like a quick - cheep cure to low compression.

And I have to ask... Sorry Gary... Why did the block crack?

I'm twisting the knife here and it is NOT fair. A cracked block is far from normal and not something that can be blamed on Lycoming. And if the crank was scored there must have been quite a bit of heat. Maybe before she purchased the plane and as you said: " I just couldn't convince her that the engine did not really get a real overhaul."

And I agree, you do get what you pay for. But you should not have to pay too much.

When it comes to repairing a problem, I say it a little differently: "Pay me now, or pay me later; the problem is not going to go away."

Smiles Gary,

Barry

On Mon, Nov 8, 2010 at 1:57 PM, Gary Vogt <teamgrumman(at)yahoo.com (teamgrumman(at)yahoo.com)> wrote:

| Quote: | Barry, I don't know why you have such a hard-on for Lycoming cylinders, they are much better cylinders. No ADs to start with. I've talked to Ken at Lycon about the various cylinders. From his perspective, they are the best and they make the most power. Building 500 engines a year, including racers and air show planes, he should know. You can pay less for a cylinder, but that's what you'll get: less.

Since the labor costs the same to remove and replace a $200 overhauled cylinder as it does to replace an $1100 new cylinder, the only advantage is, you won't have to replace the new cylinder in a hundred hours.

Oh, good, I feel a story coming on . . . .

A few years back, I had a customer with a new, to her, 1976 Tiger. Her primary reason for picking this plane was that it had an overhauled engine. Yep, only 125 hours since complete overhaul. The compressions were in the low to mid 70s. It leaked oil at the case parting line. And, in flight, it felt very weak.

Fast forward 2 years and 175 hours. Compressions were low 40s on 2 cylinders and the other two were mid 60s. "It still feels like it's flying fine." she would tell me. "The guys in Pali, (her vernacular for Palo Alto) told me I must have stuck rings. They said I should soak the cylinders in Mouse Milk and then (some other solvent I can't remember)."

So, for 2 weeks, I kept they cylinders full and pulled the engine through a full four cycles everyday. Then refilled, repeated, then refilled. What the hell, I charged her an hour a day for 2 weeks. It was her choice. I just couldn't convince her that the engine did not really get a real overhaul. She kept insisting, "It only has 300 hours since major overhaul!"

After 2 weeks, there was no change in the compressions. I ran the engine and high speed taxied it for an hour. Checked again. No change. (oh, by-the-way, these were the instructions the guys in Palo Alto wanted me to follow. It was her money.)

I pulled the cylinders to send them to LyCon. The block was cracked at the alternator mounting boss. Over the last year, when she brought it in for an oil change, I thought there was a lot of oil. (I had changed the #4 oil drain back tube the oil change prior because it was corroded through and leaking a lot. I thought that was the source of the oil).

When I called her and told her that her engine block was cracked she responded with, "How can that be? It only has 300 hours since major overhaul." I got her a deal on an overhauled engine directly from Lycoming for under $19,000. Her response, "The guys in Pali said I can have the block welded for a couple of hundred dollars." So, I put her plane back together and sent her on her way.

A year later she flew to Auburn for a fly-in. I asked about the engine. Turns out, during the tear down to get at the crack, they found bent rods, a bad cam, bad lifters, and the crank was scored. Oh, yea, all of the cylinders were so badly cracked they couldn't be repaired. Putting the engine back together cost her . . . . . drum roll . . . . $19,000. And 6 months.

When she called for an annual, I had to reply with, "I would love to work on your plane but, I'm not the right mechanic for you. Have the guys in Pali work on your plane."

Bottom line: You get what you pay for.

From: FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)>

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Sent: Mon, November 8, 2010 5:15:27 AM

Subject: TeamGrumman-List: Cylinder woes

Dj:

Not | Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

_blank">http://www.matronics.com/contribution

st" target="_blank">http://www.matronics.com/Navigator?TeamGrumman-List

tp://forums.matronics.com

|

|

--

Barry

"Chop'd Liver"

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Nov 09, 2010 10:36 am Post subject: Cylinder woes Posted: Tue Nov 09, 2010 10:36 am Post subject: Cylinder woes |

|

|

Well, Barry,

What are we talking about here? Gears? or Cylinders?

As for the gears, how many out right failures where there? Not many. For the most part, the bottom end of any Lycoming engine will run seemingly forever with a bad cam, bent rods, and a crank that needs to be turned. IF the engine has been taken care of regarding oil changes and regular use, the bottom end is good for 4000 hours.

