|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

wb2ssj(at)rochester.rr.co

Guest

|

Posted: Fri Mar 16, 2012 2:47 am Post subject: valve problem Posted: Fri Mar 16, 2012 2:47 am Post subject: valve problem |

|

|

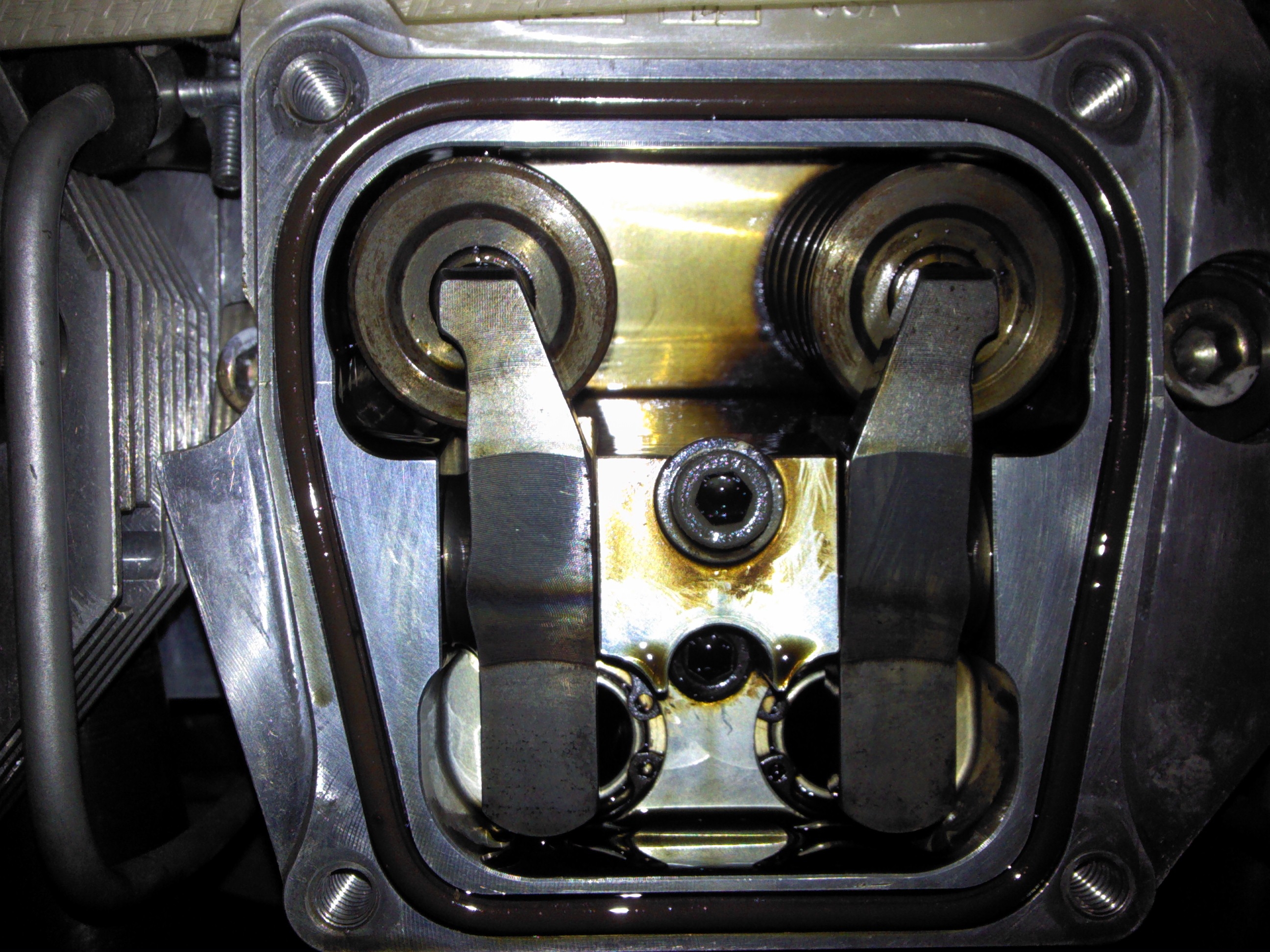

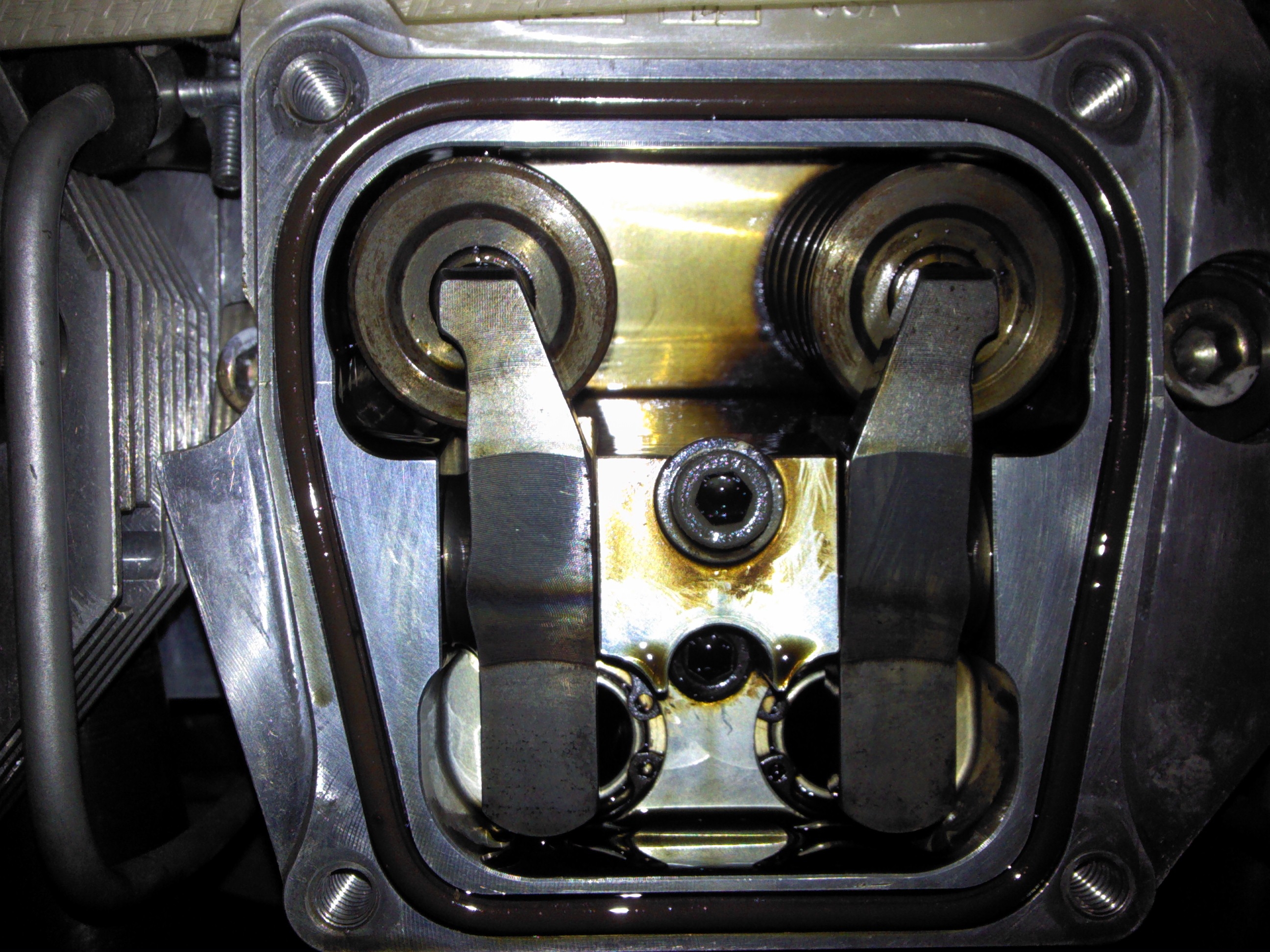

For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

| Description: |

|

| Filesize: |

2.39 MB |

| Viewed: |

11388 Time(s) |

|

|

|

| Back to top |

|

|

Kayberg(at)aol.com

Guest

|

Posted: Fri Mar 16, 2012 9:43 am Post subject: valve problem Posted: Fri Mar 16, 2012 9:43 am Post subject: valve problem |

|

|

For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

A couple years back we had a new Jab 3300 that had a real problem with valves sticking. Ultimately the valves bent and several had to be replaced. A casual notion would be that the valve guides were TOOOOO tight!!! However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate. It was that material that caused the valves to gunk up and stick. The engine was torn down and checked, then reassembled. Other than a clean up, touch up of the seats and new valves, nothing was done. It is running fine today as far as I know.

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating), from dirt or problems with the seat, from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination. We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time and other considerations. Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

While Tex wants to make his own valve guides, that would not be the solution I would pursue first. Having just discovered a cracked valve guide in a O-320 Lycoming, I tend to believe that some things just happen. Better to replace with the correct part and simply move on....if the guide is indeed out of spec.

Doug Koenigsberg

In a message dated 3/16/2012 6:51:50 A.M. Eastern Daylight Time, wb2ssj(at)rochester.rr.com writes:

| Quote: | For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Mar 16, 2012 11:27 am Post subject: valve problem Posted: Fri Mar 16, 2012 11:27 am Post subject: valve problem |

|

|

Guys - please take note:

In this age of instant�communications�it amazes me how information isolated aviation people have become. �I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. �What does amaze me it how�technical�engine manufactures can get. �"Pete K and the folks in�Tennessee�revealed the presence of a gunky contaminate." �That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. �This coke is a carbon base substance. �The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. �This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. �In engine design the valve is harder than the guide so the guide wares more. �As the coke builds up it causes the valve to stick. �History has shown when this happens the valve sticks OPEN, in the DOWN position. �Since the valve is DOWN it is met by the UP coming piston. �You can just imagine all the fun and sounds that happen in a split second. �What I do not know is: �Dose the Jabiru have an�INTERFERENCE�fit between the piston and valve? �If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. �This problem is more�prevalent�with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? �The jury is still out on that�verdict. �But, there is a test that can be performed that gives one a better than average idea on when it is happening. �Go to the Lycoming web site and down load Service Bulliten SB388C. �It explains the required equipment and how to perform what is know as "The Valve Wobble Test". �Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.�

