|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

jeffrey-j-paris(at)excite

Guest

|

Posted: Sun Jun 05, 2011 3:51 pm Post subject: CHT issues on a 3300 Posted: Sun Jun 05, 2011 3:51 pm Post subject: CHT issues on a 3300 |

|

|

Dear Gurus of the Jabiru Engine World,

I am currently back in flight test mode after finishing the "B" mods to my Zenith CH601XL. Before the Mods I was having CHT issues with the engine after I had installed the recommended " economy carb tuning kit" from Jabiru USA when we attended their excellent engine seminar. Since then I have been battling High CHT's on my #2, #3, #4, #5 cylinders. #1 runs cool and #6 is in the 260 F range.

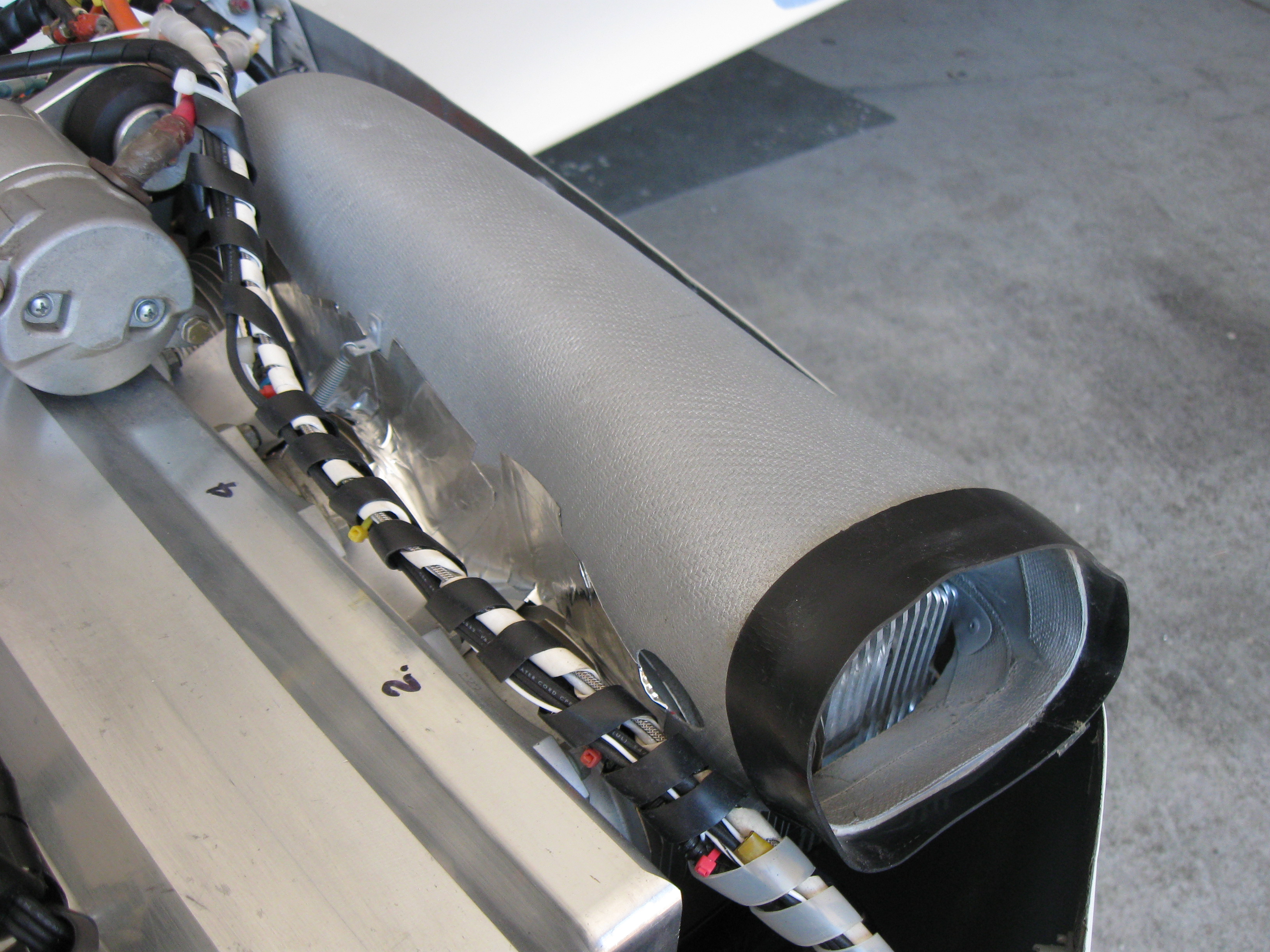

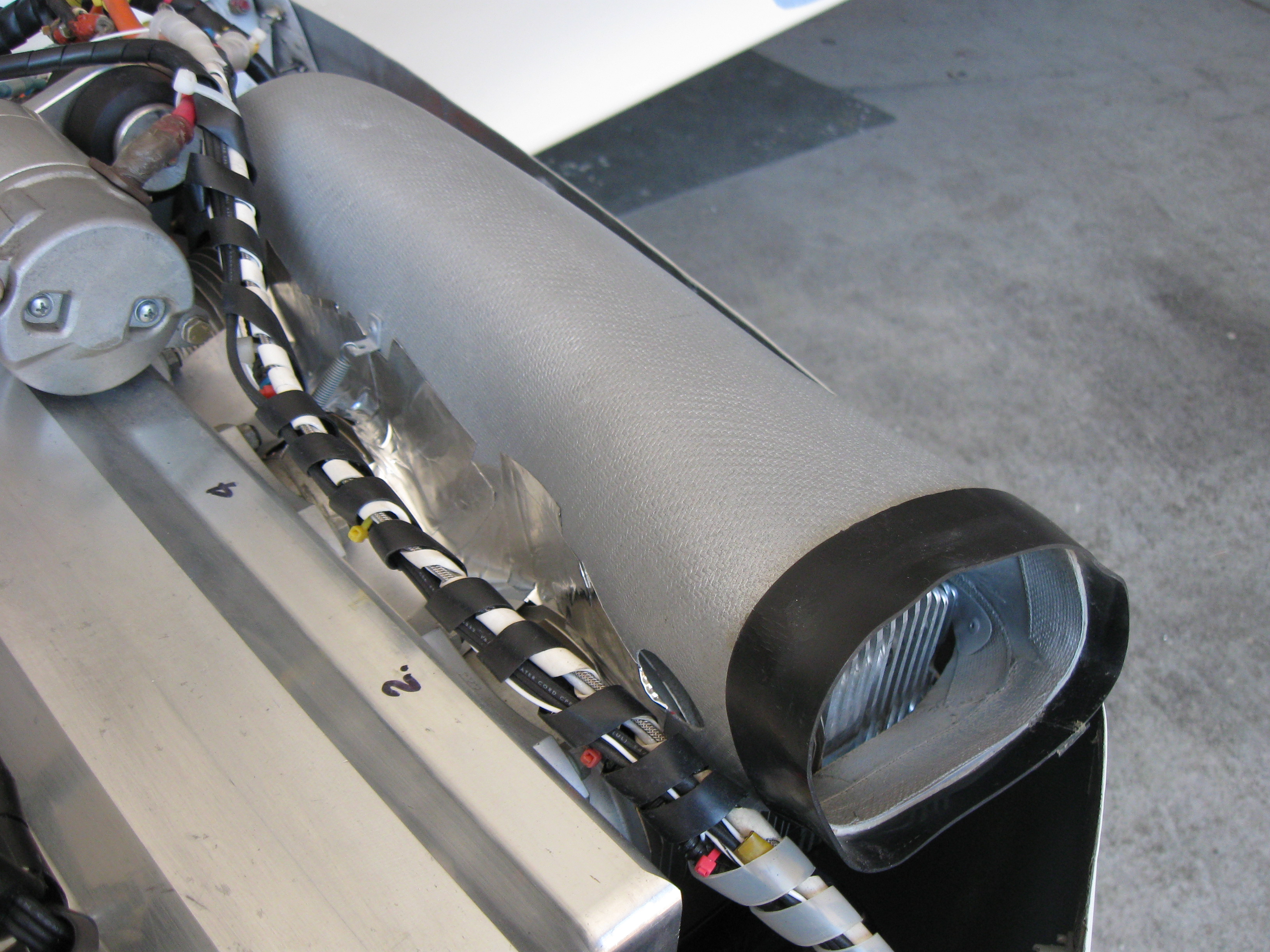

I have attempted all sorts of methods in an attempt to improve the cooling of my heads. (See attached pictures) During my second to last flight I removed all of my "enhancements" and just went back to factory FWF. Here are the known Facts of my engine:

A) All CHT senders are placed between the plug and a washer (per Pete Krotje of Jab USA)

B) I added a fiberglass cross flow to my rubber elbow to "smooth" out the air in my induction system into the carb.

C) Jettting in the Carb Main Jet #255 Needle Jet #285 ( Per Ben Krotje Jab USA)

D) My Flight Today in stabilized cruise of 2300 RPM to get my lowest CHT #'s:

Cylinder # EGT CHT

1 † 1320 256

2 † 1302 313

3 † 1306 335

4 † 1343 324

5 † 1212 296

6 † 1308 251

E) Oil temp 198 degrees F

F) Pulled plugs burning a nice tan color, exhaust soot is a nice grayish tan as well.

G) Engine starts on first throw of the starter key, but I have to get throttle up or she stalls with the choke-on ( result of Economy tuning mods)

H)m Warm engine start is a no brainer.