Rockers: Here, I'd have to agree 100%. Two nearly identical rockers with no stamping showing how they go in. In 1984, I was doing a very thorough annual on my first Cheetah. The engine had 600 hours on it since new. The rocker cover gaskets were leaking, so, I decided to change them. In the process, with a brand new Lycoming overhaul manual in hand, I decided to do a dry tappet clearance check, just for shits-n-grins. Inside the maintenance hangar, about 20 yards from the main FBO, I started carefully removing all the parts. On the work bench, I laid out everything in the order I removed them. During the cleaning process, I noticed a there was a difference between the rockers. Strange this was, from the factory, one side of the engine was one way, the other side was different. I asked the mechanic there, Jack, a guy who had been working on planes for some 30 years, which was which. He said, and I quote, "I don't know. I've never noticed a difference before." I called Lycoming and talked to an engineer. He didn't know either. Several transfers later, I got an answer.

Do you know the logic behind the different rockers? The squirter is supposed to squirt oil on the valve stem . . . exhaust only to help cool the valve. The other one is supposed to dribble oil onto the rocker . . . . intake only. These engines have no oil seal on the valve stems. Squirting oil on the intake only makes oil go into the intake port, coat the inside with residue, and burn more oil.

Waiting for more oil to be delivered to the heads: This is a major misconception. Born, in part, by Bill Scott and Bill Marvel. Sodium filled valves were first used almost 100 years ago. By the mid 30's there was a lot of research being done on sodium filled valves. Why? Because, at the time, rockers were out in the open. Sodium filled valves offered a way to shed heat without much oil. In fact, research done by Samuel Heron in the late teens, early 20s, showed that excess oil on the valve causes valve sticking. And, if you think that sticking valves are unique to Lycomings, you haven't kept up on the valve problems (using solid valves and lots of oil) in Continental engines. Do a little research regarding oil on sodium filled valves. The problem is really due to the geometry of the rocker/valve stem during operation. The side loads on the valve cause the guide to be worn excessively*. This is true of ALL engines without roller rockers. In this respect, the solid lifter engines (i.e., O235) are better. Ideally, you want to get roller rockers to get rid of the side loads. Hot Rod magazine had an excellent article on valve geometry not long ago.

* this is THE reason why I recommend a top overhaul with new cylinders at 1000 hrs. I've pulled a lot of cylinders with 1000 to 1500 hours on them. I send them to Ken for tear down and inspection. I pay for the research on this one. In every case, the cylinders have cracks in the exhaust port. Most, but not all, show excess wear in the guides. The ones that don't show no correlation between them. (that is, without getting Charlie Epps to do a math analysis of it.) It just isn't worth patching the cylinder to get another 1000 hours out of it. It'll never make it.

Fins on Superior engines: Now, I ask, was that a work of art or what? Really pretty weren't they. Problem was, those machined heads (in place of cast heads) gave up 30% of the surface area needed to shed heat.

Casting flashings: I ground out the flashings on about a half dozen engines. All with JPI engine analyzers. No change. Sloppy workmanship, for sure, but not critical. The new heads are a whole lot better.

=========

I feel you can learn many things from stories. I also enjoy your stories.

--- Thanks

My first thought was WHO did the overhaul?

--- It was done by an FBO in New Jersey

My second thought was: She is fixating on the numbers and not the situation. Everyone would like a quick - cheep cure to low compression.

--- She is a lawyer. What can I say?

And I have to ask... Sorry Gary... Why did the block crack?

--- My guess is the crack was there from the beginning (well, before I got it). Ken told me this is usually due to the alternator bracket on the bottom of the engine breaking and the alternator hanging on the upper brace. The boss the upper brace is attached to, breaks.

I'm twisting the knife here and it is NOT fair. A cracked block is far from normal and not something that can be blamed on Lycoming. And if the crank was scored there must have been quite a bit of heat. Maybe before she purchased the plane and as you said: " I just couldn't convince her that the engine did not really get a real overhaul."

And I agree, you do get what you pay for. But you should not have to pay too much.

When it comes to repairing a problem, I say it a little differently: "Pay me now, or pay me later; the problem is not going to go away."

--- She paid way too much for the plane. It was full of corrosion. Under the instrument panel was a nightmare. Someone had wired in an audio panel, one wire at a time. There were wires everywhere.

[b] --- Side note: same plane. During the first annual, I noticed a dent in the bottom of the right wing. It looked like the wheel pant had dented the wing. Now, to my way of thinking, this is impossible. Upon further investigation, the four 3/8 inch bolts holding the axle onto the fiberglass gear leg were bent. The gear leg was splintered.

