|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 2:36 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 2:36 am Post subject: Cooling issues, once again! |

|

|

Gentlemen,

Although my initial cooling issues have been improved upon, I'm not

satisfied at all with the cooling of my 914.

Now, with increasing ambient temperatures, I have to severely limit my

climb outs. Cruising is ok. During climb, both the water temperature and

oil temperature approach the red line, more or less at the same time.

Water temperature recovers faster than the oil temperature after I power

down. At this time I can barely make it to circuit height and then have

to level off, build more speed, and then limit my climb with 200 ft/min

until I'm in cooler air. The engine has now 32 hours on it, so it might

still improve somewhat further, but I don't expect miracles from that.

I had to do something.

First I made an additional exit in the cowling, under the turbo, hoping

to provide more airflow. Whether the airflow in the cowling improved I

don't know, but it had zero effect on the water and oil temperatures.

Temperatures inside the cowling seem to be ok anyway, no discoloured

spark plug indicator labels (still bright yellow), no melted tie-wraps, etc.

My conclusion was that the problem is not in cooling of the cowling, but

somewhere in the efficiency of the radiators.

So then I built a new radiator inlet, somewhat larger than previous one,

with a lip to avoid digesting the boundary layer and making sure the

inlet receives ram air, angled straight into the airflow, and with a

diffuser for which I copied a profile out of a famous book.

It was no improvement over my "free style" sleeker inlet and diffuser.

None. Very frustrating, as I ruined my nicely shaped and painted

original inlet for this.

I need to do something, but to avoid ruining again something in order to

solve this problem, I need to hear some experiences:

1) A shroud over the cylinders. I don't have it, but instead I have two

naca ducts in the upper cowling, curved down to release air aimed at the

cylinders.

Has anyone ever tried whether the Rotax shroud (or home made shroud)

makes any difference? Sure, it will cool the cylinders, but does it have

any effect over the water temperature and/or oil temperature? Or is this

again going to be a loss in time and effort?

2) In my setup the oil cooler receives exit air from the water cooler. I

know there is a "trick" mentioned in the build manual for hot climates

to lower the oil radiator 2 inches to receive cold air instead of warm

air, but I didn't opt for this as I don't consider our climate as

extremely warm, and in winter the oild could actually get too cold.

Has anyone tried both options, and did it make much difference? Also,

did it have any influence over the water temperature? Relocating the oil

radiator will be a large project, and I fear that after that I will

still have to limit my climb outs to avoid the water from boiling.

Yesterday on the airfield I took a closer look at the Rotax 914 equipped

Dimona, which is used by the glider club to tow all day long gliders,

with full power at 50 knots, in all ambient temperatures. They never

have cooling problems.

What I saw was shocking. The water radiator is fully exposed to the

airstream, no diffuser whatsoever, it is just part of the cowling, as if

someone took out some skin of the cowling and fitted the radiator in the

resulting hole. The oil radiator is mounted in an angle behind a naca

duct (I was taught that a naca duct does not provide ram air and

shouldn't be used for cooling a radiator?). Both radiators just dump the

warm air inside the cowling! It can't be easier than that.

Then, at the bottom, the Dimona has a cowl flap which just opens the

cowling to dump *all* air overboard. If it is closed, all radiators, as

well as all cowling ventilation, is blocked.

How can this system, which looks less sophisticated than our system,

while violating all rules and knowledge, work so well?

Anyway. At the moment I'm grounded, can't fly like this, and after

spending a week trying to improve things with zero effect, I'm out of

options and I'm inclined to leave the airplane in the hangar and find

another hobby.

Seriously, what should I do?

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

lgds(at)post6.tele.dk

Guest

|

Posted: Sat Jun 05, 2010 3:26 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 3:26 am Post subject: Cooling issues, once again! |

|

|

Be 100% sure that no air are bleeding out through gaps around your air baffles! Just a little gab is enough to spoil your day. Regards Gert

OY-GDS / mono / 914 / 500 hours

Den 05/06/2010 kl. 12.28 skrev Frans Veldman:

[quote]--> Europa-List message posted by: Frans Veldman <frans(at)privatepilots.nl (frans(at)privatepilots.nl)>

Gentlemen,

Although my initial cooling issues have been improved upon, I'm not

satisfied at all with the cooling of my 914.

Now, with increasing ambient temperatures, I have to severely limit my

climb outs. Cruising is ok. During climb, both the water temperature and

oil temperature approach the red line, more or less at the same time.

