|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

pdelano(at)telus.net

Guest

|

Posted: Tue Jun 05, 2012 11:05 pm Post subject: Elevator Skin, Not as expected Posted: Tue Jun 05, 2012 11:05 pm Post subject: Elevator Skin, Not as expected |

|

|

Hi All,

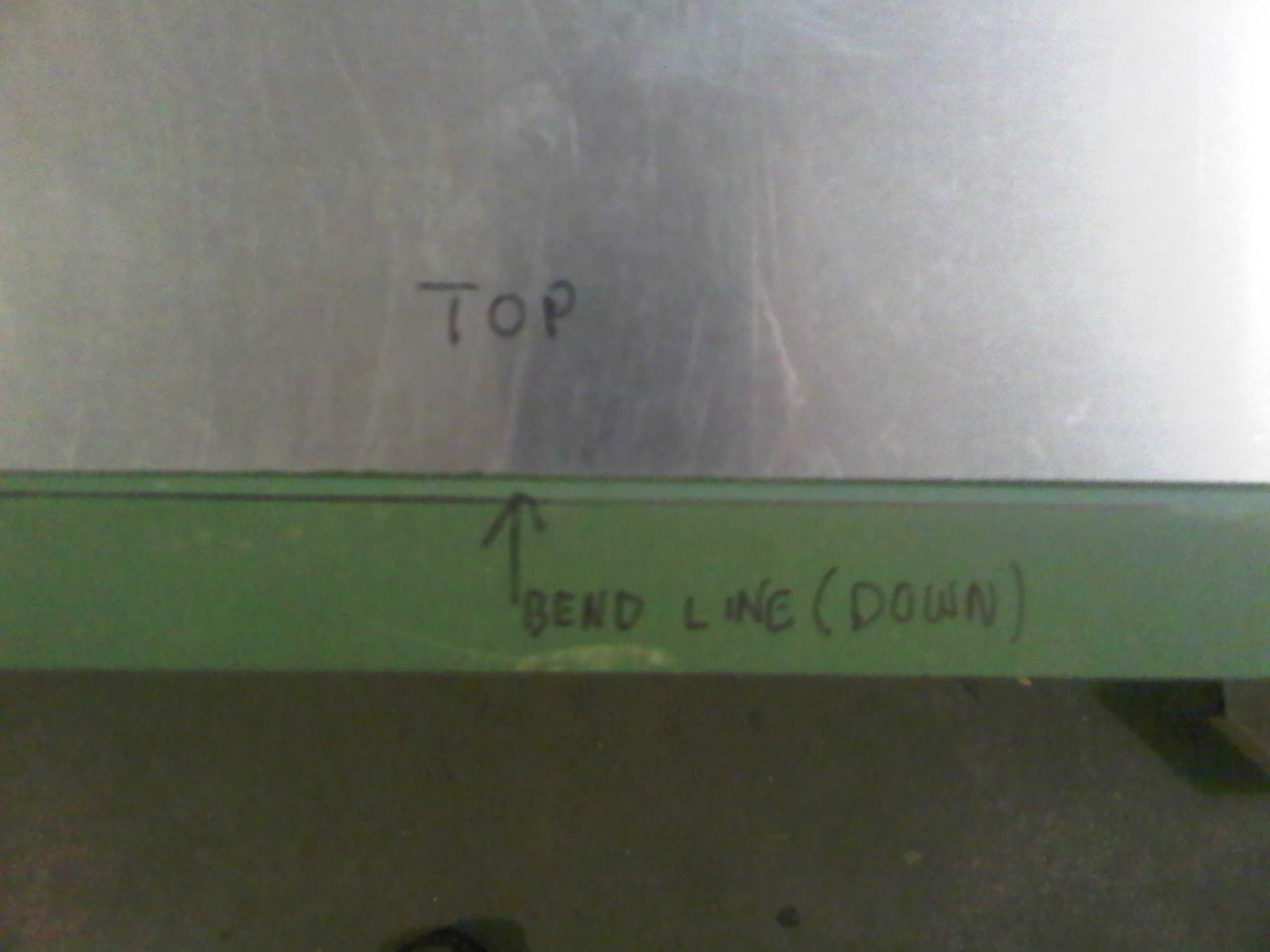

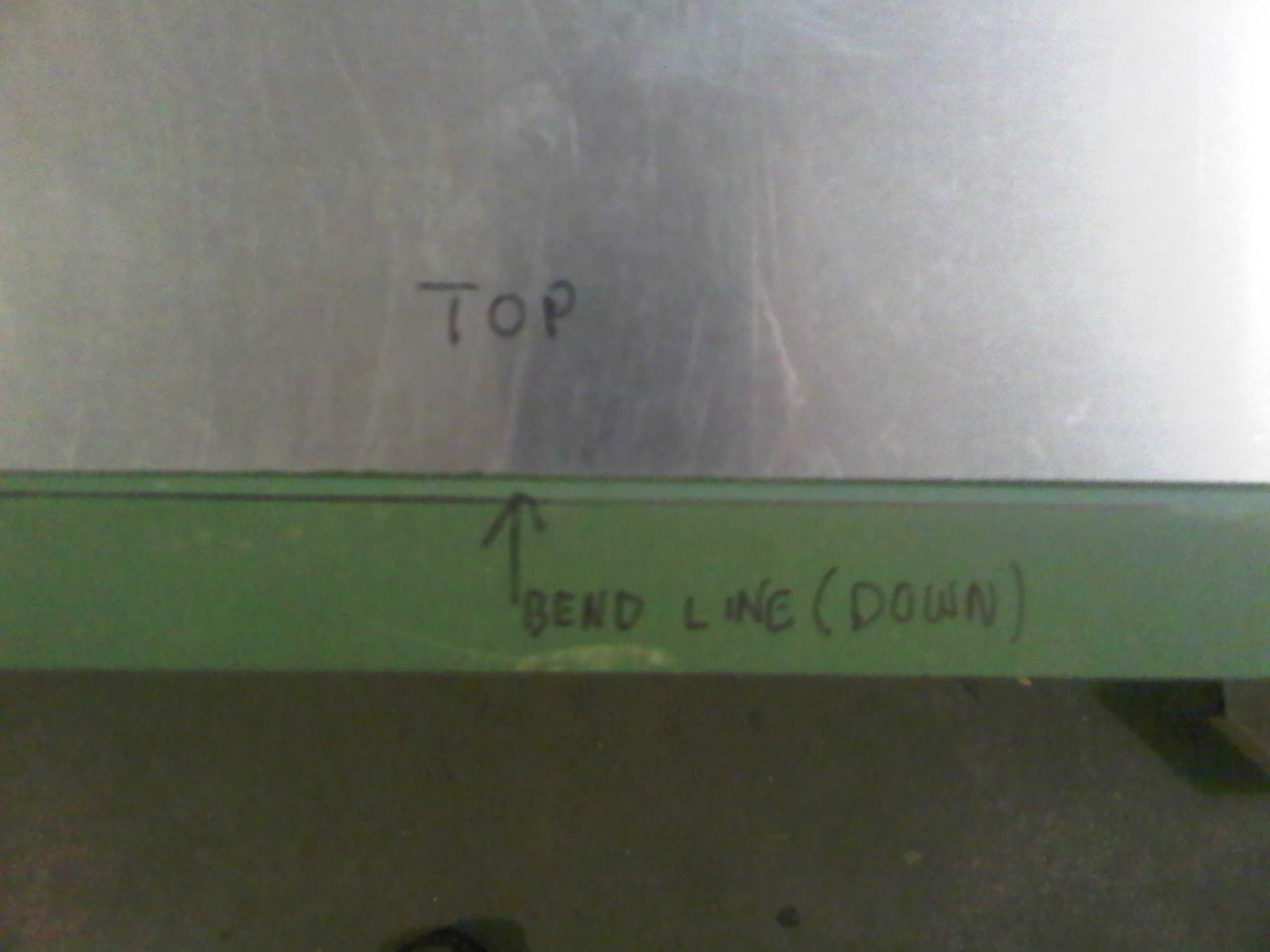

I thought being a shade tree mechanic and a mechanical engineer would serve me well in building a plane, I’m having my doubts. Please see attached photos. The elevator (kit Pieces) should be new version with the bend on the bottom skin (downward). As you can see the bent flange protrudes well past the top skin and if I were to put in the solid rivets along the trailing edge I would have to pull the skins together as they meet at point top and bottom planes intersecting rather than being parallel to each other. As you can see in one photo the bend line is out from under the top section of the skin. Thought I measured 3X and cut…..well drilled a lot of holes, anyway dazed and confused. Is this elevator scrap.

Sent same basic email to Caleb at Zenith.

