|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

donjohnston

Joined: 13 Dec 2009

Posts: 231

|

Posted: Thu Nov 14, 2013 9:45 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 9:45 am Post subject: Trim motor speed control |

|

|

I have two trim motors that I need to control. The motors provided are 24v motors (3-5amps). But they are intended for with a 12v electrical system. This is done because the 12v motors on a 12v system turn too fast and you keep overshooting when you try to adjust the trim.

This is the elevator trim motor.

http://www.grainger.com/product/WARNER-LINEAR-Linear-Actuator-18G685?s_pp=false

But my electrical system is 24v. Which means the motors will turn too fast. I looked for 48v versions and they're either too expensive or not available at all. So I'm going to have to slow down the existing motors. And to that end, I have come up with 3 possibilities:

1) Put in a DC-DC step down converter. I can get one for about $250. But it is a rather large box that I'll have to mount somewhere and put in the necessary breakers and wiring. I may need 14v for other things in the future so this wouldn't be the worst solution.

http://www.lonestaraviation.com/Step-Down-Conveter-24V-to-13.8-Volts.html

2) I had picked up a motor speed controllers for the heater fan speed controller. But it's only $10! You know the old saying about something being too good to be true?

http://www.amazon.com/dp/B009HKFAIQ/ref=pe_385040_30332190_pe_175190_21431760_M3T1_ST1_dp_1

3) Finally, I could get a dedicated trim motor controller. But I would need their "HD" version and I would need two them... at $245 each for a $490 total.

http://www.tcwtech.com/safety_trim.html

I've pretty much removed option #2 because I have to think that there's this $10 solution either generates noise, is unreliable, or... something else.

So the question(s) are: Does anyone have any experience with a situation like this and if so, which path did you chose? Or does anyone have any opinions on which would be the best solution? And finally, is there an option that I haven't considered? (and changing my entire electrical system to 14v is NOT an option)

Thanks,

Don

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

tim2542(at)sbcglobal.net

Guest

|

Posted: Thu Nov 14, 2013 10:08 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 10:08 am Post subject: Trim motor speed control |

|

|

I would call TCW. I sent my Firgelli linear actuator (pitch trim) to them for approval. It was rated well over his specification, but in this application never sees much of a load. He approved it and it I'm using it now.

I would recommend his trim controller for just the stuck trim switch over ride protection alone. Speed control is also available and 2 speeds if you want that.

I'm not sure if they work with 28 v systems.

Tim

| Quote: | On Nov 14, 2013, at 9:45 AM, "donjohnston" <don(at)velocity-xl.com> wrote:

I have two trim motors that I need to control. The motors provided are 24v motors (3-5amps). But they are intended for with a 12v electrical system. This is done because the 12v motors on a 12v system turn too fast and you keep overshooting when you try to adjust the trim.

This is the elevator trim motor.

http://www.grainger.com/product/WARNER-LINEAR-Linear-Actuator-18G685?s_pp=false

But my electrical system is 24v. Which means the motors will turn too fast. I looked for 48v versions and they're either too expensive or not available at all. So I'm going to have to slow down the existing motors. And to that end, I have come up with 3 possibilities:

1) Put in a DC-DC step down converter. I can get one for about $250. But it is a rather large box that I'll have to mount somewhere and put in the necessary breakers and wiring. I may need 14v for other things in the future so this wouldn't be the worst solution.

http://www.lonestaraviation.com/Step-Down-Conveter-24V-to-13.8-Volts.html

2) I had picked up a motor speed controllers for the heater fan speed controller. But it's only $10! You know the old saying about something being too good to be true?

http://www.amazon.com/dp/B009HKFAIQ/ref=pe_385040_30332190_pe_175190_21431760_M3T1_ST1_dp_1

3) Finally, I could get a dedicated trim motor controller. But I would need their "HD" version and I would need two them... at $245 each for a $490 total.

http://www.tcwtech.com/safety_trim.html

I've pretty much removed option #2 because I have to think that there's this $10 solution either generates noise, is unreliable, or... something else.

