|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

ploucandco

Joined: 16 Sep 2007

Posts: 69

|

Posted: Thu Aug 23, 2012 2:29 pm Post subject: Cracks on the cockpit module near to the seat belts Posted: Thu Aug 23, 2012 2:29 pm Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Hello all,

Doing a thorough check today, I found some cracks on both side of the central tunnel near the seat belts (see pictures). I would like to understand the gravity of these ones. I see the following options:

- my aircraft is grounded till repair (my current assumption)

- I can continue to fly with checking if the cracks are not further progressing after every flight

In order to repair, what do I need to organise?

- a new cockpit module -> that seems to be a drastic repair and maybe not even possible without separating the bottom from the top of the plane

- a local fix, but how to ensure structural integrity in this case?

I am not the builder but can find experienced people in fiberglass work (glider repair expert).

The plane is a monowheel. I got a gear up landing last year, about 40 hours ago. I see this one as the root cause of the cracks, but I could be wrong.

Any advice is welcome.

Jacques.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

335.34 KB |

| Viewed: |

7073 Time(s) |

|

| Description: |

|

| Filesize: |

360.86 KB |

| Viewed: |

7073 Time(s) |

|

| Description: |

|

| Filesize: |

377.15 KB |

| Viewed: |

7073 Time(s) |

|

Last edited by ploucandco on Sat Aug 25, 2012 11:25 am; edited 1 time in total |

|

| Back to top |

|

|

mau11(at)free.fr

Guest

|

Posted: Thu Aug 23, 2012 7:51 pm Post subject: Cracks on the cockpit module near to the seat belts Posted: Thu Aug 23, 2012 7:51 pm Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Hi Jacques, there is no pictures in your message

Michel AUVRAY

From: ploucandco (jacques(at)platisource.com)

Date: 2012-08-24 00:29

To: europa-list (europa-list(at)matronics.com)

Subject: Cracks on the cockpit module near to the seat belts

--> Europa-List message posted by: "ploucandco" <jacques(at)platisource.com>

Hello all,

Doing a thorough check today, I found some cracks on both side of the central tunnel near the seat belts (see pictures). I would like to understand the gravity of these ones. I see the following options:

- my aircraft is grounded till repair (my current assumption)

- I can continue to fly with checking if the cracks are not further progressing after every flight

In order to repair, what do I need to organise?

- a new cockpit module -> that seems to be a drastic repair and maybe not even possible without separating the bottom from the top of the plane

- a local fix, but how to ensure structural integrity in this case?

I am not the builder but can find experienced people in fiberglass work (glider repair expert).

The plane is a monowheel. I got a gear up landing last year, about 20 hours ago. I see this one as the root cause of the cracks, but I could be wrong.

Any advice is welcome.

Jacques.

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=381651#381651

Attachments:

http://forums.matronics.com//files/img_0181_382.jpg

http://forums.matronics.com//files/img_0180_412.jpg

http://forums.matronics.com//files/img_0179_669.jpg

======================================

sp;The Europa-List Email Forum -

avigator to browse

bsp;List Un/Subscription,

bsp;Browse, Chat, FAQ,

?Europa-List

======================================

p; - MATRONICS WEB FORUMS -

;via the Web Forums!

======================================

p; - List Contribution Web Site -

;support!

p; -Matt Dralle, List Admin.

ion

======================================

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ploucandco

Joined: 16 Sep 2007

Posts: 69

|

Posted: Fri Aug 24, 2012 12:04 am Post subject: Re: Cracks on the cockpit module near to the seat belts Posted: Fri Aug 24, 2012 12:04 am Post subject: Re: Cracks on the cockpit module near to the seat belts |

|

|

Hello, do others see the pictures? I checked with Explorer and Chrome and both show me the pictures.

Thanks for advice, Jacques.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

gholland(at)content-strea

Guest

|

Posted: Fri Aug 24, 2012 12:22 am Post subject: Cracks on the cockpit module near to the seat belts Posted: Fri Aug 24, 2012 12:22 am Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Jacques Hi.

Yes I do see the pictures embedded in my Apple Mail Note.

Any chance of one photo with out the red 'highlighting' to see 'as is'.

