|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

steve.freeman(at)syntaxds

Guest

|

Posted: Sun Dec 25, 2011 1:52 pm Post subject: Cracked Canopy Posted: Sun Dec 25, 2011 1:52 pm Post subject: Cracked Canopy |

|

|

Hi Guys,

We have all heard this story before…While installing the rear canopy on my 650 I got about a 3” crack. I stop drilled it and I am trying to decide if I can live with this or not. Roughly $650 to get a new canopy seems like a lot of money and I might wind up with the same thing again. Honestly, I am not sure how this happened. I was being super careful and I was not drilling in a location where there seemed to be any pressure. Well…it happened…It sucks but I have to move on.

Can any of you guys make recommendations for the best practice to repair the crack? I know it will never be perfect but I have heard some people have had a lot of luck. There are no spider web cracks. Just the one, it is clean and like I said I stop drilled it at the end. I have found a couple of products on AC Spruce, in particular INSTA-WELD but it says to clamp the parts together…this is not possible. Also, if I use some type of adhesive that will wick in to the crack, do I then use some type of epoxy to fill the stop drill hole?

Any help is always appreciated…

I hope everyone is having a great Christmas!

Steve

0235 Mounted will start wiring soon.

Moving along with fuselage..

[quote][b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

Ron Lendon

Joined: 10 Jan 2006

Posts: 685

Location: Clinton Twp., MI

|

Posted: Sun Dec 25, 2011 5:53 pm Post subject: Re: Cracked Canopy Posted: Sun Dec 25, 2011 5:53 pm Post subject: Re: Cracked Canopy |

|

|

Hey Steve,

Bryan Martin had that happen to his also and he used methyl Ethel, something or other, to repair the crack after stop drilling.

He monitors this list, perhaps he will reply. Otherwise, just look up his posts and you just might find how he did it.

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

_________________

Ron Lendon

WW Corvair with Roy's Garage 5th bearing

CH 601 XLB

N601LT - Flying

http://www.mykitlog.com/rlendon

Corvair Engine Prints:

https://sites.google.com/site/corvairenginedata/ |

|

| Back to top |

|

|

davgray(at)sbcglobal.net

Guest

|

Posted: Sun Dec 25, 2011 8:17 pm Post subject: Cracked Canopy Posted: Sun Dec 25, 2011 8:17 pm Post subject: Cracked Canopy |

|

|

This might be a good thread to pursue as it seems to happen too often.

I would like to hear from others that cracked a canopy. Details of drill type and size, temperature at time of drilling, and hole-to-edge distance.

Also, from those that did not have this problem..

I used a step drill, warmed the canopy over a warm air register, let the bit generate a little heat from friction as it cut, kept the drill perpendicular to the surface,

and did not accept the 7 mm edge distance that would have occurred on a few of my holes if I stuck entirely with the plans.

My closest edge distance is 27 mm after a small modification. Five years plus without any cracks.

Gary Ray

Zenith 601XL-B, William Wynne Corvair 0.060 over, Roy's 5th bearing,

Mark's Falcon Heads, Marvel Schebler MA3-SPA Carburetor, 175 Hrs TT

From: Steve Freeman (steve.freeman(at)syntaxds.com)

Sent: Sunday, December 25, 2011 4:49 PM

To: zenith-list(at)matronics.com (zenith-list(at)matronics.com)

Subject: Cracked Canopy

Hi Guys,

We have all heard this story beforeâ¦While installing the rear canopy on my 650 I got about a 3â crack. I stop drilled it and I am trying to decide if I can live with this or not. Roughly $650 to get a new canopy seems like a lot of money and I might wind up with the same thing again. Honestly, I am not sure how this happened. I was being super careful and I was not drilling in a location where there seemed to be any pressure. Wellâ¦it happenedâ¦It sucks but I have to move on.

Can any of you guys make recommendations for the best practice to repair the crack? I know it will never be perfect but I have heard some people have had a lot of luck. There are no spider web cracks. Just the one, it is clean and like I said I stop drilled it at the end. I have found a couple of products on AC Spruce, in particular INSTA-WELD but it says to clamp the parts togetherâ¦this is not possible. Also, if I use some type of adhesive that will wick in to the crack, do I then use some type of epoxy to fill the stop drill hole?

Any help is always appreciatedâ¦

I hope everyone is having a great Christmas!

Steve

0235 Mounted will start wiring soon.

Moving along with fuselage..