[b] --- Continued: Before she came to me, she bought a LoPresti nose bowl because the engine 'ran' hot. The JPI shows it anyway. After installation of the LoPresti nose bowl, it ran even hotter. This was my first LoPresti nose bowl. Turns out, you can't tuck the baffles into the top of the nose bowl inlet and form a tight seal. You really need to know what you're doing to properly seal the LoPresti nose bowl. 99% of the 75,000 mechanics out there haven't a fucking clue how to properly install baffles. That leaves 750 t[b][b][b][b][b]h

[/b]

[/b][/b]

[/b]

[/b][b][b]at have a clue. Good luck finding one.

[/b]

[/b]

When it comes to repairing a problem, I say it a little differently: "Pay me now, or pay me later; the problem is not going to go away."

[b] --- I say, "If a job isn't worth doing, it isn't worth doing twice." Get it right the first time.

[/b]

[/b]

[/b]

From: FLYaDIVE <flyadive(at)gmail.com>

To: teamgrumman-list(at)matronics.com

Sent: Mon, November 8, 2010 4:12:43 PM

Subject: Re: Cylinder woes

Hi Gary:

I don't know if I am being that unreasonable when it comes to Lycoming. They are the Fathers of the industry and my thoughts just keep telling me they should be much further on in development and quality then they are. It always seems it is the lawyers that hold back the development.

Things like the Oil Pump Gears... How many Millions did that cost aviation. Not them... ME the little guy had to foot that bill.

And remember how much ware there was in the aluminum gear? I still have mine and NONE is the answer. Then you may recall there was the sinted gear for the oil pump. Well, any engineer I know would NEVER even suggest such a thing.

And lets not forget the rocker arm ... An INTAKE and an EXHAUST and don't you mix them up... Oil will be squirting the wrong direction when it comes to the EXHAUST and YES, I lost a cylinder because of that. NO! ! ! I WAS NOT THE ONE THAT INSTALLED THEM INCORRECTLY. Paperwork indicated it was Lycoming, that did the last work on the engine. Yes, I know the paperwork could very easily be wrong.

I eliminated the mix up on rockers completely - I made ALL the rockers EXHAUST rockers. I understand Lycoming did that also?

There are other AD's that luckily I escaped only after pulling the cowl off to check part numbers and serial numbers; others did not escape so cheaply.

I would not say I have a hard-on from them. Quite the opposite. They make me go limp.

I believe in Competition, I believe in keeping the work right here in the USA. I also like to support the underdog and if you think of it. The underdog has an advantage. They can learn from Lycoming. I really liked the idea that Superior had and did with hard-coat anodizing the fin area of the cylinders. No Paint to hold heat in. Better casting without flashing.

And I am still waiting for more oil to be delivered to the heads.

Gary, I respect your knowledge and all your experimentation. So it is NOT a personal thing between you and I. AND from your experience I am learning. It is just that Lycoming has not given me the Warm & Fuzzy feeling, only a lighter wallet. I am NOT totally against Lycoming, maybe with your teachings I may see things in a different light.

==========

I feel you can learn many things from stories. I also enjoy your stories.

My first thought was WHO did the overhaul?

The people at Palo Alto or Lycoming?

My second thought was: She is fixating on the numbers and not the situation. Everyone would like a quick - cheep cure to low compression.

And I have to ask... Sorry Gary... Why did the block crack?

I'm twisting the knife here and it is NOT fair. A cracked block is far from normal and not something that can be blamed on Lycoming. And if the crank was scored there must have been quite a bit of heat. Maybe before she purchased the plane and as you said: " I just couldn't convince her that the engine did not really get a real overhaul."

And I agree, you do get what you pay for. But you should not have to pay too much.

When it comes to repairing a problem, I say it a little differently: "Pay me now, or pay me later; the problem is not going to go away."

Smiles Gary,

Barry

On Mon, Nov 8, 2010 at 1:57 PM, Gary Vogt <teamgrumman(at)yahoo.com (teamgrumman(at)yahoo.com)> wrote:

| Quote: | Barry, I don't know why you have such a hard-on for Lycoming cylinders, they are much better cylinders. No ADs to start with. I've talked to Ken at Lycon about the various cylinders. From his perspective, they are the best and they make the most power. Building 500 engines a year, including racers and air show planes, he should know. You can pay less for a cylinder, but that's what you'll get: less.

Since the labor costs the same to remove and replace a $200 overhauled cylinder as it does to replace an $1100 new cylinder, the only advantage is, you won't have to replace the new cylinder in a hundred hours.

Oh, good, I feel a story coming on . . . .

A few years back, I had a customer with a new, to her, 1976 Tiger. Her primary reason for picking this plane was that it had an overhauled engine. Yep, only 125 hours since complete overhaul. The compressions were in the low to mid 70s. It leaked oil at the case parting line. And, in flight, it felt very weak.

