|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

henry(at)pericynthion.org

Guest

|

Posted: Sun Oct 28, 2012 4:36 pm Post subject: B&C alternator diagnosis Posted: Sun Oct 28, 2012 4:36 pm Post subject: B&C alternator diagnosis |

|

|

Dear Bob et al,

I'm the owner but not the builder of a 1979 VariEze equipped with a

starterless O-200 and a B&C alternator (the 12-amp 200G model, I

believe). I don't have an ammeter in the cockpit. I do have an LED

bar-graph voltmeter in which I have placed little trust over the past

year or so, since it was showing around 12 volts rather than the

expected 13+. Perhaps I should have been more trusting.

Last week I had an electrical failure in flight, on a nice day over

familiar terrain. The first sign of trouble was the backlight

brightness decreasing on my Garmin 480; it subsequently reset itself

and then failed entirely. I have one magneto and one Lightspeed

electronic ignition, and not much else in the way of electronics in

the cockpit. Turning off the magneto resulted in rough running -

presumably the EI was trying its best to keep up with the low bus

voltage but didn't have enough juice to fire every time. Anyway I got

the green light signal from Livermore tower and landed without

incident. The battery measured 11.7 volts open-circuit.

This weekend I tried to diagnose the problem. The alternator circuit

breaker seems to be fine. I removed the regulator (see pics linked

below). The B&C alternator is a brushless model and only has two

wires coming out of it; I think the regulator is essentially a bridge

rectifier and a linear voltage regulator. B&C currently seems to sell

a separate "rectifier-type regulator" [1] and "crowbar" overvoltage

protection circuit [2]. I'm not sure if what I have is just the

regulator or a combination of the two. It looks to be completely

potted in resin except for one adjustment screw. It has four wires -

red (bus +), black (gnd) and two blue (alternator).

With a multimeter on diode mode I measured 0.55V drop from either blue

wire to the red, as you'd expect with a bridge rectifier. There was

also 1.2V drop from black to red, again as would be expected. But it

showed "open circuit" from black to either blue. Adjusting the screw

(which appeared to turn freely for 20+ revolutions, like one of those

multi-turn pots with the clutch) made no difference.

I plugged the regulator back in to the alternator (but not to the

aircraft bus), started the engine and observed 0.0V output on the red

and black wires. I disconnected the regulator again, measured the

alternator wires directly and saw around 17V AC.

So - the regulator's bad, right? It's not just trying to do something

clever in response to an open bus connection? I just want to be sure

I'm not missing something before I order a new one.

Thanks very much,

Henry

Photos:

Alternator - http://i.imgur.com/nIWgG.jpg

http://i.imgur.com/w8WlE.jpg http://i.imgur.com/ihwXI.jpg

Regulator - http://i.imgur.com/QXQUr.jpg http://i.imgur.com/ng9TH.jpg

[1] http://www.bandc.biz/regulator14vhomebuilt.aspx

[2] http://www.bandc.biz/pmovfilterandovprotectionkit14v.aspx

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henry(at)pericynthion.org

Guest

|

Posted: Sun Oct 28, 2012 5:05 pm Post subject: B&C alternator diagnosis Posted: Sun Oct 28, 2012 5:05 pm Post subject: B&C alternator diagnosis |

|

|

The mystery deepens. I connected the regulator to the alternator and

hooked the output of the regulator directly to the battery. Ran the

engine, saw the battery voltage increase from 12.15V (to which I had

previously trickle-charged it) to 12.4V and gradually over a few

minutes up to 12.8V. I removed the regulator output from the battery

(engine still running) and saw the output voltage from the regulator

rise to 15.0V. Connected it back to the battery via an ammeter and

saw 3.5A charge current - roughly what I should expect for an engine

idling around 1100 rpm. Adjusting the regulator's screw while all

this was happening didn't seem to change much.