So the question(s) are: Does anyone have any experience with a situation like this and if so, which path did you chose? Or does anyone have any opinions on which would be the best solution? And finally, is there an option that I haven't considered? (and changing my entire electrical system to 14v is NOT an option)

Thanks,

Don

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=413041#413041

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 14, 2013 10:18 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 10:18 am Post subject: Trim motor speed control |

|

|

At 11:45 AM 11/14/2013, you wrote:

I have two trim motors that I need to control. The motors provided

are 24v motors (3-5amps). But they are intended for with a 12v

electrical system. This is done because the 12v motors on a 12v

system turn too fast and you keep overshooting when you try to adjust the trim.

This is the elevator trim motor.

http://www.grainger.com/product/WARNER-LINEAR-Linear-Actuator-18G685?s_pp=false

First, why such a 'horse' of an actuator?

What are the force, speed and travel requirements

for moving the trim mechanism on your airplane?

But my electrical system is 24v. Which means the motors will turn too

fast. I looked for 48v versions and they're either too expensive or

not available at all. So I'm going to have to slow down the existing

motors. And to that end, I have come up with 3 possibilities:

With a full load current rating of 2.3A (assuming

that it's moving a 100# load), your voltage

control task is pretty simple. But with a PM motor,

inrush current is pretty high compared to the 2.3A

max running load.

1) Put in a DC-DC step down converter. I can get one for about $250.

But it is a rather large box that I'll have to mount somewhere and

put in the necessary breakers and wiring. I may need 14v for other

things in the future so this wouldn't be the worst solution.'

How about this one?

Rated for 8A (plenty of headroom) but

in addition to an adjustable output voltage

(controls speed) there's an adjustable

current limit (controls inrush).

Use this dc/dc converter upstream of your

dpdt center off polarity control switch.

Set voltage for max desired speed. Then

set the current limit to some benign value

well above max rated load for the actuator . . .

say 3A.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 14, 2013 10:29 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 10:29 am Post subject: Trim motor speed control |

|

|

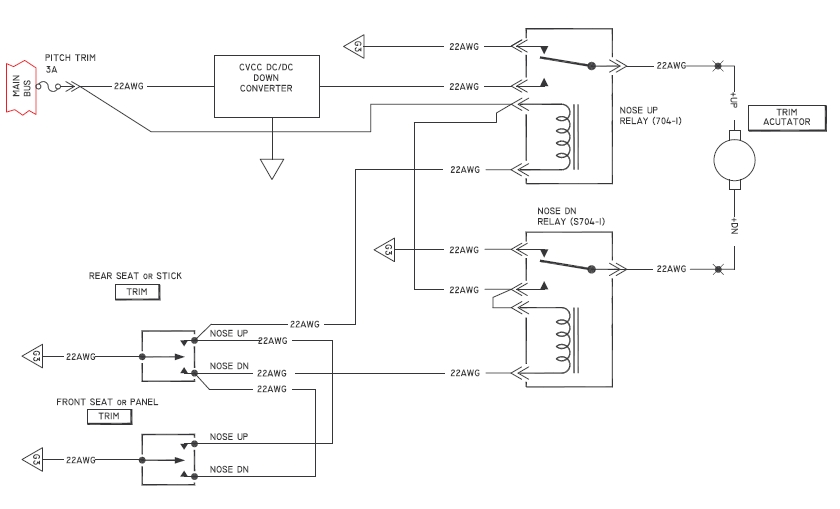

[img]cid:7.1.0.9.0.20131114122807.01f1ed78(at)aeroelectric.com.0[/img]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

81.99 KB |

| Viewed: |

16792 Time(s) |

|

|

|

| Back to top |

|

|

kuffel(at)cyberport.net

Guest

|

Posted: Thu Nov 14, 2013 11:12 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 11:12 am Post subject: Trim motor speed control |

|

|

Don,

Agree with the others about the heftiness of your actuators. 100 pounds and

4 inch travel sounds like something for a jet. Finding a lower current

actuator would ease your problem.

But assuming you can't change actuators, here is a full featured 2 axis trim

controller:

Start with the circuit published in the June 2013 issue of Kitplanes

(schematic attached).

Modify the circuit to use an LM338 (40 volt, 5 amp, 7 amp surge, $2.03 from

Mouser) instead of the LM317 shown.

Power the low current logic part of the circuit with a separate regulator

(LM317) set to supply 12 volts. The heat sink specified is more than

adequate for both jobs.

This gives you all the features of the fanciest commercial controllers for

less than $35 in parts.