Water temperature recovers faster than the oil temperature after I power

down. At this time I can barely make it to circuit height and then have

to level off, build more speed, and then limit my climb with 200 ft/min

until I'm in cooler air. The engine has now 32 hours on it, so it might

still improve somewhat further, but I don't expect miracles from that.

I had to do something.

First I made an additional exit in the cowling, under the turbo, hoping

to provide more airflow. Whether the airflow in the cowling improved I

don't know, but it had zero effect on the water and oil temperatures.

Temperatures inside the cowling seem to be ok anyway, no discoloured

spark plug indicator labels (still bright yellow), no melted tie-wraps, etc.

My conclusion was that the problem is not in cooling of the cowling, but

somewhere in the efficiency of the radiators.

So then I built a new radiator inlet, somewhat larger than previous one,

with a lip to avoid digesting the boundary layer and making sure the

inlet receives ram air, angled straight into the airflow, and with a

diffuser for which I copied a profile out of a famous book.

It was no improvement over my "free style" sleeker inlet and diffuser.

None. Very frustrating, as I ruined my nicely shaped and painted

original inlet for this.

I need to do something, but to avoid ruining again something in order to

solve this problem, I need to hear some experiences:

1) A shroud over the cylinders. I don't have it, but instead I have two

naca ducts in the upper cowling, curved down to release air aimed at the

cylinders.

Has anyone ever tried whether the Rotax shroud (or home made shroud)

makes any difference? Sure, it will cool the cylinders, but does it have

any effect over the water temperature and/or oil temperature? Or is this

again going to be a loss in time and effort?

2) In my setup the oil cooler receives exit air from the water cooler. I

know there is a "trick" mentioned in the build manual for hot climates

to lower the oil radiator 2 inches to receive cold air instead of warm

air, but I didn't opt for this as I don't consider our climate as

extremely warm, and in winter the oild could actually get too cold.

Has anyone tried both options, and did it make much difference? Also,

did it have any influence over the water temperature? Relocating the oil

radiator will be a large project, and I fear that after that I will

still have to limit my climb outs to avoid the water from boiling.

Yesterday on the airfield I took a closer look at the Rotax 914 equipped

Dimona, which is used by the glider club to tow all day long gliders,

with full power at 50 knots, in all ambient temperatures. They never

have cooling problems.

What I saw was shocking. The water radiator is fully exposed to the

airstream, no diffuser whatsoever, it is just part of the cowling, as if

someone took out some skin of the cowling and fitted the radiator in the

resulting hole. The oil radiator is mounted in an angle behind a naca

duct (I was taught that a naca duct does not provide ram air and

shouldn't be used for cooling a radiator?). Both radiators just dump the

warm air inside the cowling! It can't be easier than that.

Then, at the bottom, the Dimona has a cowl flap which just opens the

cowling to dump *all* air overboard. If it is closed, all radiators, as

well as all cowling ventilation, is blocked.

How can this system, which looks less sophisticated than our system,

while violating all rules and knowledge, work so well?

Anyway. At the moment I'm grounded, can't fly like this, and after

spending a week trying to improve things with zero effect, I'm out of

options and I'm inclined to leave the airplane in the hangar and find

another hobby.

Seriously, what should I - The Europa-List --> http://www.matroni &n - � &nbs --> http://www.matronics.com/co=================

[b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 4:51 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 4:51 am Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 01:22 PM, Lisbet og Gert Dalgaard wrote:

| Quote: | Be 100% sure that no air are bleeding out through gaps around your air

baffles!

|

I replaced the entire Europa duct, but it mates with the cowling at some

point of course. I didn't have the impression that it was very leaky,

but at the moment I'm waiting for PUR-foam to cure (one side taped off

of course) to see if there was indeed a leak. I'm hoping there was a

leak, and I saw some bugs piled up in one corner just before the

radiator, so that is a hopefull sign.

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

kevann(at)gotsky.com

Guest

|

Posted: Sat Jun 05, 2010 5:30 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 5:30 am Post subject: Cooling issues, once again! |

|

|

I have the stock Europa cooling duct with the oil cooler lowered to the bottom of the cowling. As Gert suggests below, all gaps are sealed well, including the bottom of the oil cooler to the cowling and the sides of both coolers to the aluminum duct.

I flew last week to Death Valley with a friend in the right seat. When we departed furnace creek(L06) the OAT was about 90 F. The climb from 200' below sea level to 11,000' at 90 to 100 knots indicated showed oil temps up to 240 F and the Evans coolant 230. CHT is always within 10 deg. of the coolant.

I have been climbing most of the time at airspeeds around 100 knots and 100% (34"map) which yeilds a healthy climb rate. The temps inside the cowl have gotten high enough to deform the spark plug indicator labels. I wraped the exhaust pipes, but I'm not sure if that helped really because I don't have the cowl temps monitored.