Regards

Gerry

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

gholland(at)content-strea

Guest

|

Posted: Fri Aug 24, 2012 12:26 am Post subject: Cracks on the cockpit module near to the seat belts Posted: Fri Aug 24, 2012 12:26 am Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Jacques

Pictures all open in Safari on a Mac from mail note URL.

Gerry

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

graeme bird

Joined: 15 Jul 2010

Posts: 434

|

Posted: Fri Aug 24, 2012 11:43 am Post subject: Re: Cracks on the cockpit module near to the seat belts Posted: Fri Aug 24, 2012 11:43 am Post subject: Re: Cracks on the cockpit module near to the seat belts |

|

|

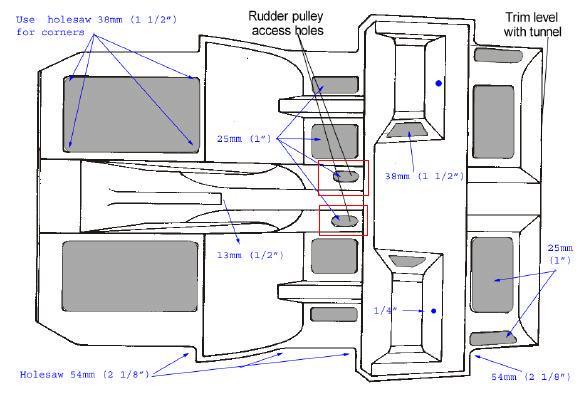

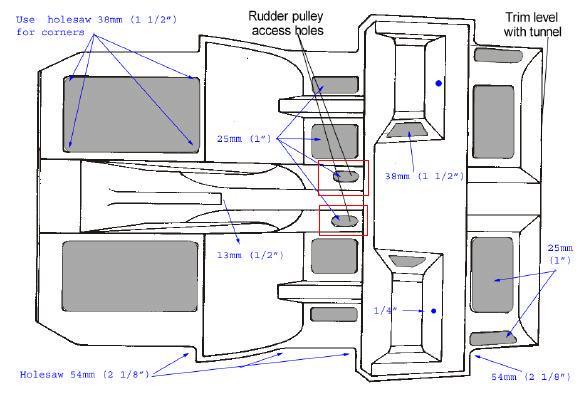

one thing I don't understand about the pictures, it looks like you have taped over slots in the tunnel which have become stress points, what are these?

I would have thought you could just clean out any damaged fibres, rough it up and add 4-5 layers of BID to cover the area including those holes, maybe to 120m -150mm from the mounting hole and drill the hole again, maybe bonding in a new penny washer. If you could get any BID on the inside that would be best.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Graeme Bird

kit4 (Wagstaff) TBD

Kit3 G-CLXU (Gregory) mono 914 xs Woodcomp

Kit2 G-PATS - (kesterton) Mono Classic 912 warpdrive

Kit 1 G-UMPY - Mono Classic/XS 912S, Woodcomp G(@)gdbmk.co.uk |

|

| Back to top |

|

|

Fred Klein

Joined: 26 Mar 2012

Posts: 503

|

Posted: Fri Aug 24, 2012 8:30 pm Post subject: Cracks on the cockpit module near to the seat belts Posted: Fri Aug 24, 2012 8:30 pm Post subject: Cracks on the cockpit module near to the seat belts |

|

|

On Aug 24, 2012, at 12:43 PM, graeme bird wrote:

| Quote: | one thing I don't understand about the pictures, it looks like you have taped over slots in the tunnel which have become stress points, what are these?

|

Jacques,

Your pixs are a bit confusing to me as well, though I interpreted the "taped over slots" to be the small access holes for viewing the rudder cable pulleys. If your pixs show what I think they show, you should be able to add some BID on the opposite side by reaching up thru the wheel well and / or reaching in thru the fuel valve access panel. Having made these comments, I nonetheless refrain from making any recommendations as this situation is way outside of my knowledge base and experience.

I hope others w/ the requisite knowledge, experience, and skills will offer some suggestions for you.

