|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

teamgrumman(at)yahoo.com

Guest

|

Posted: Mon Aug 10, 2015 1:31 pm Post subject: Hello... out there. Story time. Posted: Mon Aug 10, 2015 1:31 pm Post subject: Hello... out there. Story time. |

|

|

When I first created TeamGrumman-List, the idea was to be able to exchange jokes, theories, stories and ideas that are not permitted on the GG. Wishful thinking. I also belong to the Lycoming, Corvette, Corvair, and a whole lot of the other lists. None of them are very active either.

To break the monotony, here is the latest story.

On May 5th, I started the invoice for what was to be a simple annual. I’ve been maintaining this plane for about 10 years and have made a few improvements and fixed a number of things, here and there, over the years.

When I first saw this plane (a 1978 Tiger) in 2005, it had 1270 hrs on the engine, almost 2700 on the airframe; it was owned by 3 guys then as it is now. The plane was a mess. The previous owner had done such things as installing a piece of angle aluminum behind the panel to mount wing tip flashers/landing lights and Radio Shack electrical dimmers for instrument panel lighting. The heat sink in front of the vacuum filter prevented anyone from changing the filter. It was pretty bad. He had wired everything with automotive wire. The engine gauges were replaced with seven EI 2 1/4 inch engine gauges on an angled panel on the far right. In order to read the tach, the pilot had to lean over and look at the tiny little numbers. None of the gauges were easy to see or read without leaning over.

The vacuum gauge didn’t work on the first annual. The new owners said the vacuum gauge never worked very well. As it turned out, because of the way the panel was angled, the vacuum line was pinched against the panel. Why this wasn’t addressed earlier was beyond me.

When I tried to reset the magneto timing, I couldn’t get to the left mag because the oil cooler hoses had been routed backwards; i.e., the top hose was routed to the back of the engine accessory case and the bottom hose went to the fitting near the breather hose. They criss-crossed behind the left mag. In order to change mag timing, the hoses had to be removed.

Four separate ground wires had been added: 2 from the lower engine mounts on the firewall to the engine block, one from the upper cowling hinge to the engine block, and one from the instrument panel to the engine block.

Engine analyzer wires were draped across the back of the firewall and then across to the engine. Changing the oil was a real challenge. Wires were everywhere. The extra ground wire from the upper cowling was used as a mount to hang wires… right on top of the oil filter.

The plugs were rusty and worn. Compressions on each cylinder fell off by as much as 30 pounds at plus or minus 20 degrees BTDC; clearly the choke was gone in the chrome cylinders. Plug wires were run in such a fashion as to stretch the cables to reach the plugs. The harness was junk. Intake tubes, push rod tubes, and oil drain back tubes all leaked. No fire-sleeve on the fuel flow transducer (it rarely worked anyway). The air-oil separator had a high spot in the drain back line so it collected oil. Springs to hold up the baffle straps were missing. Baffle seals did not seal much. Lower engine mount (vibration isolators) were badly sagged. The air filter was so decomposed that it was in shreds in the bottom of the airbox. The oil had not been changed in 92 hours. None of the hoses had a data tag and appeared home made. All of the baffles were cracked and had been repaired several times. Rivnuts on the nose gear top seal had been replaced with screws and nuts; removing the top seal was interesting. The cotter pin on the nose gear was installed but not bent over. Aileron stops were bent over so they didn’t stop anything. Brake linings worn through; 60 hours on new linings according to the logbook. Brake master cylinders were from a '77. Flaps are from a '77 (no trailing edge cap). Elevator to bellcrank bolts were crowded out. Horizontal braces were cracked. Pilots side carpet soaked, I mean soaked, in brake fluid. Audio panel doesn’t work well on #2 comm. Panel mounted (portable) GPS database out of date; not a big deal, the GPS doesn’t work anyway. All of the seat bracket boys were loose. With 2700 hours on the airframe, no mention of the rudder return springs being replaced. . . . . Over the years, I gradually fixed most of the stuff.

So, this year started out as did most. I’d fix what I could and the owners would postpone what they could. Except that, with 1992+ hours on the engine and the low compressions, #1: 23/80 (leaking at exhaust valve and rings); #2: 61/80 (leaking at exhaust valve and rings), #3: 58/80 (leaking at exhaust valve and rings); #4: 75/80, the engine couldn’t be ignored this year. I called the primary owner (who I’d been working with for 10 years) and told him it was time to get a new engine. When he asked me how much, I told him, “Realistically, by the time I remove everything and fix all of the stuff that has been put off for 10 years, $30,000 to $35,000 is not out of the question.” I told him of a recent factory overhauled engine, ported and polished, “O” ringed engine case, and prepped by LyCon was $28,025. That engine was installed on 626.

The owner’s response to me was, “I really wanted to upgrade the engine analyzer to the EDM 900 and get new avionics this year.” I told him it was possible to put off the overhaul for another 1000 hours with a complete top overhaul. I told him new cylinders, ported and polished, would be around $7500 with overhauled rockers. New engine mounts (by now they were really bad. the bottom ones were separating) would be over $1000. New baffles (from AeroForm in Alaska) would be another $1400. New hoses would run about $550. And the engine analyzer at my cost would be about $3900.

The owner asked me to get an estimate for a new Garmin 340 audio panel, 650 GPS/Comm/Nav, a Garmin 225 for a second comm, and a Garmin 330ES transponder. He again told me he really wanted new avionics. I called my avionics guy as soon as we hung up.

The owner questioned the logic of just replacing the cylinders and not overhaul the engine. I told him to ask around and see if it made sense to him. The one thing he said he definitely wanted was the EDM 900. I told him to send me a check.