The OAT should exceed 100F today. Whew!

Best of luck, Kevin

Mono intercooled 914 Airmaster prop

[quote] ---

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 6:09 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 6:09 am Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 03:26 PM, Kevin Klinefelter wrote:

| Quote: | I flew last week to Death Valley with a friend in the right seat. When

we departed furnace creek(L06) the OAT was about 90 F. The climb from

200' below sea level to 11,000' at 90 to 100 knots indicated showed oil

temps up to 240 F and the Evans coolant 230. CHT is always within 10

deg. of the coolant.

|

Amazing!

Do you have the Rotax shroud fitted over the cylinders?

Has your engine had initial (< 50 hours) cooling issues?

Has your oil cooler been lowered from the beginning, or did you relocate

it later? If so, did it make some difference to the CHT's as well?

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rlborger(at)mac.com

Guest

|

Posted: Sat Jun 05, 2010 6:58 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 6:58 am Post subject: Cooling issues, once again! |

|

|

Frans,

I flew last summer in temperatures in the high 90's to low 100's (35C-41C) with no signs of overheating.

I have the stock FWF 914 setup with the following changes:

1. The lowered oil cooler.

2. I have sealed the sides of the radiators to the aluminum duct with silicone rubber seal

3. I have sealed the bottom of the oil cooler to the cowl with a foam strip

4. I replaced all the factory supplied tape for the front of the duct with wide silicone rubber seal

5. I smoothed the inside lower lip of the cowl intake with blue foam and 2 lays of glass to reduce turbulence and smooth flow

I do not have the Rotax shroud over the cylinders but will consider it should cooling be inadequate this summer.

I hope this helps,

Bob Borger

Europa Kit #A221 N914XL, XS Mono, Intercooled 914, Airmaster C/S

http://www.europaowners.org/forums/gallery2.php?g2_itemId=60232

http://www.biplaneforumgallery.com/index.php?cat=10046

Europa Flying!

3705 Lynchburg Dr.

Corinth, TX 76208

Home: 940-497-2123

Cel: 817-992-1117

On Jun 5, 2010, at 5:28, Frans Veldman wrote:

| Quote: |

Gentlemen,

Although my initial cooling issues have been improved upon, I'm not

satisfied at all with the cooling of my 914.

Seriously, what should I do?

Frans

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 7:53 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 7:53 am Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 04:56 PM, Robert Borger wrote:

| Quote: | I have the stock FWF 914 setup with the following changes:

1. The lowered oil cooler.

|

Ok, it seems the common solution here is to lower the oil cooler. As I

have fabricated my own duct, this is not possible in my setup. This

means I will probably have to relocate the oil cooler and give it a

dedicated inlet.

One question: if you lower the oil cooler, how are the two coolers

sealed against each other? Can air flow freely around the water cooler

to reach the oil cooler? This means that the air in front of the water

cooler will see an easier path and just forget about the water cooler?

Is there anyone with adequate cooling on warmer days with both radiators

behind each other, as the manual calls for? Or is this plainly

impossible to achieve?

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

paul.the.aviator(at)gmail

Guest

|

Posted: Sat Jun 05, 2010 8:44 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 8:44 am Post subject: Cooling issues, once again! |

|

|

Hi All,

I am curious to know if there are any examples of standard XS cooling set up's that do not have the oil radiator lowered that work fine.

Thanks,� Paul

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rampil

Joined: 04 May 2007

Posts: 870

|

Posted: Sat Jun 05, 2010 9:46 am Post subject: Re: Cooling issues, once again! Posted: Sat Jun 05, 2010 9:46 am Post subject: Re: Cooling issues, once again! |

|

|

>>>>How can this system, which looks less sophisticated than our system,

while violating all rules and knowledge, work so well?<<<<<

The problem is basically, when it come to the Europa, what we think

we know is actually only supposition and rules of thumb.

The Diamond setup was actually engineered, money spent, measurements

made, and the design refined to pass muster. I have been listening

intently to cowl discussions here and elsewhere, and the best we

have is a bit of trial and error, some demonstrably good suggestions,

some not so worthy.

Let me pass on a bit of advice from Eric Tucker who suggested to me,

that before I tear into a cowl, I take a spare airspeed indicator and

run the pitot hose into the engine space. While flying, make

measurements at several locations to see where the actual high and

low pressure points are, and then basing a redesign on real data to

get the air moving in the right direction!