So now I'm at a loss - it seems to be working again. Do you think

it's still a good idea to replace the regulator? The only other thing

I noticed is that one screw terminal on the battery was not tight -

not terribly loose, but I could undo it with just my fingers. I guess

I will put it all back together with a trusted voltmeter in the

cockpit and go fly in VMC for a while, but I'd love to hear ideas.

Thanks,

Henry

On Sun, Oct 28, 2012 at 5:34 PM, Henry Hallam <henry(at)pericynthion.org> wrote:

| Quote: |

Dear Bob et al,

I'm the owner but not the builder of a 1979 VariEze equipped with a

starterless O-200 and a B&C alternator (the 12-amp 200G model, I

believe). I don't have an ammeter in the cockpit. I do have an LED

bar-graph voltmeter in which I have placed little trust over the past

year or so, since it was showing around 12 volts rather than the

expected 13+. Perhaps I should have been more trusting.

Last week I had an electrical failure in flight, on a nice day over

familiar terrain. The first sign of trouble was the backlight

brightness decreasing on my Garmin 480; it subsequently reset itself

and then failed entirely. I have one magneto and one Lightspeed

electronic ignition, and not much else in the way of electronics in

the cockpit. Turning off the magneto resulted in rough running -

presumably the EI was trying its best to keep up with the low bus

voltage but didn't have enough juice to fire every time. Anyway I got

the green light signal from Livermore tower and landed without

incident. The battery measured 11.7 volts open-circuit.

This weekend I tried to diagnose the problem. The alternator circuit

breaker seems to be fine. I removed the regulator (see pics linked

below). The B&C alternator is a brushless model and only has two

wires coming out of it; I think the regulator is essentially a bridge

rectifier and a linear voltage regulator. B&C currently seems to sell

a separate "rectifier-type regulator" [1] and "crowbar" overvoltage

protection circuit [2]. I'm not sure if what I have is just the

regulator or a combination of the two. It looks to be completely

potted in resin except for one adjustment screw. It has four wires -

red (bus +), black (gnd) and two blue (alternator).

With a multimeter on diode mode I measured 0.55V drop from either blue

wire to the red, as you'd expect with a bridge rectifier. There was

also 1.2V drop from black to red, again as would be expected. But it

showed "open circuit" from black to either blue. Adjusting the screw

(which appeared to turn freely for 20+ revolutions, like one of those

multi-turn pots with the clutch) made no difference.

I plugged the regulator back in to the alternator (but not to the

aircraft bus), started the engine and observed 0.0V output on the red

and black wires. I disconnected the regulator again, measured the

alternator wires directly and saw around 17V AC.

So - the regulator's bad, right? It's not just trying to do something

clever in response to an open bus connection? I just want to be sure

I'm not missing something before I order a new one.

Thanks very much,

Henry

Photos:

Alternator - http://i.imgur.com/nIWgG.jpg

http://i.imgur.com/w8WlE.jpg http://i.imgur.com/ihwXI.jpg

Regulator - http://i.imgur.com/QXQUr.jpg http://i.imgur.com/ng9TH.jpg

[1] http://www.bandc.biz/regulator14vhomebuilt.aspx

[2] http://www.bandc.biz/pmovfilterandovprotectionkit14v.aspx

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Oct 29, 2012 8:34 am Post subject: B&C alternator diagnosis Posted: Mon Oct 29, 2012 8:34 am Post subject: B&C alternator diagnosis |

|

|

| Quote: | Adjusting the regulator's screw while all

this was happening didn't seem to change much.

|

This alternator output is too small to be set

reliably at combinations of low rpm and significant

load.

| Quote: | So now I'm at a loss - it seems to be working again. Do you think

it's still a good idea to replace the regulator? The only other thing

I noticed is that one screw terminal on the battery was not tight -

not terribly loose, but I could undo it with just my fingers. I guess

I will put it all back together with a trusted voltmeter in the

cockpit and go fly in VMC for a while, but I'd love to hear ideas.

|

The regulator can be accurately adjusted ONLY

with a fully charged battery, very light sytem

loads (suggest 2A or less) and SIGNIFICANT rpm,

like something 2000 or better.