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. �If the oil does not burn coke will not�develop. �

Side Note: �Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the�maleficent�of�expansion�of the materials. �Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <Kayberg(at)aol.com (Kayberg(at)aol.com)> wrote:

[quote] For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

�

A couple years back we had a new Jab 3300 that had a real problem with valves sticking.� Ultimately the valves bent and several had to be replaced.�� A casual notion would be that the valve guides were TOOOOO tight!!!�� However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate.�� It was that material that caused the valves to gunk up and stick.�� The engine was torn down and checked, then reassembled.� Other than a clean up, touch up of the seats�and new valves, nothing was done.� It is running fine today as far as I know.

�

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating),� from dirt or problems with the seat,� from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination.� We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time� and other considerations.�� Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

�

While Tex wants to make his own valve guides, that would not be the solution I would pursue first.�� Having just discovered a cracked valve guide in a O-320 Lycoming,� I tend to believe that some things just happen.� Better to replace with the correct part and simply move on.....if the guide is indeed out of spec.

�

�

Doug Koenigsberg

�

In a message dated 3/16/2012 6:51:50 A.M. Eastern Daylight Time, wb2ssj(at)rochester.rr.com (wb2ssj(at)rochester.rr.com) writes:

| Quote: | For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

|

| Quote: |

ist" target="_blank">http://www.matronics.com/Navigator?JabiruEngine-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Fri Mar 16, 2012 12:14 pm Post subject: valve problem Posted: Fri Mar 16, 2012 12:14 pm Post subject: valve problem |

|

|

Just as an aside,

I believe the benefits of leaded fuel extend far beyond it's anti knock qualities.The cushioning and lubricating features make it worth the difference in price as well as the fact that it stores without degradation.Any room for this thought in the valve guide discussion?Just my opinion.No offense meant.

G.Aman Jabiru 2200A approx.680 trouble free hrs so far all on 100LL

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

wb2ssj(at)rochester.rr.co

Guest

|

Posted: Fri Mar 16, 2012 12:51 pm Post subject: valve problem Posted: Fri Mar 16, 2012 12:51 pm Post subject: valve problem |

|

|

Thank you for your coments , but we already know the whats the problem.

Tex

[quote] ---

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BobsV35B(at)aol.com

Guest

|

Posted: Fri Mar 16, 2012 1:00 pm Post subject: valve problem Posted: Fri Mar 16, 2012 1:00 pm Post subject: valve problem |

|

|

Good Afternoon G.Aman,

I do like the stability aspects of 100LL, but I think any thoughts as to the cushioning and lubrication qualities of leaded fuel are pure unadulterated Old Wives' Tales.

