|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue May 17, 2011 9:31 pm Post subject: Board Soldering: Overheating and Cleaning? Posted: Tue May 17, 2011 9:31 pm Post subject: Board Soldering: Overheating and Cleaning? |

|

|

At 07:49 PM 5/17/2011, you wrote:

| Quote: |

Hi!

I think I'd like to solder wires to the back of my transponder

board. Using the supplied edge card connector housing, I couldn't

get the contacts to lock into place. Instead, they'd move around

inside the housing. I figure I could cut these contacts off the ends

and solder the 24 awg wires directly to the board.

|

Before you solder wires to the board, how many

pins (ecb tabs) are on this connector. I presume

also that they are .156" spacing on centers of

the tabs (that was a common standard way back when).

There might be a better way.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue May 17, 2011 9:48 pm Post subject: Board Soldering: Overheating and Cleaning? Posted: Tue May 17, 2011 9:48 pm Post subject: Board Soldering: Overheating and Cleaning? |

|

|

At 07:49 PM 5/17/2011, you wrote:

| Quote: | --> AeroElectric-List message posted by: "messydeer" <messydeer(at)yahoo.com>

Hi!

I think I'd like to solder wires to the back of my transponder board. Using the supplied edge card connector housing, I couldn't get the contacts to lock into place. Instead, they'd move around inside the housing. I figure I could cut these contacts off the ends and solder the 24 awg wires directly to the board. |

Before you solder wires to the board, how many

pins (ecb tabs) are on this connector. I presume

also that they are .156" spacing on centers of

the tabs (that was a common standard way back when).

There might be a better way. I'm assuming you've got

12 upper and lower ECB tabs on a 1/16" thick board.

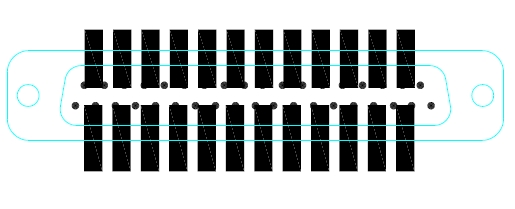

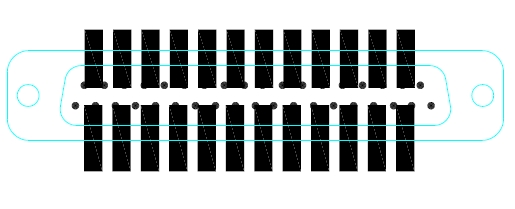

[img]cid:7.1.0.9.0.20110518014123.01db35d0(at)aeroelectric.com.0[/img]

Here's an AutoCAD plot that shows the alignment

(or lack thereof) for .156" ecb tabs and a 37-pin

d-sub connector.

You might be able to use a 37-pint, solder-cup connector

slid over the edge of the board. Note that every

ECB tab has at least ONE d-sub pin in a position

to be soldered to the tabs. There are a few d-sub

pins that fall between the ecb tabs and should

probably be totally removed from the d-sub connector

so as to reduce potential for shorting between ecb

tabs.

You might just luck out and have a relatively easy

transition from the ECB tabs to the very user friendly

d-sub technology.

Bob . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

50.18 KB |

| Viewed: |

6197 Time(s) |

|

|

|

| Back to top |

|

|

rjquillin

Joined: 13 May 2007

Posts: 123

Location: KSEE

|

Posted: Wed May 18, 2011 9:00 am Post subject: Board Soldering: Overheating and Cleaning? Posted: Wed May 18, 2011 9:00 am Post subject: Board Soldering: Overheating and Cleaning? |

|

|

At 15:49 5/17/2011, you wrote:

| Quote: |

Hi!

I think I'd like to solder wires to the back of my transponder board. <snip>

I've never soldered to a board, but imagine it's easier than the

cramped solder cups I've already done. Main questions are heat and

cleaning. I've got a 30W iron. How long can I leave a tinned tip on

the board before being concerned with overheating?