If you do not have access to the Kitplanes issue email me off list for a set

of figures, photos and text.

Tom

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

Download |

| Filename: |

KPTrimAFig1.pdf |

| Filesize: |

56.98 KB |

| Downloaded: |

367 Time(s) |

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 14, 2013 11:45 am Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 11:45 am Post subject: Trim motor speed control |

|

|

My link to the suggested power supply

didn't paste . . . her 'tis again.

| Quote: | How about this one?

|

http://tinyurl.com/mk6vs4l

| Quote: | Rated for 8A (plenty of headroom) but

in addition to an adjustable output voltage

(controls speed) there's an adjustable

current limit (controls inrush).

Use this dc/dc converter upstream of your

dpdt center off polarity control switch.

Set voltage for max desired speed. Then

set the current limit to some benign value

well above max rated load for the actuator . . .

say 3A.

Bob . . .

-----

No virus found in this message.

Checked by AVG - www.avg.com

|

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 231

|

|

| Back to top |

|

|

kuffel(at)cyberport.net

Guest

|

Posted: Thu Nov 14, 2013 5:22 pm Post subject: Trim motor speed control Posted: Thu Nov 14, 2013 5:22 pm Post subject: Trim motor speed control |

|

|

Don,

<< why such a 'horse' of an actuator? ... One word... Canard. >>

Must confess to still being confused. My Defiant had very light control

forces which were still heavier than any Eze I've seen. Assume you are

planning to use springs and not aerodynamic trim tabs? Could you supply

more information?

Tom

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 231

|

Posted: Fri Nov 15, 2013 4:37 am Post subject: Re: Trim motor speed control Posted: Fri Nov 15, 2013 4:37 am Post subject: Re: Trim motor speed control |

|

|

The aircraft is a Velocity XL. The trim motor is the one supplied by the factory.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

donjohnston

Joined: 13 Dec 2009

Posts: 231

|

Posted: Fri Nov 15, 2013 4:37 am Post subject: Re: Trim motor speed control Posted: Fri Nov 15, 2013 4:37 am Post subject: Re: Trim motor speed control |

|

|

The aircraft is a Velocity XL. The trim motor is the one supplied by the factory.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Fri Nov 15, 2013 5:56 am Post subject: Re: Trim motor speed control Posted: Fri Nov 15, 2013 5:56 am Post subject: Re: Trim motor speed control |

|

|

Motor Speed Control--

An important point of trim motor speed controlling is that the torque should not be reduced when the speed is reduced (in fact, it could go up...but not down). This makes regular voltage controllers undesirable except where torque isn't an issue.

The second point is that trim speed should usually be reduced as a function of airspeed. Often this is critical and can give the pilot sudden difficulties. Tee-ing off the pitot line and using the pressure signal is easy to do.

Many speed controls use an LM3524 modulating PWM chip and a P-fet to drive the trim motor that will take a voltage-input based on the pitot pressure. This makes the motor go faster at slow speeds and slower at high speeds. No input from the pilot is needed.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

bakerocb

Joined: 15 Jan 2006

Posts: 727

Location: FAIRFAX VA

|

Posted: Fri Nov 15, 2013 9:48 am Post subject: Trim motor speed control Posted: Fri Nov 15, 2013 9:48 am Post subject: Trim motor speed control |

|

|

11/15/2013

Hello Don, Thanks for the quick response. I�ve got the picture. Take a look at the Firgelli Automations FA-SC24 Actuator Speed Controller seen here:

http://www.firgelliauto.com/product_info.php?cPath=99&products_id=362

Note the the 12V to 40V operating range.

OC

==============================

From: Don Johnston (don(at)johnston.org)

Sent: Friday, November 15, 2013 10:36 AM

To: Owen Baker (bakerocb(at)cox.net)

Subject: Re: Trim motor speed control

Owen,

Thanks for reaching out to me.

The aircraft is a Velocity-XL. I am trimming a canard-width elevator. I have been told by the factory and other builders that existing trim is right at the upper limit of usable speed. The trim motor is connected to a fiberglass leaf spring.