Fast forward 2 years and 175 hours. Compressions were low 40s on 2 cylinders and the other two were mid 60s. "It still feels like it's flying fine." she would tell me. "The guys in Pali, (her vernacular for Palo Alto) told me I must have stuck rings. They said I should soak the cylinders in Mouse Milk and then (some other solvent I can't remember)."

So, for 2 weeks, I kept they cylinders full and pulled the engine through a full four cycles everyday. Then refilled, repeated, then refilled. What the hell, I charged her an hour a day for 2 weeks. It was her choice. I just couldn't convince her that the engine did not really get a real overhaul. She kept insisting, "It only has 300 hours since major overhaul!"

After 2 weeks, there was no change in the compressions. I ran the engine and high speed taxied it for an hour. Checked again. No change. (oh, by-the-way, these were the instructions the guys in Palo Alto wanted me to follow. It was her money.)

I pulled the cylinders to send them to LyCon. The block was cracked at the alternator mounting boss. Over the last year, when she brought it in for an oil change, I thought there was a lot of oil. (I had changed the #4 oil drain back tube the oil change prior because it was corroded through and leaking a lot. I thought that was the source of the oil).

When I called her and told her that her engine block was cracked she responded with, "How can that be? It only has 300 hours since major overhaul." I got her a deal on an overhauled engine directly from Lycoming for under $19,000. Her response, "The guys in Pali said I can have the block welded for a couple of hundred dollars." So, I put her plane back together and sent her on her way.

A year later she flew to Auburn for a fly-in. I asked about the engine. Turns out, during the tear down to get at the crack, they found bent rods, a bad cam, bad lifters, and the crank was scored. Oh, yea, all of the cylinders were so badly cracked they couldn't be repaired. Putting the engine back together cost her . . . . . drum roll . . . . $19,000. And 6 months.

When she called for an annual, I had to reply with, "I would love to work on your plane but, I'm not the right mechanic for you. Have the guys in Pali work on your plane."

Bottom line: You get what you pay for.

From: FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)>

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Sent: Mon, November 8, 2010 5:15:27 AM

Subject: Cylinder woes

Dj:

Not

|

--

Barry

"Chop'd Liver"

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

75.02 KB |

| Viewed: |

5311 Time(s) |

|

| Description: |

|

| Filesize: |

80.62 KB |

| Viewed: |

5311 Time(s) |

|

| Description: |

|

| Filesize: |

76.97 KB |

| Viewed: |

5311 Time(s) |

|

| Description: |

|

| Filesize: |

89.73 KB |

| Viewed: |

5311 Time(s) |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Tue Nov 09, 2010 4:06 pm Post subject: Cylinder woes Posted: Tue Nov 09, 2010 4:06 pm Post subject: Cylinder woes |

|

|

Hi Gary:

I'm not discriminatory. I dislike ALL of Lycoming  Cylinders, Gears, Crankshafts and Cams. Cylinders, Gears, Crankshafts and Cams.

I have embedded my other response within the body of your email

On Tue, Nov 9, 2010 at 1:33 PM, Gary Vogt <teamgrumman(at)yahoo.com (teamgrumman(at)yahoo.com)> wrote:

| Quote: | Well, Barry,

What are we talking about here? Gears? or Cylinders?

As for the gears, how many out right failures where there? Not many.

|

[Barry] - I agree 100% with you NOT MANY. That is my point. There was NO reason to force a replacement. The ONLY gears that SHOULD have been replace AT Lycoming's expense should have been the sintered gears.

| Quote: | For the most part, the bottom end of any Lycoming engine will run seemingly forever with a bad cam, bent rods, and a crank that needs to be turned. IF the engine has been taken care of regarding oil changes and regular use, the bottom end is good for 4000 hours.

Rockers: Here, I'd have to agree 100%. Two nearly identical rockers with no stamping showing how they go in. In 1984, I was doing a very thorough annual on my first Cheetah. The engine had 600 hours on it since new. The rocker cover gaskets were leaking, so, I decided to change them. In the process, with a brand new Lycoming overhaul manual in hand, I decided to do a dry tappet clearance check, just for shits-n-grins. Inside the maintenance hangar, about 20 yards from the main FBO, I started carefully removing all the parts. On the work bench, I laid out everything in the order I removed them. During the cleaning process, I noticed a there was a difference between the rockers. Strange this was, from the factory, one side of the engine was one way, the other side was different. I asked the mechanic there, Jack, a guy who had been working on planes for some 30 years, which was which. He said, and I quote, "I don't know. I've never noticed a difference before." I called Lycoming and talked to an engineer. He didn't know either. Several transfers later, I got an answer.