Another two good sources of solid information rather than heresay are:

Kent Paser's book Speed with Economy (available at MustangAero)

and the old NACA archives.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

Ira N224XS |

|

| Back to top |

|

|

Jeff(at)rmmm.net

Guest

|

Posted: Sat Jun 05, 2010 9:52 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 9:52 am Post subject: Cooling issues, once again! |

|

|

Frans,

I have the 912 set up so I might not know what I'l talking about but...

I had the very same issues for the first 150 hours. Every time it got

hot I was in trouble with temps at their limit. I made the shroud for

over the cylinders. I lowered the oil radiator 2 inches behind the

water, I sealed everything, I made new inlets in the upper cowl, and

still didn't get it solved completely. I then finally lowered the

metal duct down an inch or so, so the bottom radiator reached the

lower cowl without the sealant and bam. My temps dropped 30 to 40

degrees. I believe two things helped in this. The radiators we're

getting more air but the big thing was by lowering the duct it opened

the bottom for escaping air. Not sure if this all applies to you but

if you have the duct up to high close to the muff all you need to do

is lower it. You'l be needing to ad a flap in colder days to get

things in the proper temp range.

By the way the shroud did even the cylinder temps out but it didn't do

much to cool the water or oil.

Jeff R. N128LJ Gold Rush

On Jun 5, 2010, at 5:28 AM, Frans Veldman wrote:

| Quote: |

>

Gentlemen,

Although my initial cooling issues have been improved upon, I'm not

satisfied at all with the cooling of my 914.

Now, with increasing ambient temperatures, I have to severely limit my

climb outs. Cruising is ok. During climb, both the water temperature

and

oil temperature approach the red line, more or less at the same time.

Water temperature recovers faster than the oil temperature after I

power

down. At this time I can barely make it to circuit height and then

have

to level off, build more speed, and then limit my climb with 200 ft/

min

until I'm in cooler air. The engine has now 32 hours on it, so it

might

still improve somewhat further, but I don't expect miracles from that.

I had to do something.

First I made an additional exit in the cowling, under the turbo,

hoping

to provide more airflow. Whether the airflow in the cowling improved I

don't know, but it had zero effect on the water and oil temperatures.

Temperatures inside the cowling seem to be ok anyway, no discoloured

spark plug indicator labels (still bright yellow), no melted tie-

wraps, etc.

My conclusion was that the problem is not in cooling of the cowling,

but

somewhere in the efficiency of the radiators.

So then I built a new radiator inlet, somewhat larger than previous

one,

with a lip to avoid digesting the boundary layer and making sure the

inlet receives ram air, angled straight into the airflow, and with a

diffuser for which I copied a profile out of a famous book.

It was no improvement over my "free style" sleeker inlet and diffuser.

None. Very frustrating, as I ruined my nicely shaped and painted

original inlet for this.

I need to do something, but to avoid ruining again something in

order to

solve this problem, I need to hear some experiences:

1) A shroud over the cylinders. I don't have it, but instead I have

two

naca ducts in the upper cowling, curved down to release air aimed at

the

cylinders.

Has anyone ever tried whether the Rotax shroud (or home made shroud)

makes any difference? Sure, it will cool the cylinders, but does it

have

any effect over the water temperature and/or oil temperature? Or is

this

again going to be a loss in time and effort?

2) In my setup the oil cooler receives exit air from the water

cooler. I

know there is a "trick" mentioned in the build manual for hot climates

to lower the oil radiator 2 inches to receive cold air instead of warm

air, but I didn't opt for this as I don't consider our climate as

extremely warm, and in winter the oild could actually get too cold.

Has anyone tried both options, and did it make much difference? Also,

did it have any influence over the water temperature? Relocating the

oil

radiator will be a large project, and I fear that after that I will

still have to limit my climb outs to avoid the water from boiling.

Yesterday on the airfield I took a closer look at the Rotax 914

equipped

Dimona, which is used by the glider club to tow all day long gliders,

with full power at 50 knots, in all ambient temperatures. They never

have cooling problems.

What I saw was shocking. The water radiator is fully exposed to the

airstream, no diffuser whatsoever, it is just part of the cowling,

as if

someone took out some skin of the cowling and fitted the radiator in

the

resulting hole. The oil radiator is mounted in an angle behind a naca

duct (I was taught that a naca duct does not provide ram air and

shouldn't be used for cooling a radiator?). Both radiators just dump

the

warm air inside the cowling! It can't be easier than that.

Then, at the bottom, the Dimona has a cowl flap which just opens the

cowling to dump *all* air overboard. If it is closed, all radiators,

as

well as all cowling ventilation, is blocked.

How can this system, which looks less sophisticated than our system,

while violating all rules and knowledge, work so well?