Fon

Sent from my Android mobile device.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Nov 15, 2013 12:43 pm Post subject: Trim motor speed control Posted: Fri Nov 15, 2013 12:43 pm Post subject: Trim motor speed control |

|

|

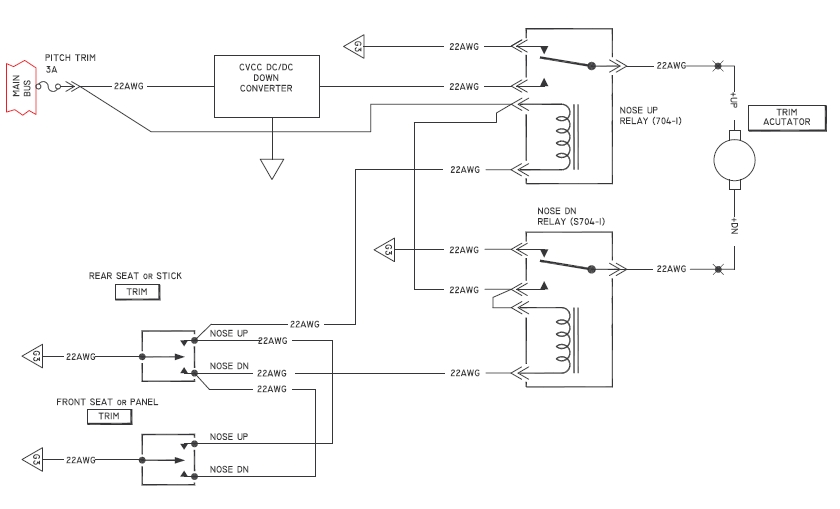

At 07:56 AM 11/15/2013, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Eric M. Jones" <emjones(at)charter.net>

Motor Speed Control--

An important point of trim motor speed controlling is that the torque should not be reduced when the speed is reduced (in fact, it could go up...but not down). This makes regular voltage controllers undesirable except where torque isn't an issue. |

Not true. Speed and torque are not directly related

in terms of motor performance. Speed of a motor is a

function of terminal voltage AND load on the motor.

Torque requirement for moving a flight control surface

is a function of aero-dynamic loads. For example, the

average torque needed to extend a flap from 0-10

degrees is often a small fraction of that required to

push it all the way out to 30 degrees.

Assuming one wishes to slow flap motion as it approaches

fully deployed, there is risk of having the motor STALL

under some conditions of load . . . the risk is a function

of motor resistance and a REDUCTION in available torque

at voltages intended to simply slow it down. It has NOTHING

to do with the manner in which voltage is controlled. You

can set the terminal voltage of the motor by means of regulated

power supply, battery, PWM controller, variable resistor,

you name it. As long as you're holding the motor voltage

constant, then it's possible to experience an unintended

STALL which is illustrated in the following plot of

an exemplar motor's performance in a pitch trim actuator.

[img]cid:.0[/img]

Folks that would like to explore all the details of

my assertion are invited to download the data package

at http://aeroelectric.com/articles/Motors

The figure above is an excerpt from one of the figures

in that data package. In high speed trim, applied voltage

was 26.5 volts which means that for ALL other conditions,

the motor speed can be predicted right off the plots.

Aerodynamic loads reflected to the motor ranged from .72 oz-in

to 1.82 oz-in. With high speed voltage applied, the motor

can be expected to run someplace between 3870 and 5304 rpm

for a variation of +/- 16%.

With low speed voltage applied, the same motor's speed

variance from center was predicted to be +/- 100

percent . . . with the motor stalling at max loads.

The data package speaks to the characterization of

motor stall current as (Eapplied-Ecemf)/Resistance

of the motor. Motors being operated at FIXED voltages

appear to 'lose torque' because their speed regulation

is terrible compared to the higher speed operation.

Note that torque-current demand on the motor at say 1.5 oz-in

is exactly the same irrespective of speed (applied

voltage). The motor appears 'crippled' because the SAME

variations in current (CAB) over designed torque range

is a LARGER PERCENTAGE of motor's predictable

behavior at the lower speed (FDE).

Virtually ALL voltage control methodologies popular

with the OBAM aviation community are simply modifications

to applied voltage. The seemingly 'crippled' behavior

of the motor will be the same no matter HOW that

voltage is adjusted. LM317, pwm . . . you pick it.

There ARE ways to close the loop on speed control

by sensing motor current and inserting a derived

correction of speed by increasing terminal voltage

as load increases . . . or by sensing motor speed

with some form of tachometer and closing the loop

on measured speed.

