|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Phil(at)ReliantAir.com

Guest

|

Posted: Mon Oct 17, 2011 8:33 am Post subject: Cowl Install Posted: Mon Oct 17, 2011 8:33 am Post subject: Cowl Install |

|

|

Gary, finally working on installing the new cowling on my Grumman. Some questions

<![if !supportLists]>- <![endif]>Do you put the plexiglass cover over the landing light as it is on the original cowl, or do you leave it off?

<![if !supportLists]>- <![endif]>On the powerflow exhaust do you align the muffler with the longitudinal axis or angle it slightly outboard?

<![if !supportLists]>- <![endif]>Do you cut the cowling in such a way as to be able to remove the right hand side of the bottom cowling without removing the muffler? I assume that to do that you fabricate a plate to close the slot and maintain integrity of the cowl.

Phil Kelsey

ReliantAir

From: owner-teamgrumman-list-server(at)matronics.com [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary Vogt

Sent: Thursday, October 06, 2011 13:45

To: teamgrumman-list(at)matronics.com

Subject: Re: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Pete,

I've made 3 different fairings that fit behind the short stack. The short one worked the best. Plus, it fits up snug behind the pipe so it closes the hole created when you cut out the exit ramp. I can have Dave make you one for $100 with shipping. You'll need to do some trial and error on the mounting to get the least drag.

My 77 Cheetah would true out at about 140 knots. That's running over redline. McCauley prop. Stock exhaust. It was light too. One radio. One GPS. No VOR. But, even with ported and polished cylinders and the HC mod, a loaded Tiger would out climb it.

Lots of drag. I buried the comm antennas, got rid of the VOR antennas and steps.

I restored a 77 Cheetah a few years back. He did everything to that plane. With a New LyCon engine and Sensenich prop, he could true at 142 knots at 2800 RPM with the steps and VOR antennas.

Gary

From: Pete Kuhns <pkuhns(at)gmail.com>

To: teamgrumman-list(at)matronics.com

Sent: Thursday, October 6, 2011 7:32 AM

Subject: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Gary: My plane has the short stack Powerflow exhaust. I think it's kinda draggy up there and was wondering if you ever made some covering for it that reduced it's airflow 'signature' (parasitic drag). The oil vent tube also is kinda draggy down there.

Just wondering where you found speed improvements on the Cheetah by reducing parasitic drag. Thank you!

-- Pete Kuhns

N27161, '79 Cheetah

GEZ, Shelbyville, IN

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18280)

http://www.pctools.com

=======

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Mon Oct 17, 2011 8:11 pm Post subject: Cowl Install Posted: Mon Oct 17, 2011 8:11 pm Post subject: Cowl Install |

|

|

1. The plexiglass goes between landing light housing and the cowling.

2. Good question. Actually, it needs to go just slightly in. Normally, I make it parallel to the longitudinal axis as a rule.

3. Cut the opening to the end of the ramp. You don't need to fill the opening. The airflow is out of the cowling. If it were an issue, I'd make you fill the hole behind the nose strut.

You can add another nut plate if you like to attach the open ends to the firewall.

Did you see the template I sent out for the cutout?

Gary

Sent from my iPad

On Oct 17, 2011, at 9:30 AM, "Phil Kelsey" <Phil(at)ReliantAir.com (Phil(at)ReliantAir.com)> wrote:

[quote]

Gary, finally working on installing the new cowling on my Grumman. Some questions

- Do you put the plexiglass cover over the landing light as it is on the original cowl, or do you leave it off?

- On the powerflow exhaust do you align the muffler with the longitudinal axis or angle it slightly outboard?

- Do you cut the cowling in such a way as to be able to remove the right hand side of the bottom cowling without removing the muffler? I assume that to do that you fabricate a plate to close the slot and maintain integrity of the cowl.

Phil Kelsey

ReliantAir

From: owner-teamgrumman-list-server(at)matronics.com (owner-teamgrumman-list-server(at)matronics.com) [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary Vogt

Sent: Thursday, October 06, 2011 13:45

To: [url=mailto:teamgrumman-list(at)matronics.com]teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)[/url]

Subject: Re: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Pete,

I've made 3 different fairings that fit behind the short stack. The short one worked the best. Plus, it fits up snug behind the pipe so it closes the hole created when you cut out the exit ramp. I can have Dave make you one for $100 with shipping. You'll need to do some trial and error on the mounting to get the least drag.