So, I finished up the annual, ordered the EDM 900, and started to remove the right side panel for the new analyzer. What I found was switches and circuit breakers for some of the engine gauges (to separately turn them on and off) wired to a panel that included the PS engineering 4-place intercom. In order to remove the panel, I could have untangled the intercom wires that were also intertwined to the Radio Shack flasher for the landing lights. Basing my approach on installing new avionics, I cut the wires to the back seat headphone jacks. I removed all of he EI engine gauges. I untangled the flasher wires and removed about 2 feet of excess (automotive) wiring to the flasher unit. While in there, I cleaned up wires to the instrument lighting and removed about 10 feet of dyked-off wires. I also removed the avionics from their trays. Then, some two weeks later, I got a call from the owner.

First off, I told him the good news was that I had already sold some of the avionics. I told him I still hadn’t heard from my avionics guy but that I would call right away. He told me that he would go along with just replacing the cylinders but that Mike Busch said only an engine shop should replace all 4 cylinders; Mike Busch says mechanics are not qualified to replace cylinders. I had already removed the baffles and was getting ready to install new cylinders. The option was for me to take the engine to LyCon and have them replace the cylinders. It took him another week to decide I could replace the cylinders. I told him to send me a check for the cylinders and the annual. He did. It bounced. He sent another.

I ordered the cylinders and it took a week to get them.

I ordered the baffle set. I was surprised to find that, although the new baffles are nice, they don’t fit well. They also wrap too far around the bottom of the cylinders. I spent about 4 hours fitting them, trimming them, and modifying them so that I could use them. I charged the owner 1 hours labor. Then, I called the owner and told him the new avionics would be about $18,000 plus installation. I also told him I had already started the avionics removal.

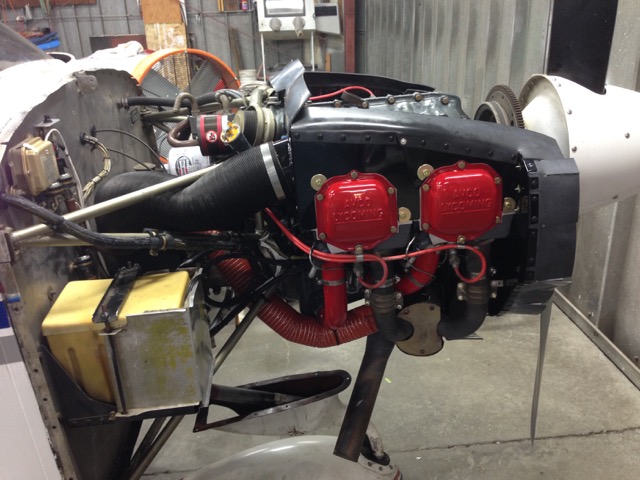

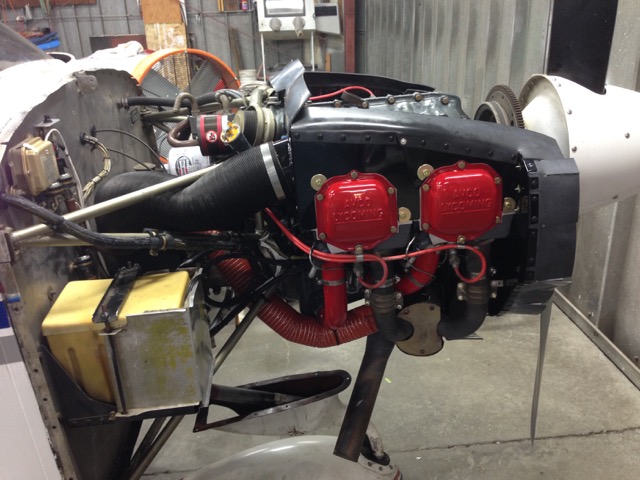

I removed the old cylinders, measured the cam (the owner wanted to know if there was any measurable wear on the cam. I used the tool for valve guide wear to measure the cam. I had to fabricate a mount.) I cleaned up the block, checked all of the bolts, fixed all of the wiring firewall forward, removed the excess grounds, replaced the mag P-lead wires with new wires, installed the engine analyzer, wired it up, and when the new cylinders came, I installed them and finished up the wiring. The new baffles were sent out for powder coating as were the push rod tubes, intake tubes and rocker covers. About this time, the owner called and said he wanted all of the old avionics replaced. It was then that the owner told me he only had $14,000 in the engine reserve to overhaul the engine at TBO. One of the other owners called and said he wanted to take the plane to Oshkosh two weeks away. He began calling everyday to determine the progress.

I guess I shouldn’t have started the avionics removal. I had to track down wiring diagrams and rewire the intercom. The good news is, I found a bad wire in the PTT, a bad mic jack for the pilot, and a broken wire in the right rear seat. I did all of this work without charging the owner. The second owner wanted a cost estimate and a time estimate to finish the plane.

So, the next morning, I pulled an estimate out of the blue and sent it to him. I’d never installed an EDM 900 so I took my average time to install an EDM 730 and added 4 hours. I forgot to include the time required to install baffle seals. I also forgot the time required to replace the DGO-10 they’d sent. I also forgot to provide an estimate to do the initial break-in of the cylinders that had been requested. My overall estimate was off by about 24-30 hours plus $650+ in parts.

As for the engine mounts, the owner never called back so I replaced the bottom mounts with some good used mounts I had on my shelf. I also replaced the #2 exhaust riser. The fabricated panel for the engine analyzer came out nice. The rear seat headphones work. I relocated the music jack to the left side near the pilot’s head phone jacks.

Six weeks after this project began, the plane was done. I tried very hard to get it done for Oshkosh. Missed it by one day. Most days were 10-12 hour days. Total labor hours just over 131 hours including the annual. The engine compartment is nice and clean and the plane flies great. No wires hanging in the way. I would like the analyzer to be closer to the pilot but the iPad mount fills the middle of the panel The final invoice came out to be about $3650 higher (including $650 in parts and after discounting $2100) than the estimate I gave them. They don’t want to pay the final invoice.

Lesson learned: always over estimate the cost to finish.

Good news is, one of my other customers has loaned me $6500 so I can pay my mortgages (two houses) and pay for parts. Another customer has offered to bring his plane in two months early to help. A big thanks to them.