Anyway. At the moment I'm grounded, can't fly like this, and after

spending a week trying to improve things with zero effect, I'm out of

options and I'm inclined to leave the airplane in the hangar and find

another hobby.

Seriously, what should I do?

Frans

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

g-iani(at)ntlworld.com

Guest

|

Posted: Sat Jun 05, 2010 10:00 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 10:00 am Post subject: Cooling issues, once again! |

|

|

Frans and all

My aircraft (G-IANI)is a 914 with no shroud and the standard cowl. The aircraft ran hot on UK “hot” days until I lowered the oil cooler. We also had the same with G-IRON.

Lowering the Oil radiator as far as possible and ensuring complete sealing all round fixed the problem. They both run cool in winter (oil temp 70 – 80c rather than the desirable 100c and this is the reason for the thermostat mod.

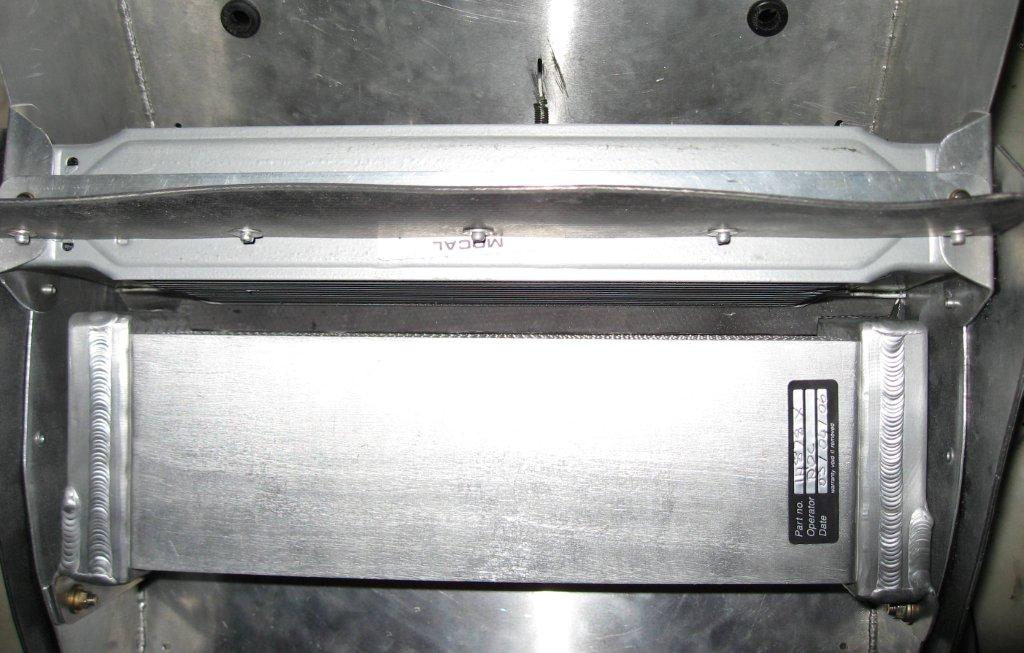

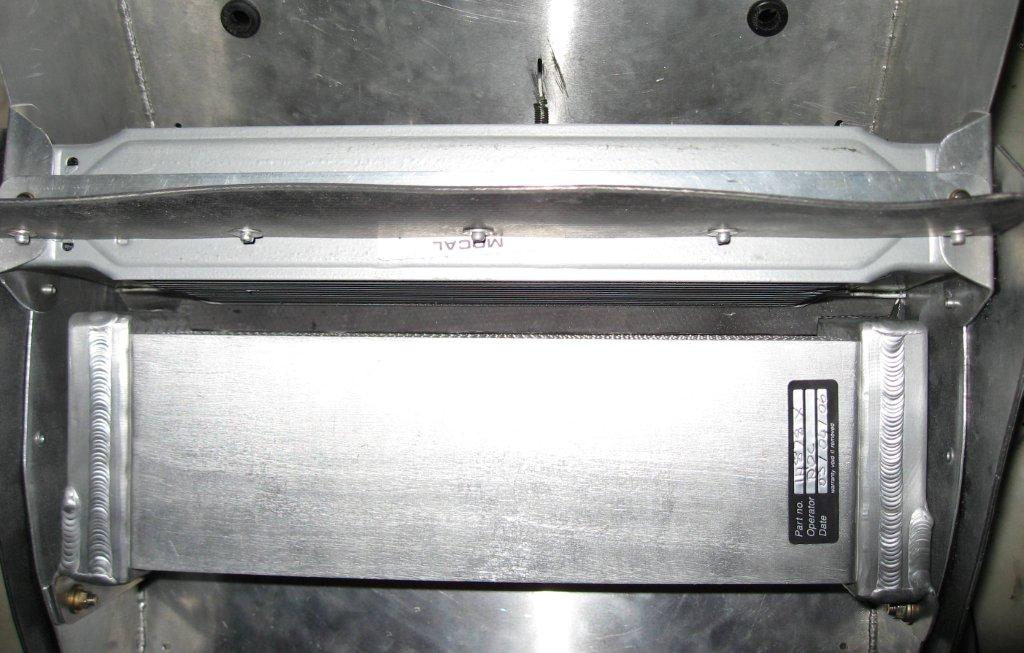

I have used a rubber strip attached to the top of the oil rad to seal the gap between it and the water rad. This stops the air taking the short cut. You can just see this seal (black rubber) in the attached picture.

I have more pictures and details if you want them.

Ian Rickard G-IANI XS Trigear, 300hours

Europa Club Mods Specialist

e-mail g-iani(at)ntlworld.com

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

105.13 KB |

| Viewed: |

14511 Time(s) |

|

|

|

| Back to top |

|

|

acrojim(at)cfl.rr.com

Guest

|

Posted: Sat Jun 05, 2010 10:02 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 10:02 am Post subject: Cooling issues, once again! |

|

|

Frans,I would suggest that you take a look at the bottom of the cowl, where all of the air escapes from inside the cowl..No cooling will take place unless the air inside the cowl can get out. You said you replaced the entire duct work...You may have restricted the exit area in some form or other. If you see anything that will restrict the flow of air to the outside, can it be moved? Can it be reduced in size? It is critical thatthe exit area does not restrict the flow of the exit air...

Jim Brown

Europa XS 914

---- Frans Veldman <frans(at)privatepilots.nl> wrote:

| Quote: |

On 06/05/2010 01:22 PM, Lisbet og Gert Dalgaard wrote:

> Be 100% sure that no air are bleeding out through gaps around your air

> baffles!

I replaced the entire Europa duct, but it mates with the cowling at some

point of course. I didn't have the impression that it was very leaky,

but at the moment I'm waiting for PUR-foam to cure (one side taped off

of course) to see if there was indeed a leak. I'm hoping there was a

