|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

carlossa52(at)gmail.com

Guest

|

Posted: Wed Oct 02, 2013 4:14 pm Post subject: a tip Posted: Wed Oct 02, 2013 4:14 pm Post subject: a tip |

|

|

I have noticed - through other builders comments, but also through my own experience - that using clecoes to keep parts together sometimes does not quite work.

The parts do remain attached, not doubt, but they can be slightly shifted from the original position when they were drilled.

Here's why, in case you don't know:

The rivet whole is slightly larger than the rivet, and a cleco, having an irregular shape, has plenty of room to move in a rivet hole.

For instance an A5 Avex rivet has a diameter between 0.140" and 0.155" (the rivet has "fins", therefore the diameter varies).

A solid rivet diameter is 0.155"

The corresponding drill bit is 0.160".

A black cleco is 0.149" at its widest point - but it is not round.

(Note: these are measurements I took from Items I have. You may find slightly different measurements.)

In longer parts (more than a foot or two) or assemblies of more than two parts, I find that if parts are not perfectly aligned, it's hard to insert the rivets. And, worse, parts will be warped or difficult to match as I proceed with construction.

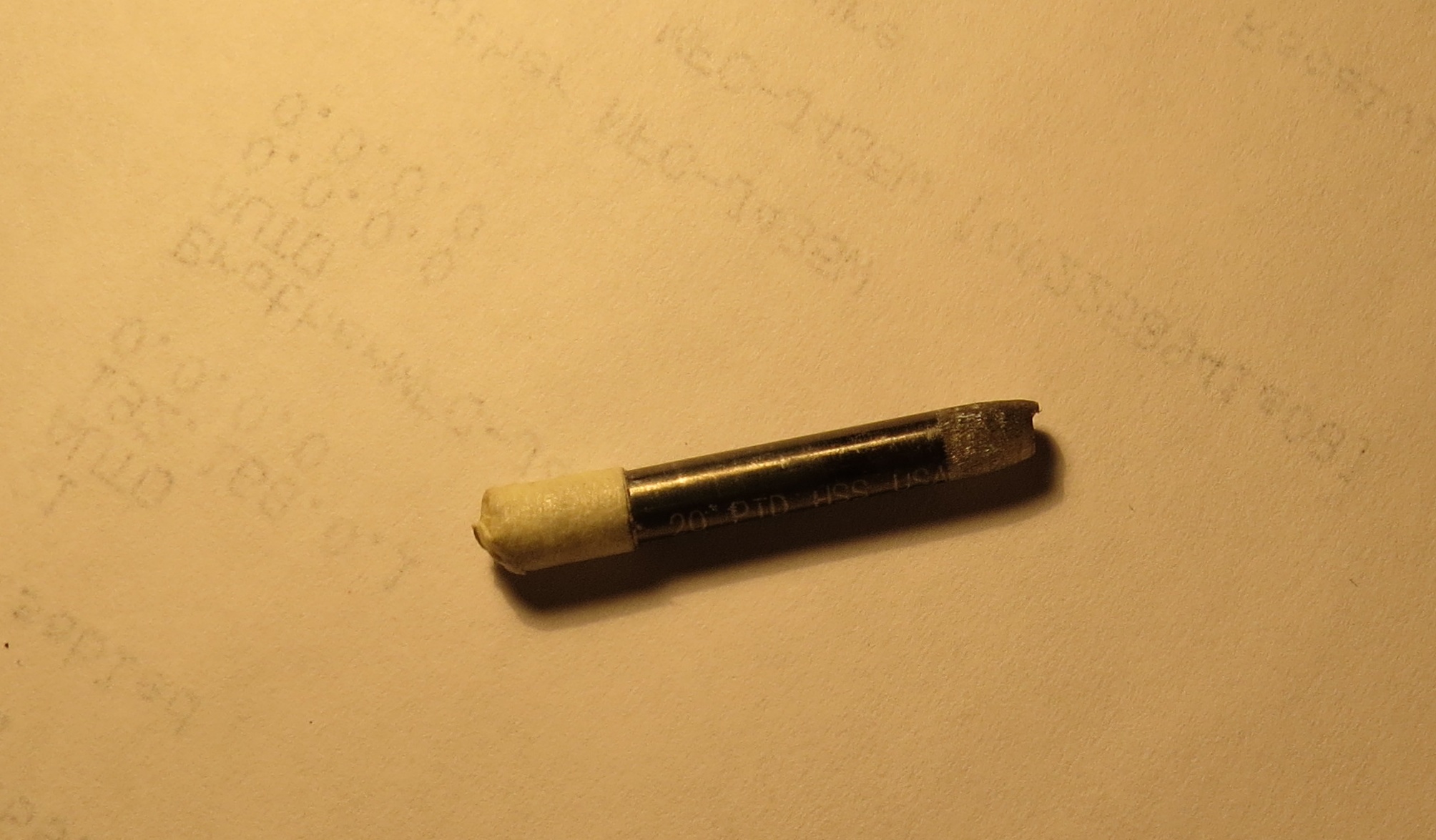

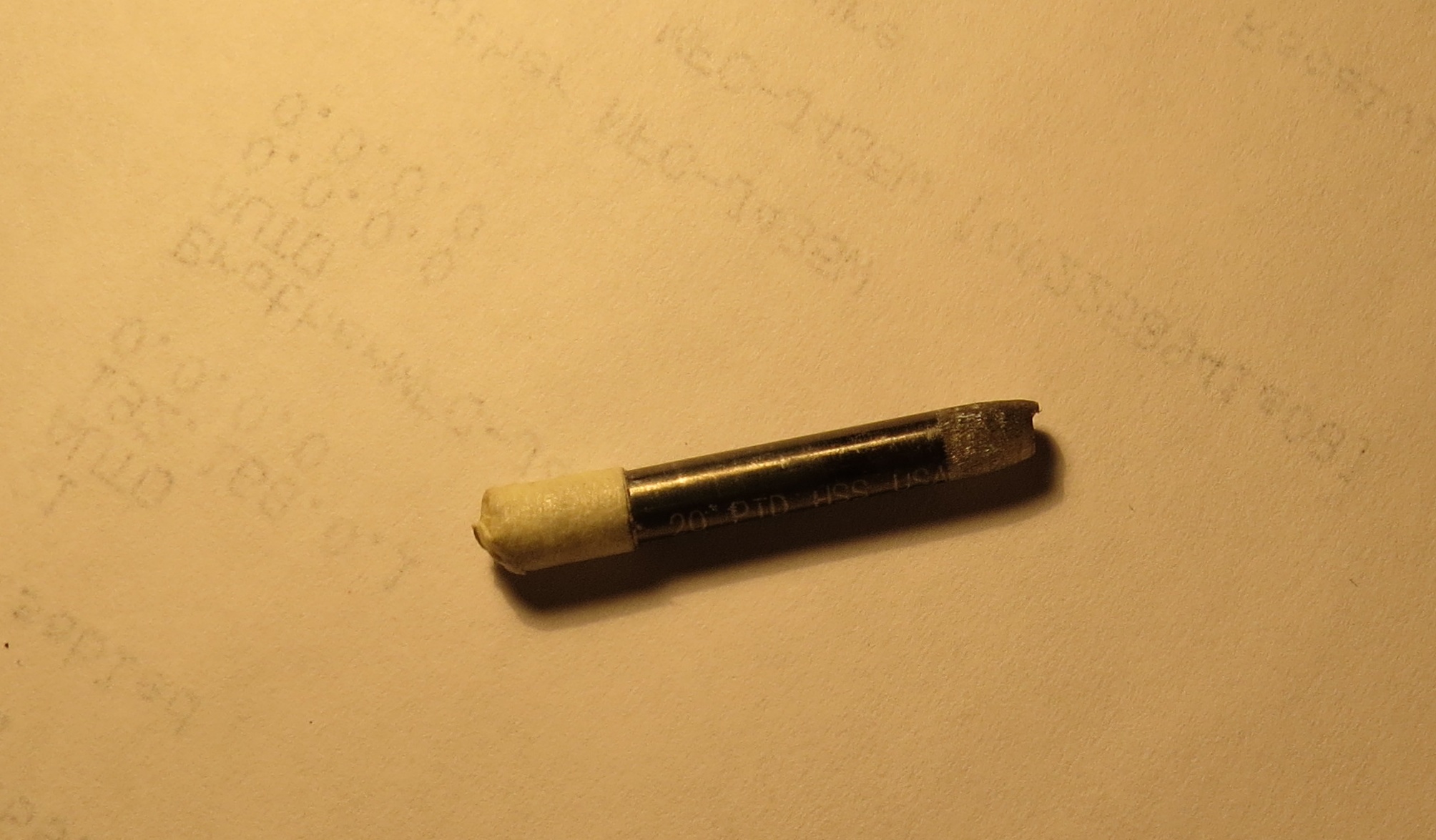

So, instead of simply trusting the clecoes, I started adding spent drill bits here and there (a solid rivet is better than a cleco, but not as good as a spent drill bit).