Time to go to work.

Gary

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Dan.Schmitz(at)calix.com

Guest

|

Posted: Mon Aug 10, 2015 2:56 pm Post subject: Hello... out there. Story time. Posted: Mon Aug 10, 2015 2:56 pm Post subject: Hello... out there. Story time. |

|

|

Ouch!  And that plane sounds scary. Or at least it was. Thanks for sharing. But now I want to find Mr. Jack Daniels. Why insist on a top overhaul at 1992 hours for an engine averaging 70 hours a year? I'm no expert, but I can't see another 1000 hours there. Those new avionics aren't much good on the ground. And that plane sounds scary. Or at least it was. Thanks for sharing. But now I want to find Mr. Jack Daniels. Why insist on a top overhaul at 1992 hours for an engine averaging 70 hours a year? I'm no expert, but I can't see another 1000 hours there. Those new avionics aren't much good on the ground.

Dan Schmitz

N4518B

KASH

| Quote: | When I first created TeamGrumman-List, the idea was to be able to

exchange jokes, theories, stories and ideas that are not permitted on the

GG. Wishful thinking. I also belong to the Lycoming, Corvette, Corvair, and

a whole lot of the other lists. None of them are very active either.

To break the monotony, here is the latest story.

On May 5th, I started the invoice for what was to be a simple annual. I’ve

been maintaining this plane for about 10 years and have made a few

improvements and fixed a number of things, here and there, over the years.

When I first saw this plane (a 1978 Tiger) in 2005, it had 1270 hrs on the

engine, almost 2700 on the airframe; it was owned by 3 guys then as it is

now. The plane was a mess. The previous owner had done such things as

installing a piece of angle aluminum behind the panel to mount wing tip

flashers/landing lights and Radio Shack electrical dimmers for instrument

panel lighting. The heat sink in front of the vacuum filter prevented anyone

from changing the filter. It was pretty bad. He had wired everything with

automotive wire. The engine gauges were replaced with seven EI 2 1/4 inch

engine gauges on an angled panel on the far right. In order to read the tach,

the pilot had to lean over and look at the tiny little numbers. None of the

gauges were easy to see or read without leaning over.

The vacuum gauge didn’t work on the first annual. The new owners said the

vacuum gauge never worked very well. As it turned out, because of the way

the panel was angled, the vacuum line was pinched against the panel. Why

this wasn’t addressed earlier was beyond me.

When I tried to reset the magneto timing, I couldn’t get to the left mag

because the oil cooler hoses had been routed backwards; i.e., the top hose

was routed to the back of the engine accessory case and the bottom hose

went to the fitting near the breather hose. They criss-crossed behind the

left mag. In order to change mag timing, the hoses had to be removed.

Four separate ground wires had been added: 2 from the lower engine

mounts on the firewall to the engine block, one from the upper cowling

hinge to the engine block, and one from the instrument panel to the engine

block.

Engine analyzer wires were draped across the back of the firewall and then

across to the engine. Changing the oil was a real challenge. Wires were

everywhere. The extra ground wire from the upper cowling was used as a

mount to hang wires… right on top of the oil filter.

The plugs were rusty and worn. Compressions on each cylinder fell off by as

much as 30 pounds at plus or minus 20 degrees BTDC; clearly the choke was

gone in the chrome cylinders. Plug wires were run in such a fashion as to

stretch the cables to reach the plugs. The harness was junk. Intake tubes,

push rod tubes, and oil drain back tubes all leaked. No fire-sleeve on the

fuel flow transducer (it rarely worked anyway). The air-oil separator had a

high spot in the drain back line so it collected oil. Springs to hold up the

baffle straps were missing. Baffle seals did not seal much. Lower engine

mount (vibration isolators) were badly sagged. The air filter was so

decomposed that it was in shreds in the bottom of the airbox. The oil had

not been changed in 92 hours. None of the hoses had a data tag and

appeared home made. All of the baffles were cracked and had been

repaired several times. Rivnuts on the nose gear top seal had been

replaced with screws and nuts; rem!

oving the top seal was interesting. The cotter pin on the nose gear was

installed but not bent over. Aileron stops were bent over so they didn’t

stop anything. Brake linings worn through; 60 hours on new linings

according to the logbook. Brake master cylinders were from a '77. Flaps are

from a '77 (no trailing edge cap). Elevator to bellcrank bolts were crowded

out. Horizontal braces were cracked. Pilots side carpet soaked, I mean

soaked, in brake fluid. Audio panel doesn’t work well on #2 comm. Panel

mounted (portable) GPS database out of date; not a big deal, the GPS

doesn’t work anyway. All of the seat bracket boys were loose. With 2700

hours on the airframe, no mention of the rudder return springs being

replaced. . . . . Over the years, I gradually fixed most of the stuff.

So, this year started out as did most. I’d fix what I could and the owners

would postpone what they could. Except that, with 1992+ hours on the

engine and the low compressions, #1: 23/80 (leaking at exhaust valve and

rings); #2: 61/80 (leaking at exhaust valve and rings), #3: 58/80 (leaking at

exhaust valve and rings); #4: 75/80, the engine couldn’t be ignored this year.

I called the primary owner (who I’d been working with for 10 years) and told

him it was time to get a new engine. When he asked me how much, I told

him, “Realistically, by the time I remove everything and fix all of the stuff

that has been put off for 10 years, $30,000 to $35,000 is not out of the

question.” I told him of a recent factory overhauled engine, ported and

polished, “O” ringed engine case, and prepped by LyCon was $28,025. That

engine was installed on 626.

The owner’s response to me was, “I really wanted to upgrade the engine

analyzer to the EDM 900 and get new avionics this year.” I told him it was

possible to put off the overhaul for another 1000 hours with a complete top

overhaul. I told him new cylinders, ported and polished, would be around

$7500 with overhauled rockers. New engine mounts (by now they were

really bad. the bottom ones were separating) would be over $1000. New

baffles (from AeroForm in Alaska) would be another $1400. New hoses

would run about $550. And the engine analyzer at my cost would be about

$3900.