The FAA ran a set of engines on an Aero Commander many years ago with one engine being fed only leaded fuel and the other fed only unleaded fuel. The one using unleaded fuel ran better, ran cleaner, and lasted easily through TBO.

Lead is strictly a relatively low cost octane enhancer. If you do not need the octane, don't use leaded fuel!

Too bad we do not have a source of unleaded aviation fuel. 80 octane would be more than enough for most small engines. Without lead, the 100 LL mix is good for 96 or 97 octane.

Happy Skies,

Old Bob

AKA

Bob Siegfried

Downers Grove, Illinois

In a message dated 3/16/2012 3:14:21 P.M. Central Daylight Time, zeprep251(at)aol.com writes:

| Quote: | Just as an aside,

I believe the benefits of leaded fuel extend far beyond it's anti knock qualities.The cushioning and lubricating features make it worth the difference in price as well as the fact that it stores without degradation.Any room for this thought in the valve guide discussion?Just my opinion.No offense meant.

G.Aman Jabiru 2200A approx.680 trouble free hrs so far all on 100LL

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Kayberg(at)aol.com

Guest

|

Posted: Fri Mar 16, 2012 1:28 pm Post subject: valve problem Posted: Fri Mar 16, 2012 1:28 pm Post subject: valve problem |

|

|

Barry, it wasn't coke. It wasn't carbon based. It was a yellowish material that we believe was present in the mogas with ethanol. It showed up in less than 3 hours of running, hardly enough to cause significant carbon deposits.

Doug

In a message dated 3/16/2012 3:27:41 P.M. Eastern Daylight Time, flyadive(at)gmail.com writes:

| Quote: | Guys - please take note:

In this age of instant communications it amazes me how information isolated aviation people have become. I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. What does amaze me it how technical engine manufactures can get. "Pete K and the folks in Tennessee revealed the presence of a gunky contaminate." That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. This coke is a carbon base substance. The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. In engine design the valve is harder than the guide so the guide wares more. As the coke builds up it causes the valve to stick. History has shown when this happens the valve sticks OPEN, in the DOWN position. Since the valve is DOWN it is met by the UP coming piston. You can just imagine all the fun and sounds that happen in a split second. What I do not know is: Dose the Jabiru have an INTERFERENCE fit between the piston and valve? If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. This problem is more prevalent with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? The jury is still out on that verdict. But, there is a test that can be performed that gives one a better than average idea on when it is happening. Go to the Lycoming web site and down load Service Bulliten SB388C. It explains the required equipment and how to perform what is know as "The Valve Wobble Test". Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. If the oil does not burn coke will not develop.

Side Note: Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the maleficent of expansion of the materials. Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <Kayberg(at)aol.com (Kayberg(at)aol.com)> wrote:

| Quote: | For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

A couple years back we had a new Jab 3300 that had a real problem with valves sticking. Ultimately the valves bent and several had to be replaced. A casual notion would be that the valve guides were TOOOOO tight!!! However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate. It was that material that caused the valves to gunk up and stick. The engine was torn down and checked, then reassembled. Other than a clean up, touch up of the seats and new valves, nothing was done. It is running fine today as far as I know.

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating), from dirt or problems with the seat,� from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination. We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time and other considerations. Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

While Tex wants to make his own valve guides, that would not be the solution I would pursue first. Having just discovered a cracked valve guide in a O-320 Lycoming, I tend to believe that some things just happen. Better to replace with the correct part and simply move on.....if the guide

|

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Fri Mar 16, 2012 2:35 pm Post subject: valve problem Posted: Fri Mar 16, 2012 2:35 pm Post subject: valve problem |

|

|

Gary:

You have been�corrupted! �Brainwashed or what ever term you want to apply...

That is such a Old Wive's Tail that the old lady's mole is growing a beard.

The EPA took that malarkey and used it�against�the aviation industry. �

Here is how it started: �We as pilots use the term LEADED FUEL. �The EPA forced feed the public those words LEAD. �And everyone knows you should not Eat or Breathe LEAD.

AND when we clean our spark plugs we remove a solid particle that WE call LEAD!

So, using that totally incorrect logic AND force feeding to the public, it only goes to say: Engines are NOT 100%�efficient�so considering that it only goes to prove that some of that lead is being exhausted and pumped into the air! �Also, since lead is a soft material and the exhaust valve is open during intake some of the raw fuel is being pumped past the valve as it closes. �It MUST be CUSHIONING the valve! �Ergo the Oral�Deification�and�development�of the Old Wife's Tail. �

RULE: �If a lie is told long enough and loud enough it becomes the truth. �

Barry

On Fri, Mar 16, 2012 at 4:13 PM, Gary Aman <zeprep251(at)aol.com (zeprep251(at)aol.com)> wrote:

[quote]Just as an aside,

I believe the benefits of leaded fuel extend far beyond it's anti knock qualities.The cushioning and lubricating features make it worth the difference in price as well as the fact that it stores without degradation.Any room for this thought in the valve guide discussion?Just my opinion.No offense meant.

G.Aman Jabiru 2200A approx.680 trouble free hrs so far all on 100LL

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

pete(at)usjabiru.com

Guest

|

Posted: Fri Mar 16, 2012 2:53 pm Post subject: valve problem Posted: Fri Mar 16, 2012 2:53 pm Post subject: valve problem |

|

|

This was not coke but some foreign substance from the fuel

Pete

From: owner-jabiruengine-list-server(at)matronics.com [mailto:owner-jabiruengine-list-server(at)matronics.com] On Behalf Of FLYaDIVE

Sent: Friday, March 16, 2012 2:27 PM

To: jabiruengine-list(at)matronics.com

Subject: Re: valve problem

Guys - please take note:

In this age of instant communications it amazes me how information isolated aviation people have become. I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. What does amaze me it how technical engine manufactures can get. "Pete K and the folks in Tennessee revealed the presence of a gunky contaminate." That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. This coke is a carbon base substance. The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. In engine design the valve is harder than the guide so the guide wares more. As the coke builds up it causes the valve to stick. History has shown when this happens the valve sticks OPEN, in the DOWN position. Since the valve is DOWN it is met by the UP coming piston. You can just imagine all the fun and sounds that happen in a split second. What I do not know is: Dose the Jabiru have an INTERFERENCE fit between the piston and valve? If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. This problem is more prevalent with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? The jury is still out on that verdict. But, there is a test that can be performed that gives one a better than average idea on when it is happening. Go to the Lycoming web site and down load Service Bulliten SB388C. It explains the required equipment and how to perform what is know as "The Valve Wobble Test". Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. If the oil does not burn coke will not develop.