I eventually started cutting drill bits and grinding one end to make it easier to insert them.

(The grinding process consists of putting the drill bit in a drill or drill press and grinding it with a dremel tool.).

The opposite end is covered with masking tape - see attached photo.

I have a bunch of these, A4 and A5, and use them frequently.

Hopefully this can be useful to someone.

Blue skies

Carlos

CH601-HD, plans

(CH650 firewall and canopy)

http://www.zenith.aero/profile/CarlosSa

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

| Description: |

|

| Filesize: |

463.43 KB |

| Viewed: |

6964 Time(s) |

|

|

|

| Back to top |

|

|

psm(at)att.net

Guest

|

Posted: Wed Oct 02, 2013 4:32 pm Post subject: a tip Posted: Wed Oct 02, 2013 4:32 pm Post subject: a tip |

|

|

Carlos,

I accept your numbers, but I think you are worrying a little bit too

much about perfection.

Clecos do line up holes pretty well because the back side of the "head"

is indeed round. This grabs the entire hole on the opposite side of the

main clamp body. Well . . . it misses the area where the crack appears

between the fingers, but it does a good job of clamping the sheet metal

in place.

The more Clecos you use, the more aligned the pieces will be. I like

starting a rivet line with Clecos in every other hole and continue

working on this line by swapping the Cleco points and empty holes as the

parts are repeatedly drilled to higher and higher sizes. I usually have

not had any problem getting the holes aligned for final riveting after

deburring. In those cases where I have difficulty inserting the rivet,

I just run the final dril through the hole again. This may mean the

holes in all the riveted pieces are not precisely the same size but I

don't think this matters. The primary gripping is done by the two heads

of the final rivet.

It is important to do a good job on your construction, but keep in mind

you are building a relatively low performance airplane rather than a

space shuttle.

Good luck,

Paul

Camas, WA

Zodiac XL, in phase II

On 10/2/2013 5:13 PM, Carlos Sa wrote:

| Quote: | I have noticed - through other builders comments, but also through my

own experience - that using clecoes to keep parts together sometimes

does not quite work.

The parts do remain attached, not doubt, but they can be slightly

shifted from the original position when they were drilled.

Here's why, in case you don't know:

The rivet whole is slightly larger than the rivet, and a cleco, having

an irregular shape, has plenty of room to move in a rivet hole.

For instance an A5 Avex rivet has a diameter between 0.140" and 0.155"

(the rivet has "fins", therefore the diameter varies).

A solid rivet diameter is 0.155"

The corresponding drill bit is 0.160".

A black cleco is 0.149" at its widest point - but it is not round.

(Note: these are measurements I took from Items I have. You may find

slightly different measurements.)

In longer parts (more than a foot or two) or assemblies of more than

two parts, I find that if parts are not perfectly aligned, it's hard

to insert the rivets. And, worse, parts will be warped or difficult to

match as I proceed with construction.

So, instead of simply trusting the clecoes, I started adding spent

drill bits here and there (a solid rivet is better than a cleco, but

not as good as a spent drill bit).

I eventually started cutting drill bits and grinding one end to make

it easier to insert them.

(The grinding process consists of putting the drill bit in a drill or

drill press and grinding it with a dremel tool.).

The opposite end is covered with masking tape - see attached photo.

I have a bunch of these, A4 and A5, and use them frequently.

Hopefully this can be useful to someone.

Blue skies

Carlos

CH601-HD, plans

(CH650 firewall and canopy)

http://www.zenith.aero/profile/CarlosSa

|

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

afterfxllc(at)aol.com

Guest

|

Posted: Wed Oct 02, 2013 6:25 pm Post subject: a tip Posted: Wed Oct 02, 2013 6:25 pm Post subject: a tip |

|

|

Carlos you have way to much time on your hands... don't over think it it's just an airplane not the space shuttle.

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

afterfxllc(at)aol.com

Guest

|

Posted: Wed Oct 02, 2013 6:26 pm Post subject: a tip Posted: Wed Oct 02, 2013 6:26 pm Post subject: a tip |

|

|

OMG I wrote the same thing and then read your message now that's funny right there I don't care who you are........