[quote]

href="http://www.aeroelectric.com">www.aeroelectric.com

href="http://www.buildersbooks.com">www.buildersbooks.com

href="http://www.homebuilthelp.com">www.homebuilthelp.com

href="http://www.matronics.com/contribution">http://www.matronics.com/chref="http://www.matronics.com/Navigator?Zenith-List">http://www.matronhref="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

jaybannist(at)cs.com

Guest

|

Posted: Mon Dec 26, 2011 7:28 am Post subject: Cracked Canopy Posted: Mon Dec 26, 2011 7:28 am Post subject: Cracked Canopy |

|

|

I did my canopy fabrication in the Summer (on purpose). Cold plastic is anxious to crack. I drilled the pilot holes for clecoes with a new drill bit that had about a 45 deg angle on the tip. I used that bit to drill right through the plastic into the bow. When I drilled the pilot holes out with a step drill bit for the washers, I got no cracking. I drilled one pilot hole way too close to the cut-out for the latch handle. I made a note to myself oi not use this hole. A year later when I went to fasten the bubble to the frame, I completely forgot that note and put a cleco in that hole. CRACK !! I quickly stop drilled the crack, but it kept running. I stop drilled again and it kept running. I finally stop drilled about a half inch beyond the end of the crack and that stopped it. In the end, I was able to cut the crack out to install a plastic air vent; so I never attempted to repair the crack. I did use one or two washers between the plastic and the bow at a couple of holes near the ends of the rear bow to insure that the screws didn't stress the plastic.

Jay

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

bryanmmartin

Joined: 10 Jan 2006

Posts: 1018

|

Posted: Mon Dec 26, 2011 7:55 am Post subject: Cracked Canopy Posted: Mon Dec 26, 2011 7:55 am Post subject: Cracked Canopy |

|

|

I had some small cracks from my drilling. I applied some methylene chloride with an insulin syringe. It wicked into the cracks and sealed them. I made sure to wipe off the excess immediately. The stuff works by dissolving the edges of the crack and fusing them together as it evaporates.

The water thin adhesive from ACS should work as well, it's probably the same ingredient. I didn't worry about the stop holes because they are hidden by the lower flashing. A little dab of Shoe-Goo or something similar might plug the hole.

On Dec 25, 2011, at 4:49 PM, Steve Freeman wrote:

| Quote: |

Can any of you guys make recommendations for the best practice to repair the crack? I know it will never be perfect but I have heard some people have had a lot of luck. There are no spider web cracks. Just the one, it is clean and like I said I stop drilled it at the end. I have found a couple of products on AC Spruce, in particular INSTA-WELD but it says to clamp the parts together

this is not possible. Also, if I use some type of adhesive that will wick in to the crack, do I then use some type of epoxy to fill the stop drill hole?

|

--

Bryan Martin

N61BM, CH 601 XL,

RAM Subaru, Stratus re-drive.

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

_________________

--

Bryan Martin

N61BM, CH 601 XL, Stratus Subaru.

do not archive. |

|

| Back to top |

|

|

jlatimer1(at)cox.net

Guest

|

Posted: Mon Dec 26, 2011 5:15 pm Post subject: Cracked Canopy Posted: Mon Dec 26, 2011 5:15 pm Post subject: Cracked Canopy |

|

|

Steve,

Sounds like you are making steady progress. Still plan on a trip to DVT to see your project.

I have a crack in my HDS canopy. It is more than 3inches long. I stopped drilled then applied a strip of "Slap Stix". Glide pilots have used it for years. It works fine. The plane has 130 hours on it and no problem.

Here is a link to where I ordered it.

http://www.skysailing.com/pages/slapstix.htm

Jerry

Flying and having a great time.

From: owner-zenith-list-server(at)matronics.com [mailto:owner-zenith-list-server(at)matronics.com] On Behalf Of Steve Freeman

Sent: Sunday, December 25, 2011 2:49 PM

To: zenith-list(at)matronics.com

Subject: Cracked Canopy

Hi Guys,

We have all heard this story before…While installing the rear canopy on my 650 I got about a 3” crack. I stop drilled it and I am trying to decide if I can live with this or not. Roughly $650 to get a new canopy seems like a lot of money and I might wind up with the same thing again. Honestly, I am not sure how this happened. I was being super careful and I was not drilling in a location where there seemed to be any pressure. Well…it happened…It sucks but I have to move on.

Can any of you guys make recommendations for the best practice to repair the crack? I know it will never be perfect but I have heard some people have had a lot of luck. There are no spider web cracks. Just the one, it is clean and like I said I stop drilled it at the end. I have found a couple of products on AC Spruce, in particular INSTA-WELD but it says to clamp the parts together…this is not possible. Also, if I use some type of adhesive that will wick in to the crack, do I then use some type of epoxy to fill the stop drill hole?

