|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

lcfitt(at)sbcglobal.net

Guest

|

Posted: Tue Apr 28, 2009 3:05 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 3:05 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

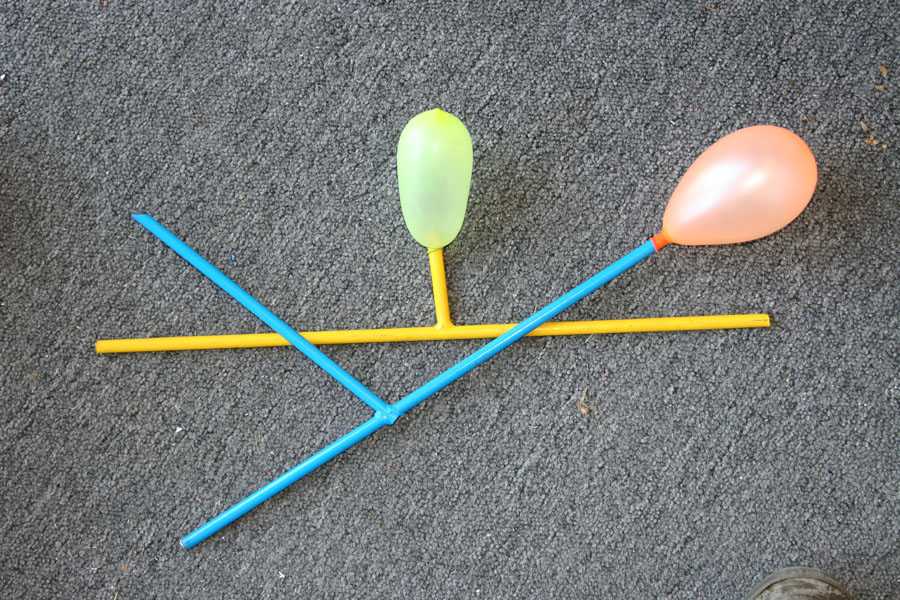

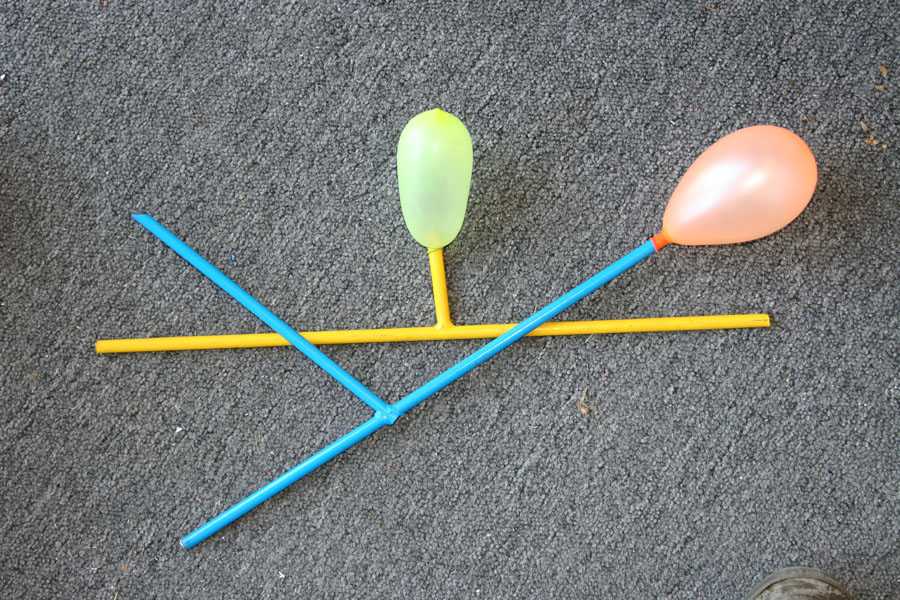

I did the deed. To illustrate the discontinuity of the tubing in the

Kitfox, I took two sections I cut out of a couple of projects and attached

filled balloons to the ends of the tubes. The yellow tubing came from an

elevator cut to fit a trim tab. The blue tubing came from the hat rack area

where that tubing was cut out to in an attempt to

improve the shoulder harness attachment points.

In the yellow tubing section, the long tube is the trailing edge with the

tube rib the closed end tube. In the blue tubing section, what appears to

be the long section is actually two tubes butted to the short piece which is

continuous.