Side Note: Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the maleficent of expansion of the materials. Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <Kayberg(at)aol.com (Kayberg(at)aol.com)> wrote:

For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

�

A couple years back we had a new Jab 3300 that had a real problem with valves sticking. Ultimately the valves bent and several had to be replaced. A casual notion would be that the valve guides were TOOOOO tight!!! However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate. It was that material that caused the valves to gunk up and stick. The engine was torn down and checked, then reassembled. Other than a clean up, touch up of the seats and new valves, nothing was done. It is running fine today as far as I know.

�

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating), from dirt or problems with the seat, from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination. We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time and other considerations. Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

�

While Tex wants to make his own valve guides, that would not be the solution I would pursue first. Having just discovered a cracked valve guide in a O-320 Lycoming, I tend to believe that some things just happen. Better to replace with the correct part and simply move on.....if the guide is indeed out of spec.

�

�

Doug Koenigsberg

�

In a message dated 3/16/2012 6:51:50 A.M. Eastern Daylight Time, wb2ssj(at)rochester.rr.com (wb2ssj(at)rochester.rr.com) writes:

01234567890123

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

matronics(at)rtist.nl

Guest

|

Posted: Fri Mar 16, 2012 3:01 pm Post subject: valve problem Posted: Fri Mar 16, 2012 3:01 pm Post subject: valve problem |

|

|

Bzzzzt... Wrong..

On 3/16/2012 10:36 PM, Naftali Horowitz wrote: [quote] Obviously overheated

From: wb2ssj(at)rochester.rr.com (wb2ssj(at)rochester.rr.com)

To: lightning-list(at)matronics.com (lightning-list(at)matronics.com); jabiruengine-list(at)matronics.com (jabiruengine-list(at)matronics.com)

Subject: valve problem

Date: Fri, 16 Mar 2012 06:45:42 -0400

For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

vettin74(at)yahoo.com

Guest

|

Posted: Fri Mar 16, 2012 3:36 pm Post subject: valve problem Posted: Fri Mar 16, 2012 3:36 pm Post subject: valve problem |

|

|

The engine the kayberg is talking about was not burned oil or fuel deposit. this "gunk" or "coke" as you call it was not found in the rocker box on this particular engine. It had gummed up the mechanical fuel pump, carb, intake plenum and tubes, and the intake valves only at the portion which is exposed to the incoming mix. This was not a oil burn or lead deposit. It had formed from a fuel contaminate and easily disolved with parts wash and solvent. It was tanish in color and clear like a varnsih.

I would belive everything else but it was not oil or lead, it had contaminated and built up on everything from the fuel tanks in. I know because i rebuilt that engine.

Nick

Sent from my pocket

On Mar 16, 2012, at 2:26 PM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

[quote]Guys - please take note:

In this age of instant communications it amazes me how information isolated aviation people have become. I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. What does amaze me it how technical engine manufactures can get. "Pete K and the folks in Tennessee revealed the presence of a gunky contaminate." That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. This coke is a carbon base substance. The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. In engine design the valve is harder than the guide so the guide wares more. As the coke builds up it causes the valve to stick. History has shown when this happens the valve sticks OPEN, in the DOWN position. Since the valve is DOWN it is met by the UP coming piston. You can just imagine all the fun and sounds that happen in a split second. What I do not know is: Dose the Jabiru have an INTERFERENCE fit between the piston and valve? If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. This problem is more prevalent with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? The jury is still out on that verdict. But, there is a test that can be performed that gives one a better than average idea on when it is happening. Go to the Lycoming web site and down load Service Bulliten SB388C. It explains the required equipment and how to perform what is know as "The Valve Wobble Test". Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. If the oil does not burn coke will not develop.

Side Note: Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the maleficent of expansion of the materials. Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <[url=mailto:Kayberg(at)aol.com]Kayberg(at)aol.com (Kayberg(at)aol.com)[/url]> wrote:

| Quote: | For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

A couple years back we had a new Jab 3300 that had a real problem with valves sticking. Ultimately the valves bent and several had to be replaced. A casual notion would be that the valve guides were TOOOOO tight!!! However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate. It was that material that caused the valves to gunk up and stick. The engine was torn down and checked, then reassembled. Other than a clean up, touch up of the seats and new valves, nothing was done. It is running fine today as far as I know.

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating), from dirt or problems with the seat, from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination. We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time and other considerations. Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

While Tex wants to make his own valve guides, that would not be the solution I would pursue first. Having just discovered a cracked valve guide in a O-320 Lycoming, I tend to believe that some things just happen. Better to replace with the correct part and simply move on.....if the guide is indeed out of spec.

Doug Koenigsberg

In a message dated 3/16/2012 6:51:50 A.M. Eastern Daylight Time, [url=mailto:wb2ssj(at)rochester.rr.com]wb2ssj(at)rochester.rr.com (wb2ssj(at)rochester.rr.com)[/url] writes:

| Quote: | For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

|

href="http://www.matronics.com/Navigator?JabiruEngine-List">http://www.matronics.com/Navigator?JabiruEngine-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

|

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

gregsmi

Joined: 01 Jan 2011

Posts: 268

Location: Topeka, KS

|

Posted: Fri Mar 16, 2012 5:44 pm Post subject: valve problem Posted: Fri Mar 16, 2012 5:44 pm Post subject: valve problem |

|

|

Could the substance be epoxy or a tank sealer? I know many epoxies will dissolve in ethanol laced fuel and some will dissolve in regular fuel. I have seen fuel systems clogged with dissolved epoxy, a brownest color. It is nasty stuff.

Greg

Jabiru 2200

In a message dated 3/16/2012 6:36:41 P.M. Central Daylight Time, vettin74(at)yahoo.com writes:

| Quote: | The engine the kayberg is talking about was not burned oil or fuel deposit. this "gunk" or "coke" as you call it was not found in the rocker box on this particular engine. It had gummed up the mechanical fuel pump, carb, intake plenum and tubes, and the intake valves only at the portion which is exposed to the incoming mix. This was not a oil burn or lead deposit. It had formed from a fuel contaminate and easily disolved with parts wash and solvent. It was tanish in color and clear like a varnsih.

I would belive everything else but it was not oil or lead, it had contaminated and built up on everything from the fuel tanks in. I know because i rebuilt that engine.