The alternator is exceedingly robust . . . very

unlikely to fail. The rectifier/regulator has

a very low parts count, is potted for mechanical

ruggedness and is vulnerable to few stresses OTHER

than overheat.

If it has a history of good performance (Not accurately

known without an accurate voltmeter) what appears to

be a transient failure may have been a poor connection

that got 'cured' as a product of removal and replacement.

If it were my airplane, I'd fit it with a voltmeter of

trustworthy accuracy. Also, a low voltage warning

light so that future failures are not a surprise.

Find out where the system voltage stabilizes under light

load after some sustained operations . . . say just before

descent to land on your next trip. Make little tweeks

of the potentiometer setting based on these observations.

Shoot for 14.2 but settle for 14.0 to 14.5.

The successful resolution starts with trustworthy

measurement and observation. Where's your rectifier/

regulator mounted? Where does it tie into the electrical

system? Do you have a wiring diagram for this airplane

that can be scanned/shared?

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henry(at)pericynthion.org

Guest

|

Posted: Mon Oct 29, 2012 7:02 pm Post subject: B&C alternator diagnosis Posted: Mon Oct 29, 2012 7:02 pm Post subject: B&C alternator diagnosis |

|

|

On Mon, Oct 29, 2012 at 9:33 AM, Robert L. Nuckolls, III

<nuckolls.bob(at)aeroelectric.com> wrote:

| Quote: |

<nuckolls.bob(at)aeroelectric.com>

> Adjusting the regulator's screw while all

> this was happening didn't seem to change much.

This alternator output is too small to be set

reliably at combinations of low rpm and significant

load.

|

Thanks for the insights! I also found this doc on B&C's site:

http://www.bandc.biz/pdfs/sd8trbreva.pdf that agrees with everything

you've said.

| Quote: | The successful resolution starts with trustworthy

measurement and observation. Where's your rectifier/

regulator mounted? Where does it tie into the electrical

system? Do you have a wiring diagram for this airplane

that can be scanned/shared?

Bob . . .

|

I will definitely be fitting a reliable voltmeter and warning light.

Unfortunately I don't have a wiring diagram, though I'm working on

putting one together from my own notes taken during maintenance and

upgrades. My rectifier/regulator is mounted on the engine side of the

firewall, in what I think is a relatively cool location (on the high

pressure side of the updraft cooling system). The positive output

goes via a 14 AWG wire to a 10-amp CB on the instrument panel and from

there to the positive battery terminal (battery in the nose of the

canard-pusher airplane). The negative output goes to a general ground

terminal on the engine mount frame and from there via a similar 14 AWG

wire to the negative battery terminal. The instrument power bus is

connected to the battery terminals by another set of wires, and

there's a third set for the electronic ignition.

Any reason not to tune the regulator voltage setpoint on the bench

with a constant-current bench supply on the blue wires and my airplane

battery on the red+black?

Thanks again for the advice.

Henry

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Oct 30, 2012 5:17 am Post subject: B&C alternator diagnosis Posted: Tue Oct 30, 2012 5:17 am Post subject: B&C alternator diagnosis |

|

|

| Quote: | I will definitely be fitting a reliable voltmeter and warning light.

Unfortunately I don't have a wiring diagram, though I'm working on

putting one together from my own notes taken during maintenance and

upgrades. My rectifier/regulator is mounted on the engine side of the

firewall, in what I think is a relatively cool location (on the high

pressure side of the updraft cooling system).

|

Good

| Quote: | The positive output

goes via a 14 AWG wire to a 10-amp CB on the instrument panel and from

there to the positive battery terminal (battery in the nose of the

canard-pusher airplane).

|

Does your airplane have a starter? If so, where

is the starter contactor located?

| Quote: | The negative output goes to a general ground

terminal on the engine mount frame and from there via a similar 14 AWG

wire to the negative battery terminal.

|

Hmmmm . . . I deduce that there is no starter

and the 14AWG ground is the only conductor between

the crankcase and the battery(-)?

| Quote: | The instrument power bus is

connected to the battery terminals by another set of wires, and

there's a third set for the electronic ignition.

|

Hmmmm . . . battery terminal used as a power distribution

point. Is there a battery switch?

| Quote: | Any reason not to tune the regulator voltage setpoint on the bench

with a constant-current bench supply on the blue wires and my airplane

battery on the red+black?

|

Yes, this is a crude form of switchmode regulator.