Lowell

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

| Description: |

|

| Filesize: |

99.62 KB |

| Viewed: |

6222 Time(s) |

|

|

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Tue Apr 28, 2009 3:40 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 3:40 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

For what it's worth, when I removed my horizontal stab supports (so I

could weld on the larger 1/4" rod ends) and cut one end off, I could

smell the line oil (tube seal) inside the tubing.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 635.2 hrs

Sensenich 62x46

Electroair direct-fire ignition system

Status: flying

do not archive

On Apr 28, 2009, at 7:03 PM, Lowell Fitt wrote:

| Quote: | I did the deed. To illustrate the discontinuity of the tubing in

the Kitfox, I took two sections I cut out of a couple of projects

and attached filled balloons to the ends of the tubes. The yellow

tubing came from an elevator cut to fit a trim tab. The blue

tubing came from the hat rack area where that tubing was cut out to

in an attempt to

improve the shoulder harness attachment points.

In the yellow tubing section, the long tube is the trailing edge

with the tube rib the closed end tube. In the blue tubing section,

what appears to be the long section is actually two tubes butted to

the short piece which is continuous.

Lowell

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Float Flyr

Joined: 19 Jul 2006

Posts: 2704

Location: Campbellton, Newfoundland

|

Posted: Tue Apr 28, 2009 4:18 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 4:18 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Looking at the big blob of beading on the plue piece it doesn't surprise me

that it is closed off inside the weld. The yellow one is a lot harder to

tell and I'm actually surprised that it is just but welded without first

being cut out and shaped.

Thanks Lowell

Noel

Rhyme not intended

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Noel Loveys

Kitfox III-A

Aerocet 1100 Floats |

|

| Back to top |

|

|

Float Flyr

Joined: 19 Jul 2006

Posts: 2704

Location: Campbellton, Newfoundland

|

Posted: Tue Apr 28, 2009 4:33 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 4:33 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Maybe Kitfox LLC inhibits the frames at the factory. John would know for

sure!

Noel

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Noel Loveys

Kitfox III-A

Aerocet 1100 Floats |

|

| Back to top |

|

|

lcfitt(at)sbcglobal.net

Guest

|

Posted: Tue Apr 28, 2009 5:40 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 5:40 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Usually I give up by now, but here goes. Noel, lets say you are fabricating

a fuselage on a jig. First the longerons on one side, top and bottom, are

clamped into the jig. then the vertical stringers and angle supports are

trimmed, as you discribe, to mate with each other without overlapping

anywhere in a nice tidy cluster. What treatement do you give the longeron

to ensure internal continuity. Do you notch it as you did the stringers or

do you drill a hole at the center of the cluster?

As you all recall, this thread started with advice on introducing a sealant

into the Kitfox tube interiors as a corrosion preventive.

With regard to the first paragraph, Kitfox did notch the tubing to get a

close joint, but they did not drill or otherwise provide for continuity

throughout the tubing interiors. And my opinion is this. I would not fly

in an airplane that would have the number of holes drilled that would be

necessary to protect every tube interior throughout the airplane, especially

if the holes were drilled by an amateur builder.

Lowell

---

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

|

|

| Back to top |

|

|

Float Flyr

Joined: 19 Jul 2006

Posts: 2704

Location: Campbellton, Newfoundland

|

Posted: Tue Apr 28, 2009 7:32 pm Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Tue Apr 28, 2009 7:32 pm Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

I would probably go along with you on that... but aren't the frames made at

a professional company by experts with many years of training and

experience? I watched a certified welder do a cluster joint one time. I

figure it took him several hours to get ready to do the actual welding. I

actually turned down a job e did for our AMO at one time. The joint was

full of pin holes and slag all over the place. Well everyone can have a bad

day. Just haven't yet figured out which one of us was having the hard day.

Him for the poor welding job or me for having to bring it to his attention.

His second try was excellent.

Noel

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Noel Loveys

Kitfox III-A

Aerocet 1100 Floats |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Apr 29, 2009 2:05 am Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 2:05 am Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Slag? On a MIG or TIG weld? Surely he did not use a (slag-generating)

stick (arc) welder?