Fred

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ploucandco

Joined: 16 Sep 2007

Posts: 69

|

Posted: Sat Aug 25, 2012 9:25 am Post subject: Re: Cracks on the cockpit module near to the seat belts Posted: Sat Aug 25, 2012 9:25 am Post subject: Re: Cracks on the cockpit module near to the seat belts |

|

|

Hi all, here is a drawing of the cockpit module that shows with red rectangles the place where the pictures have been taken and so the location of the cracks. Will 5 BID at both side of the existing panel and on the cracks location be enough to repair and prevent reoccurence?

Thanks, Jacques

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

40.48 KB |

| Viewed: |

6990 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 224

|

Posted: Sun Aug 26, 2012 12:12 am Post subject: Cracks on the cockpit module near to the seat belts Posted: Sun Aug 26, 2012 12:12 am Post subject: Cracks on the cockpit module near to the seat belts |

|

|

<<..Any advice is welcome. .>>

OK, I'll bite!

During a monowheel collapse, the weight of the aircraft (less tailwheel and

outrigger loads) is transferred from the monowheel in to the top of the

'tunnel'. Thereafter, the stress-path from the tunnel is mostly both

forwards and aftwards. In the aft direction the tunnel distributes loads in

to the seatback bulkhead then further in to the fuselage skin. This means

that the area that has cracked (being at along this stress-path is taking

abnormal loads and this is a possible cause of the cracking, as you have

surmised, compounded by the holes that have been cut at that point.

Assuming there is no evidence of any other overstress in that area, the

repair needs to put back the strength lost. This means replication of the

original strength of composite in that location, which can be determined by

counting the number of plies present. Allow a minimum 1/2 inch per ply

overlap on to the surrounding unaffected area (presuming a bond shear

strength of 500psi and cloth strength of 250lbs/in) with staggered edges. If

the holes must be recut, then double the reinforcement and cut the holes as

ellipses (at a length:width ratio of 1.414:1, if you want to be pedantic!).

Too much or overdesigned reinforcement may make the area too stiff and

introduce other issues, and makes the aircraft heavy too!

Your respective airworthiness and/or design authority will be the final

arbiter of any repair, which might be along the lines of the above.

Duncan McF.

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

paul.the.aviator(at)gmail

Guest

|

Posted: Sun Aug 26, 2012 6:15 am Post subject: Cracks on the cockpit module near to the seat belts Posted: Sun Aug 26, 2012 6:15 am Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Duncan,

Thanks for posting this, I have been meaning to post something similar so you have saved me the trouble of going into the detail.

Jacques, the only thing I would like to add is that ideally you need to use the same cloth that was used in the original construction. In this case it might prove difficult because pre-preg bid was probably used in manufacture. The reason you need to do this is that using a material that is significantly different means that this material may carry more (or less) of the required load and become a source of stress in of its self.

I would see if you can get a response from Nev or Ivan to to find out how many layers of material were used and what sort of cloth was used. I know that when I did a repair on my wing I was fortunate enough to be able to get the exact cloth that was not pre-preg'd. Ask them is it the same cloth that was used in the wing. If it was then I have a small amount of this and I can send it to you.

Failing that, it wouldn't be horrible if you can't match the cloth, but do try and find out how many layers were in the original construction.

Paul

On Sun, Aug 26, 2012 at 3:11 AM, Duncan & Ami <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)> wrote:

[quote]--> Europa-List message posted by: "Duncan & Ami" <ami-mcfadyean(at)talktalk.net (ami-mcfadyean(at)talktalk.net)>

<<..Any advice is welcome. .>>

OK, I'll bite!

During a monowheel collapse, the weight of the aircraft (less tailwheel and

outrigger loads) is transferred from the monowheel in to the top of the

'tunnel'. Thereafter, the stress-path from the tunnel is mostly both

forwards and aftwards. In the aft direction the tunnel distributes loads in

to the seatback bulkhead then further in to the fuselage skin. This means

that the area that has cracked (being at along this stress-path is taking

abnormal loads and this is a possible cause of the cracking, as you have

surmised, compounded by the holes that have been cut at that point.

Assuming there is no evidence of any other overstress in that area, the

repair needs to put back the strength lost. This means replication of the

original strength of composite in that location, which can be determined by

counting the number of plies present. Allow a minimum 1/2 inch per ply

overlap on to the surrounding unaffected area (presuming a bond shear

strength of 500psi and cloth strength of 250lbs/in) with staggered edges. If

the holes must be recut, then double the reinforcement and cut the holes as

ellipses (at a length:width ratio of 1.414:1, if you want to be pedantic!).