--

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

BARRY CHECK 6

Joined: 15 Mar 2011

Posts: 738

|

Posted: Wed Oct 02, 2013 9:14 pm Post subject: a tip Posted: Wed Oct 02, 2013 9:14 pm Post subject: a tip |

|

|

Carlos:

Good write up. But there is a trick!

On long parts and especially parts that have a curve to them...

Start in the CENTER and alternately work your way to the ends.

This goes for BOTH inserting the CLECOE'S.

The removal as you insert the rivets and...

The insertion and setting of the rivets.

AND! You know those CLECOE CLAMPS?

There are great for clamping the ends of the mating parts.

Both when drilling and inserting CLECOE'S.

Barry

On Wed, Oct 2, 2013 at 8:13 PM, Carlos Sa <carlossa52(at)gmail.com (carlossa52(at)gmail.com)> wrote:

[quote] I have noticed - through other builders comments, but also through my own experience - that using clecoes to keep parts together sometimes does not quite work.

The parts do remain attached, not doubt, but they can be slightly shifted from the original position when they were drilled.

Here's why, in case you don't know:

The rivet whole is slightly larger than the rivet, and a cleco, having an irregular shape, has plenty of room to move in a rivet hole.

For instance an A5 Avex rivet has a diameter between 0.140" and 0.155" (the rivet has "fins", therefore the diameter varies).

A solid rivet diameter is 0.155"

The corresponding drill bit is 0.160".

A black cleco is 0.149" at its widest point - but it is not round.

(Note: these are measurements I took from Items I have. You may find slightly different measurements.)

In longer parts (more than a foot or two) or assemblies of more than two parts, I find that if parts are not perfectly aligned, it's hard to insert the rivets. And, worse, parts will be warped or difficult to match as I proceed with construction.

So, instead of simply trusting the clecoes, I started adding spent drill bits here and there (a solid rivet is better than a cleco, but not as good as a spent drill bit).

I eventually started cutting drill bits and grinding one end to make it easier to insert them.

(The grinding process consists of putting the drill bit in a drill or drill press and grinding it with a dremel tool.).

The opposite end is covered with masking tape - see attached photo.

I have a bunch of these, A4 and A5, and use them frequently.

Hopefully this can be useful to someone.

Blue skies

Carlos

CH601-HD, plans

(CH650 firewall and canopy)

http://www.zenith.aero/profile/CarlosSa

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

paulrod36(at)msn.com

Guest

|

Posted: Thu Oct 03, 2013 5:58 pm Post subject: a tip Posted: Thu Oct 03, 2013 5:58 pm Post subject: a tip |

|

|

<?xml:namespace prefix="v" /><?xml:namespace prefix="o" /><![endif]--> Agreed. Aside from the philosophical "thingy" (that's Socratic talk) of making the perfect the enemy of the good, we can quote Chris, who said, "You're making a tractor, not an F-16". I've found the design to be very forgiving of human error...

Paul R

[quote] ---

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

carlossa52(at)gmail.com

Guest

|

Posted: Fri Oct 04, 2013 2:10 pm Post subject: a tip Posted: Fri Oct 04, 2013 2:10 pm Post subject: a tip |

|

|

Thanks all for the comments

Having been around the Matronics lists for more than a few years, I'm fully aware that I am not building a space shuttle.

So much so that I have returned the silica bricks (except a few that I kept to repair the fireplace) and cancelled the solid fuel boosters order.

Seriously: what I described is quite simple and does not add to the workload.

On the contrary, I strongly believe that it saves time by avoiding glitches and associated head-scratching. I have used this process in the wings and tail feathers (all done) and fuse (past "boat stage").

Happy building

Carlos

[quote]

On Wed, Oct 2, 2013 at 8:13 PM, Carlos Sa <carlossa52(at)gmail.com (carlossa52(at)gmail.com)> wrote:

| Quote: | I have noticed - through other builders comments, but also through my own experience - that using clecoes to keep parts together sometimes does not quite work.

The parts do remain attached, not doubt, but they can be slightly shifted from the original position when they were drilled.

Here's why, in case you don't know:

The rivet whole is slightly larger than the rivet, and a cleco, having an irregular shape, has plenty of room to move in a rivet hole.

For instance an A5 Avex rivet has a diameter between 0.140" and 0.155" (the rivet has "fins", therefore the diameter varies).

A solid rivet diameter is 0.155"

The corresponding drill bit is 0.160".

A black cleco is 0.149" at its widest point - but it is not round.