Any RPMs past 2300 up to 3000 results in cylinders 2, 3,4, 5 †approaching and hitting 350 degress F. I pull back on the throttle and aim my nose down to get things at least into the "yellow zone" of my AuRacle Engine Monitor indications. I have tried all sorts of baffling, extending the lip on my cowls exit for airflow, played with the jetting and induction system of my carb, and listened to all the suggestion threads on the internet and still haven't got things under control.

Any ideas or insights, pictures would be of great help. Thanks for your time and consideration.

Cheers,

Jeff Paris Jab 3300 Zenith Ch601XLB and Jab 3300 Europa Monowheel Classic Rochester, NY KSDC

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

1.92 MB |

| Viewed: |

12900 Time(s) |

|

| Description: |

|

| Filesize: |

448.13 KB |

| Viewed: |

12900 Time(s) |

|

| Description: |

|

| Filesize: |

280.41 KB |

| Viewed: |

12900 Time(s) |

|

|

|

| Back to top |

|

|

aerobiz1(at)gmail.com

Guest

|

Posted: Sun Jun 05, 2011 7:13 pm Post subject: CHT issues on a 3300 Posted: Sun Jun 05, 2011 7:13 pm Post subject: CHT issues on a 3300 |

|

|

Hi Jeff,

This is what has worked for me.......

1. Measure your actual Main Jet orifice with a metric drill or guage. I found the stamped size (#255 was actually #250, so I took it out to #260 - so from 2.5mm to 2.6mm)

2. Removed the plenum chamber airfoil-shaped flow divider and placed a 1/2 inch diam tube/rod in its place.

3. Drilled the main airbleed out to 3/16 inch _ that's the one that goes from the intake bellmouth straight to the needle jet emulsion tube.  Remove these, drill airbleed carefully and remove swarf, then before replacing the separate emulsion tube with its 4 x 2.5 mm holes, drill these 4 holes out to 3mm.

While you are about it, you can drill out the choke system fuel bleed jet in the float bowl to 1 - 1.2 mm, and the idle airbleed jet in the bellmouth to 1.2 mm and use #35 pilot jet.