leak, and I saw some bugs piled up in one corner just before the

radiator, so that is a hopefull sign.

Frans

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

rlborger(at)mac.com

Guest

|

Posted: Sat Jun 05, 2010 10:02 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 10:02 am Post subject: Cooling issues, once again! |

|

|

Paul,

I don't see how it can. Simple thermodynamics is against it. Heat transfer is directly proportional to temperature difference. Both radiators are at about the same temperature. Once the air has been heated by the first radiator its ability to accept heat from the second has been greatly reduced if not eliminated.

And this is assuming that the area below the radiators has been sealed so that the air goes through the radiators and not under them, doing no good at all.

Check six,

Bob Borger

http://www.europaowners.org/N914XL

Europa XS, Short Wing, Intercooled Rotax 914

rlborger(at)mac.com (rlborger(at)mac.com)

Cel: 817-992-1117

On Jun 5, 2010, at 11:43 AM, Paul McAllister wrote:

| Quote: | Hi All,

I am curious to know if there are any examples of standard XS cooling set up's that do not have the oil radiator lowered that work fine.

Thanks, Paul

|

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

mikenjulie.parkin(at)btin

Guest

|

Posted: Sat Jun 05, 2010 10:39 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 10:39 am Post subject: Cooling issues, once again! |

|

|

Frans,

I have a standard XS 914 installation. In the early days I had a problem

with cooling until I lowered the oil cooler in accordance with the build

manual. Once the cooler was lowered I had no problems whatsoever until I

filled the system with Evans. That pushed the temperatures close to the

limit, so I threw the Evans away. Since then I have had no issues. True,

UK summer temperatures are not in the same league as our American friends...

I recall that the temperature in my yard in Phoenix, Az occasionally was

120+. However, UK temperatures are very similar to the Netherlands.

I refer to your email dated 2 Mar 2009, your theory and confidence was most

impressive. Your penultimate paragraph was quite damming. I quote.

| Quote: | >Of course, al this is theory. Because the cooling properties of the

>factory cowling are so bad, I believe that it would actually be

>difficult to make it worse. So chances are that my cooling at least

>gives some better cooling and aerodynamics.

|

Perhaps Ivan, Andy and Neville at Europa had a better clue than you give

them credit for.

If I was one of the boys, I might be tempted to send you a big piece of

'Humble Pie'.