Not of the inductor-stored energy variety, but a

duty cycle switched series regulator with SCR's

that get triggered in a variable position along

each half-cycle of the incoming waveform.

It must be adjusted under operating conditions that

mimic the as-installed condition on the airplane.

Here's a schematic of an exemplar rectifier/regulator

for a PM alternator:

http://tinyurl.com/94585zs

When we crafted installation instructions for that

regulator/alternator combination on a no-starter

airplane years ago, I brought ac power to the

battery area on a twisted pair. The R-R was mounted

close to the battery so that series resistance in the

sense-lines shared with power-delivery lines did

not become significant impedances in the control

loop.

Later drawings published by B&C dropped that

configuration. That's been so long ago that I

don't recall if I had any conversation with them

about the change. I cannot prove that the old

configuration was demonstrably 'better' but it

was crafted with consideration for deleterious

effects of unnecessary resistance in sense

feeders shared with power feeders.

Don't know if it's an option for you but you

might consider using the 14AWG pair coming

forward as AC power feeders and move the R-R

to the forward space shared with the battery.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

henry(at)pericynthion.org

Guest

|

Posted: Tue Oct 30, 2012 9:23 am Post subject: B&C alternator diagnosis Posted: Tue Oct 30, 2012 9:23 am Post subject: B&C alternator diagnosis |

|

|

On Tue, Oct 30, 2012 at 6:11 AM, Robert L. Nuckolls, III

<nuckolls.bob(at)aeroelectric.com> wrote:

| Quote: | > The positive output

> goes via a 14 AWG wire to a 10-amp CB on the instrument panel and from

> there to the positive battery terminal (battery in the nose of the

> canard-pusher airplane).

Does your airplane have a starter? If so, where

is the starter contactor located?

|

No starter.

| Quote: |

> The negative output goes to a general ground

> terminal on the engine mount frame and from there via a similar 14 AWG

> wire to the negative battery terminal.

Hmmmm . . . I deduce that there is no starter

and the 14AWG ground is the only conductor between

the crankcase and the battery(-)?

|

Yes, except there are probably some other (skinnier) ground paths due

to engine sensors and the electronic ignition. The main ground

conductor might be 12 AWG rather than 14, I'll check tomorrow.

| Quote: | > The instrument power bus is

> connected to the battery terminals by another set of wires, and

> there's a third set for the electronic ignition.

Hmmmm . . . battery terminal used as a power distribution

point. Is there a battery switch?

|

There's a switch labeled "battery" that supplies the instrument bus

(with individual CBs after that for each instrument). Is this

arrangement a bad idea?

| Quote: |

> Any reason not to tune the regulator voltage setpoint on the bench

> with a constant-current bench supply on the blue wires and my airplane

> battery on the red+black?

Yes, this is a crude form of switchmode regulator.

Not of the inductor-stored energy variety, but a

duty cycle switched series regulator with SCR's

that get triggered in a variable position along

each half-cycle of the incoming waveform.

It must be adjusted under operating conditions that

mimic the as-installed condition on the airplane.

Here's a schematic of an exemplar rectifier/regulator

for a PM alternator:

http://tinyurl.com/94585zs

|

Makes sense, thanks!

| Quote: |

When we crafted installation instructions for that

regulator/alternator combination on a no-starter

airplane years ago, I brought ac power to the

battery area on a twisted pair. The R-R was mounted

close to the battery so that series resistance in the

sense-lines shared with power-delivery lines did

not become significant impedances in the control

loop.

|

Interesting. It's great to get insight from the designer.

| Quote: |

Later drawings published by B&C dropped that

configuration. That's been so long ago that I

don't recall if I had any conversation with them

about the change. I cannot prove that the old

configuration was demonstrably 'better' but it

was crafted with consideration for deleterious

effects of unnecessary resistance in sense

feeders shared with power feeders.