FWIW,

Martin

J230

On Mon, Jun 6, 2011 at 9:47 AM, Jeffrey J Paris <jeffrey-j-paris(at)excite.com (jeffrey-j-paris(at)excite.com)> wrote:

[quote]

Dear Gurus of the Jabiru Engine World,

I am currently back in flight test mode after finishing the "B" mods to my Zenith CH601XL. Before the Mods I was having CHT issues with the engine after I had installed the recommended " economy carb tuning kit" from Jabiru USA when we attended their excellent engine seminar.  Since then I have been battling High CHT's on my #2, #3, #4, #5 cylinders.  #1 runs cool and #6 is in the 260 F range.

I have attempted all sorts of methods in an attempt to improve the cooling of my heads.  (See attached pictures)  During my second to last flight I removed all of my "enhancements" and just went back to factory FWF.  Here are the known Facts of my engine:

A)  All CHT senders are placed between the plug and a washer (per Pete Krotje of Jab USA)

B) I added a fiberglass cross flow to my rubber elbow to "smooth" out the air in my induction system into the carb.

C) Jettting in the Carb  Main Jet #255 Needle Jet #285 ( Per Ben Krotje Jab USA)

D)  My Flight Today in stabilized cruise of 2300 RPM to get my lowest CHT #'s:

Cylinder #        EGT         CHT

1                        1320        256

2                        1302        313

3                        1306        335

4                        1343        324

5                        1212        296

6                        1308        251

E) Oil temp 198 degrees F

F) Pulled plugs burning a nice tan color, exhaust soot is a nice grayish tan as well.

G)  Engine starts on first throw of the starter key, but I have to get throttle up or she stalls with the choke-on ( result of Economy tuning mods)

H)m  Warm engine start is a no brainer.

Any RPMs past 2300 up to 3000 results in cylinders 2, 3,4, 5  approaching and hitting 350 degress F.  I pull back on the throttle and aim my nose down to get things at least into the "yellow zone" of my AuRacle Engine Monitor indications.  I have tried all sorts of baffling, extending the lip on my cowls exit for airflow,  played with the jetting and induction system of my carb, and listened to all the suggestion  threads on the internet and still haven't got things under control.

Any ideas or insights, pictures would be of great help.  Thanks for your time and consideration.

Cheers,

Jeff Paris   Jab 3300 Zenith Ch601XLB  and Jab 3300 Europa Monowheel Classic   Rochester, NY KSDC

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Clive J

Joined: 03 Nov 2007

Posts: 340

Location: UK

|

Posted: Mon Jun 06, 2011 12:31 am Post subject: CHT issues on a 3300 Posted: Mon Jun 06, 2011 12:31 am Post subject: CHT issues on a 3300 |

|

|

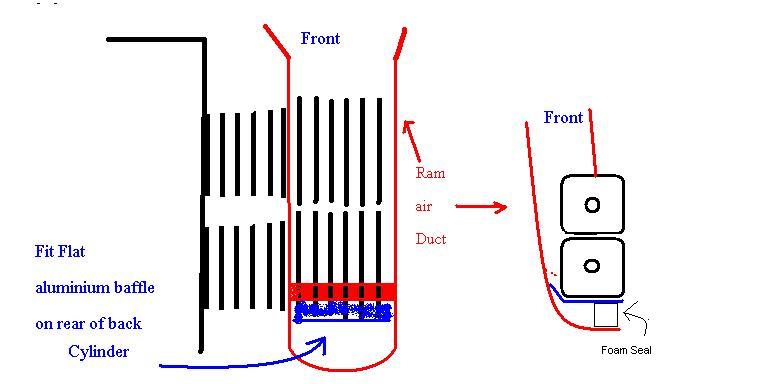

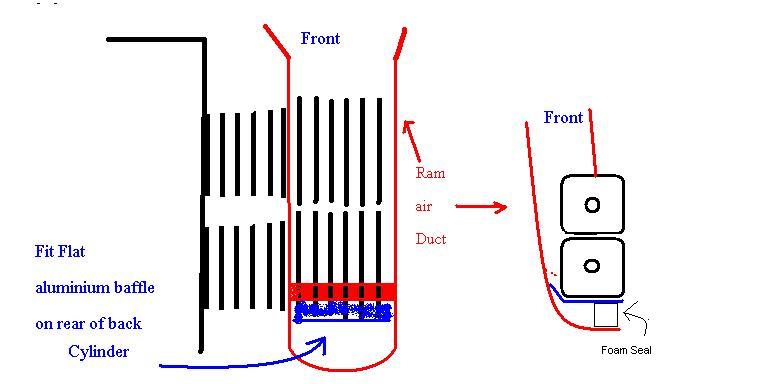

Hi Jeff, those look to be the narrrow air ducts with plugs caps outside. There is a bigger set if your cowls will take them?

Regarding the inlet holes I know there is a school of thought that with the shape you have the air can struggle to go in and would rather go over the top of the cowl.

Try a 'brow' to the holes, tape a strip of card or something over the top coming forward to see if you aren't capturing the air flow.

What's going on at the back cylinder? Is there a space for the air to escape without doing anything? My early 2200 ducts had a hole at the back you could put your hand up (see sketch).

The air will always take the easy way out. You do have the blanks in between the barrels to stop the air getting out that way? I can see a way out at the front on the front cylinder, close those gaps also.

Aside from that......

Good luck, regards, Clive

From: owner-jabiruengine-list-server(at)matronics.com [mailto:owner-jabiruengine-list-server(at)matronics.com] On Behalf Of Jeffrey J Paris

Sent: 06 June 2011 00:47

To: jabiruengines(at)yahoogroups.com; jabiruengine-list(at)matronics.com

Subject: CHT issues on a 3300

Dear Gurus of the Jabiru Engine World,

I am currently back in flight test mode after finishing the "B" mods to my Zenith CH601XL. Before the Mods I was having CHT issues with the engine after I had installed the recommended " economy carb tuning kit" from Jabiru USA when we attended their excellent engine seminar. Since then I have been battling High CHT's on my #2, #3, #4, #5 cylinders. #1 runs cool and #6 is in the 260 F range.