Regards,

Mike

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 10:52 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 10:52 am Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 08:02 PM, Robert Borger wrote:

| Quote: | Once the air has been

heated by the first radiator its ability to accept heat from the second

has been greatly reduced if not eliminated.

|

Ok, thanks everyone! The picture is much more clear to me now. It seems

that splitting up the oil and water radiator is the way to go.

About a month ago, the system was working quite ok. Amazing how little

OAT difference can spoil the setup.

When I saw the Europa radiator setup for the first time, I had some

doubts about it. But because the Europa lacks a thermostat, I figured

that the oil cooler behind the water radiator was on purpose, to prevent

the oil temps from dropping too low. The manual explicitely calls for

"hot climats" to use the "option" to lower the oil radiator. With

hindsight, I think this description is somewhat misleading.

As some have noticed, I trimmed down the cooling duct considerably,

added a diffuser, added a cowl flap, to optimize both aerodynamics and

cooling capacity. Although it seems my ship is indeed quite fast for a

tri-gear, the oil cooler is not going to work efficiently this way. Too

bad that I don't have room to lower the oil radiator, so I'm going to

have to relocate the oil cooler. I now appreciate the term "experimental

airplane". :-S

Some have mentioned that the exit area of the cowling might be a

problem. However, so far I have no indication that the exit area is the

bottleneck. In area it is bigger than the inlet, and I have no signs of

elevated cowling temperatures like discoloured spark plug labels. Also,

some experiments to open up more cowl space had zero effects on the

temperatures.

I'm glad to hear that the Rotax shroud isn't a necessary item.

Thanks everyone!

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Brian Davies

Joined: 10 Jan 2006

Posts: 124

Location: uk

|

Posted: Sat Jun 05, 2010 11:23 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 11:23 am Post subject: Cooling issues, once again! |

|

|

Yes, mine! but it is a 912S. I have always had low oil temps and have now fitted the oil thermostat so that they are not too low in winter.

Regards

Brian Davies

Kit 454, Trigear

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Paul McAllister

Sent: 05 June 2010 17:44

To: europa-list(at)matronics.com

Subject: Re: Cooling issues, once again!

Hi All,

I am curious to know if there are any examples of standard XS cooling set up's that do not have the oil radiator lowered that work fine.

Thanks, Paul

[quote]

href="http://www.matronics.com/Navigator?Europa-List">http://www.matronhref="http://forums.matronics.com">http://forums.matronics.com

href="http://www.matronics.com/contribution">http://www.matronics.com/c

[b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 11:23 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 11:23 am Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 08:38 PM, Mike Parkin wrote:

| Quote: | I have a standard XS 914 installation. In the early days I had a problem

with cooling until I lowered the oil cooler in accordance with the build

manual.

|

Ok, this is in line with other experiences. Thanks for sharing this.

| Quote: | I refer to your email dated 2 Mar 2009, your theory and confidence was most

impressive.

|

I was waiting for this to pop up.  No problem at all, I'm still No problem at all, I'm still

behind it, I just feel somewhat mislead by the strong suggestion of the

manual that the oil cooler behind the water radiator is the standard

setup for normal climats, and I followed that guideline. Granted, I

should have known better.

Anyway, if I write something on this forum, it is "sharing knowledge"

and not a competitive attempt. I will as easily explain why I divert

from the manual some times, and as easily seek for help on this forum if

I experience problems. I don't really care about ego, so I find it

somewhat humorous if an attempt to receive some experiences from others

is answered by an answer like yours.

| Quote: | Perhaps Ivan, Andy and Neville at Europa had a better clue than you give

them credit for.

|

IF their original setup, with the non-lowered oil radiator as the

factory manual calls for, works better than my current setup. And that

remains to be seen...

At least it looks like my claim to have better aerodynamics might be

true, with a cooling system that performs, let's say, not worse than the

factory setup with the radiators in the "standard" configuration.

Well, I will split up the oil and water radiator, as apparently everyone

has done, and then we can do the comparison again.

| Quote: | If I was one of the boys, I might be tempted to send you a big piece of

'Humble Pie'.

|

If I was one of these boys, I would be tempted so as well, IF my work

was a masterpiece of enginering, well thought out, working in hot

climates AND cold climates, and with no excess drag, and with even

cylinder temperatures. However, it looks like the standard factory

setup, with the coolers in series, is not exactly the best solution for

everyone.

So, have some fun about me. It is not the first time people laugh about

work in progress. Finally, I might end up with an improvement over the

factory setup, in both aerodynamics and in cooling capacity. Goal 1

appears to have been achieved already. I consider solving problems as a

privilege of building the airplane yourself, and you can't have it right

the first time everyime.