Nick

Sent from my pocket

On Mar 16, 2012, at 2:26 PM, FLYaDIVE <flyadive(at)gmail.com (flyadive(at)gmail.com)> wrote:

| Quote: | Guys - please take note:

In this age of instant communications it amazes me how information isolated aviation people have become. I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. What does amaze me it how technical engine manufactures can get. "Pete K and the folks in Tennessee revealed the presence of a gunky contaminate." That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. This coke is a carbon base substance. The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. In engine design the valve is harder than the guide so the guide wares more. As the coke builds up it causes the valve to stick. History has shown when this happens the valve sticks OPEN, in the DOWN position. Since the valve is DOWN it is met by the UP coming piston. You can just imagine all the fun and sounds that happen in a split second. What I do not know is: Dose the Jabiru have an INTERFERENCE fit between the piston and valve? If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. This problem is more prevalent with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? The jury is still out on that verdict. But, there is a test that can be performed that gives one a better than average idea on when it is happening. Go to the Lycoming web site and down load Service Bulliten SB388C. It explains the required equipment and how to perform what is know as "The Valve Wobble Test". Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. �If the oil does not burn coke will not develop.

Side Note: Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the maleficent of expansion of the materials. Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <[url=mailto:Kayberg(at)aol.com]Kayberg(at)aol.com (Kayberg(at)aol.com)[/url]> wrote:

| Quote: | For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

A couple years back we had a new Jab 3300 that had a real problem with valves sticking. Ultimately the valves bent and several had to be replaced. A casual notion would be that the valve guides were TOOOOO tight!!! However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate. It was that material that caused the valves to gunk up and stick. The engine was torn down and checked, then reassembled. Other than a clean up, touch up of the seats and new valves, nothing was done. It is running fine today as far as I know.

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating), from dirt or problems with the seat,� from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination. We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time and other considerations. Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

While Tex wants to make his own valve guides, that would not be the solution I would pursue first. Having just discovered a cracked valve guide in a O-320 Lycoming, I tend to believe that some things just happen. Better to replace with the correct part and simply move on.....if the guide is indeed out of spec.

Doug Koenigsberg

In a message dated 3/16/2012 6:51:50 A.M. Eastern Daylight Time, [url=mailto:wb2ssj(at)rochester.rr.com]wb2ssj(at)rochester.rr.com (wb2ssj(at)rochester.rr.com)[/url] writes:

| Quote: | For those interested here is a picture of the rocker box with the cover off.(as if you are doing a head bolt check) If you see the discolored area around the exhaust valve on the right,you might want to look further into the situation.

|

href="http://www.matronics.com/Navigator?JabiruEngine-List">http://www.matronics.com/Navigator?JabiruEngine-List

href="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/contribution

|

ist href="http://www.matronics.com/Navigator?JabiruEngine-List">http://www.matronics.com/Navigator?JabiruEngine-List

s.matronics.com/">http://forums.matronics.com

p://www.matronics.com/contribution">http://www.matronics.com/contribution

|

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Sat Mar 17, 2012 6:34 am Post subject: valve problem Posted: Sat Mar 17, 2012 6:34 am Post subject: valve problem |

|

|

Doug:

Is this your post?

"A couple years back we had a new Jab 3300 that had a real problem with valves sticking.� Ultimately the valves bent and several had to be replaced.�� A casual notion would be that the valve guides were TOOOOO tight!!!�� However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate.�� It was that material that caused the valves to gunk up and stick.�"

It was posted by:� Kayberg(at)aol.com (Kayberg(at)aol.com)�via�matronics.com�

And you can see the term "gunky" was used... Gunky is not a solid or a powder.

That is what I am responding to. �

=================================

I did not see the first set of pictures.

Isn't this engine out of country?

Yellow - Is a classic case of SULFUR. �So one must ask: Are these fuels�controlled�enough to keep the sulfur content equal to or lower of what we have here is the USA?

Question: �Are these Sulfur filled valves?

We are only working from pictures so there is a lot the eye can see that the pictures may not show.

Are the valves the ONLY place where the yellow is showing up?

If so the next question would be: �How hot is the engine/valves running?

Hot valves could be causing�detonation and it could be only in the�vicinity�of the valve.�You can cross check this with the burn pattern on the top of the pistons. �You want to see a very distinked swearl pattern.

Can you add any additional pertinent information?

Barry

On Fri, Mar 16, 2012 at 5:26 PM, <Kayberg(at)aol.com (Kayberg(at)aol.com)> wrote:

[quote] Barry, it wasn't coke. It wasn't carbon based.� It was a yellowish material that we believe was present in the mogas with ethanol.�� It showed up in less than 3 hours of running, hardly enough to cause significant carbon deposits.

�

Doug

�

In a message dated 3/16/2012 3:27:41 P.M. Eastern Daylight Time, flyadive(at)gmail.com (flyadive(at)gmail.com) writes:

| Quote: | Guys - please take note:

In this age of instant�communications�it amazes me how information isolated aviation people have become. �I frequent different aviation online groups and all have reported this SAME type of valve problem. It is nothing new. �What does amaze me it how�technical�engine manufactures can get. �"Pete K and the folks in�Tennessee�revealed the presence of a gunky contaminate." �That GUNK is known as coke, not the type that you drink but what happens when you expose oil to high heat. �This coke is a carbon base substance. �The coke attaches itself to the valve stem and guide; the coke is harder than the steel of the valve or the valve guide and causes ware. �This coke hardens - And, the valve stem and valve guide ware allowing more oil leaks into the space between the valve and guide. �In engine design the valve is harder than the guide so the guide wares more. �As the coke builds up it causes the valve to stick. �History has shown when this happens the valve sticks OPEN, in the DOWN position. �Since the valve is DOWN it is met by the UP coming piston. �You can just imagine all the fun and sounds that happen in a split second. �What I do not know is: �Dose the Jabiru have an�INTERFERENCE�fit between the piston and valve? �If not than all that may happen is a loss of power; otherwise it's flying parts and vibration - If you are lucky. �This problem is more�prevalent�with engines that burn AvGas but it does happen with MoGas also.

How do you prevent it? �The jury is still out on that�verdict. �But, there is a test that can be performed that gives one a better than average idea on when it is happening. �Go to the Lycoming web site and down load Service Bulliten SB388C. �It explains the required equipment and how to perform what is know as "The Valve Wobble Test". �Remember: The equipment will have to be modified and the specs (Go-No Go) limits will have to be developed to address the Jabiru Engine.�

My thought on prevention is: COOL the valves and guides as much as you can. Prevent the HEAT from burning the oil. �If the oil does not burn coke will not�develop. �

Side Note: �Engine manufactures - If cooling does work you will have to re-calculate the clearance between the valve stem and guide considering the�maleficent�of�expansion�of the materials. �Less heat means less expansion unless you go with a NPO material.