Any help is always appreciated…

I hope everyone is having a great Christmas!

Steve

0235 Mounted will start wiring soon.

Moving along with fuselage..

[quote][b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

Afterfxllc(at)aol.com

Guest

|

Posted: Tue Dec 27, 2011 5:10 am Post subject: Cracked Canopy Posted: Tue Dec 27, 2011 5:10 am Post subject: Cracked Canopy |

|

|

Guys

I found the reason for all this cracking canopy phenomenon. What I found was Zenith says to drill do a specific size (which I don't know off the top of my head) but what I found was it wasn't big enough for the counter sunk washer so when pressure is applied it exerts force around the hole thus a crack. The fix is simple (and I have never cracked a canopy) is..... Use a step bit to drill the canopy because it can't grab like a regular bit WILL. Then make the holes big enough that the counter sunk washer is loose that way the washer will rest on the rails and not be exerting outward pressure on the hole which WILL crack the canopy eventually.

Happy building

Jeff

In a message dated 12/25/2011 11:18:16 P.M. Eastern Standard Time, davgray(at)sbcglobal.net writes:

| Quote: | This might be a good thread to pursue as it seems to happen too often.

I would like to hear from others that cracked a canopy. Details of drill type and size, temperature at time of drilling, and hole-to-edge distance.

Also, from those that did not have this problem..

I used a step drill, warmed the canopy over a warm air register, let the bit generate a little heat from friction as it cut, kept the drill perpendicular to the surface,

and did not accept the 7 mm edge distance that would have occurred on a few of my holes if I stuck entirely with the plans.

My closest edge distance is 27 mm after a small modification. Five years plus without any cracks.

Gary Ray

Zenith 601XL-B, William Wynne Corvair 0.060 over, Roy's 5th bearing,

Mark's Falcon Heads, Marvel Schebler MA3-SPA Carburetor, 175 Hrs TT

From: Steve Freeman (steve.freeman(at)syntaxds.com)

Sent: Sunday, December 25, 2011 4:49 PM

To: zenith-list(at)matronics.com (zenith-list(at)matronics.com)

Subject: Cracked Canopy

Hi Guys,

We have all heard this story beforeâ¦While installing the rear canopy on my 650 I got about a 3â crack. I stop drilled it and I am trying to decide if I can live with this or not. Roughly $650 to get a new canopy seems like a lot of money and I might wind up with the same thing again. Honestly, I am not sure how this happened. I was being super careful and I was not drilling in a location where there seemed to be any pressure. Wellâ¦it happenedâ¦It sucks but I have to move on.

Can any of you guys make recommendations for the best practice to repair the crack? I know it will never be perfect but I have heard some people have had a lot of luck. There are no spider web cracks. Just the one, it is clean and like I said I stop drilled it at the end. I have found a couple of products on AC Spruce, in particular INSTA-WELD but it says to clamp the parts togetherâ¦this is not possible. Also, if I use some type of adhesive that will wick in to the crack, do I then use some type of epoxy to fill the stop drill hole?

Any help is always appreciatedâ¦

I hope everyone is having a great Christmas!

Steve

0235 Mounted will start wiring soon.

Moving along with fuselage..

|

[quote][b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

foxatgibsons(at)gmail.com

Guest

|

Posted: Tue Dec 27, 2011 10:39 am Post subject: Cracked Canopy Posted: Tue Dec 27, 2011 10:39 am Post subject: Cracked Canopy |

|

|

hello builders

take a really {40-100x} close look at any hole drilled in any lexan /poly

sheet and if one used a regular or even a ultra sharp bit you should see a

dozen or so very tiny cracks that appear at the boundary area {clear to

opaque} i believe to avoid this propagating in to a crack later

you must

1. drill in steps

2 ream or melt to the proper size

3 inspect to see if the cracks are gone

4 slightly break the edges

5 make sure the fastener does not contact the sheet plastic on the inside

of the hole{ allow for the thermal and vibration stress }

take a really close look at any hole you drill in plastic sheets and what

appears to be perfect

still has the cracks

it has to be viewed with a loupe at least 40 power and they are on the

bottom only

cheers Peter

Fox

On Tue, Dec 27, 2011 at 5:08 AM, <Afterfxllc(at)aol.com> wrote:

[quote] **

Guys

I found the reason for all this cracking canopy phenomenon. What I found

was Zenith says to drill do a specific size (which I don't know off the

top of my head) but what I found was it wasn't big enough for the counter

sunk washer so when pressure is applied it exerts force around the hole

thus a crack. The fix is simple (and I have never cracked a canopy) is....