Regards,

Perry

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

| Description: |

|

| Filesize: |

128.4 KB |

| Viewed: |

6802 Time(s) |

|

| Description: |

|

| Filesize: |

101.6 KB |

| Viewed: |

6802 Time(s) |

|

| Description: |

|

| Filesize: |

189.94 KB |

| Viewed: |

6802 Time(s) |

|

|

|

| Back to top |

|

|

dougsnash

Joined: 14 Apr 2008

Posts: 281

|

Posted: Wed Jun 06, 2012 4:18 am Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 4:18 am Post subject: Elevator Skin, Not as expected |

|

|

Perry, I don't remember the exact mistake I made with my first elevator as it was about six years ago, but whatever it was, you've duplicated it perfectly. I scrapped my entire elevator but didn't need too. You will likely need a new skin though and then match drill the holes moved by 20mm or so. In the assembly manual there is about half a chapter about finding the center point on the nose of the end ribs. The steps kind of seem redundant and should be pretty self explanatory but belive it or not, each of those steps is fairly critical to follow or you end up exactly as you have.

Another point to consider is the little duck tail bend in the elevator was meant to help the trim with a light two stroke on the nose. With a 912 Rotax or any other engine which is heavier, the duck tail actually causes insuficient trim and most builders end up bending it back to neutral. It would be easier to eliminate the ducktail bend while building the elevator instead of on an assembled and painted aircraft.

Hope this information helps.

Doug M

CH-701 from scratch

NW Ontario, Canada

From: Perry Delano <pdelano(at)telus.net>

To: zenith701801-list(at)matronics.com

Sent: Wednesday, June 6, 2012 1:37:56 AM

Subject: Elevator Skin, Not as expected

Hi All,

I thought being a shade tree mechanic and a mechanical engineer would serve me well in building a plane, I’m having my doubts. Please see attached photos. The elevator (kit Pieces) should be new version with the bend on the bottom skin (downward). As you can see the bent flange protrudes well past the top skin and if I were to put in the solid rivets along the trailing edge I would have to pull the skins together as they meet at point top and bottom planes intersecting rather than being parallel to each other. As you can see in one photo the bend line is out from under the top section of the skin. Thought I measured 3X and cut…..well drilled a lot of holes, anyway dazed and confused. Is this elevator scrap.

Sent same basic email to Caleb at Zenith.

Regards,

Perry

[quote][b]

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

john.marzulli(at)gmail.co

Guest

|

Posted: Wed Jun 06, 2012 5:16 am Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 5:16 am Post subject: Elevator Skin, Not as expected |

|

|

Yes, reverse the ducktail now!

I left it "from-factory" but ended up bending it during my phase 1 period. Bending it while the elevator is completed and on the plane is a pain.

John Marzullihttp://701Builder.blogspot.com

http://MarzulliPhoto.net

On Jun 6, 2012, at 5:17 AM, MacDonald Doug <dougsnash(at)yahoo.com (dougsnash(at)yahoo.com)> wrote:

[quote]Perry, I don't remember the exact mistake I made with my first elevator as it was about six years ago, but whatever it was, you've duplicated it perfectly. I scrapped my entire elevator but didn't need too. You will likely need a new skin though and then match drill the holes moved by 20mm or so. In the assembly manual there is about half a chapter about finding the center point on the nose of the end ribs. The steps kind of seem redundant and should be pretty self explanatory but belive it or not, each of those steps is fairly critical to follow or you end up exactly as you have.

Another point to consider is the little duck tail bend in the elevator was meant to help the trim with a light two stroke on the nose. With a 912 Rotax or any other engine which is heavier, the duck tail actually causes insuficient trim and most builders end up bending it back to neutral. It would be easier to eliminate the ducktail bend while building the elevator instead of on an assembled and painted aircraft.

Hope this information helps.

Doug M

CH-701 from scratch

NW Ontario, Canada

From: Perry Delano <pdelano(at)telus.net (pdelano(at)telus.net)>

To: zenith701801-list(at)matronics.com (zenith701801-list(at)matronics.com)

Sent: Wednesday, June 6, 2012 1:37:56 AM

Subject: Zenith701801-List: Elevator Skin, Not as expected

Hi All,

I thought being a shade tree mechanic and a mechanical engineer would serve me well in building a plane, I’m having my doubts. Please see attached photos. The elevator (kit Pieces) should be new version with the bend on the bottom skin (downward). As you can see the bent flange protrudes well past the top skin and if I were to put in the solid rivets along the trailing edge I would have to pull the skins together as they meet at point top and bottom planes intersecting rather than being parallel to each other. As you can see in one photo the bend line is out from under the top section of the skin. Thought I measured 3X and cut…..well drilled a lot of holes, anyway dazed and confused. Is this elevator scrap.