Don't know if it's an option for you but you

might consider using the 14AWG pair coming

forward as AC power feeders and move the R-R

to the forward space shared with the battery.

|

I'll look into it - I agree that sounds like a better arrangement

feedback-wise, but I don't think the existing wire run I have is a

twisted pair, so I'd be a bit concerned about EMI emissions from that

long of a run of chopped AC. I'll see how much trouble a new wire run

would be. If I had the time it could be a fun project to design my

own switching regulator with separate sense lines... for that matter,

do you know why these brushless alternator designs didn't use three

phases like a modern BLDC motor?

Thanks again

Henry

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Tue Oct 30, 2012 1:30 pm Post subject: B&C alternator diagnosis Posted: Tue Oct 30, 2012 1:30 pm Post subject: B&C alternator diagnosis |

|

|

| Quote: |

I'll look into it - I agree that sounds like a better arrangement

feedback-wise, but I don't think the existing wire run I have is a

twisted pair, so I'd be a bit concerned about EMI emissions from that

long of a run of chopped AC. |

I've not had an opportunity to run a PM alternator in

the lab . . . so the twisted pair was simple a prophylactic

derived from common sense. In any case, I doubt that

EMI products go very high in frequency. Given that ADF

is gone (taking am radio with it), the probability

for real interference is small. It would be a relatively

easy experiment. See if you can use the existing 14AWG

pair as an AC power feeder and then fly it.

| Quote: | | I'll see how much trouble a new wire run would be. |

Many moons ago, I was able to use an existing wire as

a pull-tape to run in a new instrumentation wire . . .

a shielded trio. The bundles between firewall and the nose

section were not tightly tied.

You might see if tugging on the 14AWG produces any

significant motion at non-scary forces.

| Quote: | If I had the time it could be a fun project to design my

own switching regulator with separate sense lines... |

Yeah, I have such a design somewhere. I'll see if I

can dig it out. The design is a buck-regulator scaled

to run off the un-regulated, full wave rectified DC

out of the alternator. I looked at that product about

20 years ago but some new kids on the block might

re-open the door. Consider this:

A full wave rectifier on the firewall and local

capacitor would get you unregulated, HV dc. I don't

recall now what the open circuit AC votlage is for

your alternator at cruise . . . you might get a measurement

at some known ramp RPM from which we can extrapolate

the higher rpm value. Use a rectifier and filter capacitor

with a light load, say 100 ohms across it. Measure the resulting

DC at some handy RPM.

If max DC is below 28, then this regulator might have

promise:

http://tinyurl.com/8fm6reh

Given that you do not have a starter, there may not

be a good reason to keep a battery on board . . .

or the battery could be scaled down to deal with

only with taxi rpm situations. These regulators provide

constant, clean output as long as the input is

high enough. You might even consider two regulators.

They're light and smaller than a battery. One could

be a standby. It's exceedingly unlikely that you would

ever loose the alternator.

Food for thought.

for that matter,

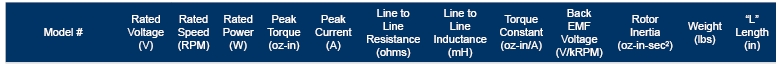

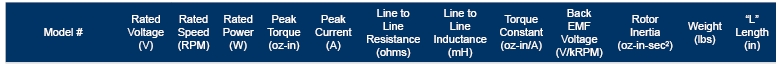

| Quote: | do you know why these brushless alternator designs didn't use three

phases like a modern BLDC motor? |

You could do that . . . here's an interesting

motor

[img]cid:.0[/img]

[img]cid:.0[/img]

BEMF of 6v/krpm says you'll get about 24 volts at

4000 pad drive speeds. The winding resistances are

low. It seems that you would get 10A plus out of this

motor back-driven as a PM, 3-phase alternator.