My 77 Cheetah would true out at about 140 knots. That's running over redline. McCauley prop. Stock exhaust. It was light too. One radio. One GPS. No VOR. But, even with ported and polished cylinders and the HC mod, a loaded Tiger would out climb it.

Lots of drag. I buried the comm antennas, got rid of the VOR antennas and steps.

I restored a 77 Cheetah a few years back. He did everything to that plane. With a New LyCon engine and Sensenich prop, he could true at 142 knots at 2800 RPM with the steps and VOR antennas.

Gary

From: Pete Kuhns <pkuhns(at)gmail.com (pkuhns(at)gmail.com)>

To: [url=mailto:teamgrumman-list(at)matronics.com]teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)[/url]

Sent: Thursday, October 6, 2011 7:32 AM

Subject: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Gary: My plane has the short stack Powerflow exhaust. I think it's kinda draggy up there and was wondering if you ever made some covering for it that reduced it's airflow 'signature' (parasitic drag). The oil vent tube also is kinda draggy down there.

Just wondering where you found speed improvements on the Cheetah by reducing parasitic drag. Thank you!

-- Pete Kuhns

N27161, '79 Cheetah

GEZ, Shelbyville, IN

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18280)

http://www.pctools.com

=======

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Phil(at)ReliantAir.com

Guest

|

Posted: Tue Oct 18, 2011 5:13 am Post subject: Cowl Install Posted: Tue Oct 18, 2011 5:13 am Post subject: Cowl Install |

|

|

Gary thanks for the info. I know I saw that template in my email at one time, can’t find it now. Could you resend it to me?

Phil

From: owner-teamgrumman-list-server(at)matronics.com [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary L Vogt

Sent: Monday, October 17, 2011 23:59

To: teamgrumman-list(at)matronics.com

Subject: Re: Cowl Install

1. The plexiglass goes between landing light housing and the cowling.

2. Good question. Actually, it needs to go just slightly in. Normally, I make it parallel to the longitudinal axis as a rule.

3. Cut the opening to the end of the ramp. You don't need to fill the opening. The airflow is out of the cowling. If it were an issue, I'd make you fill the hole behind the nose strut.

You can add another nut plate if you like to attach the open ends to the firewall.

Did you see the template I sent out for the cutout?

Gary

Sent from my iPad

On Oct 17, 2011, at 9:30 AM, "Phil Kelsey" <Phil(at)ReliantAir.com (Phil(at)ReliantAir.com)> wrote:

| Quote: |

Gary, finally working on installing the new cowling on my Grumman. Some questions

- Do you put the plexiglass cover over the landing light as it is on the original cowl, or do you leave it off?

- On the powerflow exhaust do you align the muffler with the longitudinal axis or angle it slightly outboard?

- Do you cut the cowling in such a way as to be able to remove the right hand side of the bottom cowling without removing the muffler? I assume that to do that you fabricate a plate to close the slot and maintain integrity of the cowl.

Phil Kelsey

ReliantAir

From: owner-teamgrumman-list-server(at)matronics.com (owner-teamgrumman-list-server(at)matronics.com) [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary Vogt

Sent: Thursday, October 06, 2011 13:45

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Subject: Re: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Pete,

I've made 3 different fairings that fit behind the short stack. The short one worked the best. Plus, it fits up snug behind the pipe so it closes the hole created when you cut out the exit ramp. I can have Dave make you one for $100 with shipping. You'll need to do some trial and error on the mounting to get the least drag.

My 77 Cheetah would true out at about 140 knots. That's running over redline. McCauley prop. Stock exhaust. It was light too. One radio. One GPS. No VOR. But, even with ported and polished cylinders and the HC mod, a loaded Tiger would out climb it.

Lots of drag. I buried the comm antennas, got rid of the VOR antennas and steps.

I restored a 77 Cheetah a few years back. He did everything to that plane. With a New LyCon engine and Sensenich prop, he could true at 142 knots at 2800 RPM with the steps and VOR antennas.