Barry

On Fri, Mar 16, 2012 at 1:42 PM, <Kayberg(at)aol.com (Kayberg(at)aol.com)> wrote:

| Quote: | For the folks following this thread, I would urge some level of caution and a high trust in USA Jabiru.

�

A couple years back we had a new Jab 3300 that had a real problem with valves sticking.� Ultimately the valves bent and several had to be replaced.�� A casual notion would be that the valve guides were TOOOOO tight!!!�� However, inspection by Pete K and the folks in Tennesee revealed the presence of a gunky contaminate.�� It was that material that caused the valves to gunk up and stick.�� The engine was torn down and checked, then reassembled.� Other than a clean up, touch up of the seats�and new valves, nothing was done.� It is running fine today as far as I know.

�

The heads in Tex's picture could have a bent exhaust valve (which can come from overheating),� from dirt or problems with the seat,� from overheating cooking the oil in that spot, or perhaps other causes, not excluding a problem with fuel contamination.� We are not told of the number of hours on the engine, the compression numbers obtained on multiple occasions, CHT's and EGT's over time� and other considerations.�� Frankly, if the compression is up, particularly a differential compression check, I would not do anything unless Pete, et al, said it was an indicator.

�

While Tex wants to make his own valve guides, that would not be the solution I would pursue first.�� Having just discovered a cracked valve guide in a O-320 Lycoming,� I tend to believe that some things just happen.� Better to replace with the correct part and simply move on.....if the guide

|

|

| Quote: |

ist" target="_blank">http://www.matronics.com/Navigator?JabiruEngine-List

tp://forums.matronics.com

_blank">http://www.matronics.com/contribution

|

[b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

zeprep251(at)aol.com

Guest

|

Posted: Sat Mar 17, 2012 11:26 am Post subject: valve problem Posted: Sat Mar 17, 2012 11:26 am Post subject: valve problem |

|

|

Bob,

The issue of valve seat recession with early on unleaded fuel comes to mind, but you may never have had to deal with that in your frame of experience.That was addressed with additives as well as other additives for other issues like alcohol separation,one of the reasons motor fuel smells so nice and does such a good job of removing sloshing compound from older aircraft fuel tanks.I could run the 87octane in the D35 with the E series engine, but after a while the fuel selector got too stiff to turn.A dose of 100LL freed it up quickly,so I figured it lubed it some as well,just had to run some 100 now and then.But you could be right and I don't mind.You will probably get your wish for unleaded 100 sooner than you might think.It's high on the EPA's list. Thanks,always enjoy your input,Gary Aman Mk3c Jabiru 2200a

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

BobsV35B(at)aol.com

Guest

|

Posted: Sat Mar 17, 2012 12:16 pm Post subject: valve problem Posted: Sat Mar 17, 2012 12:16 pm Post subject: valve problem |

|

|

Good Afternoon Gary,

Just parroting what I have been taught by George Braly, Tim Roehl and many others who have seriously studied the issue.

The folks who promote lead for cushioning and lubrication seem to be those same folks who claim that lean side operations are hard on our engines.� As George is fond of saying: "It is not how hard we run our engines it is how we run our engines hard!"

First heard such things back when I had a sail boat with an auxiliary engine (Atomic Four) of which the hand book said should only be fed "white" gas. About that same time there was an article in Sail Magazine purportedly written by the retired Ethyl engineer who had developed Tetra Ethyl Lead for octane enhancement. He mentioned that the lead had no real good properties at all other than as an Octane enhancer. It was, in fact, poisonous and bad stuff to handle. He wrote that when the PR people were trying to sell the public on using the Ethyl compound, they invented the idea that it may help lubrication and may cushion the valves.

The engineers that worked for the Ethyl corporation stated that there was NO basis for making that claim, but the brass went with the PR folks and we are still suffering from that false premise.

I do hope we get rid of lead. I also feel it is imperative that we get a 100 octane fuel by whatever means it can be done without using lead.

I agree with those who say the amount of lead we use is not a health problem, but the lead is not good for our engines either!

I hope George gets his no lead fuel (100UL he calls it) approved and I hope Swift fuel is also successful. Meanwhile, I want the lowest quantity of lead in my fuel that can do the job.

Sure would make the plugs last longer!

I figure the higher end solvents loosened up your fuel valve, but that is strictly a WAG!

Happy Skies,

Old Bob

TN IO-550-B that needs that fancy fuel!

W670 that doesn't care at all.

Downers Grove, Illinois

In a message dated 3/17/2012 2:26:56 P.M. Central Daylight Time, zeprep251(at)aol.com writes:

| Quote: | Bob,

The issue of valve seat recession with early on unleaded fuel comes to mind, but you may never have had to deal with that in your frame of experience.That was addressed with additives as well as other additives for other issues like alcohol separation,one of the reasons motor fuel smells so nice and does such a good job of removing sloshing compound from older aircraft fuel tanks.I could run the 87octane in the D35 with the E series engine, but after a while the fuel selector got too stiff to turn.A dose of 100LL freed it up quickly,so I figured it lubed it some as well,just had to run some 100 now and then.But you could be right and I don't mind.You will probably get your wish for unleaded 100 sooner than you might think.It's high on the EPA's list. Thanks,always enjoy your input,Gary Aman Mk3c Jabiru 2200a

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Sun Mar 18, 2012 3:50 am Post subject: valve problem Posted: Sun Mar 18, 2012 3:50 am Post subject: valve problem |

|

|

Good morning Bob-

I haven't spoken with you for a while now...good to hear from you

As to the "cushioning" effect of the lead in leaded gasoline, I offer

the following two anecdotes that I had first-hand knowledge of:

First, I used to work at the Chrysler Proving Grounds as a driver/

mechanic. When the talk of unleaded fuels first appeared, we had a

big-block engine...either a 383 or 413 cu. inch...that we were going

to use as a test vehicle for this fuel. In short order...I don't

recall how long....the engine began to run roughly, and it was

revealed that the valve seats were being "pounded" into the heads.

(The hydraulic valve adjusters compensated for the change in valve

geometry until they ran out of compensation) A few days later a new

set of heads arrived, and they had been "induction hardened"

according to one of the engineers involved in the project. I could

see an area of blue around the valve seats....my memory has faded

enough that I don't recall if all the valve seats were done or only

the exhausts, but it seems like it was only the exhausts.