The owner asked me to get an estimate for a new Garmin 340 audio panel,

650 GPS/Comm/Nav, a Garmin 225 for a second comm, and a Garmin 330ES

transponder. He again told me he really wanted new avionics. I called my

avionics guy as soon as we hung up.

The owner questioned the logic of just replacing the cylinders and not

overhaul the engine. I told him to ask around and see if it made sense to

him. The one thing he said he definitely wanted was the EDM 900. I told

him to send me a check.

So, I finished up the annual, ordered the EDM 900, and started to remove

the right side panel for the new analyzer. What I found was switches and

circuit breakers for some of the engine gauges (to separately turn them on

and off) wired to a panel that included the PS engineering 4-place intercom.

In order to remove the panel, I could have untangled the intercom wires

that were also intertwined to the Radio Shack flasher for the landing lights.

Basing my approach on installing new avionics, I cut the wires to the back

seat headphone jacks. I removed all of he EI engine gauges. I untangled the

flasher wires and removed about 2 feet of excess (automotive) wiring to the

flasher unit. While in there, I cleaned up wires to the instrument lighting

and removed about 10 feet of dyked-off wires. I also removed the avionics

from their trays. Then, some two weeks later, I got a call from the owner.

First off, I told him the good news was that I had already sold some of the

avionics. I told him I still hadn’t heard from my avionics guy but that I would

call right away. He told me that he would go along with just replacing the

cylinders but that Mike Busch said only an engine shop should replace all 4

cylinders; Mike Busch says mechanics are not qualified to replace cylinders.

I had already removed the baffles and was getting ready to install new

cylinders. The option was for me to take the engine to LyCon and have

them replace the cylinders. It took him another week to decide I could

replace the cylinders. I told him to send me a check for the cylinders and

the annual. He did. It bounced. He sent another.

I ordered the cylinders and it took a week to get them.

I ordered the baffle set. I was surprised to find that, although the new

baffles are nice, they don’t fit well. They also wrap too far around the

bottom of the cylinders. I spent about 4 hours fitting them, trimming them,

and modifying them so that I could use them. I charged the owner 1 hours

labor. Then, I called the owner and told him the new avionics would be

about $18,000 plus installation. I also told him I had already started the

avionics removal.

I removed the old cylinders, measured the cam (the owner wanted to know

if there was any measurable wear on the cam. I used the tool for valve

guide wear to measure the cam. I had to fabricate a mount.) I cleaned up

the block, checked all of the bolts, fixed all of the wiring firewall forward,

removed the excess grounds, replaced the mag P-lead wires with new

wires, installed the engine analyzer, wired it up, and when the new

cylinders came, I installed them and finished up the wiring. The new baffles

were sent out for powder coating as were the push rod tubes, intake tubes

and rocker covers. About this time, the owner called and said he wanted all

of the old avionics replaced. It was then that the owner told me he only had

$14,000 in the engine reserve to overhaul the engine at TBO. One of the

other owners called and said he wanted to take the plane to Oshkosh two

weeks away. He began calling everyday to determine the progress.

I guess I shouldn’t have started the avionics removal. I had to track down

wiring diagrams and rewire the intercom. The good news is, I found a bad

wire in the PTT, a bad mic jack for the pilot, and a broken wire in the right

rear seat. I did all of this work without charging the owner. The second

owner wanted a cost estimate and a time estimate to finish the plane.

So, the next morning, I pulled an estimate out of the blue and sent it to him.

I’d never installed an EDM 900 so I took my average time to install an EDM

730 and added 4 hours. I forgot to include the time required to install baffle

seals. I also forgot the time required to replace the DGO-10 they’d sent. I

also forgot to provide an estimate to do the initial break-in of the cylinders

that had been requested. My overall estimate was off by about 24-30 hours

plus $650+ in parts.

As for the engine mounts, the owner never called back so I replaced the

bottom mounts with some good used mounts I had on my shelf. I also

replaced the #2 exhaust riser. The fabricated panel for the engine analyzer

came out nice. The rear seat headphones work. I relocated the music jack

to the left side near the pilot’s head phone jacks.

Six weeks after this project began, the plane was done. I tried very hard to

get it done for Oshkosh. Missed it by one day. Most days were 10-12 hour

days. Total labor hours just over 131 hours including the annual. The engine

compartment is nice and clean and the plane flies great. No wires hanging

in the way. I would like the analyzer to be closer to the pilot but the iPad

mount fills the middle of the panel The final invoice came out to be about

$3650 higher (including $650 in parts and after discounting $2100) than the

estimate I gave them. They don’t want to pay the final invoice.

Lesson learned: always over estimate the cost to finish.

Good news is, one of my other customers has loaned me $6500 so I can pay

my mortgages (two houses) and pay for parts. Another customer has

offered to bring his plane in two months early to help. A big thanks to

them.

Time to go to work.

Gary

|

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

xwe(at)shaw.ca

Guest

|

Posted: Mon Aug 10, 2015 3:13 pm Post subject: Hello... out there. Story time. Posted: Mon Aug 10, 2015 3:13 pm Post subject: Hello... out there. Story time. |

|

|

Hi Gary, sounds like their priorities are a little skewed. Like Dan says, new radios on the ground aren't too useful...

Also, an estimate is just that.

I hope you feel a little better getting it off your chest anyway.

--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Aug 11, 2015 11:37 am Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 11:37 am Post subject: Hello... out there. Story time. |

|

|

Dan,

Well, yes and no. The bottom end is pretty durable. The engine was overhauled about 16 years ago. This is it’s second life. I have a customer, Tiger, with 2800+ hours on the engine. It was topped at about 2200 hours. This is an original engine. It is going strong. There is nothing magic about the 2400 hour TBO.