Sent same basic email to Caleb at Zenith.

Regards,

Perry

[quote][b]

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

pdelano(at)telus.net

Guest

|

Posted: Wed Jun 06, 2012 5:29 am Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 5:29 am Post subject: Elevator Skin, Not as expected |

|

|

Hi Doug,

Thanks for your speedy reply. I was pretty disappointed when I finally clued in last night that things had gone very wrong and was thinking I better think about a different hobby and was hoping someone would send something this morning to help me soldier on.  I’d already replaced a rear rib on the elevator because I mucked it up after noticing too much of a gap between it and the skin after riveting.

I know you are right about the new skin, I just did not want to believe it.

Regards,

Perry

From: owner-zenith701801-list-server(at)matronics.com [mailto:owner-zenith701801-list-server(at)matronics.com] On Behalf Of MacDonald Doug

Sent: Wednesday, June 06, 2012 5:17 AM

To: zenith701801-list(at)matronics.com

Subject: Re: Elevator Skin, Not as expected

Perry, I don't remember the exact mistake I made with my first elevator as it was about six years ago, but whatever it was, you've duplicated it perfectly. I scrapped my entire elevator but didn't need too. You will likely need a new skin though and then match drill the holes moved by 20mm or so. In the assembly manual there is about half a chapter about finding the center point on the nose of the end ribs. The steps kind of seem redundant and should be pretty self explanatory but belive it or not, each of those steps is fairly critical to follow or you end up exactly as you have.

Another point to consider is the little duck tail bend in the elevator was meant to help the trim with a light two stroke on the nose. With a 912 Rotax or any other engine which is heavier, the duck tail actually causes insuficient trim and most builders end up bending it back to neutral. It would be easier to eliminate the ducktail bend while building the elevator instead of on an assembled and painted aircraft.

Hope this information helps.

Doug M

CH-701 from scratch

NW Ontario, Canada

From: Perry Delano <pdelano(at)telus.net (pdelano(at)telus.net)>

To: zenith701801-list(at)matronics.com (zenith701801-list(at)matronics.com)

Sent: Wednesday, June 6, 2012 1:37:56 AM

Subject: Elevator Skin, Not as expected

Hi All,

I thought being a shade tree mechanic and a mechanical engineer would serve me well in building a plane, I’m having my doubts. Please see attached photos. The elevator (kit Pieces) should be new version with the bend on the bottom skin (downward). As you can see the bent flange protrudes well past the top skin and if I were to put in the solid rivets along the trailing edge I would have to pull the skins together as they meet at point top and bottom planes intersecting rather than being parallel to each other. As you can see in one photo the bend line is out from under the top section of the skin. Thought I measured 3X and cut…..well drilled a lot of holes, anyway dazed and confused. Is this elevator scrap.

Sent same basic email to Caleb at Zenith.

Regards,

Perry

| Quote: | | http://www.matronics.com/Navigator?Zenith701801-List |

01234567

[quote][b]

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

graeme(at)coletoolcentre.

Guest

|

Posted: Wed Jun 06, 2012 1:54 pm Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 1:54 pm Post subject: Elevator Skin, Not as expected |

|

|

Perry It is a bit hard to see from pictures but jpg 2 seems to indicate the top skin is protruding further out than the bottom skin.

which indicates the top skin should have been back further towards the elevator frame.

When you had it test fitted on the bench with ratchet tie downs holding the skin in place as per instructions you should have been able to get the skin trailing edge to match and clamp in position.

Unless you want to start again you will probably have to put a patch the length of the elevator in the bottom trailing edge with the bend in it (cut the bend out of old skin) looks like it needs to be approx 20mm longer to intersect correctly.

I wouldnt rely 100% on all measurements in plans some things may need to be fixed as you build make sure every thing is where it is surposed to be when you test fit.

Graemecns

[quote] ---

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

JohnDRead(at)aol.com

Guest

|

Posted: Wed Jun 06, 2012 7:11 pm Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 7:11 pm Post subject: Elevator Skin, Not as expected |

|

|

Hi Perry,

With the amount of overlap showing I think the skin is on the ribs upside down. You should be able to reverse it and with luck drill new holes in the ribs. The spar holes will be a mile off though so perhaps a new skin is the way to go.