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 635.2 hrs

Sensenich 62x46

Electroair direct-fire ignition system

Status: flying

On Apr 28, 2009, at 11:28 PM, Noel Loveys wrote:

| Quote: |

I would probably go along with you on that... but aren't the

frames made at

a professional company by experts with many years of training and

experience? I watched a certified welder do a cluster joint one

time. I

figure it took him several hours to get ready to do the actual

welding. I

actually turned down a job e did for our AMO at one time. The

joint was

full of pin holes and slag all over the place. Well everyone can

have a bad

day. Just haven't yet figured out which one of us was having the

hard day.

Him for the poor welding job or me for having to bring it to his

attention.

His second try was excellent.

Noel

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

akflyer

Joined: 07 May 2007

Posts: 574

Location: Soldotna AK

|

Posted: Wed Apr 29, 2009 5:16 am Post subject: Re: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 5:16 am Post subject: Re: Corrosion Prevention Kitfox welded tube joints |

|

|

You can get slag inclusions on both mig and tig. Slag is defined as a non-metallic inclusion in the weldement. If the filler wire is not cleaned properly, you can indeed leave nice little slag inclusions in the form of silicon.

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

DO NOT ARCHIVE

Leonard Perry aka SNAKE

Soldotna AK

Avid "C" / Mk IV

582 (147 hrs and counting on the rebuild)

IVO IFA

Full Lotus 1450

#1 snake oil salesman since 1-22-2009

I would rather die trying to live, than to live trying not to die.... |

|

| Back to top |

|

|

Float Flyr

Joined: 19 Jul 2006

Posts: 2704

Location: Campbellton, Newfoundland

|

Posted: Wed Apr 29, 2009 5:49 am Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 5:49 am Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Hell no it was just an off day for him. He let a job go that he knew he

never should have. I was just unlucky enough to find it and report it ot my

boss who ordered it redone.

Noel

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Noel Loveys

Kitfox III-A

Aerocet 1100 Floats |

|

| Back to top |

|

|

Float Flyr

Joined: 19 Jul 2006

Posts: 2704

Location: Campbellton, Newfoundland

|

Posted: Wed Apr 29, 2009 5:51 am Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 5:51 am Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Lynn:

I forgot to mention that it was a TIG weld. Stick and MIG are not used in

certified welds here. I think there is some applications for Oxy/Fuel

welding. (a.k.a. oxy acetlyne)

Noel

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Noel Loveys

Kitfox III-A

Aerocet 1100 Floats |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Apr 29, 2009 7:35 am Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 7:35 am Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

Hmmmm.....I was thinking only of the thick crap that is left after an

arc job. Maybe my welds are so clean, there is no slag to speak

of....and I'll sell a bottle of snake oil to go along with that

excuse. : )

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 635.2 hrs

Sensenich 62x46

Electroair direct-fire ignition system

Status: flying

do not archive

On Apr 29, 2009, at 9:16 AM, akflyer wrote:

| Quote: |

You can get slag inclusions on both mig and tig. Slag is defined

as a non-metallic inclusion in the weldement. If the filler wire

is not cleaned properly, you can indeed leave nice little slag

inclusions in the form of silicon.

--------

DO NOT ARCHIVE

Leonard Perry aka SNAKE

Soldotna AK

Avid "C" / Mk IV

582 IVO IFA

Full Lotus 1260

#1 snake oil salesman since 1-22-2009

hander outer of humorless darwin awards

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p 41893#241893

|

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

Lynn Matteson

Joined: 10 Jan 2006

Posts: 2778

Location: Grass Lake, Michigan

|

Posted: Wed Apr 29, 2009 7:37 am Post subject: Corrosion Prevention Kitfox welded tube joints Posted: Wed Apr 29, 2009 7:37 am Post subject: Corrosion Prevention Kitfox welded tube joints |

|

|

I wasn't even thinking of it being a certified weld...I guess I

didn't read the thing thoroughly enough...my bad.

Lynn Matteson

Kitfox IV Speedster, taildragger

Jabiru 2200, #2062, 635.2 hrs

Sensenich 62x46

Electroair direct-fire ignition system

Status: flying

do not archive

On Apr 29, 2009, at 9:51 AM, Noel Loveys wrote:

[quote]

Lynn:

I forgot to mention that it was a TIG weld. Stick and MIG are not

used in

certified welds here. I think there is some applications for Oxy/Fuel

welding. (a.k.a. oxy acetlyne)

Noel

--

| | - The Matronics Kitfox-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Kitfox-List |

|

_________________

Lynn

Kitfox IV-Jabiru 2200

N369LM |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|