Years ago, I read of a flight school that ran the bottom end to 4800 hours before major overhaul. They would top the engine at 1000 hours. But, again, they flew the hell out of them.

Gary

| Quote: | On Aug 10, 2015, at 3:55 PM, Dan Schmitz <Dan.Schmitz(at)calix.com> wrote:

Ouch!  And that plane sounds scary. Or at least it was. Thanks for sharing. But now I want to find Mr. Jack Daniels. Why insist on a top overhaul at 1992 hours for an engine averaging 70 hours a year? I'm no expert, but I can't see another 1000 hours there. Those new avionics aren't much good on the ground. And that plane sounds scary. Or at least it was. Thanks for sharing. But now I want to find Mr. Jack Daniels. Why insist on a top overhaul at 1992 hours for an engine averaging 70 hours a year? I'm no expert, but I can't see another 1000 hours there. Those new avionics aren't much good on the ground.

Dan Schmitz

N4518B

KASH

> When I first created TeamGrumman-List, the idea was to be able to

> exchange jokes, theories, stories and ideas that are not permitted on the

> GG. Wishful thinking. I also belong to the Lycoming, Corvette, Corvair, and

> a whole lot of the other lists. None of them are very active either.

>

> To break the monotony, here is the latest story.

>

> On May 5th, I started the invoice for what was to be a simple annual. I’ve

> been maintaining this plane for about 10 years and have made a few

> improvements and fixed a number of things, here and there, over the years.

>

> When I first saw this plane (a 1978 Tiger) in 2005, it had 1270 hrs on the

> engine, almost 2700 on the airframe; it was owned by 3 guys then as it is

> now. The plane was a mess. The previous owner had done such things as

> installing a piece of angle aluminum behind the panel to mount wing tip

> flashers/landing lights and Radio Shack electrical dimmers for instrument

> panel lighting. The heat sink in front of the vacuum filter prevented anyone

> from changing the filter. It was pretty bad. He had wired everything with

> automotive wire. The engine gauges were replaced with seven EI 2 1/4 inch

> engine gauges on an angled panel on the far right. In order to read the tach,

> the pilot had to lean over and look at the tiny little numbers. None of the

> gauges were easy to see or read without leaning over.

>

> The vacuum gauge didn’t work on the first annual. The new owners said the

> vacuum gauge never worked very well. As it turned out, because of the way

> the panel was angled, the vacuum line was pinched against the panel. Why

> this wasn’t addressed earlier was beyond me.

>

> When I tried to reset the magneto timing, I couldn’t get to the left mag

> because the oil cooler hoses had been routed backwards; i.e., the top hose

> was routed to the back of the engine accessory case and the bottom hose

> went to the fitting near the breather hose. They criss-crossed behind the

> left mag. In order to change mag timing, the hoses had to be removed.

>

> Four separate ground wires had been added: 2 from the lower engine

> mounts on the firewall to the engine block, one from the upper cowling

> hinge to the engine block, and one from the instrument panel to the engine

> block.

>

> Engine analyzer wires were draped across the back of the firewall and then

> across to the engine. Changing the oil was a real challenge. Wires were

> everywhere. The extra ground wire from the upper cowling was used as a

> mount to hang wires… right on top of the oil filter.

>

> The plugs were rusty and worn. Compressions on each cylinder fell off by as

> much as 30 pounds at plus or minus 20 degrees BTDC; clearly the choke was

> gone in the chrome cylinders. Plug wires were run in such a fashion as to

> stretch the cables to reach the plugs. The harness was junk. Intake tubes,

> push rod tubes, and oil drain back tubes all leaked. No fire-sleeve on the

> fuel flow transducer (it rarely worked anyway). The air-oil separator had a

> high spot in the drain back line so it collected oil. Springs to hold up the

> baffle straps were missing. Baffle seals did not seal much. Lower engine

> mount (vibration isolators) were badly sagged. The air filter was so

> decomposed that it was in shreds in the bottom of the airbox. The oil had

> not been changed in 92 hours. None of the hoses had a data tag and

> appeared home made. All of the baffles were cracked and had been

> repaired several times. Rivnuts on the nose gear top seal had been

> replaced with screws and nuts; rem!

> oving the top seal was interesting. The cotter pin on the nose gear was

> installed but not bent over. Aileron stops were bent over so they didn’t

> stop anything. Brake linings worn through; 60 hours on new linings

> according to the logbook. Brake master cylinders were from a '77. Flaps are

> from a '77 (no trailing edge cap). Elevator to bellcrank bolts were crowded

> out. Horizontal braces were cracked. Pilots side carpet soaked, I mean

> soaked, in brake fluid. Audio panel doesn’t work well on #2 comm. Panel

> mounted (portable) GPS database out of date; not a big deal, the GPS

> doesn’t work anyway. All of the seat bracket boys were loose. With 2700

> hours on the airframe, no mention of the rudder return springs being

> replaced. . . . . Over the years, I gradually fixed most of the stuff.

>

> So, this year started out as did most. I’d fix what I could and the owners

> would postpone what they could. Except that, with 1992+ hours on the

> engine and the low compressions, #1: 23/80 (leaking at exhaust valve and

> rings); #2: 61/80 (leaking at exhaust valve and rings), #3: 58/80 (leaking at

> exhaust valve and rings); #4: 75/80, the engine couldn’t be ignored this year.

> I called the primary owner (who I’d been working with for 10 years) and told

> him it was time to get a new engine. When he asked me how much, I told

> him, “Realistically, by the time I remove everything and fix all of the stuff

> that has been put off for 10 years, $30,000 to $35,000 is not out of the

> question.” I told him of a recent factory overhauled engine, ported and

> polished, “O” ringed engine case, and prepped by LyCon was $28,025. That

> engine was installed on 626.