I have attempted all sorts of methods in an attempt to improve the cooling of my heads. (See attached pictures) During my second to last flight I removed all of my "enhancements" and just went back to factory FWF. Here are the known Facts of my engine:

A) All CHT senders are placed between the plug and a washer (per Pete Krotje of Jab USA)

B) I added a fiberglass cross flow to my rubber elbow to "smooth" out the air in my induction system into the carb.

C) Jettting in the Carb Main Jet #255 Needle Jet #285 ( Per Ben Krotje Jab USA)

D) My Flight Today in stabilized cruise of 2300 RPM to get my lowest CHT #'s:

Cylinder # EGT CHT

1 1320 256

2 1302 313

3 1306 335

4 1343 324

5 1212 296

6 1308 251

E) Oil temp 198 degrees F

F) Pulled plugs burning a nice tan color, exhaust soot is a nice grayish tan as well.

G) Engine starts on first throw of the starter key, but I have to get throttle up or she stalls with the choke-on ( result of Economy tuning mods)

H)m Warm engine start is a no brainer.

Any RPMs past 2300 up to 3000 results in cylinders 2, 3,4, 5 approaching and hitting 350 degress F. I pull back on the throttle and aim my nose down to get things at least into the "yellow zone" of my AuRacle Engine Monitor indications. I have tried all sorts of baffling, extending the lip on my cowls exit for airflow, played with the jetting and induction system of my carb, and listened to all the suggestion threads on the internet and still haven't got things under control.

Any ideas or insights, pictures would be of great help. Thanks for your time and consideration.

Cheers,

Jeff Paris Jab 3300 Zenith Ch601XLB and Jab 3300 Europa Monowheel Classic Rochester, NY KSDC

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

30.74 KB |

| Viewed: |

12889 Time(s) |

|

|

|

| Back to top |

|

|

wb2ssj(at)frontiernet.net

Guest

|

Posted: Mon Jun 06, 2011 2:48 am Post subject: CHT issues on a 3300 Posted: Mon Jun 06, 2011 2:48 am Post subject: CHT issues on a 3300 |

|

|

Jeff, call me tonight. Tex 223-3220

[quote] ---

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

info(at)flylightning.net

Guest

|

Posted: Mon Jun 06, 2011 12:33 pm Post subject: CHT issues on a 3300 Posted: Mon Jun 06, 2011 12:33 pm Post subject: CHT issues on a 3300 |