Regards, John

CH701 - Colorado - Jabiru 3300

Cell: 719-494-4567

Home: 303-648-3261

[quote][b]

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

pdelano(at)telus.net

Guest

|

Posted: Wed Jun 06, 2012 10:39 pm Post subject: Elevator Skin, Not as expected Posted: Wed Jun 06, 2012 10:39 pm Post subject: Elevator Skin, Not as expected |

|

|

Hi John,

Thanks for the feedback. It appears a new skin or a patch strip are both an option. Although I’m building from plans that called for the bent edge up on the top skin. The newer kit parts come with bent flange down on the bottom skin. The latter added some complexity to the issue which I thought I had sorted out pre drilling anything. Low and Behold, Not. In any case I will move ahead with one or the other. I’ll try the patch as others have suggested and feedback from zenith seems to support. If it looks suspect, I’ll go for a new skin.

Regards,

Perry

From: owner-zenith701801-list-server(at)matronics.com [mailto:owner-zenith701801-list-server(at)matronics.com] On Behalf Of JohnDRead(at)aol.com

Sent: Wednesday, June 06, 2012 7:45 PM

To: zenith701801-list(at)matronics.com

Subject: Re: Elevator Skin, Not as expected

Hi Perry,

With the amount of overlap showing I think the skin is on the ribs upside down. You should be able to reverse it and with luck drill new holes in the ribs. The spar holes will be a mile off though so perhaps a new skin is the way to go.

Regards, John

CH701 - Colorado - Jabiru 3300

Cell: 719-494-4567

Home: 303-648-3261

| Quote: | | http://www.matronics.com/Navigator?Zenith701801-List |

01234567

[quote][b]

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

Viper_on_line

Joined: 27 Apr 2008

Posts: 3

Location: Maitland Australia

|

Posted: Thu Jun 07, 2012 5:05 pm Post subject: Re: Elevator Skin, Not as expected Posted: Thu Jun 07, 2012 5:05 pm Post subject: Re: Elevator Skin, Not as expected |

|

|

I had the same problem scratch building, mine was really close but didn't give enough edge distance for the trailing edge rivet line on the top skin aft of the ribs.

So new skin, match drilled and left the skin a bit longer, then cut to fit once clecoed in place.

Much better second time around.

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

_________________

701 scratch builder

one day it will fly |

|

| Back to top |

|

|

klondike(at)megalink.net

Guest

|

Posted: Fri Jun 08, 2012 5:11 am Post subject: Elevator Skin, Not as expected Posted: Fri Jun 08, 2012 5:11 am Post subject: Elevator Skin, Not as expected |

|

|

Well said--- it is important that scratch builders realize the plans are

telling you "what you have to end up for the final measurements", not

necessarily "cut to this dimension now".

I found it is best to overcut the aluminum by at least 10 mm if it requires

any bending.

And as said below, trim it after being fit. Also the second cut leaves a

much nicer edge.

If multiple bends, I'd leave more than 10 mm.

Fritz (701, 601)

---

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

pdelano(at)telus.net

Guest

|

Posted: Sat Jun 09, 2012 6:26 am Post subject: Elevator Skin, Not as expected Posted: Sat Jun 09, 2012 6:26 am Post subject: Elevator Skin, Not as expected |

|

|

Hi all,

After getting a lot of good responses here and talking with Caleb at zenith,

the solution to the miss measured skin (still not sure that is what it is as

everthing seems right exept the top skin shy about 20 mm) is to cut the

short skin back to the trailing edge of the spar and slide a new piece

underneath it to the leading edge of the spar (maybe a little more in each

case to ensure edge distance),thus both pieces will overlap each other.

Prior to doing any cutting ensure the new piece is long enough, wide enough

and alligned, I'll match drill the new piece through the old piece (already

drilled) and that I will cut off. End result, one extra seam line, no extra

rivets, no drilling out all the rivets in the bottom side of the skin and no

need to start from scratch on the elevator, "pheuuuww".

My challenge now is to find some .016 - .020 6061-T6 here on the west coast

or North West (US). Does anybody have a recommendation?

As an aside, I have gotten great support from Caleb at Zenith on too many

queries.

Regards,

Perry

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

dan(at)hillsgun.com

Guest

|

Posted: Sat Jun 09, 2012 7:22 am Post subject: Elevator Skin, Not as expected Posted: Sat Jun 09, 2012 7:22 am Post subject: Elevator Skin, Not as expected |

|

|

Hi Perry: I think you will find it easiest (and in the long run cheapest) to

order it from aircraft spruce. I have sourced a few other local sources for

some raw materials, but for most part spruce has been the best supplier as

the service has been very good, and they know what you want when you order.

You can have the .016 rolled. Dan Hill 701 scratch builder.

--

| | - The Matronics Zenith701801-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith701801-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|