>

> The owner’s response to me was, “I really wanted to upgrade the engine

> analyzer to the EDM 900 and get new avionics this year.” I told him it was

> possible to put off the overhaul for another 1000 hours with a complete top

> overhaul. I told him new cylinders, ported and polished, would be around

> $7500 with overhauled rockers. New engine mounts (by now they were

> really bad. the bottom ones were separating) would be over $1000. New

> baffles (from AeroForm in Alaska) would be another $1400. New hoses

> would run about $550. And the engine analyzer at my cost would be about

> $3900.

>

> The owner asked me to get an estimate for a new Garmin 340 audio panel,

> 650 GPS/Comm/Nav, a Garmin 225 for a second comm, and a Garmin 330ES

> transponder. He again told me he really wanted new avionics. I called my

> avionics guy as soon as we hung up.

>

> The owner questioned the logic of just replacing the cylinders and not

> overhaul the engine. I told him to ask around and see if it made sense to

> him. The one thing he said he definitely wanted was the EDM 900. I told

> him to send me a check.

>

> So, I finished up the annual, ordered the EDM 900, and started to remove

> the right side panel for the new analyzer. What I found was switches and

> circuit breakers for some of the engine gauges (to separately turn them on

> and off) wired to a panel that included the PS engineering 4-place intercom.

> In order to remove the panel, I could have untangled the intercom wires

> that were also intertwined to the Radio Shack flasher for the landing lights.

> Basing my approach on installing new avionics, I cut the wires to the back

> seat headphone jacks. I removed all of he EI engine gauges. I untangled the

> flasher wires and removed about 2 feet of excess (automotive) wiring to the

> flasher unit. While in there, I cleaned up wires to the instrument lighting

> and removed about 10 feet of dyked-off wires. I also removed the avionics

> from their trays. Then, some two weeks later, I got a call from the owner.

>

> First off, I told him the good news was that I had already sold some of the

> avionics. I told him I still hadn’t heard from my avionics guy but that I would

> call right away. He told me that he would go along with just replacing the

> cylinders but that Mike Busch said only an engine shop should replace all 4

> cylinders; Mike Busch says mechanics are not qualified to replace cylinders.

> I had already removed the baffles and was getting ready to install new

> cylinders. The option was for me to take the engine to LyCon and have

> them replace the cylinders. It took him another week to decide I could

> replace the cylinders. I told him to send me a check for the cylinders and

> the annual. He did. It bounced. He sent another.

>

> I ordered the cylinders and it took a week to get them.

>

> I ordered the baffle set. I was surprised to find that, although the new

> baffles are nice, they don’t fit well. They also wrap too far around the

> bottom of the cylinders. I spent about 4 hours fitting them, trimming them,

> and modifying them so that I could use them. I charged the owner 1 hours

> labor. Then, I called the owner and told him the new avionics would be

> about $18,000 plus installation. I also told him I had already started the

> avionics removal.

>

> I removed the old cylinders, measured the cam (the owner wanted to know

> if there was any measurable wear on the cam. I used the tool for valve

> guide wear to measure the cam. I had to fabricate a mount.) I cleaned up

> the block, checked all of the bolts, fixed all of the wiring firewall forward,

> removed the excess grounds, replaced the mag P-lead wires with new

> wires, installed the engine analyzer, wired it up, and when the new

> cylinders came, I installed them and finished up the wiring. The new baffles

> were sent out for powder coating as were the push rod tubes, intake tubes

> and rocker covers. About this time, the owner called and said he wanted all

> of the old avionics replaced. It was then that the owner told me he only had

> $14,000 in the engine reserve to overhaul the engine at TBO. One of the

> other owners called and said he wanted to take the plane to Oshkosh two

> weeks away. He began calling everyday to determine the progress.

>

> I guess I shouldn’t have started the avionics removal. I had to track down

> wiring diagrams and rewire the intercom. The good news is, I found a bad

> wire in the PTT, a bad mic jack for the pilot, and a broken wire in the right

> rear seat. I did all of this work without charging the owner. The second

> owner wanted a cost estimate and a time estimate to finish the plane.

>

> So, the next morning, I pulled an estimate out of the blue and sent it to him.

> I’d never installed an EDM 900 so I took my average time to install an EDM

> 730 and added 4 hours. I forgot to include the time required to install baffle

> seals. I also forgot the time required to replace the DGO-10 they’d sent. I

> also forgot to provide an estimate to do the initial break-in of the cylinders

> that had been requested. My overall estimate was off by about 24-30 hours

> plus $650+ in parts.

>

> As for the engine mounts, the owner never called back so I replaced the

> bottom mounts with some good used mounts I had on my shelf. I also

> replaced the #2 exhaust riser. The fabricated panel for the engine analyzer

> came out nice. The rear seat headphones work. I relocated the music jack

> to the left side near the pilot’s head phone jacks.

>

> Six weeks after this project began, the plane was done. I tried very hard to

> get it done for Oshkosh. Missed it by one day. Most days were 10-12 hour

> days. Total labor hours just over 131 hours including the annual. The engine

> compartment is nice and clean and the plane flies great. No wires hanging

> in the way. I would like the analyzer to be closer to the pilot but the iPad

> mount fills the middle of the panel The final invoice came out to be about

> $3650 higher (including $650 in parts and after discounting $2100) than the

> estimate I gave them. They don’t want to pay the final invoice.

>

> Lesson learned: always over estimate the cost to finish.

>

> Good news is, one of my other customers has loaned me $6500 so I can pay

> my mortgages (two houses) and pay for parts. Another customer has

> offered to bring his plane in two months early to help. A big thanks to

> them.

>

> Time to go to work.

>

> Gary

|

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Aug 11, 2015 11:49 am Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 11:49 am Post subject: Hello... out there. Story time. |

|

|

Don,

Well, yes I do feel a little better. I’ve been working on planes for 33 years. I’ve been charging for my labor (and parts) for 25 years.

(Interesting side note: I met a guy here, who had the same last name as my very first customer. I was telling him the story of how he and I had met and the first fly-in we went to. He looks at me and says, “That’s my brother.” Small world.)