Use a step bit to drill the canopy because it can't grab like a regular bit

WILL. Then make the holes big enough that the counter sunk washer is loose

that way the washer will rest on the rails and not be exerting outward

pressure on the hole which WILL crack the canopy eventually.

Happy building

Jeff

In a message dated 12/25/2011 11:18:16 P.M. Eastern Standard Time,

davgray(at)sbcglobal.net writes:

This might be a good thread to pursue as it seems to happen too often.

I would like to hear from others that cracked a canopy. Details of drill

type and size, temperature at time of drilling, and hole-to-edge distance

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

bryanmmartin

Joined: 10 Jan 2006

Posts: 1018

|

Posted: Wed Dec 28, 2011 1:00 pm Post subject: Cracked Canopy Posted: Wed Dec 28, 2011 1:00 pm Post subject: Cracked Canopy |

|

|

The canopy is made of acrylic (Plexiglas), It must be handled with extreme care, it is very easy to crack.

Polycarbonate (Lexan) is very forgiving. You can treat it like plywood as far as cutting and drilling are concerned. It's almost impossible to crack.

Lexan is much more expensive than Plexiglas, which is one reason it's not used in the canopy.

On Dec 27, 2011, at 1:37 PM, Peter Fox wrote:

| Quote: | hello builders

take a really {40-100x} close look at any hole drilled in any lexan /poly sheet and if one used a regular or even a ultra sharp bit you should see a dozen or so very tiny cracks that appear at the boundary area {clear to opaque} i believe to avoid this propagating in to a crack later

you must

1. drill in steps

2 ream or melt to the proper size

3 inspect to see if the cracks are gone

4 slightly break the edges

5 make sure the fastener does not contact the sheet plastic on the inside of the hole{ allow for the thermal and vibration stress }

|

--

Bryan Martin

N61BM, CH 601 XL,

RAM Subaru, Stratus re-drive.

do not archive.

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

_________________

--

Bryan Martin

N61BM, CH 601 XL, Stratus Subaru.

do not archive. |

|

| Back to top |

|

|

Scotsman

Joined: 27 Aug 2007

Posts: 89

Location: Johannesburg, South Africa

|

Posted: Thu Dec 29, 2011 5:14 am Post subject: Re: Cracked Canopy Posted: Thu Dec 29, 2011 5:14 am Post subject: Re: Cracked Canopy |

|

|

hi guys, I had received advice to blunt the drill bit so that it grinds as opposed to bites into the material. Some of the local guys referred me to this US video on the subject.

http://www.eaavideo.org/video.aspx?v=1200008869001

I have not tried it yet but believe that it may be correct as my second crack in the canopy occurred with almost no pressure and a brand new unused high quality drill bit.

I would be interested to hear your thoughts on it.

Cheers

James

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

_________________

Cell +27 83 675 0815 |

|

| Back to top |

|

|

jaybannist(at)cs.com

Guest

|

Posted: Thu Dec 29, 2011 5:43 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 5:43 am Post subject: Cracked Canopy |

|

|

James,

I used a very sharp pointed drill bit to drill pilot holes. This bit was recommended for drilling acrylic plastic and it worked well for me. Others have recommended a really flat point drill bit. That tells me that either pointed or flat is OK, but not in between, ie "normal" bits. I was able to drill right through the plastic and into the aluminum tube, which you probably couldn't do with the flat pointed bit.

Jay

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

psm(at)att.net

Guest

|

Posted: Thu Dec 29, 2011 6:13 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 6:13 am Post subject: Cracked Canopy |

|

|

Hi Guys,

The classic trick for drilling acrylic is to reduce the "Rake" on the drill bits used. This means the bit cannot bite into the plastic but rather takes either a very shallow chip or just melts through the plastic.

I hand grind my own drill points, so it is easy for me to reduce the rake to zero on drills for acrylic. I'm not sure that is what I did. Instead, What I tend to do is to use a very slow speed on my battery powered drill and also I tend to use step drills for this kind of drilling. Step drilling can be done either by using a store bought step drill (looks like a Christmas tree) or buy using steps of drill size so you are only taking a small bite out of the existing hole to enlarge it a little bit.

The reduced rake trick can be simulated by running the drill backwards. This ensures you don't take any bite at all out of the plastic but melt your way through. It is an extreme approach, but works just fine.