|

|

Jeff,

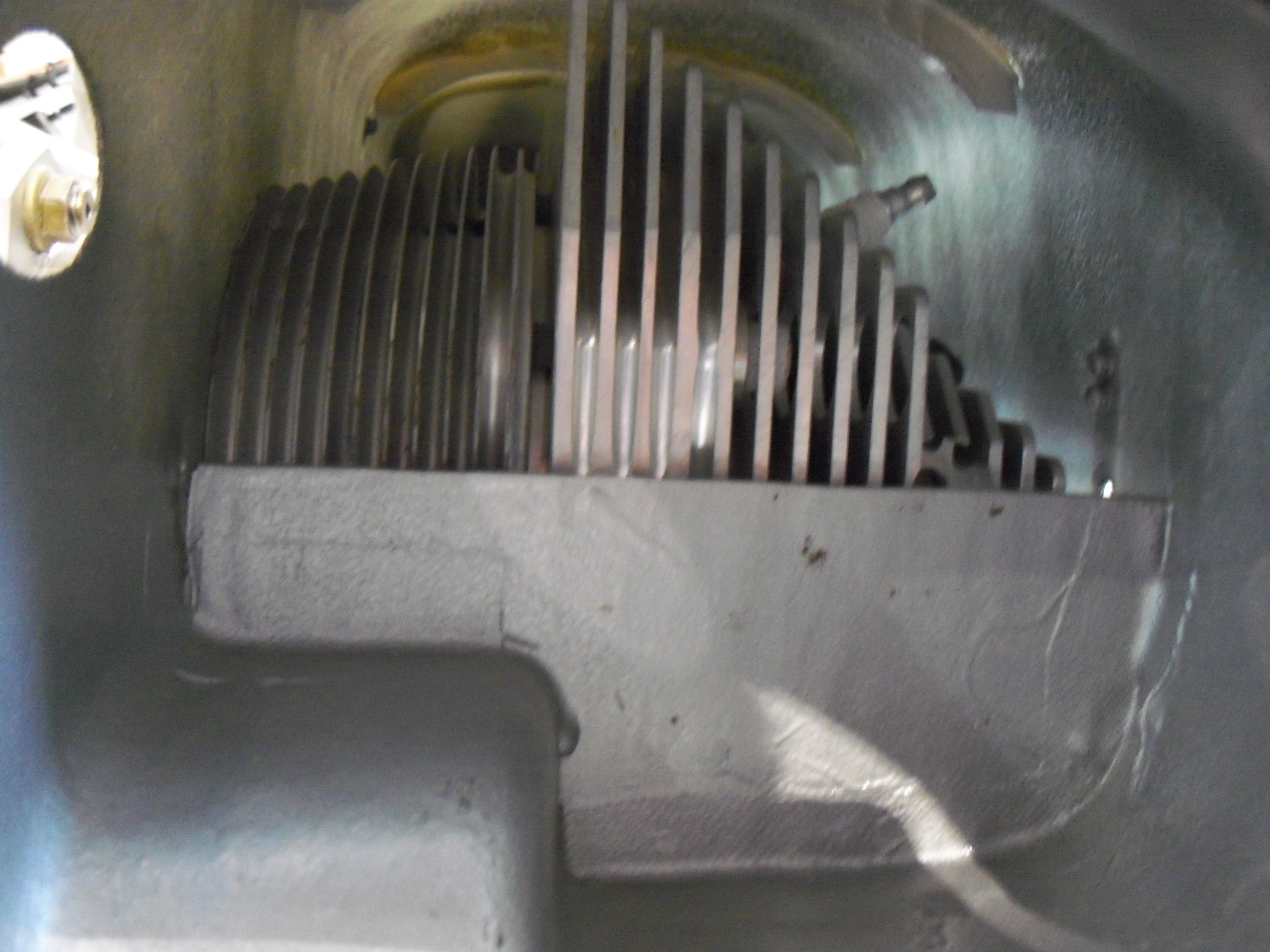

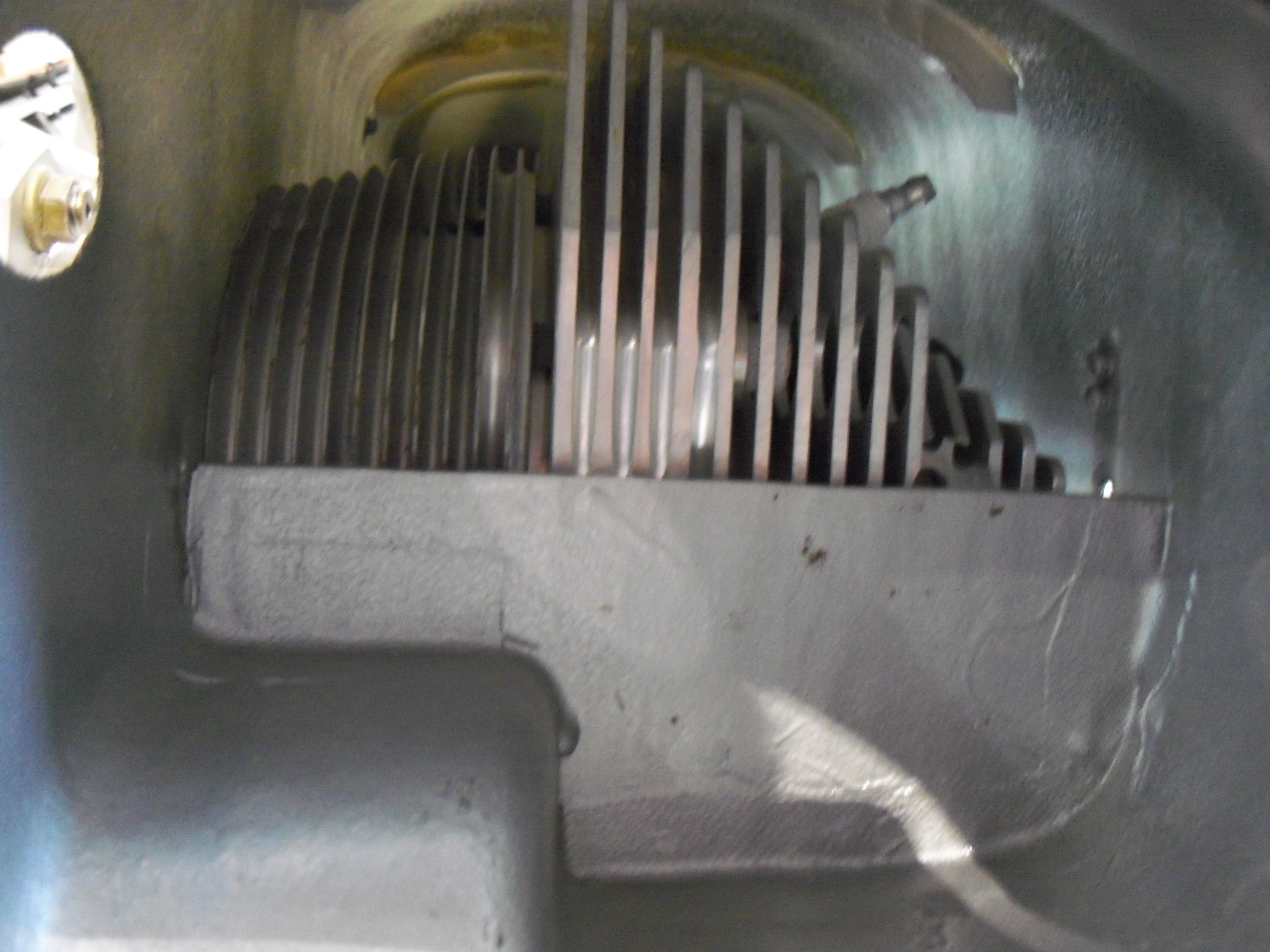

One thing missing is the dam in the front of the air-duct. This starts in the bottom of the duct and runs up to about the welsh plug in the head above the rocker shaft, may be about 2” tall.

If both ducts are like this in the front the majority of your cooling air is going underneath the front cylinder. This will also contribute to a lower pressure differential between the cowl and the duct, limiting the amount of air passing the cylinders.

I can provide a picture or two if you like.

Nick Otterback

Arion Aircraft

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

info(at)flylightning.net

Guest

|

Posted: Mon Jun 06, 2011 12:39 pm Post subject: CHT issues on a 3300 Posted: Mon Jun 06, 2011 12:39 pm Post subject: CHT issues on a 3300 |

|

|

Jeff,

Along with my last email here is a picture. These are a new set of ducts, however it is important to put this air-dam in the front of the older ones as well.

Note in the right side of the picture is a cut out in the fins and a small half moon shape plug visible. That plug is for an oil galley, I would suggest making that dam this tall.

Thanks

Nick Otterback

Arion Aircraft

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

1.3 MB |

| Viewed: |

12879 Time(s) |

|

|

|

| Back to top |

|

|

jeffrey-j-paris(at)excite

Guest

|

Posted: Tue Jun 07, 2011 12:48 pm Post subject: CHT issues on a 3300 Posted: Tue Jun 07, 2011 12:48 pm Post subject: CHT issues on a 3300 |

|

|

Dear Jabiru 3300 Guru's,

First of all thank you for all of your input I appreciate as I battle the heat demons in my cowl. Yesterday I spent the day working on my CHT cooling issues. I have attached some pictures for everyone to look at. †Anyways in addition to adding some aluminum sheet which profiles and seals in inboard baffles to the cylinders I attempted to add airdams to the front of the baffles, per Nick Otterback's suggestion. In addition, I added some rubber stuffing to seal up the back of baffles and I added rubber washers over each sparkplug to seal up and air leaks from the plugs as they protrude through the old style baffles.