In 25 years I’ve had hundreds of jobs take a lot longer than I expected. I can’t predict everything. If a job takes twice as long as I expect, I usually cut the owner some slack. Especially if it’s a big job. A (less than complete major) restoration I did last year had a final invoice of over $50,000. I gave the owner a $7,500 discount. He appreciated the discount.

here are a couple of pics of the plane the owners don’t want to pay for.

[img]cid:A689E8A9-4651-4B0B-A2B8-6C5A3FFE58BC[/img]

[img]cid:586C2033-DB2B-4C22-BE2D-451FDF6C8E1E[/img]

[quote]On Aug 10, 2015, at 4:12 PM, Don Metz <xwe(at)shaw.ca (xwe(at)shaw.ca)> wrote:

--> TeamGrumman-List message posted by: "Don Metz" <xwe(at)shaw.ca (xwe(at)shaw.ca)>Hi Gary, sounds like their priorities are a little skewed. Like Dan says, new radios on the ground aren't too useful...Also, an estimate is just that.I hope you feel a little better getting it off your chest anyway.--

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

| Description: |

|

| Filesize: |

94.17 KB |

| Viewed: |

12377 Time(s) |

|

| Description: |

|

| Filesize: |

102.11 KB |

| Viewed: |

12377 Time(s) |

|

|

|

| Back to top |

|

|

flying-nut(at)cfl.rr.com

Guest

|

Posted: Tue Aug 11, 2015 12:46 pm Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 12:46 pm Post subject: Hello... out there. Story time. |

|

|

So, you let them have the airplane to go to Airventure before you got paid??? How'd that happen???

I'll relate a sad tale ..... the FBO that I bought my AA-1B from ran into difficulties a few years later. He had a good business model .... at least for his airplanes. He bought two '73 AA-1Bs on borrowed money. He used them as trainers for a year and then sold them for the balance on the loan. The then bought two more -1Bs and the cycle continued. He always had 'brand new' airplanes to train in. I bought the one I got my ticket in. Still have it. So, a few years later he's in trouble with the Feds for not paying his Employee taxes. They came in, locked up the building and auctioned off all the assets to pay the bill. Ruined him big time. The reason he got so far in the hole was his maintenance area ..... he let people take their planes before the total bill was paid .... mostly on promises to 'send a check' or 'pay $XX a month'. Guess how much money that brought in???

So much for being a 'nice guy'!!!

So, I see two mistakes .... not communicating the rising costs as things stretched out, and letting them have the airplane before the bill is paid. Seems like call to the attorney on the TV might be the only option ..... other than filing a mechanics lien on the plane.

Nice pics though!

Linn

On 8/11/2015 3:48 PM, Gary L Vogt wrote:

[quote] Don,

Well, yes I do feel a little better. I’ve been working on planes for 33 years. I’ve been charging for my labor (and parts) for 25 years.

(Interesting side note: I met a guy here, who had the same last name as my very first customer. I was telling him the story of how he and I had met and the first fly-in we went to. He looks at me and says, “That’s my brother.” Small world.)

In 25 years I’ve had hundreds of jobs take a lot longer than I expected. I can’t predict everything. If a job takes twice as long as I expect, I usually cut the owner some slack. Especially if it’s a big job. A (less than complete major) restoration I did last year had a final invoice of over $50,000. I gave the owner a $7,500 discount. He appreciated the discount.

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

deej(at)deej.net

Guest

|

Posted: Tue Aug 11, 2015 4:25 pm Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 4:25 pm Post subject: Hello... out there. Story time. |

|

|

On 8/11/2015 3:36 PM, Gary L Vogt wrote:

| Quote: | There is nothing magic about the 2400 hour TBO.

|

In reality "TBO" is something of a misnomer. It is pretty rare for an

engine to make it all the way to the published "Time Before Overhaul"

time without having at least one partial overhaul (top end) done along

the way.

-Dj

--

Dj Merrill - N1JOV - EAA Chapter 87

Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Glastar Flyer N866RH - http://deej.net/glastar/

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

Discover

Joined: 26 Feb 2007

Posts: 429

|

Posted: Tue Aug 11, 2015 4:41 pm Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 4:41 pm Post subject: Hello... out there. Story time. |

|

|

Making TBO and beyond may have a lot to do with how often you run your engine hard

The longer you run it hard the longer it may last.....

http://grumman.net/archive/1997/msg07331.html

On Aug 11, 2015, at 7:24 PM, Dj Merrill <deej(at)deej.net> wrote:

| Quote: | On 8/11/2015 3:36 PM, Gary L Vogt wrote:

There is nothing magic about the 2400 hour TBO.

|

In reality "TBO" is something of a misnomer. It is pretty rare for an engine to make it all the way to the published "Time Before Overhaul" time without having at least one partial overhaul (top end) done along the way.

-Dj

--

Dj Merrill - N1JOV - EAA Chapter 87

Sportsman 2+2 Builder #7118 N421DJ - http://deej.net/sportsman/

Glastar Flyer N866RH - http://deej.net/glastar/

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

flying-nut(at)cfl.rr.com

Guest

|

Posted: Tue Aug 11, 2015 5:11 pm Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 5:11 pm Post subject: Hello... out there. Story time. |

|

|

On 8/11/2015 8:24 PM, Dj Merrill wrote:

| Quote: |

On 8/11/2015 3:36 PM, Gary L Vogt wrote:

> There is nothing magic about the 2400 hour TBO.

In reality "TBO" is something of a misnomer. It is pretty rare for an

engine to make it all the way to the published "Time Before Overhaul"

time without having at least one partial overhaul (top end) done along

the way.

-Dj

I'm going to disagree ..... kinda. I've had three engines, O-235,

|

O-320, and O-360 that went quite a ways beyond that 2400 TBO without

even a top. All you have to do is fly them often, change the oil (I do

every 25 hours) and keep the plugs in good shape. Let them sit for

months without running and I'd say those engines won't make TBO.