Paul

Camas, WA

On 12/29/2011 5:40 AM, Jay Bannister wrote: [quote]James,

I used a very sharp pointed drill bit to drill pilot holes. This bit was recommended for drilling acrylic plastic and it worked well for me. Others have recommended a really flat point drill bit. That tells me that either pointed or flat is OK, but not in between, ie "normal" bits. I was able to drill right through the plastic and into the aluminum tube, which you probably couldn't do with the flat pointed bit.

Jay

-----Original Message-----

From: Scotsman <james.Roberts(at)standardbank.co.za> (james.Roberts(at)standardbank.co.za)

To: zenith-list <zenith-list(at)matronics.com> (zenith-list(at)matronics.com)

Sent: Thu, Dec 29, 2011 7:20 am

Subject: Re: Cracked Canopy

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

steve.freeman(at)syntaxds

Guest

|

Posted: Thu Dec 29, 2011 6:39 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 6:39 am Post subject: Cracked Canopy |

|

|

Hi Guys,

I have seen many notes on this topic suggesting “step drills” (are we talking about a Uni-Bit) but I have never seen a step drill small enough for the holes required for the canopy. Can anyone provide a link to where I can find a small hole step drill?

When my canopy cracked I don’t think it had anything to do with the bit I was using. What I “think” happened is a small piece of debris got trapped between the glass and the rear canopy flashing which caused a pressure point. As I drilled this caused a small lever point and the canopy cracked at that point. I suspect this is the case because when I examined the location a small bead of plastic (but big enough to do the job) fell from the space between the canopy and the flashing. Until that point and at all points after the drilling was not an issue but I will admit I am nervous about enlarging the holes to accept the hardware.

Steve

From: owner-zenith-list-server(at)matronics.com [mailto:owner-zenith-list-server(at)matronics.com] On Behalf Of Paul Mulwitz

Sent: Thursday, December 29, 2011 7:11 AM

To: zenith-list(at)matronics.com

Subject: Re: Re: Cracked Canopy

Hi Guys,

The classic trick for drilling acrylic is to reduce the "Rake" on the drill bits used. This means the bit cannot bite into the plastic but rather takes either a very shallow chip or just melts through the plastic.

I hand grind my own drill points, so it is easy for me to reduce the rake to zero on drills for acrylic. I'm not sure that is what I did. Instead, What I tend to do is to use a very slow speed on my battery powered drill and also I tend to use step drills for this kind of drilling. Step drilling can be done either by using a store bought step drill (looks like a Christmas tree) or buy using steps of drill size so you are only taking a small bite out of the existing hole to enlarge it a little bit.

The reduced rake trick can be simulated by running the drill backwards. This ensures you don't take any bite at all out of the plastic but melt your way through. It is an extreme approach, but works just fine.

Paul

Camas, WA

On 12/29/2011 5:40 AM, Jay Bannister wrote:

James,

I used a very sharp pointed drill bit to drill pilot holes. This bit was recommended for drilling acrylic plastic and it worked well for me. Others have recommended a really flat point drill bit. That tells me that either pointed or flat is OK, but not in between, ie "normal" bits. I was able to drill right through the plastic and into the aluminum tube, which you probably couldn't do with the flat pointed bit.

Jay

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

larrycmcfarland(at)gmail.

Guest

|

Posted: Thu Dec 29, 2011 7:02 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 7:02 am Post subject: Cracked Canopy |

|

|

Paul,

You can find a small Uni-Bit drill at Harbor Freight. See link.

These work very well in canopy plastics.

http://www.harborfreight.com/catalogsearch/result?keyword=unibit

Larry McFarland 601HDS at www.macsmachine.com

From: owner-zenith-list-server(at)matronics.com [mailto:owner-zenith-list-server(at)matronics.com] On Behalf Of Steve Freeman

Sent: Thursday, December 29, 2011 8:37 AM

To: zenith-list(at)matronics.com

Subject: RE: Re: Cracked Canopy

Hi Guys,

I have seen many notes on this topic suggesting “step drills” (are we talking about a Uni-Bit) but I have never seen a step drill small enough for the holes required for the canopy. Can anyone provide a link to where I can find a small hole step drill?

When my canopy cracked I don’t think it had anything to do with the bit I was using. What I “think” happened is a small piece of debris got trapped between the glass and the rear canopy flashing which caused a pressure point. As I drilled this caused a small lever point and the canopy cracked at that point. I suspect this is the case because when I examined the location a small bead of plastic (but big enough to do the job) fell from the space between the canopy and the flashing. Until that point and at all points after the drilling was not an issue but I will admit I am nervous about enlarging the holes to accept the hardware.