Too much or overdesigned reinforcement may make the area too stiff and

introduce other issues, and makes the aircraft heavy too!

Your respective airworthiness and/or design authority will be the final

arbiter of any repair, which might be along the lines of the above.

Duncan McF.

[b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 224

|

Posted: Sun Aug 26, 2012 11:46 pm Post subject: Cracks on the cockpit module near to the seat belts Posted: Sun Aug 26, 2012 11:46 pm Post subject: Cracks on the cockpit module near to the seat belts |

|

|

Doesn't really matter which cloth, as the replacement cloth will be carrying al of the load across the cracks.

Number of plies can be determined by burning a sample taken from the damaged area.

D McF.

[quote]

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

ivanshaw(at)btinternet.co

Guest

|

Posted: Mon Aug 27, 2012 2:11 am Post subject: Cracks on the cockpit module near to the seat belts Posted: Mon Aug 27, 2012 2:11 am Post subject: Cracks on the cockpit module near to the seat belts |

|

|

The only comment I have to add is that it is generally wise with ‘small’ repair areas to, after replacing what was there with same strength cloth and ply orientation, overlapping plies half an inch is to add one ply of bid over the whole repair area as a belt and braces, peal plying all the edges or the whole repair if a small area. This covers the possibility of lack of strength due to less than perfect layup conditions/lack of perfect preparation etc, when done ‘in the field’

Ivan

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Duncan & Ami

Sent: 27 August 2012 08:46

To: europa-list(at)matronics.com

Subject: RE: Re: Cracks on the cockpit module near to the seat belts

Doesn't really matter which cloth, as the replacement cloth will be carrying al of the load across the cracks.

Number of plies can be determined by burning a sample taken from the damaged area.

D McF.

[quote]

--

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

budyerly(at)msn.com

Guest

|

Posted: Mon Aug 27, 2012 12:29 pm Post subject: Cracks on the cockpit module near to the seat belts Posted: Mon Aug 27, 2012 12:29 pm Post subject: Cracks on the cockpit module near to the seat belts |

|

|

<?xml:namespace prefix="v" /><?xml:namespace prefix="o" /><![endif]--> Jacques,

I have just been able to see your photos of your cracks.

As others and you suspect, the crack was the result of the gear up landing and the main wheel and arm impacting the top of the gear well (and the choke, throttle, locking arm and all the other stuff) and forcing the module to bend upward. The aft bulkhead to rear back rest distance is short and the stress looks to be a tension crack.

The area should be de-painted by sanding carefully to the upper layer of glass and the glass properly inspected as well as the Redux (Araldite 420A/B) joints in that area. Rudder cable, fuel lines, etc. should be removed to provide for proper visual inspection and repair...

The layup repair is similar to any composite repair. Grind down the crack and taper. Fill the foam with flox and glass with 2 layers of bid inside and out with the overlap to be at least 2 inches either side of the crack. Delamination of the Redux joints in the module must be checked also. Tapping with a large coin or drift can detect a hollow sound and possible delamination of your glue joint.

I prefer not to paint the interior of an airplane but it is expedient as an interior, however, it makes inspection more difficult and can hide damage.

I do not have a specific gear up landing checklist for my guys, but I have them use our hard landing checklist to start, which is attached.

Basically, on a gear up we remove the gear and inspect and repair the well and cockpit, because there is a good chance damage has occurred unless the collapse was very benign.

Please to a de-paint and do a thorough inspection. Tape up the instrument panel or remove it and grind away. There is a 50/50 chance that this is the only damage. However I'm unlucky and a 50/50 chance seems to be a 100% chance of more problems.

Regards,

Bud Yerly

Europa Tech Support,

or

Custom Flight Creations, Inc.

www.customflightcreations.com

(813) 653-4989

[quote] ---

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

Download |

| Filename: |

Europa_Over_Gross_or_Hard_Landing_Inspection.docx |

| Filesize: |

15.17 KB |

| Downloaded: |

248 Time(s) |

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|