Gary

From: Pete Kuhns <pkuhns(at)gmail.com (pkuhns(at)gmail.com)>

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Sent: Thursday, October 6, 2011 7:32 AM

Subject: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Gary: My plane has the short stack Powerflow exhaust. I think it's kinda draggy up there and was wondering if you ever made some covering for it that reduced it's airflow 'signature' (parasitic drag). The oil vent tube also is kinda draggy down there.

Just wondering where you found speed improvements on the Cheetah by reducing parasitic drag. Thank you!

-- Pete Kuhns

N27161, '79 Cheetah

GEZ, Shelbyville, IN

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18280)

http://www.pctools.com

=======

|

01234567890123456

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18530)

http://www.pctools.com

=======

[quote][b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Oct 18, 2011 7:35 pm Post subject: Cowl Install Posted: Tue Oct 18, 2011 7:35 pm Post subject: Cowl Install |

|

|

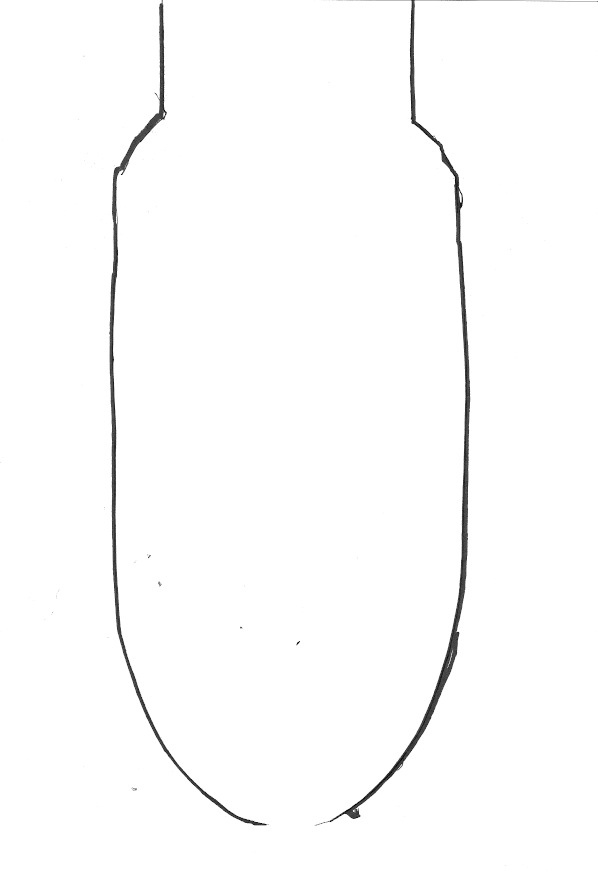

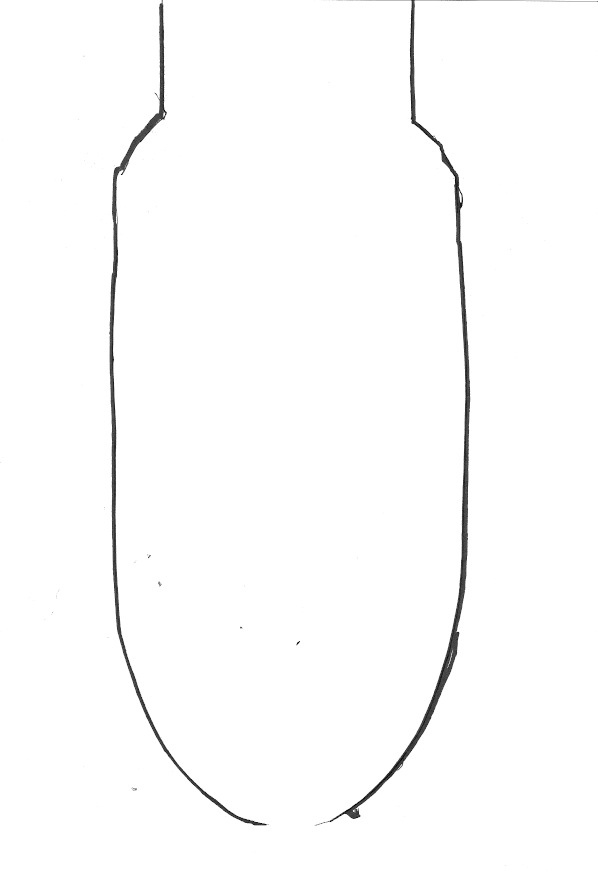

Phil,

Sure, no problem.