Steve

From: owner-zenith-list-server(at)matronics.com (owner-zenith-list-server(at)matronics.com) [mailto:owner-zenith-list-server(at)matronics.com] ([email][mailto:owner-zenith-list-server(at)matronics.com][/email]) On Behalf Of Paul Mulwitz

Sent: Thursday, December 29, 2011 7:11 AM

To: zenith-list(at)matronics.com (zenith-list(at)matronics.com)

Subject: Re: Re: Cracked Canopy

Hi Guys,

The classic trick for drilling acrylic is to reduce the "Rake" on the drill bits used. This means the bit cannot bite into the plastic but rather takes either a very shallow chip or just melts through the plastic.

I hand grind my own drill points, so it is easy for me to reduce the rake to zero on drills for acrylic. I'm not sure that is what I did. Instead, What I tend to do is to use a very slow speed on my battery powered drill and also I tend to use step drills for this kind of drilling. Step drilling can be done either by using a store bought step drill (looks like a Christmas tree) or buy using steps of drill size so you are only taking a small bite out of the existing hole to enlarge it a little bit.

The reduced rake trick can be simulated by running the drill backwards. This ensures you don't take any bite at all out of the plastic but melt your way through. It is an extreme approach, but works just fine.

Paul

Camas, WA

On 12/29/2011 5:40 AM, Jay Bannister wrote:

James,

I used a very sharp pointed drill bit to drill pilot holes. This bit was recommended for drilling acrylic plastic and it worked well for me. Others have recommended a really flat point drill bit. That tells me that either pointed or flat is OK, but not in between, ie "normal" bits. I was able to drill right through the plastic and into the aluminum tube, which you probably couldn't do with the flat pointed bit.

Jay

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

jlatimer1(at)cox.net

Guest

|

Posted: Thu Dec 29, 2011 7:38 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 7:38 am Post subject: Cracked Canopy |

|

|

Steve,

I used a small regular well used dull bit (#20 I think) to drill the pilot holes and then a Uni Bit to enlarge the holes for the mounting hardware.

Jerry

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

psm(at)att.net

Guest

|

Posted: Thu Dec 29, 2011 8:24 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 8:24 am Post subject: Cracked Canopy |

|

|

Steve,

The final size of the holes in the plastic canopy is around 3/8 inch. This allows the tinnerman washers to rest on the flat flange to hold the canopy in place. The angled (cone) shape of the tinnerman washer holds the canopy approximately in place while allowing a little movement as temperature changes create different expansion in the plastic and metal parts.

I've never seen a step drill that was so large it couldn't enlarge a hole from #40 to 3/8 inch. I tend to use ones from Harbor Freight because I'm too cheap to buy the expensive Unibits.

Paul

Camas, WA

On 12/29/2011 6:37 AM, Steve Freeman wrote: [quote]

I have seen many notes on this topic suggesting “step drills” (are we talking about a Uni-Bit) but I have never seen a step drill small enough for the holes required for the canopy. Can anyone provide a link to where I can find a small hole step drill? [b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

n4546v(at)mindspring.com

Guest

|

Posted: Thu Dec 29, 2011 9:54 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 9:54 am Post subject: Cracked Canopy |

|

|

do not archive

Hello Listers:

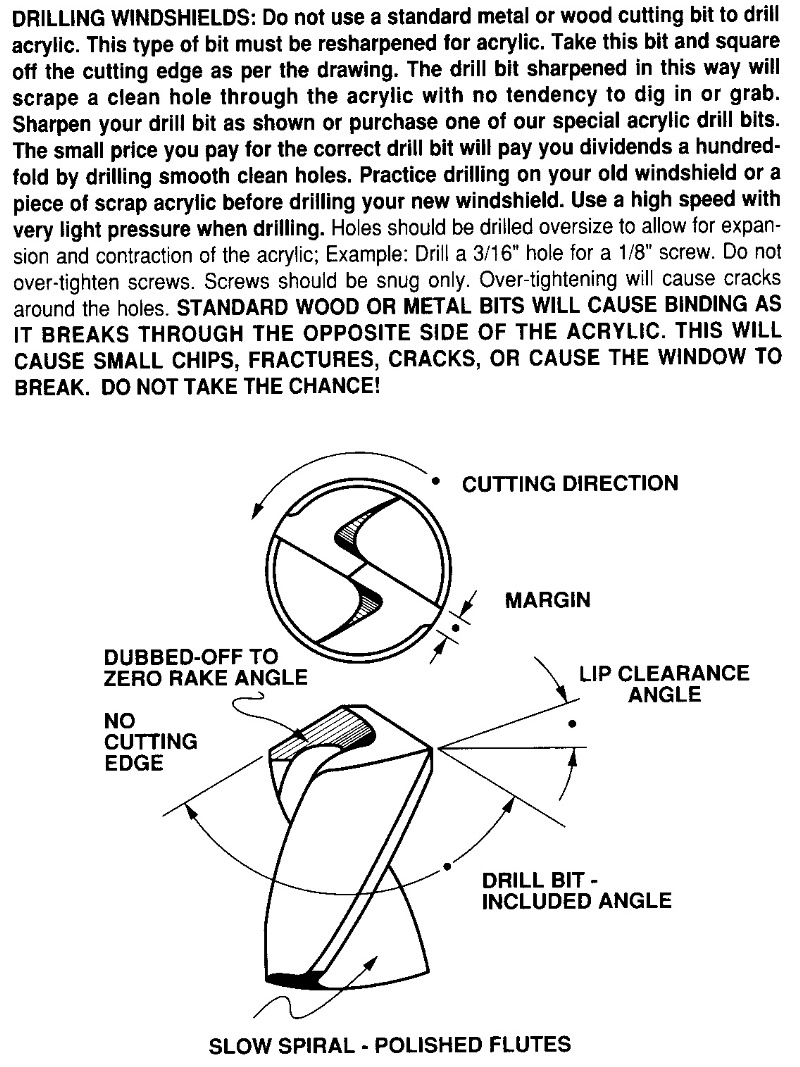

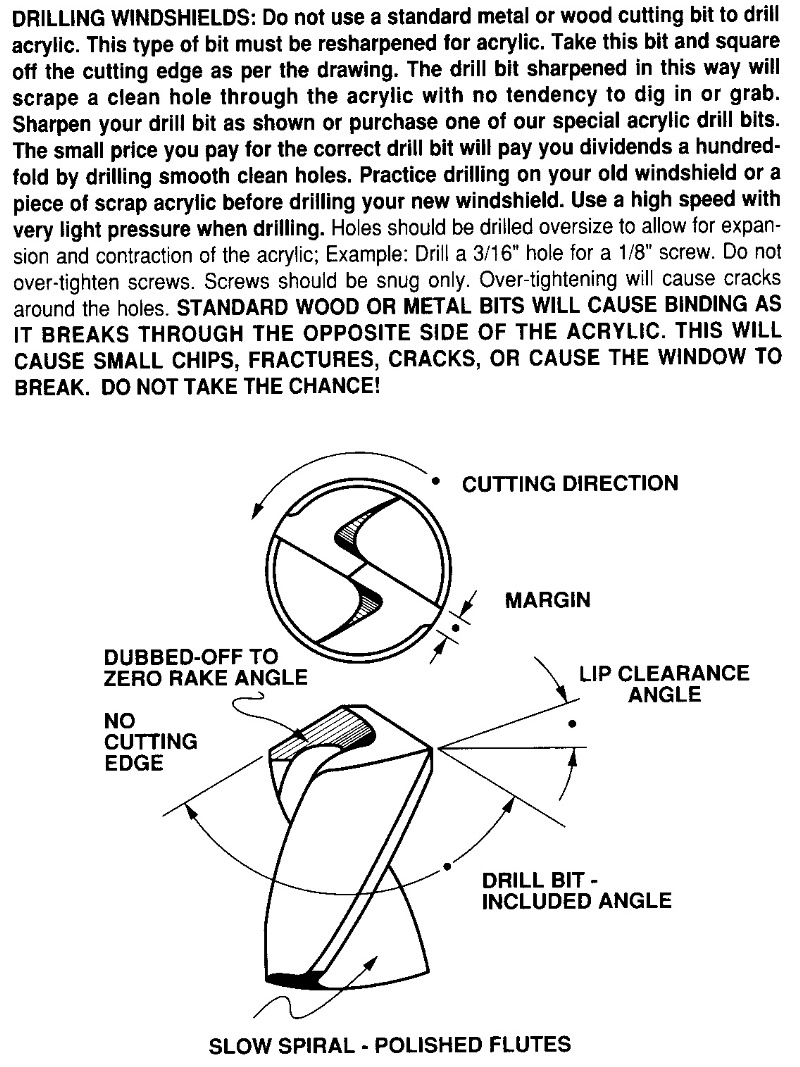

Attached is the drill geometry LP Plastics, the people who make the windows, suggest.