It would cost you about $200 to put your hands on one

to play with.

http://tinyurl.com/95jny8c

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

48.08 KB |

| Viewed: |

8576 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Oct 31, 2012 7:32 am Post subject: B&C alternator diagnosis Posted: Wed Oct 31, 2012 7:32 am Post subject: B&C alternator diagnosis |

|

|

At 07:14 PM 10/30/2012, you wrote:

Yeah, those little RC BLDC motors are amazing products.

I've got a couple here that have been played with a bit.

A few years ago, I was asked to proposed a table-top

demonstrator for quantifying both brushed and

brushless DC motor performance. Never got a response

back on my proposal. But it was an opportunity to

sample what was out there.

I've considered studying their application in a wind-driven

power source for ultra-lights and antiques. But that's

a project WAAAAaaayyy back on the burners!

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1927

Location: Riley TWP Michigan

|

Posted: Wed Oct 31, 2012 10:02 am Post subject: Re: B&C alternator diagnosis Posted: Wed Oct 31, 2012 10:02 am Post subject: Re: B&C alternator diagnosis |

|

|

| Quote: | do you know why these brushless alternator designs didn't use three

phases like a modern BLDC motor? |

This is pure speculation on my part; so correct me if wrong.

If the coils of a single phase alternator were rewired to make a 3 phase alternator, then voltage output would be only 1/3 of the single phase voltage. In order for a 3 phase alternator to have the same voltage output as a single phase alternator, it would have to have two more windings of the same size. Then it would weigh more and cost more.

Joe

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Oct 31, 2012 12:11 pm Post subject: B&C alternator diagnosis Posted: Wed Oct 31, 2012 12:11 pm Post subject: B&C alternator diagnosis |

|

|

At 01:02 PM 10/31/2012, you wrote:

> do you know why these brushless alternator designs didn't use three

> phases like a modern BLDC motor?

This is pure speculation on my part; so correct me if wrong.

If the coils of a single phase alternator were rewired to make a 3

phase alternator, then voltage output would be only 1/3 of the single

phase voltage. In order for a 3 phase alternator to have the same

voltage output as a single phase alternator, it would have to have

two more windings of the same size. Then it would weigh more and cost more.

Joe

--------

Joe Gores

The power output from an AC device is roughly proportional

to the weight of the active magnetic material (core), magnetic

strength and speed (rpm). I'm recalling from memory now but

back when I was winding my own transformers, a 1 pound core

was good for about 60 watts at 60 Hz. The same weight of core

in a 400 Hz system was good for 6.5 times that power . . .

400 watts. This assumes similar levels of magnetic flux

that can be carried in the core without saturation or

increases losses at higher frequencies.

An automotive alternator is already crafted as a 3-phase

device. The configuration requires that pole-pairs on the

rotating magnet come in some multiple of 3 (usually

6 pairs but can be more on larger machines).

The output voltage of any given widing is proportional

to speed x flux value x number of turns. When you 'rewind'

to get more voltage, it generally has to be done with

smaller wire . . . the winding window in the core is fixed.

The practical power output is not a linear function because

of heating effects of I-squared x R in the wires and the

windings ability to reject heat into the core and end turns.

There's not a great deal to be gained in power by going from

single to three-phase . . . it's that weight,flux,speed thing.

The BIG toe-stubber is pole piece configuration. The magnets

glued to the inside of the popular PM alternator shells (or

wound-field machines) are already optimized for their as-

manufactured condition. It takes more than a 'rewinding'

to morph from single to 3-phase configuration. But assuming

all other things are held the same, the watts-per-pound-per-

velocity will be the same for both configurations.

The BIG advantage of 3-phase is the smoother output with

simple full-wave rectification . . . about 5% ripple as

compared to 100% ripple for single-phase. But if the designer

sets out to do a clean piece of paper, 3-phase design it

will be only moderately more expensive. The power can be

a little better because the windings share duties . . . i.e.

there is never a time when current goes to zero in more than

one winding.

Bob . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|