Cut to about 20 years later (as I recall) and I was living in

California and driving a 1973 Datsun Z, and when California stopped

selling leaded fuel, and I was forced to use it in my Z, the engine

began to run a bit roughly, and I found some valves that were too

tight in their adjustments for clearance. I adjusted accordingly, and

a few weeks later, had to adjust again. And on and on, until I ran

out of adjustment on the rocker arms. Because I needed to keep the Z

running for transportation to work, I got another head from a scrap

yard and dropped it off at the auto machine shop for a valve job and

the installation of hardened seats. To my surprise, the techie called

me and said that this head already had hardened seats installed. That

head is still on my Z and is still running.

So whatever the reason, the leaded fuel did not harm my engine as it

relates to valve operation, but that unleaded stuff sure did a number

on it.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062

Prince prop 64 x 30, P-tip

Electroair direct-fire ignition system

Rotec TBI-40 injection (sleeved to 36mm)

Status: flying with 1236 hrs... (since 3-27-2006)

On Mar 17, 2012, at 4:15 PM, BobsV35B(at)aol.com wrote:

| Quote: | Good Afternoon Gary,

Just parroting what I have been taught by George Braly, Tim Roehl

and many others who have seriously studied the issue.

The folks who promote lead for cushioning and lubrication seem to

be those same folks who claim that lean side operations are hard on

our engines. As George is fond of saying: "It is not how hard we

run our engines it is how we run our engines hard!"

First heard such things back when I had a sail boat with an

auxiliary engine (Atomic Four) of which the hand book said should

only be fed "white" gas. About that same time there was an article

in Sail Magazine purportedly written by the retired Ethyl engineer

who had developed Tetra Ethyl Lead for octane enhancement. He

mentioned that the lead had no real good properties at all other

than as an Octane enhancer. It was, in fact, poisonous and bad

stuff to handle. He wrote that when the PR people were trying to

sell the public on using the Ethyl compound, they invented the idea

that it may help lubrication and may cushion the valves.

The engineers that worked for the Ethyl corporation stated that

there was NO basis for making that claim, but the brass went with

the PR folks and we are still suffering from that false premise.

I do hope we get rid of lead. I also feel it is imperative that we

get a 100 octane fuel by whatever means it can be done without

using lead.

I agree with those who say the amount of lead we use is not a

health problem, but the lead is not good for our engines either!

I hope George gets his no lead fuel (100UL he calls it) approved

and I hope Swift fuel is also successful. Meanwhile, I want the

lowest quantity of lead in my fuel that can do the job.

Sure would make the plugs last longer!

I figure the higher end solvents loosened up your fuel valve, but

that is strictly a WAG!

Happy Skies,

Old Bob

TN IO-550-B that needs that fancy fuel!

W670 that doesn't care at all.

Downers Grove, Illinois

In a message dated 3/17/2012 2:26:56 P.M. Central Daylight Time,

zeprep251(at)aol.com writes:

Bob,

The issue of valve seat recession with early on unleaded fuel comes

to mind, but you may never have had to deal with that in your frame

of experience.That was addressed with additives as well as other

additives for other issues like alcohol separation,one of the

reasons motor fuel smells so nice and does such a good job of

removing sloshing compound from older aircraft fuel tanks.I could

run the 87octane in the D35 with the E series engine, but after a

while the fuel selector got too stiff to turn.A dose of 100LL freed

it up quickly,so I figured it lubed it some as well,just had to run

some 100 now and then.But you could be right and I don't mind.You

will probably get your wish for unleaded 100 sooner than you might

think.It's high on the EPA's list. Thanks,always enjoy your

input,Gary Aman Mk3c Jabiru 2200a

www.matronics.com/contribution _-

============================================================

|

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

BobsV35B(at)aol.com

Guest

|

Posted: Sun Mar 18, 2012 5:31 am Post subject: valve problem Posted: Sun Mar 18, 2012 5:31 am Post subject: valve problem |

|

|

Good Morning Lynn,

Do you recall what the engineers decided was the problem at Chrysler?�

When I attended school concerning engine operation, such problems were noted.

Lead does a good low cost job of controlling the rate of combustion. Take away the lead and the combustion characteristics may change in a negative direction. It seems reasonable that changing the combustion characteristics will affect engine operations and the change needs to be considered.

In a very general way, take out the lead and you need to lower the compression ratio.

There are ways of controlling the timing of fuel into the cylinder that can allow higher compression with unleaded fuel, but such things are way above my pay grade!

Once again. I am not an engineer, just an interested student of the results.

I have never found a graduate engineer trained in the field that felt lead was beneficial to the engine, though the lead was the cheapest way to eliminate detonation.

I think we can all agree that detonation is a bad thing!

Taking away the lead will certainly change the combustion characteristics. That we do have to consider when we set up the engine.

Your experience certainly emphasizes the point that small changes often have unforeseen results.

Happy Skies,

Old Bob

In a message dated 3/18/2012 6:50:31 A.M. Central Daylight Time, lynnmatt(at)jps.net writes:

| Quote: | --> JabiruEngine-List message posted by: Lynn Matteson <lynnmatt(at)jps.net>

Good morning Bob-

I haven't spoken with you for a while now...good to hear from you

As to the "cushioning" effect of the lead in leaded gasoline, I offer

the following two anecdotes that I had first-hand knowledge of:

First, I used to work at the Chrysler Proving Grounds as a driver/

mechanic. When the talk of unleaded fuels first appeared, we had a

big-block engine...either a 383 or 413 cu. inch...that we were going

to use as a test vehicle for this fuel. In short order...I don't

recall how long....the engine began to run roughly, and it was

revealed that the valve seats were being "pounded" into the heads.

(The hydraulic valve adjusters compensated for the change in valve

geometry until they ran out of compensation) A few days later a new

set of heads arrived, and they had been "induction hardened"

according to one of the engineers involved in the project. I could

see an area of blue around the valve seats....my memory has faded

enough that I don't recall if all the valve seats were done or only

the exhausts, but it seems like it was only the exhausts.

Cut to about 20 years later (as I recall) and I was living in

California and driving a 1973 Datsun Z, and when California stopped

selling leaded fuel, and I was forced to use it in my Z, the engine

began to run a bit roughly, and I found some valves that were too

tight in their adjustments for clearance. I adjusted accordingly, and

a few weeks later, had to adjust again. And on and on, until I ran

out of adjustment on the rocker arms. Because I needed to keep the Z

running for transportation to work, I got another head from a scrap

yard and dropped it off at the auto machine shop for a valve job and

the installation of hardened seats. To my surprise, the techie called

me and said that this head already had hardened seats installed. That

head is still on my Z and is still running.