First flight today yielded these numbers in cruise:

RPM 2500-Note had to use to keep CHTs in at least the yellow range. All powered climbs yielded high temps approachin 350F. air temp at time of flight was 75 F and oil temp was 212F.

Cylinder EGT (F) CHT (F)

1 1315 265

2 1271 330

3 1311 315

4 1353 315

5 1219 326

6 1338 292

RPM 2400-Note had to use to keep CHTs in at least the yellow range. All powered climbs yielded high temps approachin 350F. In addition, I changed these items I removed the rubber from the back of the baffles, removed the butterfly baffles from underneath the cylinders, and added improved airdams to the fron of the 2,4,6 cylinder bank. Outside temp at flight was 88 F Oil Temp. 212F

Cylinder EGT (F) CHT (F)

1 1285 256

2 1258 316

3 1282 318

4 1347 315

5 1204 271

In a sense I have made some progress. However, I cannot do a normal rate of climb without cylinders 2,3,4,5 heading for the races towards 350F and I can't even imagine what temps I would see at max gross weight with a passenger. So I am obviously not getting the utility out of the aircraft as I would like.

Thanks for your time and consideration. I just want to go out flying like the old days before I messed things up! LOL

Cheers Jeff Paris 2 Jabs in the nest/both sick

2514.jpg Shows a "scoop" that I added to aid in my old style oil cooler Seems to work temps on cooler days 190F hot days 212F.

2515.jpg Top of engine looking forward.

2529.jpg I added some aluminum sheet, cut precisely to the cylinder profile to seal up both inside baffles.

2530.jpg Per Nick Otterback's / Flylightning suggestion I added an air dam to the front right baffle on the 2,4,6 cylinder bank

2531.jpg Shows the 1,3,5 cylinder baffle entrance

2532.jpg I experimented with adding the butterfly cylinder baffles to the underside of the cylinders, I tested them during my first flight today and removed them for the second flight

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

301.76 KB |

| Viewed: |

12859 Time(s) |

|

| Description: |

|

| Filesize: |

304.41 KB |

| Viewed: |

12859 Time(s) |

|

| Description: |

|

| Filesize: |

296.32 KB |

| Viewed: |

12859 Time(s) |

|

| Description: |

|

| Filesize: |

268.04 KB |

| Viewed: |

12859 Time(s) |

|

| Description: |

|

| Filesize: |

281.84 KB |

| Viewed: |

12859 Time(s) |

|

| Description: |

|

| Filesize: |

243.04 KB |

| Viewed: |

12859 Time(s) |

|

|

|

| Back to top |

|

|

aerobiz1(at)gmail.com

Guest

|

Posted: Tue Jun 07, 2011 1:39 pm Post subject: CHT issues on a 3300 Posted: Tue Jun 07, 2011 1:39 pm Post subject: CHT issues on a 3300 |

|

|

Jeff,

I reckon the angle that your oil cooler is presenting to the incoming air is too great.  A normal tube and fin radiator like that does NOT like any more than 20 degrees before the air 'bounces' off.  Less than 7 degrees is ideal.

Remind me, what instrumentation are you using to gain these numbers ?

We have had issues with a Dynon reading high....

Martin

On Wed, Jun 8, 2011 at 6:44 AM, Jeffrey J Paris <jeffrey-j-paris(at)excite.com (jeffrey-j-paris(at)excite.com)> wrote:

[quote] Dear Jabiru 3300 Guru's,

First of all thank you for all of your input I appreciate as I battle the heat demons in my cowl.  Yesterday I spent the day working on my CHT cooling issues.  I have attached some pictures for everyone to look at.  Anyways in addition to adding some aluminum sheet which profiles and seals in inboard baffles to the  cylinders I attempted to add airdams to the front of the baffles, per Nick Otterback's suggestion.  In addition, I added some rubber stuffing to seal up the back of baffles and I added rubber washers over each sparkplug to seal up and air leaks from the plugs as they protrude through the old style baffles.

First flight today yielded these numbers in cruise:

RPM 2500-Note had to use to keep CHTs in at least the yellow range. All powered climbs yielded high temps approachin 350F. air temp at time of flight was 75 F  and oil temp was 212F.

Cylinder      EGT (F)       CHT (F)

1                   1315            265

2                   1271            330

3                   1311            315

4                   1353            315

5                   1219            326

6                   1338            292

RPM 2400-Note had to use to keep CHTs in at least the yellow range. All powered climbs yielded high temps approachin 350F.  In addition, I changed these items I removed the rubber from the back of the baffles, removed the butterfly baffles from underneath the cylinders, and added improved airdams to the fron of the 2,4,6 cylinder bank.  Outside temp at flight was 88 F  Oil Temp.  212F

Cylinder      EGT (F)       CHT (F)

1                   1285            256

2                   1258            316

3                   1282            318

4                   1347            315

5                   1204            271

In a sense I have made some progress.  However,  I cannot do a normal rate of climb without cylinders 2,3,4,5 heading for the races towards 350F  and I can't even imagine what temps I would see at max gross weight with a passenger.  So I am obviously not getting the utility out of the aircraft as I would like.

Thanks for your time and consideration.  I just want to go out flying like the old days before I messed things up!  LOL

Cheers Jeff Paris  2 Jabs in the nest/both sick

2514.jpg   Shows a "scoop" that I added to aid in my old style oil cooler Seems to work temps on cooler days 190F  hot days 212F.

2515.jpg   Top of engine looking forward.

2529.jpg   I added some aluminum sheet, cut precisely to the cylinder profile to seal up both inside baffles.