(Note: these are measurements I took from Items I have. You may find slightly different measurements.)

In longer parts (more than a foot or two) or assemblies of more than two parts, I find that if parts are not perfectly aligned, it's hard to insert the rivets. And, worse, parts will be warped or difficult to match as I proceed with construction.

So, instead of simply trusting the clecoes, I started adding spent drill bits here and there (a solid rivet is better than a cleco, but not as good as a spent drill bit).

I eventually started cutting drill bits and grinding one end to make it easier to insert them.

(The grinding process consists of putting the drill bit in a drill or drill press and grinding it with a dremel tool.).

The opposite end is covered with masking tape - see attached photo.

I have a bunch of these, A4 and A5, and use them frequently.

Hopefully this can be useful to someone.

Blue skies

Carlos

CH601-HD, plans

(CH650 firewall and canopy)

http://www.zenith.aero/profile/CarlosSa

|

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

entecrj(at)sbcglobal.net

Guest

|

Posted: Fri Oct 04, 2013 6:39 pm Post subject: a tip Posted: Fri Oct 04, 2013 6:39 pm Post subject: a tip |

|

|

Carlos:

Don’t let anyone discourage you from trying to achieve perfection when building anything.

When you are finished you don’t have to explain any misfits, wrinkles or misalignments.

Russell Johnson

601-HDS (with misfits, wrinkles & misalignments)

From: Carlos Sa (carlossa52(at)gmail.com)

Sent: Friday, October 04, 2013 5:09 PM

To: zenith-list(at)matronics.com (zenith-list(at)matronics.com)

Subject: Re: a tip

Thanks all for the comments

Having been around the Matronics lists for more than a few years, I'm fully aware that I am not building a space shuttle.

So much so that I have returned the silica bricks (except a few that I kept to repair the fireplace) and cancelled the solid fuel boosters order.

Seriously: what I described is quite simple and does not add to the workload.

On the contrary, I strongly believe that it saves time by avoiding glitches and associated head-scratching. I have used this process in the wings and tail feathers (all done) and fuse (past "boat stage").

Happy building

Carlos

[quote]

On Wed, Oct 2, 2013 at 8:13 PM, Carlos Sa <carlossa52(at)gmail.com (carlossa52(at)gmail.com)> wrote:

| Quote: | I have noticed - through other builders comments, but also through my own experience - that using clecoes to keep parts together sometimes does not quite work.

The parts do remain attached, not doubt, but they can be slightly shifted from the original position when they were drilled.

Here's why, in case you don't know:

The rivet whole is slightly larger than the rivet, and a cleco, having an irregular shape, has plenty of room to move in a rivet hole.

For instance an A5 Avex rivet has a diameter between 0.140" and 0.155" (the rivet has "fins", therefore the diameter varies).

A solid rivet diameter is 0.155"

The corresponding drill bit is 0.160".

A black cleco is 0.149" at its widest point - but it is not round.

(Note: these are measurements I took from Items I have. You may find slightly different measurements.)

In longer parts (more than a foot or two) or assemblies of more than two parts, I find that if parts are not perfectly aligned, it's hard to insert the rivets. And, worse, parts will be warped or difficult to match as I proceed with construction.

So, instead of simply trusting the clecoes, I started adding spent drill bits here and there (a solid rivet is better than a cleco, but not as good as a spent drill bit).

I eventually started cutting drill bits and grinding one end to make it easier to insert them.

(The grinding process consists of putting the drill bit in a drill or drill press and grinding it with a dremel tool.).

The opposite end is covered with masking tape - see attached photo.

I have a bunch of these, A4 and A5, and use them frequently.

Hopefully this can be useful to someone.

Blue skies

Carlos

CH601-HD, plans

(CH650 firewall and canopy)

http://www.zenith.aero/profile/CarlosSa

|

href="http://www.matronics.com/Navigator?Zenith-List">http://www.matronhref="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

paulrod36(at)msn.com

Guest

|

Posted: Sat Oct 05, 2013 9:26 am Post subject: a tip Posted: Sat Oct 05, 2013 9:26 am Post subject: a tip |

|

|

<?xml:namespace prefix="v" /><?xml:namespace prefix="o" /><![endif]--> Boosters, huh? hhhmmmm....40 inches between gear leg attachments, pretty close to the CG, AN3 bolts,......Hey Carlos, you still got those boosters?

[quote] ---

| | - The Matronics Zenith-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Zenith-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|