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

RobHousman

Joined: 29 Mar 2010

Posts: 7

Location: Irvine, CA

|

Posted: Sat Jun 05, 2010 11:38 am Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 11:38 am Post subject: Cooling issues, once again! |

|

|

While it is true that “heat transfer is directly proportional to temperature difference” that does not tell the whole story. First, remember that the relevant temperature difference is the difference between the temperature of the fluid on the inside and the air on the outside, and even with pre-heated air the second radiator could have the same delta T as the first radiator. I’ll grant you that there is probably a difference, however.

Also relevant, and non-trivial, are the area of the heat transfer surface, the flow rate of the liquids inside the heat exchangers (radiators, in common aircraft and automotive parlance), the flow rate of the air outside these heat exchangers, the heat transfer coefficients for each of the fluids involved, the heat transfer coefficients of the materials from which the radiators are made, the effect of any scale or similar deposits on the heat transfer surfaces (both inside and outside), Reynolds numbers for the flowing fluids (a function of flow rates and fluid properties), and the physical properties the radiators and of the coolant and oil flowing within the heat exchangers.

Having said all of that, there is no doubt that “re-using” the cooling air will affect heat transfer within the radiator using pre-heated air, and this is undoubtedly why Europa recommend placing one below the other.

Best regards,

Rob Housman

Irvine, CA

Europa XS Tri-Gear

A070

Airframe complete

From: owner-europa-list-server(at)matronics.com [mailto:owner-europa-list-server(at)matronics.com] On Behalf Of Robert Borger

Sent: Saturday, June 05, 2010 11:02 AM

To: europa-list(at)matronics.com

Subject: Re: Cooling issues, once again!

Paul,

I don't see how it can. Simple thermodynamics is against it. Heat transfer is directly proportional to temperature difference. Both radiators are at about the same temperature. Once the air has been heated by the first radiator its ability to accept heat from the second has been greatly reduced if not eliminated.

And this is assuming that the area below the radiators has been sealed so that the air goes through the radiators and not under them, doing no good at all.

Check six,

Bob Borger

http://www.europaowners.org/N914XL

Europa XS, Short Wing, Intercooled Rotax 914

rlborger(at)mac.com (rlborger(at)mac.com)

Cel: 817-992-1117

On Jun 5, 2010, at 11:43 AM, Paul McAllister wrote:

Hi All,

I am curious to know if there are any examples of standard XS cooling set up's that do not have the oil radiator lowered that work fine.

Thanks, Paul

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

frans(at)privatepilots.nl

Guest

|

Posted: Sat Jun 05, 2010 12:34 pm Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 12:34 pm Post subject: Cooling issues, once again! |

|

|

On 06/05/2010 09:26 PM, Rob Housman wrote:

| Quote: | Having said all of that, there is no doubt that �re-using� the cooling

air will affect heat transfer within the radiator using pre-heated air,

and this is undoubtedly why Europa recommend placing one below the other.

|

Another reason might be that the oil cooler in the air exit path of the

water radiator is an obstacle that hinders the air flow in the water

radiator?

Looking closer to both radiators, It appears to me that the oil cooler

has closer spaced fins, thicker fluid canals, and an overall smaller

useful area.

It might be that this is the reason why lowering the oil radiator also

causes the water temperatures to drop.

Frans

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

grahamsingleton(at)btinte

Guest

|

Posted: Sat Jun 05, 2010 12:41 pm Post subject: Cooling issues, once again! Posted: Sat Jun 05, 2010 12:41 pm Post subject: Cooling issues, once again! |

|

|

You could be right there Frans. btw theory says that cowl inlet should be much smaller than rad area so that some pressure recovery can happen, also lips must be smooth.

Graham

From: Frans Veldman <frans(at)privatepilots.nl>

To: europa-list(at)matronics.com

Sent: Saturday, 5 June, 2010 21:27:33

Subject: Re: Cooling issues, once again!

--> Europa-List message posted by: Frans Veldman <frans(at)privatepilots.nl (frans(at)privatepilots.nl)>

On 06/05/2010 09:26 PM, Rob Housman wrote:

Looking closer to both radiators, It appears to me that the oil cooler

has closer spaced fins, thicker fluid canals, and an overall smaller

useful area.

It might be that this is the reason why lowering the oil radiator also

causes the water tem/Navigator?Europa-List" ="http://forums.matronics.com" target="_blank">http://forums.matronics.  tronics.com/contribution" target="_blank">http://www.matronics.com/contri================

[quote][b]

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|