2530.jpg  Per Nick Otterback's / Flylightning suggestion I added an air dam to the front right baffle on the 2,4,6 cylinder bank

2531.jpg  Shows the 1,3,5 cylinder baffle entrance

2532.jpg   I experimented with adding the butterfly cylinder baffles to the underside of the cylinders, I tested them during my first flight today and                    removed them for the second flight

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

jerryvmd

Joined: 18 Apr 2008

Posts: 25

|

Posted: Wed Jun 08, 2011 10:04 am Post subject: CHT issues on a 3300 Posted: Wed Jun 08, 2011 10:04 am Post subject: CHT issues on a 3300 |

|

|

Jeff,

I had similar issues early on. Check the archives as there is alot of

info on cooling issues. Two things that worked for me. 1. It appears

that your air dams at the entrance to the Ram Ducts my be too low. 2.

Remove some of the cowl on the bottom half at the air exit around the

nose wheel strut. Then temporarily duct tape a piece of aluminum to

make the rim bevel larger. This causes a negative air pressure actually

drawing more air out the bottom. In effect creating more air moving

from the inlets through the cowl/cylinders to the exit. The size of the

exit hole is important but the larger lip helped alot. I now have the

opposite problem. In the winter my cylinder head temps tend to run cold

(several read only 220 to 250) with a Grand Rapids EIS. In summer

(Pennsylvania) in a long climb number 3 cylinder might get to 350 but

returns to upper 200's after lowering nose to cruise.

Jerry

On 6/7/2011 4:44 PM, Jeffrey J Paris wrote:

| Quote: | Dear Jabiru 3300 Guru's,

First of all thank you for all of your input I appreciate as I battle

the heat demons in my cowl. Yesterday I spent the day working on my

CHT cooling issues.

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

dons701

Joined: 22 May 2009

Posts: 80

Location: Hershey, PA

|

Posted: Wed Jun 08, 2011 10:26 am Post subject: Re: CHT issues on a 3300 Posted: Wed Jun 08, 2011 10:26 am Post subject: Re: CHT issues on a 3300 |

|

|

Exactly what I had to do with my CH701 Jerry. Cut the exit much larger and bought some white aluminum flashing to make a 4 inch lip to start with. My temps took a dive. My inlets are about 3 to 4 times the size of Jeff's much faster plane......Don B

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Zenith 701 #76120

Jabiru 2200A #2456 95 hours

Sensenich Wood 64-PJ-36 Prop |

|

| Back to top |

|

|

Clive J

Joined: 03 Nov 2007

Posts: 340

Location: UK

|

Posted: Wed Jun 08, 2011 12:11 pm Post subject: CHT issues on a 3300 Posted: Wed Jun 08, 2011 12:11 pm Post subject: CHT issues on a 3300 |