Assertions for expecting loads on a motor to

go UP as shaft speed goes down are incorrect,

the flight surface has no way to know that it's

moving slower . . . it IS influenced only by change

of dynamic pressure and moment arms.

| Quote: | | The second point is that trim speed should usually be reduced as a function of airspeed. Often this is critical and can give the pilot sudden difficulties. Tee-ing off the pitot line and using the pressure signal is easy to do. |

I've designed a number of pitch trim controllers.

The first two went on the Lear 55 and the second

was a fleet retrofit to the 30 series. I

proposed a continuously variable pitch trim rate

based on IAS but it proved unnecessary. Trim rates

optimized for cruising flight fell into one fairly

narrow range, speeds for approach to landing in another

narrow range. Turns out that approach:cruise trims

in the Lear systems were 4:1 ratio. Use a flaps-not-stowed

switch to select high speed and we were done.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Nov 15, 2013 12:55 pm Post subject: Trim motor speed control Posted: Fri Nov 15, 2013 12:55 pm Post subject: Trim motor speed control |

|

|

At 11:46 AM 11/15/2013, you wrote:

Note also the notation:

The FA-SC24 is intended to control the speed of one Linear actuator or motor, Do not connect two actuators/motors to the same FA-SC24. The slowest the actuator/motor will run is about 10% of the full speed. Reducing the speed can affect the maximum load the actuator can move.

Motor current is proportional to load torque

at any speed. There will come a time as voltage

falls that STALL torque (Eapplied/Resistance of

Motor) is some number smaller than load torque

and the motor stalls.

The load torque doesn't rise because the speed

went down; ability to CARRY rated torque fell

off because stall current came down proportionally

with the drop in applied voltage.

If we could wind the motor with unobtainium having

zero resistance, the speed torque curve would not

have that left-to-right, downward slope . . . it would

be flat. This means that speed is absolutely locked

to applied voltage no matter what load is applied.

The same motor would be 100% efficient because it

doesn't get hot!

I've worked with designs that deliberately picked

a too-large motor with lower values of internal

resistance just to get a flatter speed-torque

curve without use of external electronic controls.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Eric M. Jones

Joined: 10 Jan 2006

Posts: 565

Location: Massachusetts

|

Posted: Mon Nov 18, 2013 12:52 pm Post subject: Re: Trim motor speed control Posted: Mon Nov 18, 2013 12:52 pm Post subject: Re: Trim motor speed control |

|

|

EMJ said: An important point of trim motor speed controlling is that the torque should not be reduced when the speed is reduced (in fact, it could go up...but not down). This makes regular voltage controllers undesirable except where torque isn't an issue.

BN said: Not true. Speed and torque are not directly related in terms of motor performance. Speed of a motor is a function of terminal voltage AND load on the motor.

EMJ said: That’s absurd and examples are so trivial I won’t even bother to note one. Besides, I didn’t say they were related. The point is that motor speed for trimming and flaps should be reduced at high airspeed to prevent overstressing the pilot and the aircraft. This is common practice. I didn’t invent this idea. Furthermore reducing the voltage is a poor man’s way to reduce the speed of any actuator. I didn't invent that idea either.

BN said: Torque requirement for moving a flight control surface is a function of aero-dynamic loads. For example, the average torque needed to extend a flap from 0-10 degrees is often a small fraction of that required to push it all the way out to 30 degrees….

Folks that would like to explore all the details of my assertion are invited to download the data package at http://aeroelectric.com/articles/Motors ....

Virtually ALL voltage control methodologies popular with the OBAM aviation community are simply modifications to applied voltage….

EMJ said: And they are all wrong. Start with yours. The modern methods for changing motor speed without reducing torque … as I said…should be used.

BN said: Assertions for expecting loads on a motor to go UP as shaft speed goes down are incorrect…

EMJ said: And WHO said that Bob? I said the torque should not be reduced as the motor speed decreases…as is the case if the voltage is merely reduced.

EMJ said: The second point is that trim speed should usually be reduced as a function of airspeed. Often this is critical and can give the pilot sudden difficulties. Tee-ing off the pitot line and using the pressure signal is easy to do.