I also read a little about cleaning the board after soldering, cuz

of the flux. I'm using Kester 44 resin core. Should I wipe the board

with rubbing alcohol after I'm done?

Suggestions appreciated.

|

There is an excellent guide to soldered electrical connections from

NASA I sent to Bob a couple yeas back and he archived. Not sure of

the exact name it's stored as, but look for something like NASA

STD-8739.3. I find it difficult to imagine a hand soldering question

not addressed in that document, unless it pertains to SMD components.

Ethanol or Isopropyl are both accepted cleaners for common RMA fluxes.

| Quote: | Are the edge connector fingers gold plated? If so, it's doubtful

you'll even need flux.

When soldering to gold, NASA requires multiple 'tinning' operations

|

to remove the gold to prevent embrittlement of the joint.

Another commonly overlooked issue is moisture in the board, that,

when heated, turns to steam and causes delamination and bubbles; a

few hours in a warm to medium oven dries out the board.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed May 18, 2011 11:10 am Post subject: Board Soldering: Overheating and Cleaning? Posted: Wed May 18, 2011 11:10 am Post subject: Board Soldering: Overheating and Cleaning? |

|

|

| Quote: | > There might be a better way. I'm assuming you've got

> 12 upper and lower ECB tabs on a 1/16" thick board.

>

Thanks, Bob, except I've got 15 tabs on the bottom 3 or 4 on the top. At this point, since I've got all the pieces to do the direct soldering and D-Sub 15 connections, I'm leaning in that direction. Soldering the male pins to the board wouldn't be very easy either, since the metal shell would protect the pins from the solder tip. But if there was room to maneuver, it would make for a slick connection, all right. |