I was having a discussion with a Lycoming engineer about the O-360 in my

Pitts. He kept saying 'you can't do that' over and over. High test auto

fuel and 3300 RPMs weren't within the limits! Finally, he went 'off the

record' and I learned a great deal. Almost all the 'limits' (RPM, type

of fuel, TBO etc,) are there so the engine will pass certification. The

limits are conservative because failure during certification is hugely

expensive and just not an option.

Linn

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

teamgrumman(at)yahoo.com

Guest

|

Posted: Tue Aug 11, 2015 7:38 pm Post subject: Hello... out there. Story time. Posted: Tue Aug 11, 2015 7:38 pm Post subject: Hello... out there. Story time. |

|

|

No, I still have the plane and the logbooks.

Can anyone say, "Lien sale?"

Gary

Sent from my iPad

On Aug 11, 2015, at 1:45 PM, Linn Walters <flying-nut(at)cfl.rr.com (flying-nut(at)cfl.rr.com)> wrote:

[quote] So, you let them have the airplane to go to Airventure before you got paid??? How'd that happen???

I'll relate a sad tale ..... the FBO that I bought my AA-1B from ran into difficulties a few years later. He had a good business model .... at least for his airplanes. He bought two '73 AA-1Bs on borrowed money. He used them as trainers for a year and then sold them for the balance on the loan. The then bought two more -1Bs and the cycle continued. He always had 'brand new' airplanes to train in. I bought the one I got my ticket in. Still have it. So, a few years later he's in trouble with the Feds for not paying his Employee taxes. They came in, locked up the building and auctioned off all the assets to pay the bill. Ruined him big time. The reason he got so far in the hole was his maintenance area ..... he let people take their planes before the total bill was paid .... mostly on promises to 'send a check' or 'pay $XX a month'. Guess how much money that brought in???

So much for being a 'nice guy'!!!

So, I see two mistakes .... not communicating the rising costs as things stretched out, and letting them have the airplane before the bill is paid. Seems like call to the attorney on the TV might be the only option ..... other than filing a mechanics lien on the plane.

Nice pics though!

Linn

On 8/11/2015 3:48 PM, Gary L Vogt wrote:

| Quote: | Don,

Well, yes I do feel a little better. I’ve been working on planes for 33 years. I’ve been charging for my labor (and parts) for 25 years.

(Interesting side note: I met a guy here, who had the same last name as my very first customer. I was telling him the story of how he and I had met and the first fly-in we went to. He looks at me and says, “That’s my brother.” Small world.)

In 25 years I’ve had hundreds of jobs take a lot longer than I expected. I can’t predict everything. �If a job takes twice as long as I expect, I usually cut the owner some slack. Especially if it’s a big job. A (less than complete major) restoration I did last year had a final invoice of over $50,000. I gave the owner a $7,500 discount. He appreciated the discount.

===================================

t">http://www.matronics.com/Navigator?TeamGrumman-List

===================================

cs.com

===================================

matronics.com/contribution

===================================

|

[b]

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

rcmutz

Joined: 12 Sep 2010

Posts: 12

|

Posted: Wed Aug 12, 2015 9:51 am Post subject: Hello... out there. Story time. Posted: Wed Aug 12, 2015 9:51 am Post subject: Hello... out there. Story time. |

|

|

They call it de-rating.

�

Richard

�

[quote] Subject: Re: Hello... out there. Story time.

To: teamgrumman-list(at)matronics.com

From: flying-nut(at)cfl.rr.com

Date: Tue, 11 Aug 2015 21:11:14 -0400

--> TeamGrumman-List message posted by: Linn Walters <flying-nut(at)cfl.rr.com>

On 8/11/2015 8:24 PM, Dj Merrill wrote:

> --> TeamGrumman-List message posted by: Dj Merrill <deej(at)deej.net>

>

> On 8/11/2015 3:36 PM, Gary L Vogt wrote:

>> There is nothing magic about the 2400 hour TBO.

>

> In reality "TBO" is something of a misnomer. It is pretty rare for an

> engine to make it all the way to the published "Time Before Overhaul"

> time without having at least one partial overhaul (top end) done along

> the way.

>

> -Dj

>

I'm going to disagree ..... kinda. I've had three engines, O-235,

O-320, and O-360 that went quite a ways beyond that 2400 TBO without

even a top. All you have to do is fly them often, change the oil (I do

every 25 hours) and keep the plugs in good shape. Let them sit for

months without running and I'd say those engines won't make TBO.

I was having a discussion with a Lycoming engineer about the O-360 in my

Pitts. He kept saying 'you can't do that' over and over. High test auto

fuel and 3300 RPMs weren't within the limits! Finally, he went 'off the

record' and I learned a great deal. Almost all the 'limits' (RPM, type

of fuel, TBO etc,) are there so the engine will pass certification. The

limits are conservative because failure during certification is hugely

expensive and just not an option.

Linn

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

|

|

| Back to top |

|

|

cannuck

Joined: 09 Mar 2013

Posts: 14

Location: SK Canada

|

Posted: Sun Aug 16, 2015 8:55 am Post subject: Re: Hello... out there. Story time. Posted: Sun Aug 16, 2015 8:55 am Post subject: Re: Hello... out there. Story time. |

|

|

Gary: Now you know (and I remember) why we stopped doing private work after our first season in the business. Up here (Candian North then) I NEVER saw a single airplane imported from the US that was anywhere near airworthy, and we would not sign out without actually doing all ADs and outstanding squawks. Made me wonder how the hell they got through the IRAN before being first registered in Canada. Guess enough of our AMEs were as sloppy as the guys who did whatever they did or did not do on the other side of the 49th.

At least doing commercial work, the MoT (Ministry of Transport) airworthiness inspectors would back us strongly if an operator was trying to stiff us on their bill. Cheapest bill collectors on the planet (figure a few steak dinners a year).

| | - The Matronics TeamGrumman-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?TeamGrumman-List |

|

_________________

AA1 and AA5B former (future?) owner |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|