Here is the template.

From: Phil Kelsey <Phil(at)ReliantAir.com>

To: teamgrumman-list(at)matronics.com

Sent: Tuesday, October 18, 2011 6:10 AM

Subject: RE: Cowl Install

Gary thanks for the info. I know I saw that template in my email at one time, can’t find it now. Could you resend it to me?

Phil

From: owner-teamgrumman-list-server(at)matronics.com [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary L Vogt

Sent: Monday, October 17, 2011 23:59

To: teamgrumman-list(at)matronics.com

Subject: Re: TeamGrumman-List: Cowl Install

1. The plexiglass goes between landing light housing and the cowling.

2. Good question. Actually, it needs to go just slightly in. Normally, I make it parallel to the longitudinal axis as a rule.

3. Cut the opening to the end of the ramp. You don't need to fill the opening. The airflow is out of the cowling. If it were an issue, I'd make you fill the hole behind the nose strut.

You can add another nut plate if you like to attach the open ends to the firewall.

Did you see the template I sent out for the cutout?

Gary

Sent from my iPad

On Oct 17, 2011, at 9:30 AM, "Phil Kelsey" <Phil(at)ReliantAir.com (Phil(at)ReliantAir.com)> wrote:

| Quote: | Gary, finally working on installing the new cowling on my Grumman. Some questions

- Do you put the plexiglass cover over the landing light as it is on the original cowl, or do you leave it off?

- On the powerflow exhaust do you align the muffler with the longitudinal axis or angle it slightly outboard?

- Do you cut the cowling in such a way as to be able to remove the right hand side of the bottom cowling without removing the muffler? I assume that to do that you fabricate a plate to close the slot and maintain integrity of the cowl.

Phil Kelsey

ReliantAir

From: owner-teamgrumman-list-server(at)matronics.com (owner-teamgrumman-list-server(at)matronics.com) [mailto:owner-teamgrumman-list-server(at)matronics.com] On Behalf Of Gary Vogt

Sent: Thursday, October 06, 2011 13:45

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Subject: Re: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Pete,

I've made 3 different fairings that fit behind the short stack. The short one worked the best. Plus, it fits up snug behind the pipe so it closes the hole created when you cut out the exit ramp. I can have Dave make you one for $100 with shipping. You'll need to do some trial and error on the mounting to get the least drag.

My 77 Cheetah would true out at about 140 knots. That's running over redline. McCauley prop. Stock exhaust. It was light too. One radio. One GPS. No VOR. But, even with ported and polished cylinders and the HC mod, a loaded Tiger would out climb it.

Lots of drag. I buried the comm antennas, got rid of the VOR antennas and steps.

I restored a 77 Cheetah a few years back. He did everything to that plane. With a New LyCon engine and Sensenich prop, he could true at 142 knots at 2800 RPM with the steps and VOR antennas.

Gary

From: Pete Kuhns <pkuhns(at)gmail.com (pkuhns(at)gmail.com)>

To: teamgrumman-list(at)matronics.com (teamgrumman-list(at)matronics.com)

Sent: Thursday, October 6, 2011 7:32 AM

Subject: Short-stack Powerflow exhaust - aerodynamic cover for it?

Hi Gary: My plane has the short stack Powerflow exhaust. I think it's kinda draggy up there and was wondering if you ever made some covering for it that reduced it's airflow 'signature' (parasitic drag). The oil vent tube also is kinda draggy down there.

Just wondering where you found speed improvements on the Cheetah by reducing parasitic drag. Thank you!

-- Pete Kuhns

N27161, '79 Cheetah

GEZ, Shelbyville, IN

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18280)

http://www.pctools.com

=======

|

01234567890123456

=======

Email scanned by PC Tools - No viruses or spyware found.

(Email Guard: 7.0.0.26, Virus/Spyware Database: 6.18530)

http://www.pctools.com

=======

7

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

25.11 KB |

| Viewed: |

1489 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|