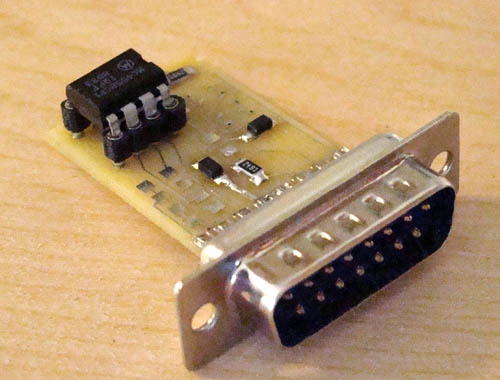

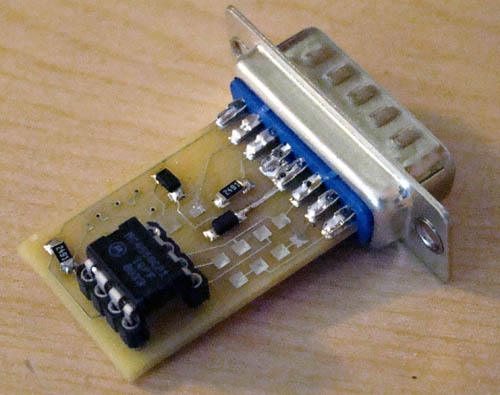

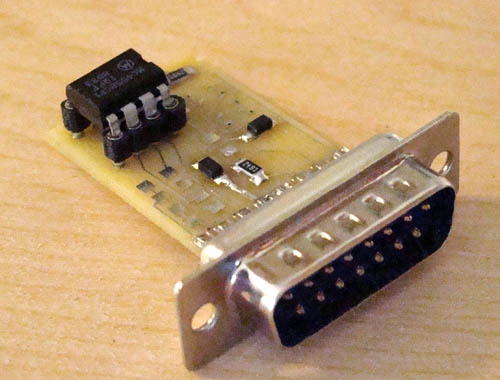

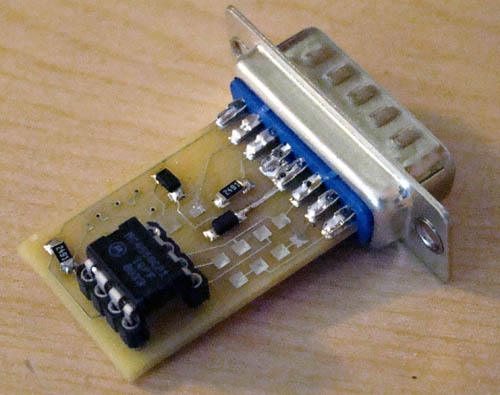

You got it backwards. What I proposed was converting

your card-edge male to a d-sub by soldering the wire-cups

of the connector to the tabs. Here is an example of a product

that uses solder-cup d-subs to bring the connections

off an ECB.

[img]cid:.0[/img]

[img]cid:.1[/img]

Like so.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

112.79 KB |

| Viewed: |

6172 Time(s) |

|

| Description: |

|

| Filesize: |

119.26 KB |

| Viewed: |

6172 Time(s) |

|

|

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Thu May 19, 2011 6:16 am Post subject: Re: Board Soldering: Overheating and Cleaning? Posted: Thu May 19, 2011 6:16 am Post subject: Re: Board Soldering: Overheating and Cleaning? |

|

|

| Quote: | | You got it backwards |

Doh!

| Quote: | There is an excellent guide to soldered electrical connections from

NASA |

Thanks! Here's a link I found:

http://www.hq.nasa.gov/office/codeq/doctree/NS87393.pdf

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Dan |

|

| Back to top |

|

|

messydeer

Joined: 13 Feb 2006

Posts: 214

Location: Bellingham, WA

|

Posted: Fri May 20, 2011 6:51 am Post subject: Re: Board Soldering: Overheating and Cleaning? Posted: Fri May 20, 2011 6:51 am Post subject: Re: Board Soldering: Overheating and Cleaning? |

|

|

Yesterday I soldered the wires to the transponder board leaving them about 6" long, which I soldered to a female dsub 15. Also made up the mating male dsub. At first I tinned the board and wire ends then came back with the iron with a minimal bead of solder on the tip. It took only a couple seconds to solder them. I found it was difficult coming back to put more solder after this initial soldering to make a nice little mound over the wire. I found it worked better for me to put that extra solder on first, during the board tinning, so I wouldn't have to come back a second time. I scrubbed the contacts afterwards with a toothbrush and rubbing alcohol. It's not super pretty, but I'm happy with how it went.

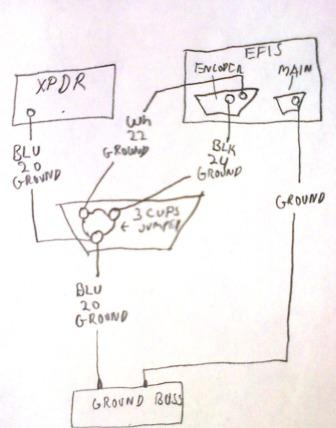

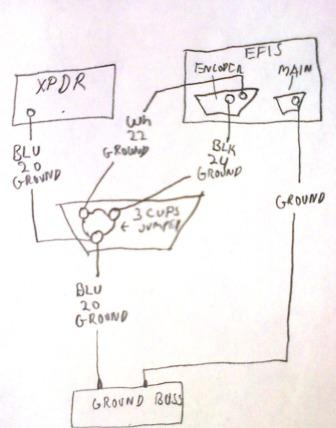

Grounding

I also needed to run grounds from the transponder to the encoder on the EFIS and to the common ground buss. My solder cups aren't big enough to put more than one wire in. Instead of splicing the wires together, I recalled that Bob had jumped a bunch of dsub solder cups together by placing a section of wire between them and soldering it all together. I did that for 3 of the cups and connected ground wires from the transponder and encoder to this. I wanted a 20 awg ground from the encoder, but only had one spare 24 awg wire left over in the cable. I used a 22 awg along with this 24 awg wire for this. Diagram below.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

38.23 KB |

| Viewed: |

6139 Time(s) |

|

_________________

Dan |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|