So whatever the reason, the leaded fuel did not harm my engine as it

relates to valve operation, but that unleaded stuff sure did a number

on it.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062

Prince prop 64 x 30, P-tip

Electroair direct-fire ignition system

Rotec TBI-40 injection (sleeved to 36mm)

Status: flying with 1236 hrs... (since 3-27-2006)

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

dwwilt

Joined: 06 Dec 2010

Posts: 192

|

Posted: Sun Mar 18, 2012 10:04 am Post subject: valve problem Posted: Sun Mar 18, 2012 10:04 am Post subject: valve problem |

|

|

I am an owner of a 1967 Mustang, 390cid. These engines were designed to run on 100 octane leaded gas. When I rebuilt the engine in 1998, I had the machine shop install hardened valve seats and they also hardened the exhaust ports. Unleaded fuel burns much hotter than leaded fuel and will absolutely eat up the valve seats on an engine designed to run on leaded fuel. The exhaust ports may not have needed to be hardened, but what the heck, I did it anyway. BTW, when I can (and this is usually all the time) I run aviation 100LL in my Mustang.

Have a wonderful day,

Dennis

N616DW (Arion Lightning S/N 132)

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Dennis |

|

| Back to top |

|

|

BobsV35B(at)aol.com

Guest

|

Posted: Sun Mar 18, 2012 10:45 am Post subject: valve problem Posted: Sun Mar 18, 2012 10:45 am Post subject: valve problem |

|

|

Good Afternoon Dennis,

I really do not feel you can make a flat statement that leaded fuel burns cooler than unleaded fuel.

It IS true that some engines will run hotter using unleaded fuel than they will using leaded fuel, but that is because the cylinder pressure is too high. Has nothing to do with lead or no lead.

Fuel formulations are different all over the country. The fuel is a mixture of chemicals that meet industry standards. That is true for aviation fuel as well as non aviation fuel.

If you are running a low compression engine, the lead is just a waste of money and has no effect on how hot the mixture will burn. Using aviation fuel does help if the car is not used often. Aviation fuel has a more stable nature and can be left in the tank for months without gumming up anything.

If you are burning valves when using unleaded fuel, you are probably getting detonation. Possibly even pre-ignition. If that happens, the engine will definitely run hotter!

What substantiation do you have that the leaded fuel burns cooler? I have never heard that nor have I read anything that makes that statement, but am always willing to learn.

There is more energy in each gallon of lower octane fuel. The higher octane fuels weigh just a bit less than the low octane fuels and we therefore can get a bit more energy out of low octane fuel than we can from high octane fuel, but we cannot run at as high a cylinder pressure when running low octane fuel.

We use high compression ratios to get more power out of the same size engine and the high compression can gain some efficiency provided it has a high octane fuel.

There are other formulations that can raise the octane of the fuel, but the components are much more expensive than Tetra Ethyl Lead.

If you can point me toward a reliable source that will tell us that leaded fuel burns cooler than unleaded fuel, I would sure like to find out where I am wrong.

Always learning something new!

Happy Skies,

Old Bob

In a message dated 3/18/2012 1:04:10 P.M. Central Daylight Time, dwwilt(at)aol.com writes:

| Quote: | I am an owner of a 1967 Mustang, 390cid. These engines were designed to run on 100 octane leaded gas. When I rebuilt the engine in 1998, I had the machine shop install hardened valve seats and they also hardened the exhaust ports. Unleaded fuel burns much hotter than leaded fuel and will absolutely eat up the valve seats on an engine designed to run on leaded fuel. The exhaust ports may not have needed to be hardened, but what the heck, I did it anyway. BTW, when I can (and this is usually all the time) I run aviation 100LL in my Mustang.

Have a wonderful day,

Dennis

N616DW (Arion Lightning S/N 132)

-----Original Message-----

From: BobsV35B <BobsV35B(at)aol.com>

To: jabiruengine-list <jabiruengine-list(at)matronics.com>

Sent: Sun, Mar 18, 2012 9:31 am

Subject: Re: valve problem

Good Morning Lynn,

Do you recall what the engineers decided was the problem at Chrysler?

When I attended school concerning engine operation, such problems were noted.

Lead does a good low cost job of controlling the rate of combustion. Take away the lead and the combustion characteristics may change in a negative direction. It seems reasonable that changing the combustion characteristics will affect engine operations and the change needs to be considered.

In a very general way, take out the lead and you need to lower the compression ratio.

There are ways of controlling the timing of fuel into the cylinder that can allow higher compression with unleaded fuel, but such things are way above my pay grade!

Once again. I am not an engineer, just an interested student of the results.

I have never found a graduate engineer trained in the field that felt lead was beneficial to the engine, though the lead was the cheapest way to eliminate detonation.

I think we can all agree that detonation is a bad thing!

Taking away the lead will certainly change the combustion characteristics. That we do have to consider when we set up the engine.

Your experience certainly emphasizes the point that small changes often have unforeseen results.

Happy Skies,

Old Bob

|

[quote][b]

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

|

|

| Back to top |

|

|

dwwilt

Joined: 06 Dec 2010

Posts: 192

|

Posted: Sun Mar 18, 2012 11:44 am Post subject: valve problem Posted: Sun Mar 18, 2012 11:44 am Post subject: valve problem |

|

|

Bob,

If you are running an engine designed to run on 100 octane fuel and you can only get less than that, you will burn the valve seats. Any classic car guy will tell you that. Every old classic car engine that gets rebuilt will have hardened seats installed or the machine shop doesn't understand older engines running on unleaded / lower octane fuel. Especially those with higher compression engines. I could probably get buy without using hardened seats in a 200cid 6 cylinder from the 60's. You must know 100 octane anything burns cooler than 91 or less octane fuel. I should have said that since you can't buy 100 octane unleaded fuel (in most places) that auto fuel is lower octane and burns hotter than 100LL.

Ethanol is horrible for older cars and their fuel lines that have not been changed in a while. After about 4 years, all of my fuel lines began to leak because there is something in there that just makes them deteriorate. Another problem with auto fuel is finding non-ethanol gas. Unless you go to a marina, it is very difficult to find just anywhere. You surely can't use ethanol in a fiberglass tank. Talk to the marine folks about that one. I have fiberglass tanks in my Lightning. I choose to use 100LL. Too hard to find unleaded premium without ethanol and who is to say it may have it anyway since ethanol is standard now for car fuel.

Have a wonderful day,

Dennis

N616DW (Arion Lightning S/N 132)

--

| | - The Matronics JabiruEngine-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?JabiruEngine-List |

|

_________________

Dennis |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|