Do you know the logic behind the different rockers? The squirter is supposed to squirt oil on the valve stem . . . exhaust only to help cool the valve. The other one is supposed to dribble oil onto the rocker . . . . intake only. These engines have no oil seal on the valve stems. Squirting oil on the intake only makes oil go into the intake port, coat the inside with residue, and burn more oil.

|

[Barry] - Yes, I am very familiar with how to determine which rocker goes where. The way you describe the the NO SEAL condition on the valve stem is what I was thinking about... My thought process was:

If the oil squirted on the stem BURNS and COKES the stem must be HOT.

So, if I could lower the temps of the valve stem I would not get burning and coking. The MORE oil to the head would lower those temps.

The idea seems to fit the logic BUT I have no real numbers to work with.

As I mentioned I did replace ALL the rockers with Exhaust Rockers. And I understand Lycoming has done the same thing. Makes sense as it would also reduce inventory and chance of mix-up.

| Quote: |

Waiting for more oil to be delivered to the heads: This is a major misconception. Born, in part, by Bill Scott and Bill Marvel. Sodium filled valves were first used almost 100 years ago. By the mid 30's there was a lot of research being done on sodium filled valves. Why? Because, at the time, rockers were out in the open. Sodium filled valves offered a way to shed heat without much oil. In fact, research done by Samuel Heron in the late teens, early 20s, showed that excess oil on the valve causes valve sticking. And, if you think that sticking valves are unique to Lycomings, you haven't kept up on the valve problems (using solid valves and lots of oil) in Continental engines. Do a little research regarding oil on sodium filled valves. The problem is really due to the geometry of the rocker/valve stem during operation. The side loads on the valve cause the guide to be worn excessively*. This is true of ALL engines without roller rockers. In this respect, the solid lifter engines (i.e., O235) are better. Ideally, you want to get roller rockers to get rid of the side loads. Hot Rod magazine had an excellent article on valve geometry not long ago.

* this is THE reason why I recommend a top overhaul with new cylinders at 1000 hrs. I've pulled a lot of cylinders with 1000 to 1500 hours on them. I send them to Ken for tear down and inspection. I pay for the research on this one. In every case, the cylinders have cracks in the exhaust port. Most, but not all, show excess wear in the guides. The ones that don't show no correlation between them. (that is, without getting Charlie Epps to do a math analysis of it.) It just isn't worth patching the cylinder to get another 1000 hours out of it. It'll never make it.

|

[Barry] - Gary, I am lacking experience of the ages in this area (You Old Fart  ). You have posted a few times that you see cylinders with 1000 to 1500 Hours on them. The limited experience I have in this area and ONLY from reading Logbooks is cylinders usually last 500 to 600 Hours, before a Top is required. ). You have posted a few times that you see cylinders with 1000 to 1500 Hours on them. The limited experience I have in this area and ONLY from reading Logbooks is cylinders usually last 500 to 600 Hours, before a Top is required.

I know there are thousands of reasons why, but... Is there any advice or information you can offer to reach 1000 Hours?

| Quote: |

Fins on Superior engines: Now, I ask, was that a work of art or what? Really pretty weren't they. Problem was, those machined heads (in place of cast heads) gave up 30% of the surface area needed to shed heat.

|

[Barry] - When you say 30% less surface area. How is that calculated, 30% less fin count or smaller fins?

I wonder how much cooling was gained since the fins were NOT painted?

| Quote: |

Casting flashings: I ground out the flashings on about a half dozen engines. All with JPI engine analyzers. No change. Sloppy workmanship, for sure, but not critical. The new heads are a whole lot better.

|

[Barry] - You may have seen one of my posts from years back and recently re-posted about an RV6 that I did a fin clean-up on. We saw 40 F drop in CHT. The CHT instrument is a Grand Rapids with screw in probes. This in no way is what I expected or would cal typical. Of course temperature is a fleeting thing and OAT has an effect but CHT's now do NOT go above 400 F.

Later Gary,

Barry

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flyadive(at)gmail.com

Guest

|

Posted: Tue Nov 09, 2010 4:14 pm Post subject: Cylinder woes Posted: Tue Nov 09, 2010 4:14 pm Post subject: Cylinder woes |

|

|

WOW ! ! !

Gary,

That crack is impressive.

A dirty engine would surely hide that very easily.

HMmmmmmm, I'm working on finding an oil leak on an AA-1 with an O-320. You just gave me another location to look at.

And GUAD! Trying to find a leak on a dirty engine is like trying to find Georgia Mud on a South Carolina pig.

Barry

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|