BN said: I've designed a number of pitch trim controllers. The first two went on the Lear 55 and the second was a fleet retrofit to the 30 series. I proposed a continuously variable pitch trim rate based on IAS but it proved unnecessary. Trim rates optimized for cruising flight fell into one fairly narrow range, speeds for approach to landing in another narrow range. Turns out that approach: cruise trims in the Lear systems were 4:1 ratio. Use a flaps-not-stowed switch to select high speed and we were done.

EMJ said: Whatever... but I’m not sure Learjet experience (where the amount of trim motion needed at 500 knots is tiny and the motor are big) is relevant for the stock RVs that have speed/trim problems using reduced voltage at high airspeeds.

Thanks...the loyal (occasional) opposition.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Eric M. Jones

www.PerihelionDesign.com

113 Brentwood Drive

Southbridge, MA 01550

(508) 764-2072

emjones(at)charter.net |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Nov 18, 2013 1:54 pm Post subject: Trim motor speed control Posted: Mon Nov 18, 2013 1:54 pm Post subject: Trim motor speed control |

|

|

At 02:52 PM 11/18/2013, you wrote:

| Quote: |

EMJ said: An important point of trim motor speed

controlling is that the torque should not be

reduced when the speed is reduced (in fact, it

could go up...but not down). This makes regular

voltage controllers undesirable except where torque isn't an issue.

|

Help me out. Are you talking about available torque or

demanded torque? In the examples I cited and data plots

published, torque demanded is a function of the mechanism

being powered. I'm aware of no piece of machinery that

demands more torque as the speed is reduced.

A speed/torque 'curve' is not really curved but a

straight line that depicts motor speed/torque performance

based on terminal voltage applied. The 'curve' has

downward slope and is set by the motor's internal

resistance. Internal resistance limits AVAILABLE torque

at that voltage. My assertion is that for any applied

voltage you choose, performance of the motor is

predictable and easily illustrated by plotting the

appropriate 'curve'.

| Quote: | EMJ said: And they are all wrong. Start with

yours. The modern methods for changing motor

speed without reducing torque … as I said…should be used.

|

Okay, suppose the target speed is satisfied

by reducing applied voltage to say, 5 volts.

Describe the mechanism by which a motor's performance

is improved by using one form of voltage 'adjustment'

over some other form. I.e., what is the "modern method"

to which you refer?

| Quote: | EMJ said: And WHO said that Bob? I said the

torque should not be reduced as the motor speed

decreases…as is the case if the voltage is merely reduced.

|

Okay, you've answered the question. My apologies. Yes,

AVAILABLE torque can be degraded to the point where a

motor is at risk for stalling at the lower extreme of

RPM vs. available torque for the voltage applied. My

assertion is that 5 volts average applied voltage produces

the same performance irrespective of the mechanism by

which that voltage is produced.

| Quote: | EMJ said: Whatever... but I’m not sure Learjet

experience (where the amount of trim motion

needed at 500 knots is tiny and the motor are

big) is relevant for the stock RVs that have

speed/trim problems using reduced voltage at high airspeeds.

|

No argument that adjustable trim rates for aircraft

with broader operating speeds is a good thing and

may apply to airplanes of any size . . .

Pilots would like to ask for and get very tiny movements

in the trim system at cruise. If the motor speed is

optimized for that condition, then it's painfully slow

for setting the airplane up to land. The idea that

there was value in crafting a continuously adjustable

trim rate was rejected as unnecessarily complex. Lear's

pilots were quite happy with the 4:1 ratio.

Trim motor motion on a Beechjet at Mach cruise needed

to be so small that servoing to a speed was impossible.

The smallest trim adjustment offered by the autopilot

is a mere 133 milliseconds long.

The Lear systems were SERVOed speed controllers where

motor characteristics did not impact available torque

from the motors. Voltage was adjusted to hold target speed

irrespective of voltage or load. The controller that

finally went onto the airplanes held +/- 1% of target

speed over the full range of load, voltage and temperature.

In the Lear system, tachometers on the motor shafts

provided speed feedback data. The motors used in

OBAM aircraft are seldom fitted with such devices.

The PM motor CAN be used as it's own tach generator.

If you PWM the applied voltage 0ne can sample the Cemf

of the motor and use that value to report motor speed

to the servo-loop.

With a servoed speed control loop, the motor's

speed/torque curve no longer defines performance

limits at slow speed. The controller drives voltage to

maintain target speed even at the maximum expected load.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|