|

|

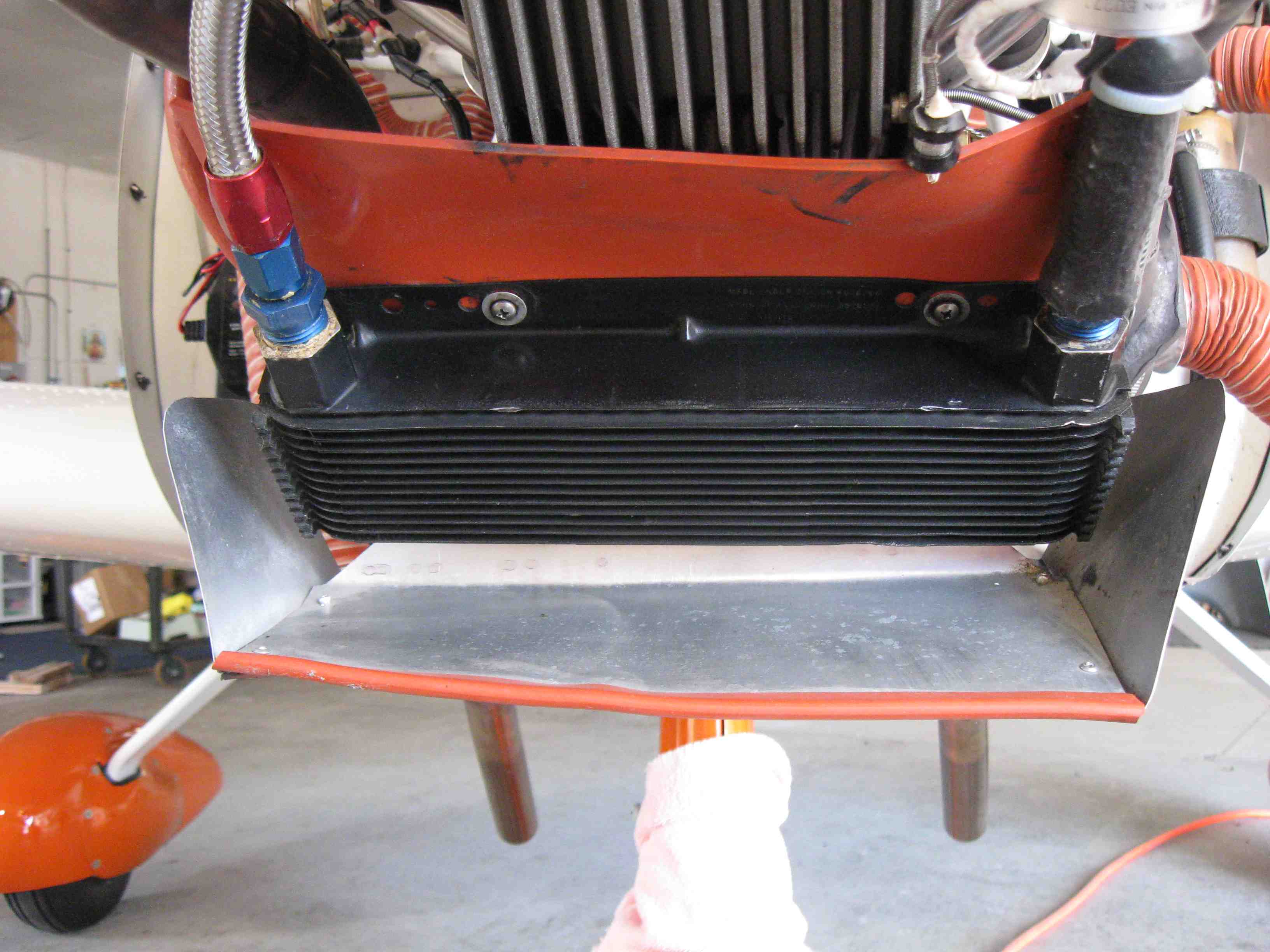

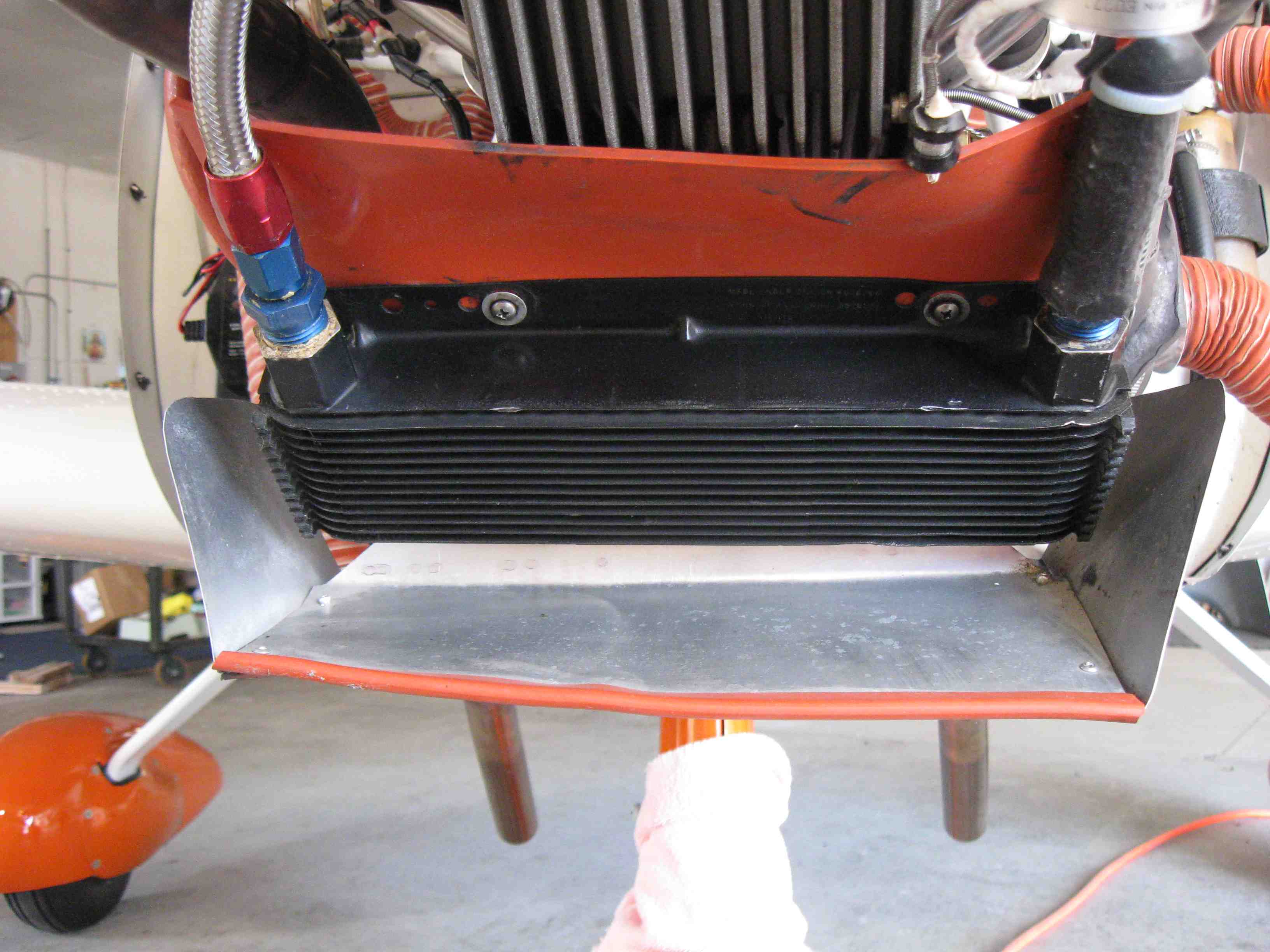

When I had the Rotax cowl on my Esqual I got a step change in the

cooling by adding an outlet baffle.

It went back three times as far as it went down, so it was more

streamlined than the 'lips' that I've seen added by others. I don't have

a picture of mine but I do of the one I copied, Dave Mc was good enough

to send me the attached.

If you think about it, a hanging baffle on the cowl outlet will create

some suction but not as much as something more streamlined. I cured my

head cooling with the duct like this but went on to change to a new cowl

for oil cooling reasons.

I would recommend trying a more streamlined 'baffle/duct' on the outlet.

Regarding the dam on the inlet, there is a school of thought that the

tumbling effect of a vertical baffle is better than a 'ramp' I recall

someone trying both and finding the vertical baffle better.

The hanging baffles inside the ducts that restrict airflow, restrict

airflow so there is a balance between how much they restrict and how

much they deflect, any restriction is not a good thing with marginal

cooling.

Roger mentioned the smoke test's to see where the airflow goes, this

will show mow much air gets deflected over the cowl and so bypasses the

ram air entry. Another reason why creating more 'pull' on the outlet is

so successful.....IMHO.

Regards, Clive

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

40.85 KB |

| Viewed: |

12845 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|