The important part is the "dubbing" of the cutting lip rake angle. An off the shelf drill has a positive cutting lip angle which will "dig" into soft materials like brass, AL, or plexi. By dubbing the rake angle to "0" or a slightly negative angle, the cutting edge "scrapes" the material in front of it rather than digging in which is what cracks plexi. Since this scraping action does not result in the drill self feeding or pulling itsself into the material, it only cuts by you applying pressure. Dub the cutting edge, apply pressure judiciously, and always back up the work with a piece of wood so the drill doesn't burst through upon penetration.

The drill still "drills" the hole by removing meteral, it doesn't burn through it. To see many other diagrams to clarify, Google search "drill dubbing", lots comes up.

RE Lexan: Arn't there two very good reasons Lexan isn't used for aircraft cabin windows?

1. It scratches much easier than plexi.

2. And more importantly, it's what is used for bullet proof and shatter proof glass, so in a crash, rescuers can't break through to get occupants out, that's especially bad if there's a fire!

Regards,

Randy, Las Vegas

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

307.93 KB |

| Viewed: |

17604 Time(s) |

|

|

|

| Back to top |

|

|

psm(at)att.net

Guest

|

Posted: Thu Dec 29, 2011 10:26 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 10:26 am Post subject: Cracked Canopy |

|

|

Hi Randy,

Mostly the reason for not using Lexan (polycarbonate) on home built airplanes is the expense.

You are correct that it is soft and scratches easily. For that reason it is necessary to "Hard Coat" it with polyurethane in any normal application. This solves the scratch problem but adds cost. You can get an idea of the cost increment if you go to your local eyeglasses store. They charge a significant increment price for polycarbonate lenses over standard (mostly acrylic) lenses. Even in small quantities this is often a $50 increment.

I don't understand the issue of being "Bullet Proof". In reality it is just as easy, maybe easier, to hack away at Lexan as Plexiglass.

Best regards,

Paul

Camas, WA

On 12/29/2011 9:48 AM, Randy L. Thwing wrote: [quote] RE Lexan: Arn't there two very good reasons Lexan isn't used for aircraft cabin windows?

1. It scratches much easier than plexi.

2. And more importantly, it's what is used for bullet proof and shatter proof glass, so in a crash, rescuers can't break through to get occupants out, that's especially bad if there's a fire!

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

wjones(at)brazoriainet.co

Guest

|

Posted: Thu Dec 29, 2011 10:36 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 10:36 am Post subject: Cracked Canopy |

|

|

A 1/4" thickness will stop a 38 caliber ,sounds bullet proof to me . Wade

[quote] ---

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

steve.freeman(at)syntaxds

Guest

|

Posted: Thu Dec 29, 2011 10:58 am Post subject: Cracked Canopy Posted: Thu Dec 29, 2011 10:58 am Post subject: Cracked Canopy |

|

|

Hi Paul,

Thanks for the input. I was thinking of the original pilot hole not the finished hole size. Thanks for clarifying.

Steve

From: owner-zenith-list-server(at)matronics.com [mailto:owner-zenith-list-server(at)matronics.com] On Behalf Of Paul Mulwitz

Sent: Thursday, December 29, 2011 9:21 AM

To: zenith-list(at)matronics.com

Subject: Re: Re: Cracked Canopy

Steve,

The final size of the holes in the plastic canopy is around 3/8 inch. This allows the tinnerman washers to rest on the flat flange to hold the canopy in place. The angled (cone) shape of the tinnerman washer holds the canopy approximately in place while allowing a little movement as temperature changes create different expansion in the plastic and metal parts.

I've never seen a step drill that was so large it couldn't enlarge a hole from #40 to 3/8 inch. I tend to use ones from Harbor Freight because I'm too cheap to buy the expensive Unibits.

Paul

Camas, WA

On 12/29/2011 6:37 AM, Steve Freeman wrote:

I have seen many notes on this topic suggesting “step drills” (are we talking about a Uni-Bit) but I have never seen a step drill small enough for the holes required for the canopy. Can anyone provide a link to where I can find a small hole step drill? | Quote: | | </ -- Please Support Your Lists This Month nbsp; (And Get Some AWESOME FREE November is the Annual List Fund Raiser. Click below to find out more Free Incentive Gifts AeroElectric www.aeroelectric.com<www.buildersbooks.comwww.homebuilthelp.comhttp://www.matron===================http://forums.matronics.com[/url] - List Contribution Web generous nbsp; --> http://www.matronics.com/c=[/b] |

[quote][b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|